|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Engine Tech Technical discussion related to all relevant engines such as KA, SR, RB, CA, 2JZ , L24/26/28, VG, VQ, and LSx series. |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Nissanaholic!

Join Date: Jan 2009

Location: Definitely NOT FL....

Age: 29

Posts: 2,491

Trader Rating: (25)

Feedback Score: 25 reviews

|

Is the timing in my tune too aggressive?

I know this is a longshot, but I know nothing about tuning and just got yet another cracked ringland on my freshly rebuilt ka-t running only 8-9psi. It was running 14-16psi when originally tuned but handled it great until I blew the headgasket and kept driving because I thought it was just air in the system. This last instance, the motor was freshly rebuilt with new rings and bearing. I compression tested it a month ago, 750 miles in and it made 190psi across the board. Last night I drove to a friends, didn't beat on it or anything, and when I went to leave I immediately noticed it sounded down a cylinder while turning over. Sure enough, I tested it today and it made 190-185-190-115. I've suspected my tune my be an issue, but it ran absolutely fine with no detonation or knock. I also figured by lowering the boost I wouldn't have an issue.

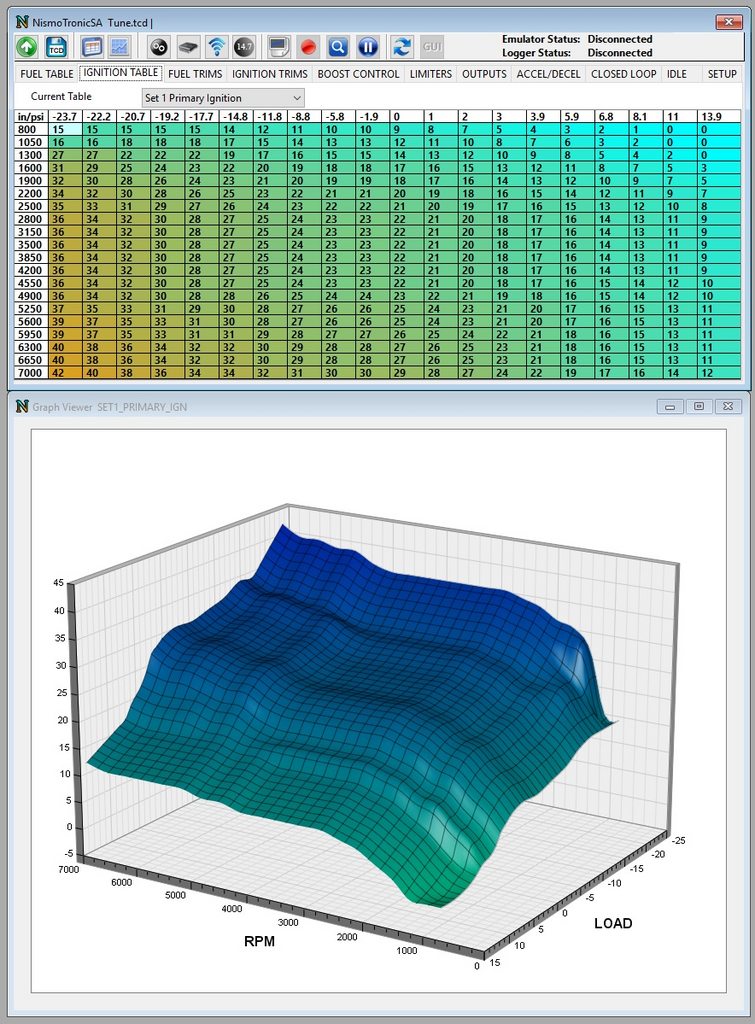

So, rambling aside, I plan to have it retuned once fixed, but I'm really curious to know if my timing is too aggressive or if there's anything that stands out on my Nismotronic tune. My setup is stock ka, STI 525cc injectors, twisted motion 2871 turbo, speed density, and typical bolt ons. Thanks in advance. My Tune

__________________

|

|

|

|

| Sponsored Links |

|

|

#2 |

|

Leaky Injector

|

I don't know much about ka-t.

