|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Builds (and builds only) Got a build thread? It goes here, build threads anywhere else on the forum will be locked and never moved. |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Core4 Motorsports Endurance Racing Saga...

Hey guys, I figured I'd migrate my build thread from www.nissanroadracing.com to here since it is like a morgue over there these days. It's a long read initially so hopefully you get through it and enjoy it. It covers a lot of time.

***SUBSCRIBE to my YouTube channel to catch live streaming of my racing events as well as other videos: https://www.youtube.com/channel/UCed...=subscriber*** Follow us on Facebook: https://www.facebook.com/core4motorsports/ https://www.instagram.com/core4motorsports/ www.core4motorsports.com ---------------------------------------------------------------------------------------------------------------------------------------------- New Years resolution: BUILD THREAD! This is something I've been wanting to do for a long time. Not only to document and share my journey through the rapidly growing grassroots endurance road racing genre that's happening in the US, but for my own compiling of information and progress with the development of myself, my car and team. I’m treating this like I started back in 2013 so IT’S A LOT. I have posts scattered all throughout the forum since then that cover technical issues of my first S13 race cars, but to get that all in here ordered properly is tough. From this point onward however, I will do my best to post everything I do in here. I’d also like to mention that I have access to lots of equipment at my work, including CNC vertical milling machines and professional CAD/CAM software that I always use for designing and making stuff for this racing adventure. Some of the stuff I’ve made I intend on offering, including a bolt-on rear Wilwood BBK that doesn’t require cutting the stock caliper mounting ears (only works with OEM steel and Z32 uprights for now) that will cost you less than $900 for everything. I will also offer radial mount caliper brackets (based off of a design Def created) to run Wilwood FSL6R calipers with Defsport rotor hats. Hopefully a full kit in the future for people who don’t have Defsport hats already. I can now finally brake confidently along side BMW’s with this setup. More on these later, I’ll start rambling now… Ever since the introduction of the 24 Hours of Lemons racing series in 2008, the endurance genre of amateur racing has grown tremendously. There are now no less than 5 entry level endurance racing series (24HoL, WRL, ChumpCar/ChampCar, AER, LDRL) across the country that cater to different rule sets and regions, but all mutually related as one spun off another and snowballed from there. All of them fill the grid for every single event. Although late to the game, SCCA also created something called "bracket enduro." And there's good reason for it; nowhere else will you find the bang for buck that endurance racing provides without sometimes irritating, stickler rule sets (with the exception of maybe Chump/ChampCar). You literally accumulate 1000's of laps of wheel-to-wheel racing experience with relative speeds between different classes of cars that compare to pro racing. The laps per dollar can’t be beat at the grassroots level. So if you and a group of friends/family have been considering entering an event or campaigning, I'd highly recommend doing it if you're getting bored and trust each other. I started HPDE's in 2005 and have been driving on track several times per year since then. I took a more unorthodox approach to racing vs. the standard NASA/SCCA HPDE ladder climb to getting a comp license by starting in the 24 Hours of Lemons in 2011 with my boss's 1985 Alfa Romeo Milano (Team Pro-Crash-Duh-Nation). He's an Alfa Romeo junkie and also vintage races older Alfa's. His car is cursed. He started racing it in 2009 and still hasn't won a race overall, but has multiple 2nd place finishes that I've been a part of almost every time. Does the picture look familiar?:  Yea, that’s his car nailing the deer. It does sounds incredible though!: Alfa V6 Aural Bliss Fast forward to 2013; I've learned a ton on what it takes to actually win one of these events. My brother, myself and a couple of friends decided to embark on building an S13 to run in 24 Hours of Lemons and ChumpCar (which recently acquired the rights to and renamed to the ChampCar Endurance Series). We picked the S-chassis for obvious reasons, and ironically I went full circle as a S13 hatch was the first car I ever owned 20 years ago (which I bought for less than what they are going for today). This one was found in New Jersey from the all-too-common aspiring drifter in January, 2013: Sorted the car out for the teams inaugural race at New Jersey Motorsports Park (NJMP) in August, 2013 using a cage kit from rollcagecomponents.com (highly recommended) and built to simplicity, lightness and reliability. Welcome team "Abe Froman Racing." We didn't care about the gimmicks, we just wanted to race and win like all the A-class 24HoL cars. Of course some chassis prep: Cat hump clearance removal  Custom seat bracketry  rollcagecomponents.com cage kit installation:  Some custom front ARB brackets:  The goal was just to finish the 1st race without a mechanical issue. To finish first, you must first finish! The car was reliable as ever, but the drivers weren't. We were black flagged out of the race on Saturday about 6ish hours in (4 black flags in a day gets you parked for the rest of the day in 24HoL), but had a flagless and incident free Sunday. Finished a paltry 36th out of 136 cars, but had the 3rd or 4th fastest lap of the weekend. Comical black flag penalty when the judges had enough of our passing under yellow shenanigans:  BMW’s forever haunt us:  when there were 6:  So fast forward a couple other mediocre finishes (but with 3rd or 4th FLW’s) to the May, 2014 NJMP race. The weekend from hell. First, the OEM fuel pump wiring circuit decided to start going haywire on race day when on practice day it was perfectly fine. Got towed in no less than 4 times. Finally bypassed the OE circuit completely and direct wired the fuel pump from the switch panel and all was well.....for about 1.5 hours... then this:    (yes those are plastic Salami’s/sausages lol. Abe Froman Racing!) An E30 blew its engine a few seconds ahead of our driver (also least experienced) thru the fastest turn at NJMP Thunderbolt. A turn that’s WOT, starts the main straight and well known for eating cars on the inside tire wall when people lift. With no in-car video or data, we’ll never really know what happened, but it’s probably a combination of a bit of oil and panic braking mid-turn. After a couple days of deep depression and deliberation about salvaging the chassis, we wasted no time and picked up another S13 that was in drifter purgatory in Queens, NYC. My wife was due in a week and a half with our 2nd baby at the time so it was a now or wait-many-months moment with getting another chassis.   The thing was terrible. Teal spray paint covering everything. What the hell are dudes/dudettes smoking? The build continued in early-mid 2015 to hit the August ChumpCar race at Limerock Park, CT. 2 guys had quit the team after the last race and we were down to 4 members. New team name also. Team Failken: Formula D-Bags. The decision was made to re-use the cage from the wreck vs starting from scratch. Whether or not this is less work like we had envisioned is debatable. Anything roll cage related is a **** ton of work, even if it’s a “kit.” We cut the roof off of both cars, removed the cage and hoisted the cage into the new chassis. We braced the new chassis with some square stock on the frame rails and A to B pillars. The cage had some preload in it from welding so it moved a bit once it was released from the wreck. Of course it required some manipulation to get it right in the new chassis. In 5 weeks time we went from this:   to this:  to race ready:  The Limerock ChumpCar race was an ok result. We had zero sleep and were beyond exhausted. We placed 4th in class and 15th out of 60 cars, another top 5 fastest lap. We had issues with overheating due to using a crap stock radiator to comply with ChumpCar rules, and our clutch was slipping in 5th gear because we forgot to adjust pedal actuation during the re-build and were too dumb/brain dead to realize it at the race.   Next race was 24HoL New Hampshire Motor Speedway in October, 2015. WE WON! 1st place overall in a field of 107 and had the 2nd fastest lap of the weekend. The car didn’t miss a beat. The start of Sunday morning was cold and raining, with P1 thru P3 on the same lap (we were P3). We were gifted when P2 got wrapped up in P1’s spin in the first lap and took both out of contention: Short clip of P1 taking out P2 Talk about luck. The rain eventually dissipated and we were able to pull away from the field. Our first race win and last race with the 24HoL. The payout in 24HoL is in rolls of nickels. Some eyebrows raised when I went to the bank to exchange the $500 in nickels lol. The KA24DE now had about 70 hours of racing.    |

