|

Zilvia Junkie

Join Date: Sep 2011

Location: Richmond

Posts: 506

Feedback Score: 1 reviews

|

How to turbo a KA24DE with a 250-300whp goal

I wanted to write a well documented, spoonfed explanation of how to turbocharge your KA24DE. A short caution must be taken as this is by no means the only way of reaching this goal but due to certain deals on parts and plans for more power down the road, I opted for a larger turbocharger than some may deem necessary for only 250-300whp. Before I start you should read this thread from nissanclub. It gives more general advice but OPs are well versed in KA-T knowledge. My thread is more documenting my experience for others to learn from.

240sx KA-T Turbo Guide => http://www.nissanclub.com/forums/gen...rbo-guide.html

KA-T.org DOHC Turbo for Dummies => http://www.ka-t.org/viewtopic.php?f=12&t=6263

KA-T.org KA24DET Walkthrough=> http://www.ka-t.org/viewtopic.php?f=12&t=57570

Nissanforums The KA Turbo Thread=> http://www.nissanforums.com/general-...bo-thread.html

Procedure1. Acquire Parts

2. Precautionary Steps & Installs

3. Ensure health of the motor and no leaks

4. Install Turbo and Supporting Parts

5. Break-In Diagnosis 1. Acquire Parts

Parts I used: - RS Enthaply Tuned Engine Control Unit (ECU)

- Emusa T3/T04 50 trim turbocharger

- Emusa log turbo manifold

- HKS SSQV V2 Blow off valve (BOV)

- Sport JDM wastegate (10psi spring)

- Hallman Manual Boost Controller

- Greddy intercooler

- S13 SR Greddy intercooler piping

- Isis 255 LPH fuel pump

- Five-O 550cc injectors (sidefeed)

- Isis intake filter

- Exhaust Gas Recirculation (EGR) block plate

- J30/Z32 mass air flow (MAF) sensor (N62)

- Deka ETX30 Battery

- Glowshift Boost Gauge

- Glowshift Oil Pressure Gauge

- AEM Wideband

- Oil Pan Tap

- Isis Radiator

- NGK BKR6E spark plugs

- Beck Arnley Water Pump

- ISIS 3" blast pipes

- Various oil lines, fittings, vacuum line, T-bolts, zipties, fresh oil, oil filter, small filter/breather, etc Many of these parts I got for silly cheap from mostly Craigslist, Zilvia, friends, and Enjuku Racing. This is not recommended or advised but I was on a tight college budget and took a risk. If you can spend money on a few of these items it would be Tune, Turbo, and Wastegate/BOV.. in that order. Instead of scraping by just to turbo my car I spent money on food, beer, rent, mountain biking and other fun things too so this build took around 1.5 years to acquire while in college. All in all I spent around $1400 preparing, installing and getting this project running. Anyone that says you can do it for cheaper is either neglecting other costs such as oil, coolant, radiator, tune, etc or got it for free from some buddy deal. Even doing it cheap you still have to pay to play. This is also on a stock block with 260,000 miles on it, 165psi across all four cylinders. Please realize just because I chose some cheaper alternatives does not mean I cut corners. If you have broken parts on your car before installing this stuff, you're going to have a terrible time when your car doesn't run.

Some small advice now: 2. Precautionary Steps & Installs

This is when you install everything you possibly can without actually seeing forced induction.

Engine:This will likely be the downfall of this build for me. Ideally you should rebuild your motor at the very least when at such high mileage as myself (260k miles), but if the compression test checks out I'm willing to try for pushing the limits of a high-mileage KA. If the money is there though, you really should go with forged internals and refurbish the head for optimum power output and hopefully a lower chance of grenading the KA. I've come to learn that stock internal KA's are good to about 350hp but don't think that's a guarantee or a limit. I'm sure plenty of people have popped their motors on T25 setups and I also know people who have made stupid power (576whp on stock KA with new head gasket & 200,000 miles). Power, cost and reliability...choose two.