Screenshot of your timing map from your TCD.  After doing some reading on KA-T timing you're values seem about right, and since you had it tuned professionally I'll assume they had some way to read knock. I'd rely that they backed it off from any knock threshold vs. my uneducated internet opinion. Sorry, not much help. Good luck!

__________________

1990 240SX SR20DET GTX2863R Last edited by nick_d_240sx; 01-21-2020 at 08:23 AM.. |

|

|

|

|

|

#4 | |

|

Nissanaholic!

Join Date: Jan 2009

Location: Definitely NOT FL....

Age: 29

Posts: 2,491

Trader Rating: (25)

Feedback Score: 25 reviews

|

Quote:

They are stock pistons. The motor is completely stock internally. I just did a hone, new rings, and had the crank checked and polished and new bearings. The only "crazy" thing I have going on is 248/232 cams which were on there when it was tuned. Since the original tune I haven't changed anything about the setup.

__________________

|

|

|

|

|

|

|

#5 |

|

Premium Member

Join Date: Jun 2003

Location: torrance, ca

Age: 39

Posts: 12,407

Trader Rating: (129)

Feedback Score: 129 reviews

|

first things first, do a leakdown to confirm that the low compression is caused by the rings, and not a damaged valve or valve seat.

once you get the head off you can see if theres damage to the piston (i'm thinking maybe you have an injector that's clogged/failed, causing that cyl to run way lean) do you have any provisions to adjust the timing on the cam gears? JWT gears? |

|

|

|

|

|

#6 | |

|

Nissanaholic!

Join Date: Jan 2009

Location: Definitely NOT FL....

Age: 29

Posts: 2,491

Trader Rating: (25)

Feedback Score: 25 reviews

|

Quote:

__________________

|

|

|

|

|

|

|

#7 |

|

BANNED

Join Date: May 2019

Location: Florida-FAIL

Posts: 2,497

Trader Rating: (8)

Feedback Score: 8 reviews

|

Said its the 3rd cracked ringland u had...is it always the same cylinder?

And at this point why not just invest in some aftermarket pistons n rods? Seems like a waste to keep pulln motors and keep rebuilding with oem internals |

|

|

|

|

|

#9 | |

|

Nissanaholic!

Join Date: Jan 2009

Location: Definitely NOT FL....

Age: 29

Posts: 2,491

Trader Rating: (25)

Feedback Score: 25 reviews

|

Quote:

As for the original question, no. It has never been the same cylinder. The first time was I believe number 3, second time number 1, and this time number 4. Until now I had assumed it was due to driving with a blown headgasket. The first time the car hit, according to nismotronic, 380F mid run. After that there was constant smoke out the pcv and the motor shot out a bunch of oil at the next event after replacing the head gasket. The second, which was the last event I drove, the head gasket didn't make a spectacular blowout like the time before but it started idling at 200F and would climb as soon as I started driving, came to find out there were combustion gases in the coolant. It had been hitting 240F throughout the day after multiple lap runs, which seems normal for ka's, but by the end was taking longer and long to cool back down until it didn't cool down at all. This time it was completely out of nowhere. Since this refresh and installing a swirl pot the motor hasn't seen over 160F and I'm also running MLS hg and ARP studs this time around. I'm still going to get a retune. I figure the issue has to be fuel or tune related so I will change both. I'm also going to replace my o2 sensor for the wideband just to ensure that's working correctly

__________________

|

|

|

|

|

|

|

#10 |

|

Post Whore!

|

The point of forged pistons isn’t always to make big power. It is for reliability purposes as well. They are far superior for absorbing some of the detonation that comes with bad fuel, or errors in the tune. You can put stock sized forged slugs in and call it good. Worth the investment if you’re opening it up for the 4th time.

__________________

My SR20VET |

|

|

|

|

|

#11 |

|

Zilvia Member

|

Whatre you gapping your rings at? I skimmed and could have missed but you could be causing this running stock gap on the rings.