|

|

|

| Sponsored Links |

|

|

#2 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

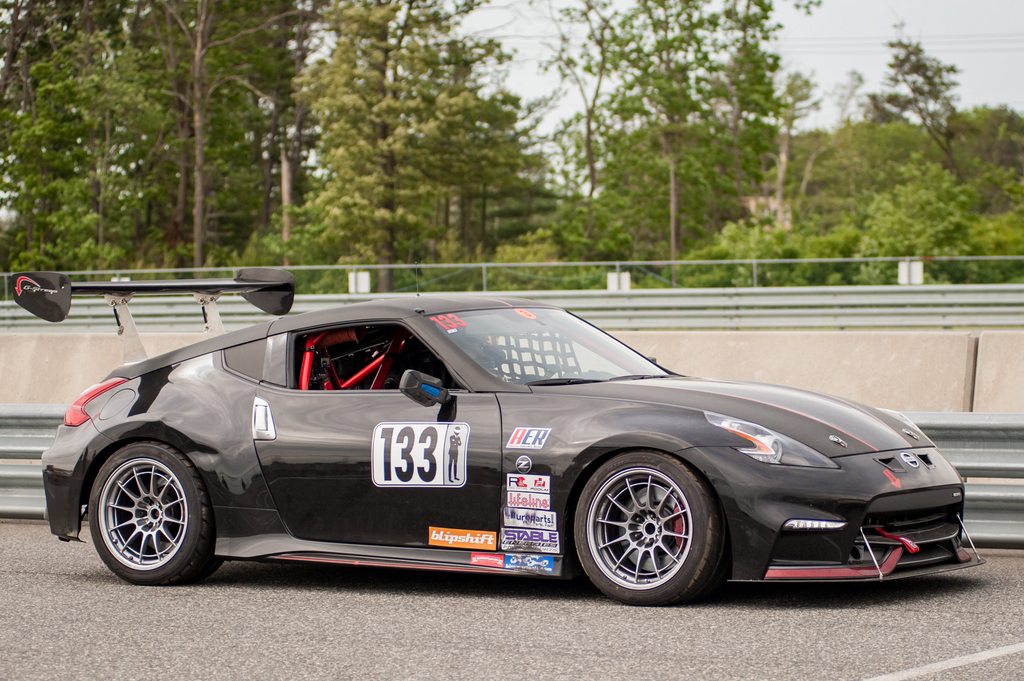

In 2016 we decided to focus solely on AER (www.americanenduranceracing.com). The minimalist rule set, run what ya’ brung mantra, East region focus, and level of competition was enough incentive to go all in. A similar feel to WRL (www.racewrl.com), but with a different classing system (AER = Lap time based, WRL = power-to-weight). We got the car up to snuff aesthetically and with some fancier suspension bits. We also changed our team name to our current Core4 Motorsports.