Engine build discussion/SR consideration => http://www.ka-t.org/forums/viewtopic.php?t=46682

KA-T.org How to build KA24DE => http://www.ka-t.org/forums/viewtopic.php?t=4156

How to build KA24DE or KA-T => http://www.240sxforums.com/forums/ka...24de-de-t.html Upgraded Radiator:You will need this to help cool your turbo engine. Whether the turbo is water cooled or not, the additional heat from forced induction will have an adverse effect on the rest of your cooling system. While you're here change the coolant, coolant hoses and/or thermostat as need be. Read up and choose at your discretion the temperature thermostat you should use. My opinion is to not use a colder thermostat and just replace with OEM temperature (I believe its 170 F, order from RockAuto). I also chose to only install an upgraded radiator and retained my mechanical fan. I went with the ISIS radiator and have had no complaints. Beat on it through summer mountain runs and drift event and never seen my OEM thermostat gauge move. Maybe a real water temp gauge would tell a different story?

NICO Radiator Install => http://forums.nicoclub.com/isis-prod...s-t427793.html Altima Electric Fans:Another modification I was at first intimidated by but realized this is pretty easy as well. I used the first generation Altima fans (93-97). The fans and shroud costs $30 at a junkyard. Unfortunately the S13 is a litte more difficult to fit the fans in. I measured around 26.25" clearance between frame rails while the Altima fan shroud measured just over 28" wide. I was doubtful but if you trim the Altima fan shroud it surprisingly fits well.

My Tutorial => http://zilvia.net/f/showthread.php?p...13#post5750513

BADASS information on Cooling Setups: http://texasnissans.com/tx/forums/sh...ad.php?t=10117 Water pump:This is straightforward, your KA likely has ~200k miles on it at this point so replace the water pump. OEM replacement is fine. In hindsight, might not be a bad idea to change your front main seal while you're there as I did. Oil pump would probably be a good one to consider as well. If I had to do it over again I would've done the oil pump too for safe measures but it's all up to you in the end.

NICO Water Pump Install => http://forums.nicoclub.com/1991-1994...e-t220947.html KA Coolant Bleeding Procedure:This is the easiest and most simple way I've found to efficiently clear our cooling systems of air. I can't remember which forum I sourced this from but read carefully.1. Fill cooling system with whatever you want mix-wise with the bleeder closed. Fill it until it doesn't take any more.

2. Open the bleeder screw, squeeze the upper radiator hose frequently, fill it until no more air (only liquid) comes out.

3. Leave the radiator cap off and bleeder off if you don't get pure liquid out of it.

4. (Optional) Jack the front of the car up with floor jack or park on steep hill, front of the car facing uphill.

5. Turn the car on, put temp slider to full heat, turn blower on. Let car run and close bleeder once pure liquid comes out. Leave radiator cap off, let car warm up, add coolant as needed when it goes down (thermostat opens).

6. Once you have the thermostat open and heat coming out the vents, top off the radiator. If you want to double check the bleeder for pure liquid open it back up and see. Close bleeder, put rad cap on, and fill the coolant reservoir up to the line. Done  Intake:Most of you I'm sure already installed a cone filter but if you haven't, purchase one and install for now. Odds are nothing will fault here but it's worth making sure one more thing won't go wrong (advice from sleepy_steve). Gauges:The choice in gauges is all up to the driver. Some people want every gauge under the sun, others don't want any at all. I would recommend boost and oil pressure for someone low on budget while still providing some decent insight on how the turbo motor is running. A wideband O2 would be nice if you can tune and/or want to monitor combustion. Water temp is another good gauge to have as the factory gauge is not very accurate. Here is a quick DIY of a boost gauge install I did temporarily before the turbo was installed. Also, don't buy stupid tinted gauges like I did haha. I thought it was cool and would look nice but you can't see them worth anything, especially with a convertible.

First, choose your mounting location and test fit. I chose to get rid of my center vent and installed this gauge pod from eBay. I attempted to make one myself but sheet metal I had lying around was too thin.

Wire according to gauge manufacture. Most gauges don't draw much anyways so if you have three gauges you're looking to find a power wire for, the radio harness should have plenty to splice into.

