|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Chat General Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

#31 | |

|

Zilvia Addict

|

Quote:

I also agree that all these huge shiny catch cans and meters of hoses connected to them change volumes and pressures in PCV system which might actually change things for worse. I still want to prevent having oily deposits before throttle plate and was considering replacing "that black can" with slightly smaller can to keep volumes similar to stock. And, ... there is a restrictor in the hose connected to that "T" on valve cover to regulate the flow and pressures I assume. I think that removing it and adding small catch can between "T" and intake pipe will help keep things more clean. The only problem and question is how to keep that catch can accurately restrictive for healthy engine? So, instead of that small filters that vents to atmosphere a good designed catch can should have means to monitor pressure and vacum, and to adjust baffling accordingly. Am I right, or should we just keep all system stock and let intercooler collect all oil vapors like in VW and Audis lol. |

|

|

|

|

| Sponsored Links |

|

|

#32 | |||||

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,648

Trader Rating: (17)

Feedback Score: 17 reviews

|

Quote:

Yes, worse is a possibility. Anything we do can make it worse. The key is to simply MONITOR with a gauge. Either using a 2-bar map sensor can work, or a gauge which reads in inches of water like this https://www.ebay.com/itm/Dwyer-Magne...EAAOSwGzNeHODB 60" of water = roughly 2psi so this is a very accurate high resolution gauge for monitoring crankcase pressure (example) in case you can't log the 2-bar data. Quote:

Quote:

Quote:

Quote:

If we look at an engine with a broken piston, we see that it gushes oil when it goes WOT. That is, crankcase pressure (blow-by) is pushing oil right through the baffle. So it stands to reason that crankcase pressure is what is pushing oil into the baffles in the first place. I don't know why this is so hard for people to understand. So if positive pressure (Broken piston, etc...) can push oil OUT of the engine, THROUGH the baffle, What do we think logically that negative pressure can/will do for the engine? Answer: A pressure drop inside the crankcase will pull oil INTO the engine, it will pull AWAY from the baffle. It will pull oil OUT of the engine's seals, or at least impede the progress of oil somewhat. This doesn't take calculations, just a logical conclusion based on experience. I see pressure pushes oil out of the engine, therefore, vacuum must do the opposite. Does it make sense? If we look at engines with vacuum pumps, their success depends heavily on the engine seals being superior, they need very strong seals to resist the high vacuum from the pump. And the reward is a superior RING seal, and more engine HP. What many people forget is that the crankcase pressure DIRECTLY influences ring behavior. All this talk of oil flowing into and out of baffles and everyone is ignoring the fact that blow-by gasses are impeded by the crankcase pressure, e.g. when there is a positive pressure in the crankcase, it will hinder the piston ring performance, it will prevent blow-by from gaining access to the crankcase via the second ring, blowby gas pressure differential becomes elevated between the first and second piston rings, which leads to all manner of piston ring issue, poor sealing, flutter, whatever Its so hard for me to understand how people can see what vacuum pumps do for an engine and then not to be able to put 1:1 together with their own crankcase systems. ----- Here is another way to look at our situation, typical evaluation The engine starts out with a correct filter and pressure drop from the OEM factory. Along comes an unaware enthusiast and he uses a high flow air filter to gain 5% HP or whatever by eliminating PCV function and ruining the WOT pressure drop. Now the engine will push oil into it's baffle system at WOT and the intake manifold will become soaked saturated over time with oil as a strong manifold vacuum will pull all that oil right out of the baffle after it's done pushing oil at WOT. Condition similar to a partially broken piston ring. The high WOT pressure further hinders ring function so blow-by is increased above natural quantities, i.e. not only is there MORE blow by, there is now even MORE oil going into the baffle system. Then he complains about the oil in the intake manifold a couple weeks later "holy cow look at all this oil! OMG I need a catch can... whats wrong with those stupid engineers??" So along comes the catch can, which is going to collect a stagnant reservoir of engine oil over time. Everytime the engine starts the can heats up with 200*F oil and everytime it cools, water vapor from combustion can settle "condense" inside the can and mix with engine oil, and this will get re-heated everytime the engine is re-warmed and mix back with the existing oil supply. Thus the stagnant can quickly acidifies and 'waters' down the engine oil (its alot easier for water molecules already dissolved into engine oil to move through engine oil), accelerating the oil's destruction, increasing the rate of oil consumption and engine wear over time if the oil isn't constantly changed at higher than typically necessary intervals. This is plain, due negligence for an engine, and adds unnecessary cost. And if that wasn't enough, the additional volume of the added can is making it more difficult for the existing pcv system whats left of it, to pull a pressure drop on the crankcase, ruining ring function and increasing the blow-by and oil aspiration further. The larger catch can is making matters worse all around, its like treating the symptoms of cancer instead of preventing the cancer in the first place, i.e. they gave the engine cancer by eliminating WOT pcv pressure drop and then treated the symptoms with a harsh drug(stagnant catch can volume) that further damages the engine over time (chemotherapy). Instead they should remove the can, and induce the proper PCV pressure drop at WOT, and the cancer won't be there in the first place. You won't need a can if the WOT pcv pressure drop can prevent oil from flowing into the engine's baffle in the first place. Just don't forget to clean the baffle out, you know once every 100k or so is fine, sometimes 200k. Its not rocket science, cleaning a valve cover, if you can install a can you can wash a valve cover once every 10-20 years. |