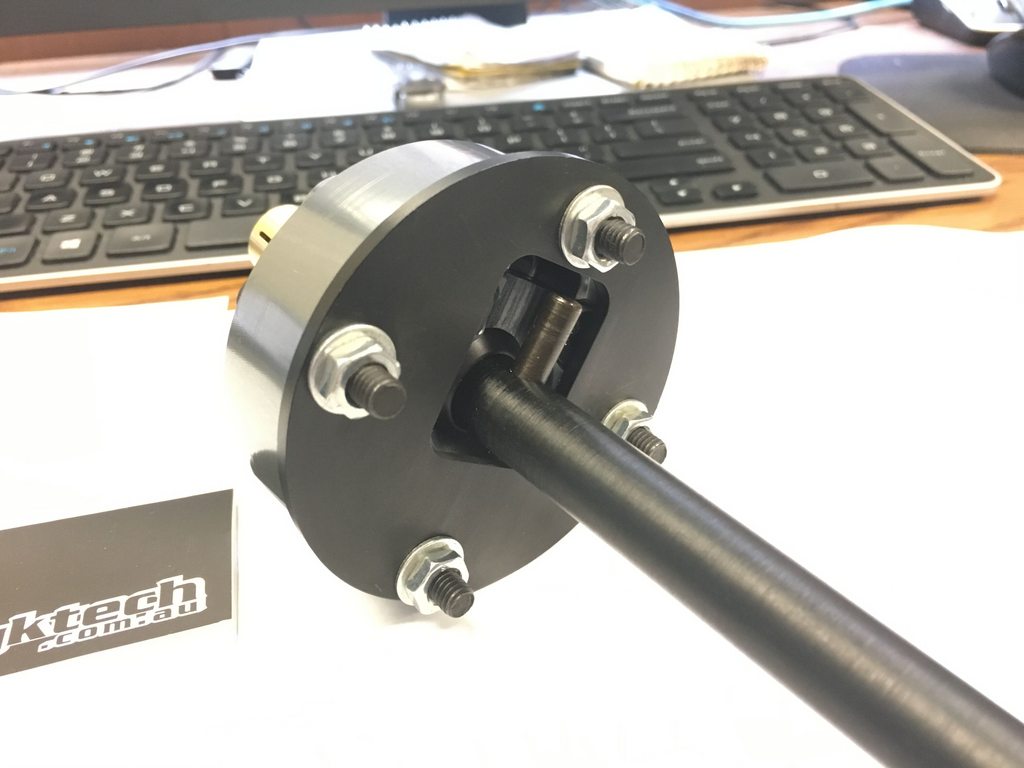

Made a custom high capacity oil pan with trap doors for 6qt capacity:  AER Watkins Glen in April, 2016 Our expectations were pretty high considering we won our last race. The format of AER races is Friday qualifying day, and 9 hour races on Saturday and Sunday. AER typically sets 5 classes; class 1 thru 5 with 5 being the fastest of the bunch, and a class of attrition because the hardware is fast and expensive. Since it is lap time based, it is very driver dependent, but an idea on the class 5 cars are well prepped E46 & E92 M3’s, Porsche Caymans, Boss 302R’s, etc, and class 1 cars being spec Miatas, spec E30, 4 cylinder E36, NA 944’s, 90’s Honda/Acura, etc. So about 2 hours into practice/qualifying day, the KA24DE spun a rod bearing. [Some may remember reading this thread I started about the oil pressure relief bypass valve inside the KA block failing here: http://www.nissanroadracing.com/showthread.php?t=5879 that I thought was the root cause. It actually turned out to be one of the most embarrassing things I think I can ever admit and was NOT the bypass valve. I used an oil filter sandwich plate adapter for oil sensors that was meant for an oil cooler rather than one that’s just used for sensors. Thing is I never did install an oil cooler, so oil was never actually being filtered in this KA for the 70+ hours of racing we put on it. I only discovered this after I plugged the bypass valve hole on a rebuild a few months later and there was no oil pressure getting to the head. I took the oil filter off, cut it open and it was bone dry. The level of facepalm was high. It’s an amazing thing that it didn’t spin a rod bearing earlier.] So just as we were about ready to bail on the weekend, we manned up and found a kid selling a KA and trans about 2 hours away on CL. 2 guys went to pick it up, 2 guys stayed back to pull the motor and trans late Friday night.  We took our sweet ass time and managed to get the car running again in time for the full 9 hour race on Sunday. Amazingly, the engine didn’t blow. There were significant oil pressure drops in turns toward the end of everyone’s stint because it was burning 1.5 quarts every 1.75ish hours. This motor felt like a dog compared to our first. Especially painful on a track like Watkins Glen. Finished 6th out of 15 in class and 24th overall.   Short clip of a good HP vs handling battle with a fox body mustang: https://youtu.be/FMUbRNOwi8M?t=1m55s This race ended up causing a lot of discussion about the direction I wanted to take since AER is very open. We all wanted more power and we had to deal with a trashed KA and one that needed to be rebuilt. AER Class 4 is the place where we all really wanted to be. The E36 M3 is the standard/template of this class. At first we were thinking of building a turbo KA, or VQ30/VQ35 swap, or possibly BMW S52 swap since most of us have BMW’s to begin with and and it’s different (why we’re endurance racing a 240 instead of an E30/36/46 in the first place). An LS swap would put us in class 5 and would require a monster fuel cell so that was out of the question. So I slowly started to accumulate parts to do a basic KA turbo build, but I soon realized that this beauty was still for sale on this forum: http://www.nissanroadracing.com/showthread.php?t=5770 After talking to the seller for about an hour, I sent him a deposit. It was a no brainer for me. The VQ35DE is not a high strung motor at all, but still plenty powerful in a 2500lbs chassis and the chassis was prepped 98% how I would do it. We saved thousands of dollars and many, many hours buying a race car already done. As much as I like building my own, time is limited as 3 of the 4 team members have 2 small kids each.  |