This might also be a good time to start simplifying vacuum lines. I've seen some remove many of the lines coming from under the throttle body with the intention of having a vacuum block in the brake booster line. I chose to retain close to stock vacuum routing, will edit this if I have problems and modify. Battery:

You have two choices here: Relocate or resize your battery. I initially thought relocating to be cheaper and better but ended up choosing resizing. Smaller batteryYou will read everywhere about every which option to use. The most frequent options I see are:- Lawn mower battery

- Miata battery

- CRX battery

- Odyssey battery

- Deka battery (Rebadged as BigCrank, Braille and other brands)

In my opinion the lawn mower battery is underpowered for most applications and cuts too many corners, might be good for a track car but I am looking for daily duty in the always variable Virginia weather (100+ degree summers, below freezing winters). The Miata battery appeared to be a overpriced lawn mower battery as they have nearly the same CCA. The Odyssey battery was my initial first choice but after reading up on it I wasn't sold on this pulse technology capable of 680 CA but only rated at 220 CCA. The CRX battery sounded great too at 500CCA but was too wide at 9.5".

I found that the longest your battery could be for a quick and painless install was ~7" and the minimal CCA to turn over a KA is 356CCA (refer to FSM). This led me to the ever popular Deka battery. Some use the lightweight, small, low CCA versions but I opted for the Deka ETX30 that fit very snug in the stock battery location and rated at 400CCA. Not a lot of comfort room for starting but it'll have to do.

More battery Info=> http://www.freshalloy.com/showthread...weight-battery

Remove stock battery, rotate Deka battery as necessary and install.

I also modified some things and made a tie down. Photo above does not show tie down and only a temporary configuration. RelocateI chose against this for a number of reasons: my battery was old and about to go, venting the battery properly when in the contained space was initially difficult to account for, and 2GA wire is more expensive than I expected. Regardless...here's a tutorial.

Budget Battery Relocation=> http://www.nicoclub.com/archives/low...elocation.html Emissions (EGR, PCV, Charcoal Canister): One of the most confusing aspects of the turbo install for me, there really is many ways of doing this as well. I still can't tell you what works best. In my opinion this is the worst part of turboing a KA is figuring this out.Reading material:

240SX One EGR Removal => http://tech.240sxone.com/115/ka24de-egr-removal/

Zilvia PCV Discussion => http://zilvia.net/f/chat/285145-conc...worthless.html

KA-T PCV Discussion => http://www.ka-t.org/forums/viewtopic.php?f=2&t=27437

Zilvia Vacuum Discussion => http://zilvia.net/f/tech-talk/362347...help-pics.html EGRThe EGR system has been given a bad name but I don't think it's inherently bad. Positively the EGR system reburns exhaust while in vacuum to improve fuel economy (unburnt hydrocarbons), lower combustion temperatures which are already enhanced from the turbo, and lower emissions specifically NOx. The reason this is so commonly removed is because most are too lazy to weld a bung in the downpipe to continue to operate the system correctly. Admittedly, I have also ditched the system as well because it frees up quite a bit of space in the already tightly packed KA intake manifold and I didn't have easy access to a welder. In the future I'd like to reinstall this system. Below is block off plate that can be made from nearly anything. Trace the shape from the removed valve. Refer to the tutorial above this section on how to remove.

PCVHere's an example of the OEM crankcase PCV configuration:

Quote:

|

Originally Posted by S14DB

|

Here the red lines are connected in the factory NA setup.

I run the crankcase vent to a catch can (air-oil separator) that will draw air pressure out via the turbo intake. The valve cover port will have a breather filter on it and the 4-1 vacuum tree will be closed as indicated here. This a common method but some prefer an 'old school' method where you create a venturi effect by using your exhaust. The intake is an easier setup in my opinion but you do you, eventually I'd like to try the exhaust setup. Again, emissions are debated quite a bit and this is just my opinion.