|||||

|

|

|

|

|

#33 | |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,648

Trader Rating: (17)

Feedback Score: 17 reviews

|

Quote:

I forgot to comment on this fully. Not all engines are turbocharged, and would those will not benefit from any oil coating. This is a good line of thinking which I believe many engineers have also reasoned with, since we cannot prevent 100% of the oil from exiting the crankcase at WOT for 200,000 miles, and many consumers will not be savvy enough to realize the need to wash their intake plumbing every so often (sigh), why not design a very small "catch" device which can be easily cleaned and is small enough to not impede WOT pressure drop? Such a device does exist, I've seen it. Here is one such company which offers that device. They make some catch devices for corvettes, naturally aspirated, which will reduce or eliminate the oil which can gradually coat the throttle body (since there is no turbocharger or intercooler plumbing). Its not really a can. Its just a small air/oil separator, and excellent idea and minimal volume. The same company also offers inline restrictors to correct pcv function as necessary. So you are correct to imagine such a thing. It is not such a bad idea. I am not against oil CONTROL. Its just that there are soooo many ways to screw up the necessary design of a PCV system... you really have to be a master enthusiast or an actually experienced+engineer to relate the details... volume, flow, viscosity of fluids, intended effect. And this is the most critical system on the engine in my opinion. It literally controls the quality of engine oil, the longevity of an engine, the leakiness or potential for oil leaks of the engine, the piston ring function, and the cleanliness of the engine's internals over a long period of time. It is the most important thing to understand about performance, and often the last thing, most highly neglected aspect of all that people will understand... if ever. Ironic |

|

|

|

|

|

|

#36 |

|

Premium Member

Join Date: Dec 2006

Location: 717, PA

Age: 35

Posts: 3,153

Trader Rating: (5)

Feedback Score: 5 reviews

|

I've used greddy ones in the past, but was never super impressed with the results, mainly because I never liked the idea of the oil never returning to the system. Instead I'm going to run this moroso oil separator and instead of having the drain at the bottom that's shut off, run a line that connects down where the factory line goes on the SR (ex mani side). I saw the piece at a moroso booth at FD a few years ago, it's a little larger than I expected, but a nice piece.

__________________

|

|

|

|

|

|

#38 |

|

Premium Member

Join Date: Dec 2006

Location: 717, PA

Age: 35

Posts: 3,153

Trader Rating: (5)

Feedback Score: 5 reviews

|

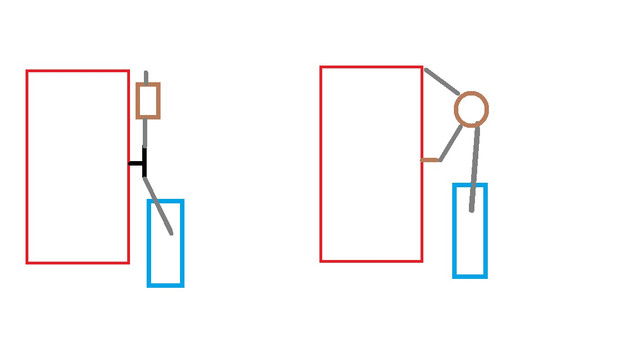

hmm, so is there a check valve in the oem unit? I can understand that while under load, the turbo would create some vacuum, But really so much that I'd pull oil out of the pan? How does the OEM setup not do this? It's been awhile, so I may be wrong about this, but there's a line that comes out of the bottom of the block, goes to the OEM oil separator, another short line to the "T" on the valve cover (S13SR), then another hose that goes to the inlet for the turbo.