|

|

|

|

|

#3 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

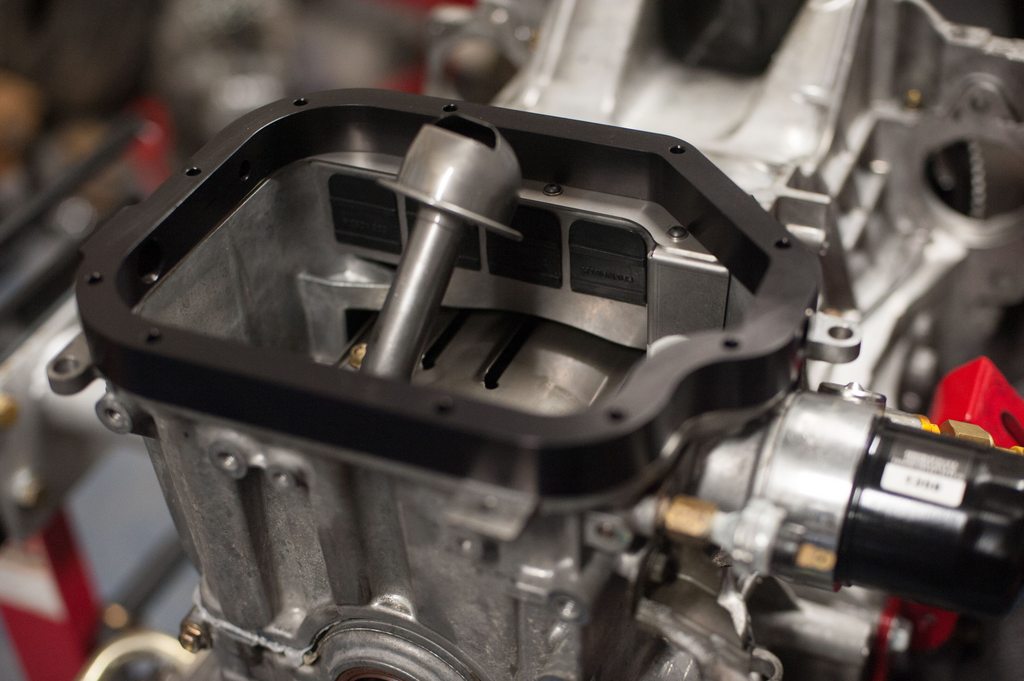

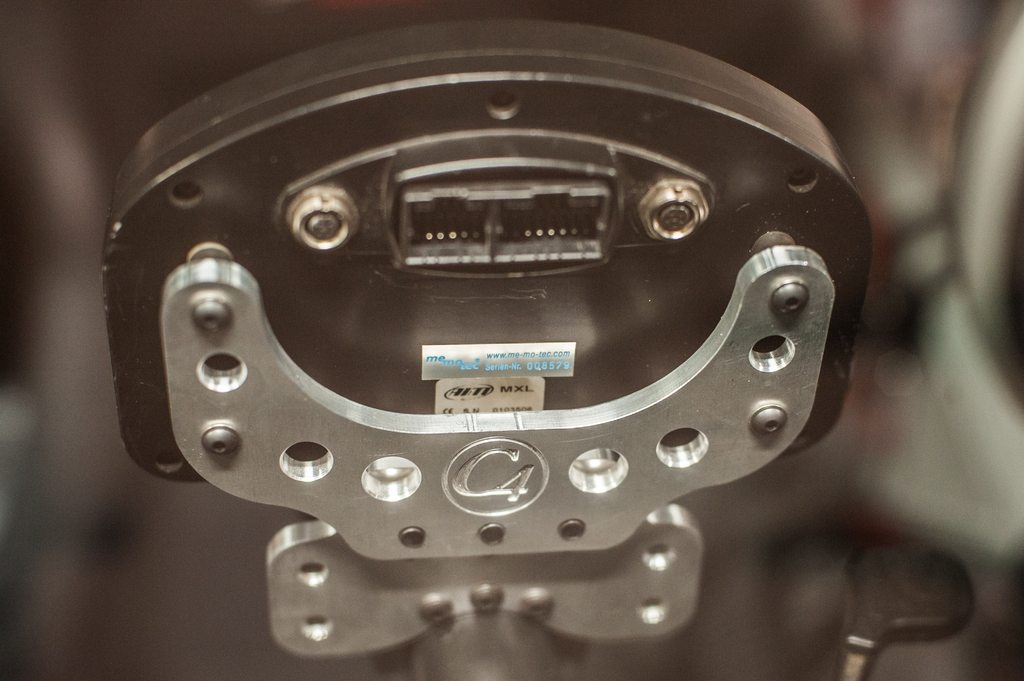

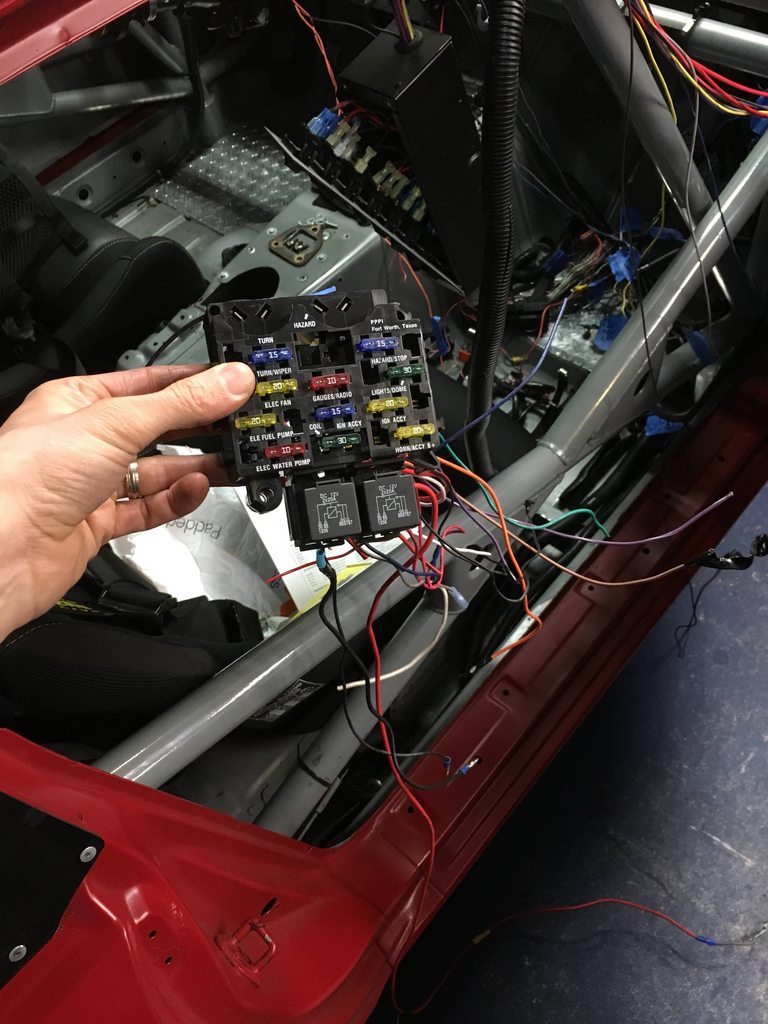

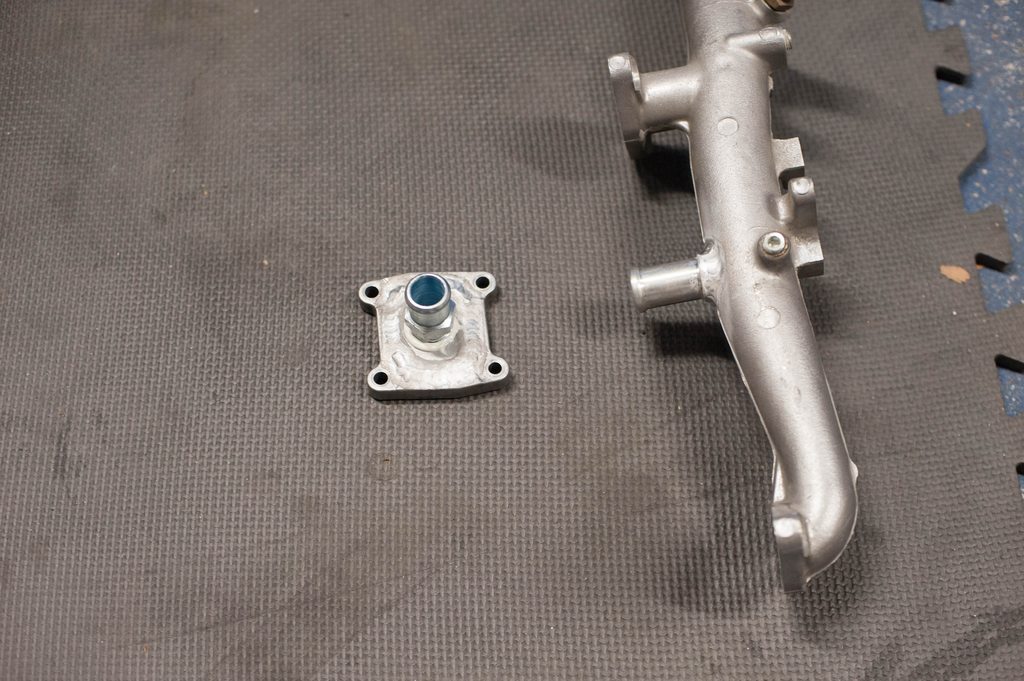

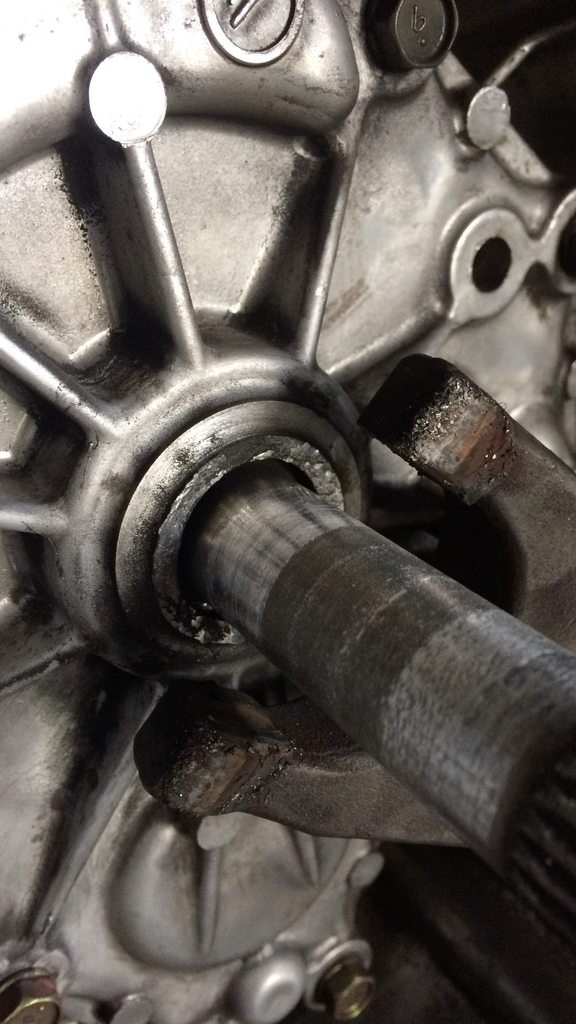

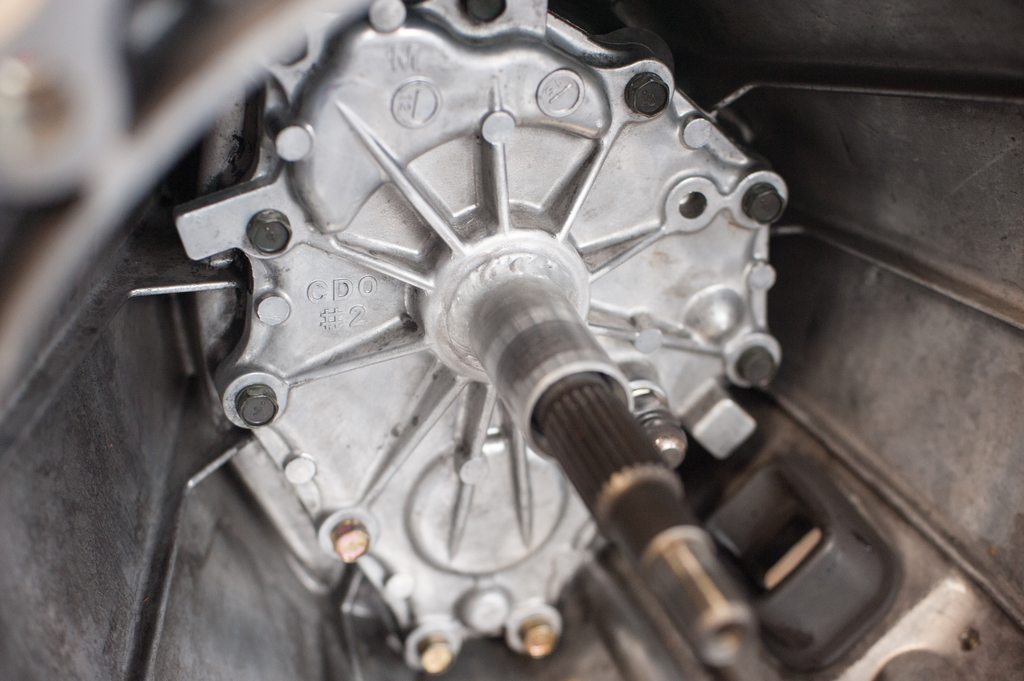

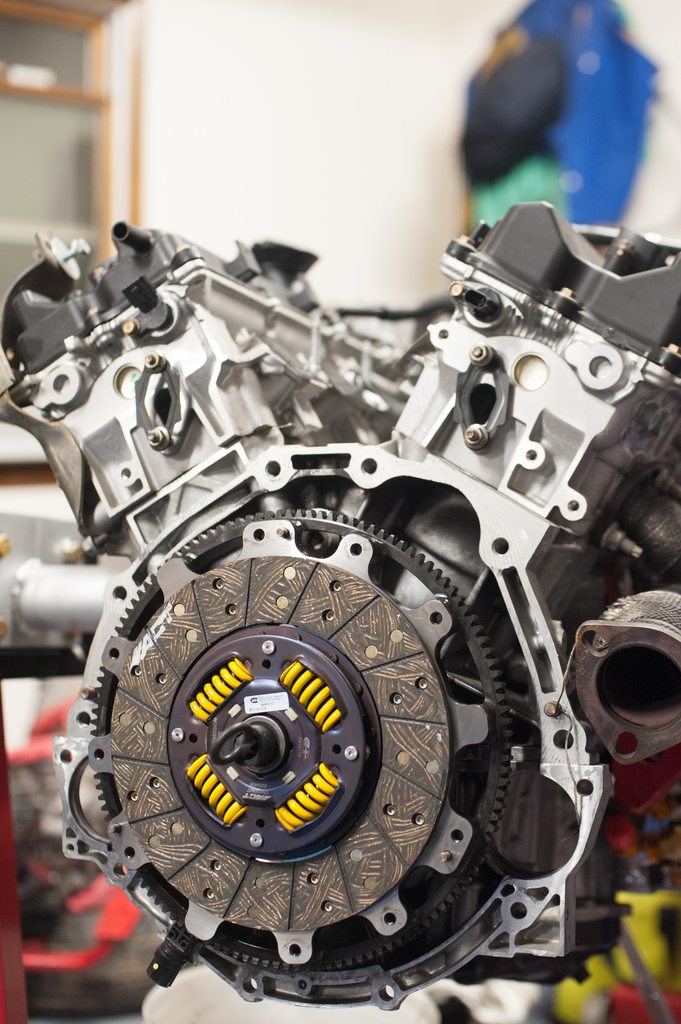

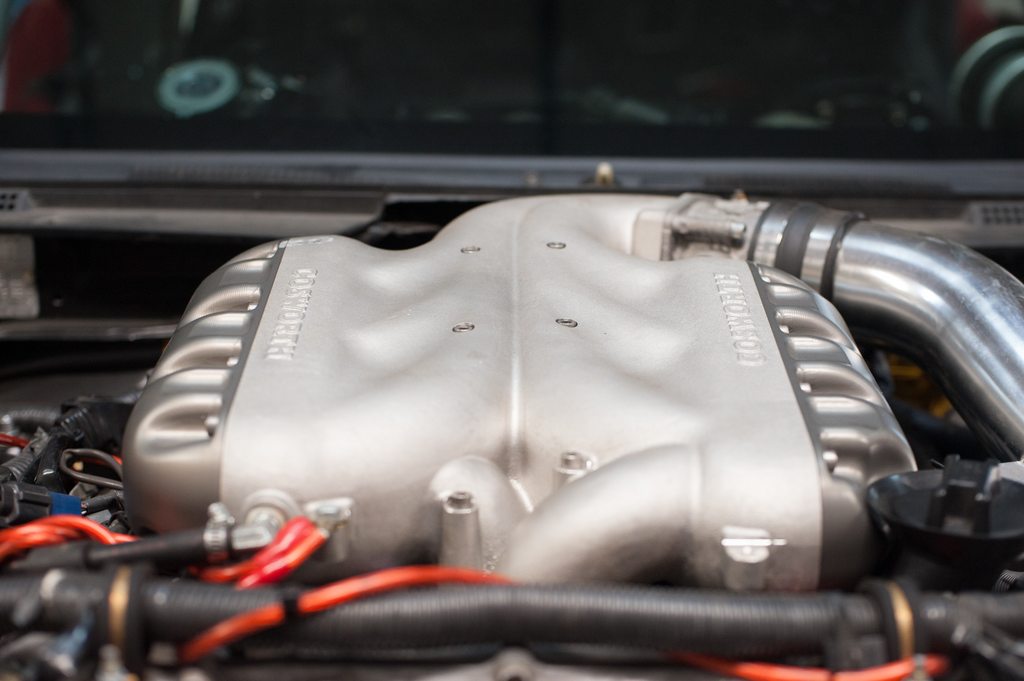

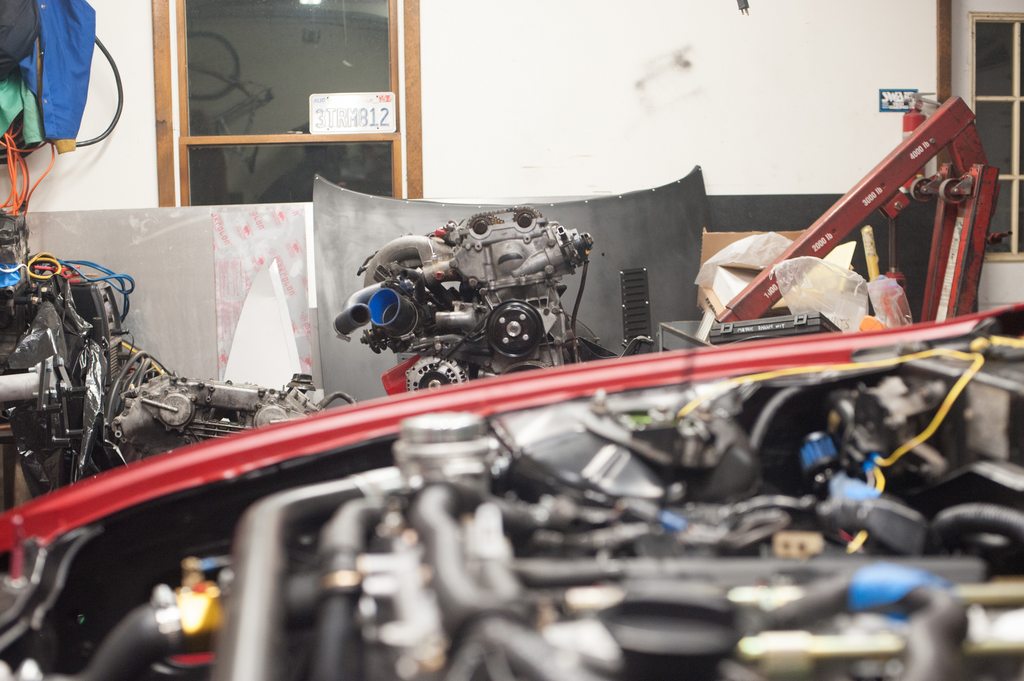

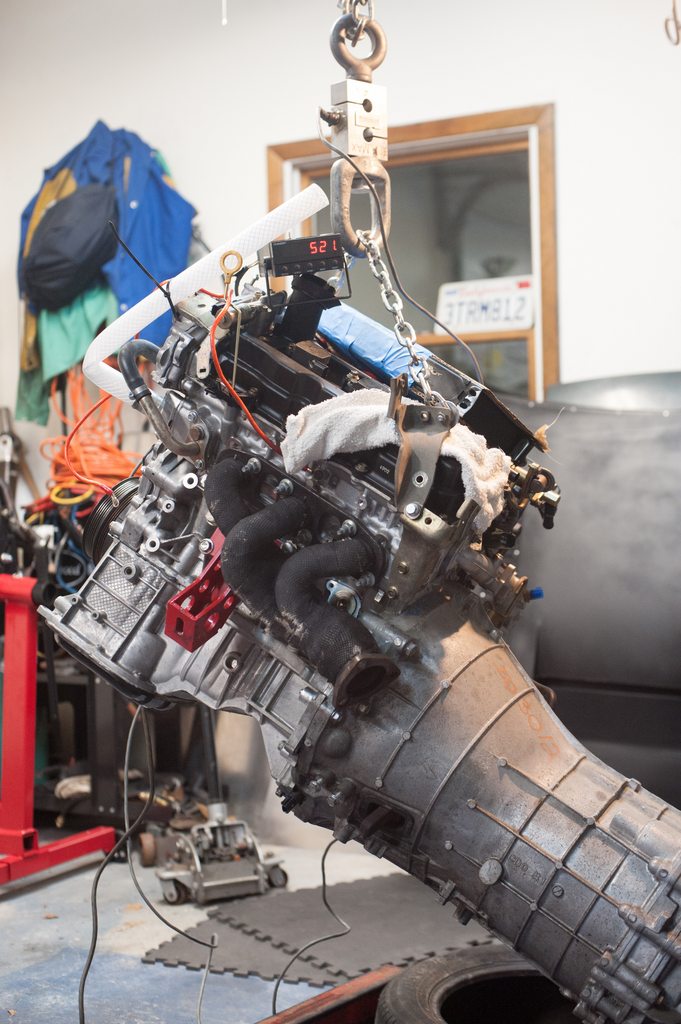

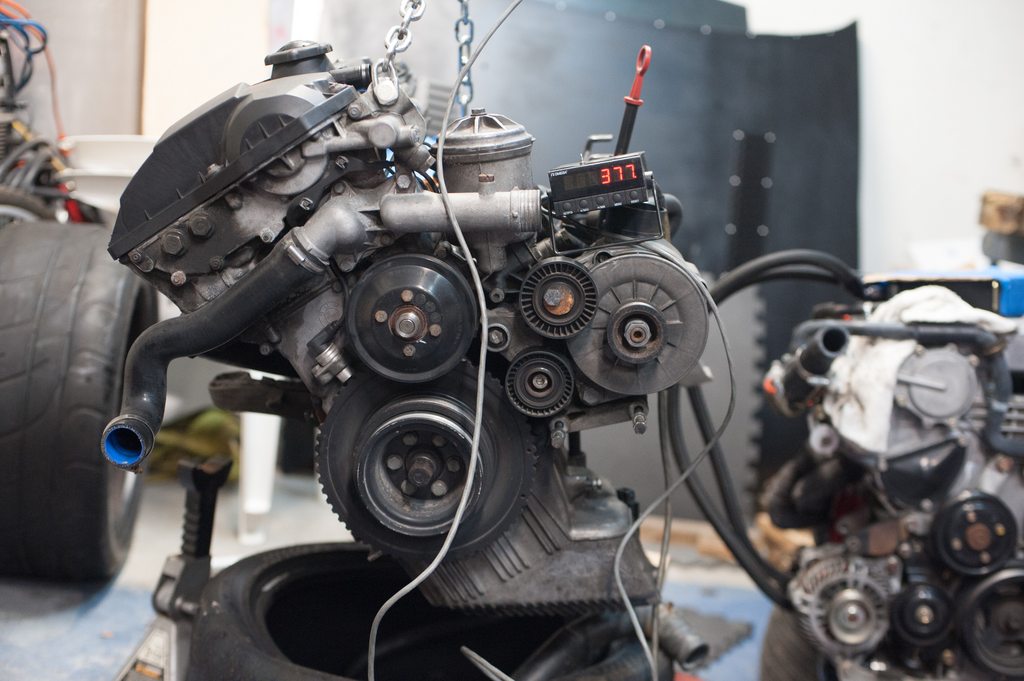