PCV valve replacement => http://www.240sxforums.com/forums/ka...-dohc-dyi.html

More PCV info => http://forums.nicoclub.com/positive-...d-t446254.html

Even more PCV info => http://www.lotustalk.com/forums/f25/...r-vent-100572/

Summary of Different Crankcase Evacuation Methods => http://honda-tech.com/showthread.php?t=1199935 Charcoal CanisterMany simply remove all lines and canister then bend the hard line in the engine bay coming from the gas tank downwards. This is one option but I chose to remain close to emission legal ...err at least look like I am. I simply removed the two lines coming off the valve on top of the canister. The smaller, top one was then placed in vacuum by being attached to the turbo intake pipe while the other, larger bottom hose of the valve is VTA and pointed downward. This keeps the appearance of no modification even though it is VTA. AIV PAIR Valve (S13 only)Remove this.

NICO Tutorial => http://forums.nicoclub.com/1989-1994...l-t254273.html Oil Feed & Drain Lines:Ensure no leak and that the bung isn't too low on the pan or the oil drain line will not drain correctly. Incorrect drainage from the turbo from either too small of a drain line or incorrectly positioned oil pan bung is a failure point for any KA-T. Also account for the slight angle at which the KA sits at on the subframe. Cap the fitting once installed while still NA. Below is a pic of my turbo oil drain line.

Oil Feed/Return Line info =>

Great Links: http://forums.nicoclub.com/pics-oil-...g-t140446.html

http://zilvia.net/f/showthread.php?t=176575

For feed lines refer to this post:

Quote:

|

Originally Posted by Northwest Nissans forum

There are a few ways of going about this. Its really all about personal preference (some ways look cleaner then others but all work very well)

Greddy makes Two different ways to do an oil feed line.

The first one is an oil filter relocation kit. This one is the most expensive. This one is nice though because you can run the oil feed line to the turbo with the provided Oil filter block adapter (Sandwich plate) and it also is set up to let you run an oil cooler. (I dont have any pictures of this set up but its what I'm planing on running)

The second one is to just get the Greddy Oil filter block adapter (Sandwich plate) This will allow you to run a oil feed line around to the turbo and it looks pretty clean.

Greddy Sandwich plate

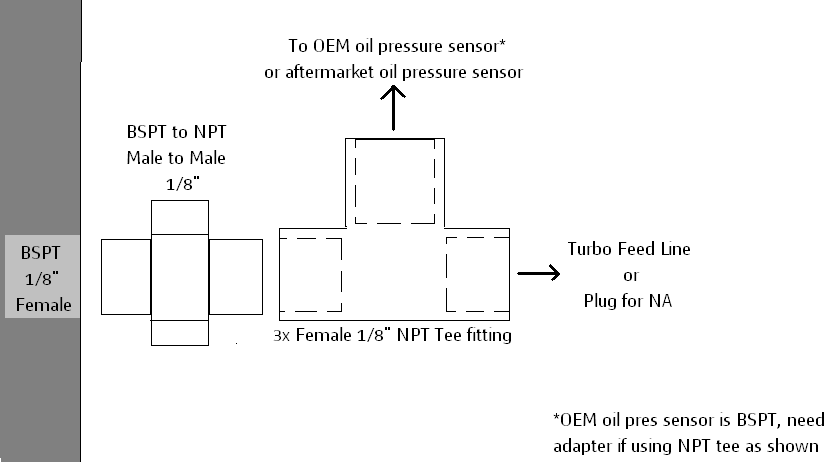

The third way to do this is from the oil pressure sending unit. Like the previous post said its just a few brass fittings and then run the oil feed line around the back of the motor and to the turbo. Its not always the cleanest looking way though, unless you take the time to make it look clean. Its probly the most cost effective way to oil your turbo.