I was going to ditch the "T" fitting on the valve cover, run one line to the moroso tank from the V.C. , another line to the inlet tube for the turbo, then run another line from the bottom of the tank to the bottom of a block, to reintroduce the recovered oil. I even made a little doodle of this and compared it to the OEM setup. If I'm being stupid, that's fine...not the first time. My thinking was the oil would get trapped in the separator under load, then off throttle , the oil would make its way back down to the pan.

__________________

|

|

|

|

|

|

#39 | |

|

Zilvia.net Advertiser

Join Date: Nov 2005

Location: Michigan

Age: 33

Posts: 5,430

Trader Rating: (16)

Feedback Score: 16 reviews

|

Quote:

Then my welded -10 fitting to a different catch can, with a -10 line back to the turbo intake. This can will also have a small drain line returning to the sump. If there's good airflow in the system, there's no way you should be able to pull oil up through the drains. Path of least resistance and all that.

__________________

Build: http://zilvia.net/f/showthread.php?t=643065 Friends don't let friends buy knock-offs. |

|

|

|

|

|

|

#40 |

|

BANNED

|

Ah, i see what you mean now. No that would work as long as the return line is large enough for the air and oil to bypass eachother like the oem one is designed. You could have a multitude of issues if the crankcase vent/oil return line is too small or restricted by a 'U' shape in the line where oil could pool. Oil has to have gravity pull it back down into the pan

On second thought, you may need some kind of oil baffling inline for the crankcase side depending on how the can is designed. The oil vapers need to be consolidated from the air before it enters back into the intake |

|

|

|

|

|

#41 | |

|

Premium Member

Join Date: Dec 2006

Location: 717, PA

Age: 35

Posts: 3,153

Trader Rating: (5)

Feedback Score: 5 reviews

|

Quote:

It's just a street car, its nothing crazy. I'm not going for the end all, be all, solution. I just want to keep oil out of the turbo if I can help it.

__________________

|

|

|

|

|

|

|

#42 |

|

Zilvia Addict

Join Date: Jul 2006

Location: Boston Area

Age: 36

Posts: 663

Trader Rating: (15)

Feedback Score: 15 reviews

|

http://www.eliteengineeringusa.com/flow-restrictor/

For those of us that don't have the factory restrictor (in my case never did) what do you think of adding this in-line to the turbo with no catch can? Also, i've never had the factory black air/oil sep. box either. So that means the crank case volume is less than OEM. Which means from all this jumbo i've read. my PCV system pressure is probably not ideal. what do we do here? especially taking into account running a "high flow air filter." Honestly, reading that 21 page oil catch can thread and now this I don't know exactly what to do.. haha. Are we over-complicating things? not facing bottom end issues? not tuning accordingly? I understand everything everyone is saying here and taking it into account on my current setup. Ive never interrupted the PCV valve, just replaced it once. This past year the car didn't get driven much.. but I did not run a catch can. stock turbo @ 12psi

__________________

95 SR Zenki | @ e_form daily - A34 Maxima | A36 Maxima |

|

|

|

|

|

#43 |

|

Premium Member

Join Date: Oct 2004

Location: San Francisco, CA

Posts: 5,824

Trader Rating: (13)

Feedback Score: 13 reviews

|

On the 21 page thing, that is really more towards track use / elevation change / and just more boost. I was running 19 to 21 psi on a 2871r and big elevation change like Laguna Seca or Sears Point or Thunderhill. So it depends.

I would love my catch to drain back, but problem is that I would need a check valve cause on the track, I am rarely off throttle or not on boost. For street setup, just get the radium dual catch system and call it a day. Daily isn't going to do much, heck I would just run some form of air oil separator between the T and the crankcase and call it day. This is on the S13 T fitting. S14 and 15s you are fine. So depends, if you don't drive it like REALLY hard and live only between 5k and 8k.... this isn't going to happen that often

__________________

Turn and Burn! Turn and Burn!

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|