Just bringing this up as detonation/preignition aren't the only things that cause your ringlands to give up the ghost. Like another said, time for forgies. I cracked ringlands without causing detonation on my oem slugs. Granted they had a hundred or so thousand miles on your build. The stock cast aluminum pistons in the KA just arent designed for the kind of pressure you subject them to with a turbo on there. If youre staying under 400 crank hp take the stock rods and have them peened. Theyll hold up fine. If you have any inkling of going over that, just build it now. Id also give calico a call in NC. I had them coat my main and rod bearings. Wasnt much more and a good investment in a motor you're going to be wailing on. |

|

|

|

|

|

#12 | |

|

Nissanaholic!

Join Date: Jan 2009

Location: Definitely NOT FL....

Age: 29

Posts: 2,491

Trader Rating: (25)

Feedback Score: 25 reviews

|

Quote:

My power goal is no more than 275whp. I'm heavily contemplating switching to an sr t28 while it's out, so I'm going to stick with stock internals. If it blows again, so be it, I'll just slap a na ka back in and drive it like I used to. That said, I made an important discovery. My wideband is wired into the nismotronic, so no factory o2. I noticed that what's reported to the ecu is different than what shows on the gauge itself by almost a full number. So when the gauge shows 11.7 WOT the ecu shows ~12.7. I'm assuming what the the ecu is showing is what it actually is, which means it's leaning out. Pretty stupid. I posted on the nismotronic page and the only suggestion I got was to reground it, which I did to no avail. They have since stopped replying over there.

__________________

|

|

|

|

|

|

|

#13 |

|

Zilvia Member

|

That cant help (your wideband issue). I think you're pushing the stock pistons up to their bleeding edge. Your rods will hold up just fine but over 300 crank hp you,ve over doubled what they run in factory form. Just my .02 but if it were me I'd do an eigth overbore to control tolerances and get a good set of 9:1 forged pistons in there an never worry about getting in the engine again. Ring gaps dont seem too crazy.

Does nismotronic allow you to program a custom curve in? Usually grounding directly with the ecu ground will align the wideband output with the ecu reading. Weird. |

|

|

|

|

|

#14 |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,649

Trader Rating: (17)

Feedback Score: 17 reviews

|

according to the table its around 13-15* at 9-11 psi of boost

Which is what i would have used. However, how do you know the timing is actually staying there at that rpm? Did you ever run the engine to redline on the dyno with a timing light to check? (who does that anyways) I know that isn't easy to do or always possible. Its just a mental check for you to look into how the dwell and coils are configured. Sometimes it makes a difference. What you can do however is use the dynojet wideband to verify your own. I think that is very important. Okay you want to use a cast piston, thats fine. They are great pistons for daily driving because they don't expand much so when you start the engine cold they fit great and the engine keeps it's oil quality up over time. However if you get cast pistons hot, they expand a bit like any material would, and the cast aluminum is very brittle and easy to break in that state. They already fit tightly and are very easy to overheat. I think this is your issue if you are 'tracking' the car. That is, repeatedly boost back to back. As opposed to say, drag race run followed by a cooldown/shutdown, then another run etc... Luckily this issue is extremely familiar and easy to correct. You probably need to simply control the piston surface temperature using water injection. Aux 100% distilled water at the correct flow-rate to hold the EGT down below say 1250*F~ pre-turbine should/could solve your problem. The piston/chamber temp getting too hot is what is causing pressure spikes which blow holes in things like head gaskets and pistons. This happens when using poor fuel like gasoline in a hot track setting with no cooling what so ever. EGT climbs rapidly especially when compression is high and engine flow rate goes up due to turbocharging which tends to promote high EGT in the first place. This is compounded further by small-size turbocharging and high exhaust gas pressure (small turbines). In other words, a large/huge turbo with slightly reduced compression would be more tolerant of the heat with the same piston at the same boost pressure. Just sayin' you could take steps, open the cam duration, open the exhaust (tubular or larger) bigger turbo, better intercooling, all of that would help, they all lower EGT/chamber temps. But the shortest path is water injection. |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|