Oil pressure sending unit

|

Brass Fittings => http://www.mcmaster.com/#catalog/119/36/=q6hwn4

Turbo End of the feed line info for T3 or T4 (with part numbers!) => http://forums.nicoclub.com/oil-feed-...ll-t96306.html

Here is my parts order from McMaster Carr:- 50785K219 Medium-Pressure Brass Threaded Pipe Fitting, 1/8 Pipe Size, Female X Female X Male Tee $2.81

- 5832T111 BSPT-to-NPT Threaded Brass Pipe Nipple, 1/8 Pipe Size X 3/4" Length, Fully Threaded $2.79

- 50695K171 Steel 37 Degree Flared Tube Fitting, Straight Adapter for 1/4" Tube OD X 1/8 NPTF Female $1.86

- 50785K161 Medium-Pressure Brass Threaded Pipe Fitting, 1/8 Pipe Size, Cap $0.91

I was already given a -4AN oil feed line, a -8AN drain line, and turbo fittings so they are not found on my list. For reference:

Fuel Pump:Thanks to the stock fuel pressure regulator, an upgraded fuel pump can be installed in a stock 240SX. Some have reported fuel pressure can be found to be 3psi higher at idle due to a more powerful fuel pump but performance should remain the same. There are plenty of tutorials out there on this, check out some of the following links:

Zilvia Fuel Pump Install => http://zilvia.net/f/archive-faqs/143...-approved.html

If you wish to do so, an adjustable fuel pressure regulator can be installed at this time too but I had no use for it just yet. All this allows you to do is exactly what it sounds like...adjust the fuel pressure if you wish to alter or tune the performance of your engine. Hot-wiring Your Fuel Pump:After installing the turbo, I had issues with an erratic AFR at idle and lean in boost (13.2). After reading a few threads and talking with Martin at RS Enthalpy, it was suggested I do this procedure. The basic premise is that stock fuel pump relays and/or wiring can become faulty and fail to send your fuel pump the full 12V signal. Typically fuel pump relays are designed for low load (9V) to enhance the life of the fuel pump and high load (12+V) to keep a rich combustion. This modification allows your fuel pump to see the high load setting all the time by wiring it directly to the battery through a relay (important!). Do not just run a wire from the battery to the fuel pump or use just a switch. For electrical noobs, a relay and an inline fuse close to the battery are a necessity for safe electrical operation.

Tutorial: http://www.ka-t.org/viewtopic.php?f=12&t=59949

More info: http://blog.amsperformance.com/2009/...r-to-run-lean/ Intercooler routing:Like many aspects of this project, this is another with quite a few different ways of doing so. Most use eBay S13 SR intercooler kits and have no issues. Some that do a low boost don’t run an intercooler at all. Others run a custom assortment of bends and couplings found on eBay, source at shops, etc. I was lucky enough to acquire an SR Greddy intercooler kit with piping that only required small modification to fit for cheap.

This is also a time to consider which layout you choose to place your MAF or convert to MAP. I will not lay out every detail there is to know on reliability, performance, etc of each but I'll explain briefly what I know. All requires different tunes so be aware when ordering pretuned ECUs and what not. The green box is the MAF.1. Draw through MAF

This method seems to be the most common and easiest to install but boost leaks would be a nightmare. One leak in the system and that's metered air going out the piping. This is most common because installation is the most straightforward. Be careful and don't place the MAF too close to the turbo inlet, it can cause screwy readings especially at idle.

2. Blow through MAF

My personal preference, this setup is more difficult to install and account for but provides better driveability and reliability. Please be aware that the tuner must know about this setup if applied. As many understand, the MAF readings are based off of a hot wire in the center of the MAF housing. This wire is then cooled by airflow, changes the resistance of the wire and as a result sends a proportional voltage signal to the ECU. Due to the effects of compressing air, flow from the turbocharger, even after intercooled, is still warmer than ambient air seen at the turbo inlet. This can result in a lean condition of operation due to reduced cooling effects on the MAF hot wire. My reasoning behind choosing blow through is that in the event of a boost leak, it is just boost lost at the MAF since it is placed so closely (~within a foot or so) of the throttle body. In other words you could blow a coupler off and continue on without incident. It’s important to note that the MAF should be placed in the center of a straight section to avoid turbulence generated at corners and what not. In Greg Banish's Engine Management: Advanced Tuning he also makes a point that

Quote:

|

Originally Posted by Greg Banish

Since airflow is biased towards the of outside radius of a bend, placing the metering element on the outside radius of a bend yields an output that indicates higher total flow than is currently present. The opposite is also true with reduced outputs resulting from element placement on the inside radius of a bend. Generally speaking, if the MAF must be placed following a bend in the inlet plumbing, it should be done such that the element in perpendicular to the plane of the bend...

Constant diameter approaching the MAF sensor is also desirable. Remember that the same mass flow through a smaller diameter increases velocity. If the diameter of the inlet plumbing increases immediately ahead of the MAF sensor, it often results in an unstable charge flow with plenty of tumbling. This tumbling air may cause the wire element to read incorrectly depending on inlet flow and velocity. A length of straight, constant diameter pipe is preferred before any mAF sensor. Typically this length should be at least double the diameter. This gives any tumbling flow an opportunity to stabilize before entering the sensor.

Many OEM applications reduce clocking and velocity effects by integrating a laminar flow element into the MAF sensor assembly. The design of these flow straighteners ranges from simple wire screens to honeycombs with an exceptionally high Reynolds number. Many performance enthusiasts looking for extra power mistake the laminar flow element for a genuine restriction and remove them. Benefits of removal rarely justify the loss in metering accuracy and usually fall well below statistical accuracy of most chassis dynamometers. Typical changes I have seen from such modification rarely exceed 4 hp at the wheels even on modified V8 engines. If a vehicle has a modified inlet system and erratic MAF sensor output, it is often helpful to install some sort of flow straightening. This can be done with a simple wire mesh or length of straight pipe leading into the MAF sensor.

|

3. MAP or manifold absolute pressure is virtually what a blow through setup wants to be. KA's are not factory equipped with MAP sensors so this is a completely custom job. Basically instead of measuring the flow rate of the air passing by the hot wire of a MAF, MAP sensors read intake air pressure in the manifold or plenum. You will have to research this yourself as I'm not well versed in this. Global Tech Engineering => https://www.globaltecheng.com/Produc...idCategory=145

Race Part Solutions => http://www.racepartsolutions.com/ind.../mandrel-bends

eBay

Make sure you aren't missing bungs for said Idle Air Control Valve (IACV). Although, no big deal if you do not have a bung for IACV on your intercooler pipe, you can be super racecar and 'crack' the throttle body open.

Quote:

|

Originally Posted by KA-T.org

What we mean when we "crack" the throttle body open, is just adjusting the stopping point of the throttle plate within the throttle body.

Basically, if you move the point where the throttle plate stops (in closed throttle position), you are allowing air into the intake. This supplies more air to the motor and raises your idle.

That is all the IACV does, is allow air into the intake to raise the idle and maintain it. It's just electrically controlled, and has been known to be a common failure point on intakes (I had this happen on my last 240 and it was a pain to deal with).

|

Quote:

|

Originally Posted by KA-T.org Photos

This is a picture from the passenger side of the car. The picture is of the throttle plate "cam" / wheel (whatever you want to call it). You can see the throttle cable coming in from the top. It's tied to your gas pedal.

When you push in on the gas pedal, the cable retracts and pulls the wheel counter-clockwise.

Full throttle stop

What I have circled is the full throttle stop. You should never have to mess with it, so don't worry about adjusting it. I just wanted to show it cause it's easier to see... The line points to the jam nut (retaining nut) that holds the position of the set screw. By adjusting the set screw, it changes how "open" the throttle plate goes.

180° from this position is the closed throttle stop which you will see in the pictures below.

This is the "closed" position throttle stop. It is on the bottom side of the throttle body. This is the piece we're talking about having cracked open just a bit to raise your idle when you have no other means of doing it (removed IACV, etc.)

Closed throttle stop

The green arrow points to the jam nut. It takes an 8mm wrench to loosen the nut. Once the nut is loose, you can use a 2.5mm allen wrench ( http://en.wikipedia.org/wiki/Allen_wrench ) to either screw in, or screw out the adjustment set screw (red arrow). By adjusting the set screw either in or out, you effectively change the position of the throttle plate when there is no gas pedal input. By screwing more of the set screw towards the wheel stop, you raise the idle. By retracting the set screw, you reduce your idle.

Here is a picture showing the throttle plate open a little bit (as if you're applying the gas pedal).

Hope that helps... |

Power Steering Reservoir:Potentially relocated if you choose to face the outlet of your compressor housing to the drivers fender. Conversely,you can clock the compressor housing downward and avoid the relocation of this PS reservoir and external coil at the cost of additional bends in the hot pipe. I have my turbo clocked downward and initially had to unbolt the reservoir for it to fit.

A more permanent solution will be a reservoir relocation, placing it in the corner with clutch master cylinder and brake booster. This is the way to go. Not only will the reservoir heat soak next to the compressor housing, but your power steering fluid will be more likely to boil over. I had issues while NA KA with boiling over my PS fluid at drift events. To correct this, relocate the power steering reservoir in the corner of engine bay right next to clutch master cylinder. It's so easy, don't stress it.

INSERT IMAGE

And while you're at it get some extra power steering lines and add a PS cooler. Super cheap to do. Here's a tutorial but it really only costs like $45 including lines, cooler, and ATF fluid (you should always use ATF for power steering fluid).

IMAGE

External Coil:Again, this may not need to be moved but this is all dependent on hot pipe routing. I didn't have to move mine and doubled the location as a holster for my manual boost controller

IMAGE Adjustable Fuel Pressure Regulator:Stock FPR is fine for 99% of turbo KA setups. I ended up installing one of these for future applications and experimentation. Spend the money on a decent one (SARD, Aeromotive, Tomei) to save yourself the headache of poor regulatory performance. My Aeromotive setup ran me around $200 which is steep but worth it. Also I read to remove the gauge once you're done because under the hood temps can damage it. If you just want a way to ensure fuel pressure is correct, I would recommend an inline fuel pressure gauge so you can ensure the fuel system is operating correctly for a fraction of the cost of an AFPR.

[PIC of AFPR] Upgraded Clutch:Another item I thought wasn't all that necessary but first time in boost and I was already kicking myself for not doing this beforehand. You can do your typical 240SX clutch upgrade or look into the White Bunny. I will leave the story-telling behind the name in other threads detailing this White Bunny setup but basically you can retain stock clutch pedal feel with greatly enhanced performance. I spent around $250 for a 13lb RB25 flywheel and Exedy RB25 stock clutch. A cheaper setup can be easily had but I valued the lighter flywheel.

http://forums.ma240sx.net/showthread.php?tid=16

http://www.nicoclub.com/archives/240...heel-swap.html

Tuning Options This section is still in progress (7/29/2014) as I hope to make this more of a general section. You have three tuning options as I see it:1. ROM "Mail Order" tune

2. Full standalone

3. Piggy-back tuning

And for those of you looking to tune or even modify a ROM tune with a SAFC...just don't do it..

Quote:

Originally Posted by Croustibat

Quote:

|

Originally Posted by Zilvia member

It doesnt hurt, thats what I did with my first S14. Enthalphy romtuned, AFR was dipping down to 10s, leaned it out a tad bit to 11-11.5 at WOT with a SAFC.

|

Congrats ! You just ruined the timing part of the tune

This goes to all SAFC users: do yourself and your engine a favor : throw that piece of crap in the nearest bin. What is does is altering the MAF signal to make the ECU believe there is more/less air going in. Problem is, that MAF signal is used to compute the "load" of the engine (TP value), and that value is used as an axis on the main and secondary fuel map AND timing map, amongst other things.

Lowering fueling by changing the TP value means you are most likely to be adding timing advance. Enriching usually does the opposite... usually, because there is a reason there are TWO distinct maps with the same axis : the values between the fuel map and the timing map are not proportional.

SAFC users don't know anything about tuning, because anyone who does would not touch an SAFC, even with a pole (a hammer is ok though)

that being said, if you want a spot on tune, SORT THE CAR, then get it tuned on a dyno. There is no other way.

If you can be satisfied with a conservative, generic tune, then get a rom tune.

And by all means, if you don't know enough about engine tuning to do it yourself ... DONT do it yourself with a SAFC... |

__________________

Last edited by bmaddock; 12-02-2014 at 01:51 PM..

|