The rest of 2016 was used for testing and feeling out the S14 at a bunch track/test days and rebuilding the KA so we could sell the S13. We found a few gremlins in it, like any car. Mainly the high pressure power steering supply fitting at the rack (the Fragola/Earls fitting everyone uses to convert to AN lines) blowing O-rings every 2ish hours of track time. The shoulder diameter that the o-ring seals to was a hair too small causing the O-ring to slightly stretch into a void and rupture. So I machined my own from an M14x1.5 bolt on the lathe based on the OEM fitting dimensions, which resolved that:

The transmission (CD009) shifter linkage that came with the car also had terrible feel and vagueness to it that was not confidence inspiring at all. I think it was a McKinney unit. I ordered the GKTech shifter setup to replace it, which does away completely with the OEM U-Joint linkage and picks up the selector rod directly. It is a significant difference in feel. The spacing between gates is very close, almost too close, but I think that’s the nature of picking up the selector rod directly. It’s something that is much easier to get used to than the weirdness from the original setup.    [Interesting comparo vid I made to see how I differ from my co-driver when we first got the car. Also notice I have issues shifting into 6th. 4.08 final drive): https://youtu.be/bATszqztrko?t=30s ] It didn’t come without its issues though. First being the reverse lockout pin and plate was incorrectly spec’d in my batch with mild steel. Within only about 4 hours of track time, they wore enough to make it almost impossible to shift into 5th and 6th without readjusting it:    I informed GK of the situation and he sent new shift rods with pins and plates to everyone who got a kit from that batch. That didn’t happen quick enough for me at that moment so I made an overkill solution with O1 tool steel plate hardened to ~50 Rc and dowel pin stock.   The other issue is the shifter getting stuck when you go to push it down to get it into reverse. Still need to delve into this. The shifter rod sits in a plastic housing that sits on top of a spring in the main metal housing that you compress to clear the lockout plate. My guess is that the plastic is scuffed or messed up from the heat generated from racing and not sitting properly in the main metal housing where the spring sits. It’s something GK is aware of and awaiting my findings. The customer service from them has been excellent. Race prep time for AER Watkins Glen April, 2017. Engine pulled:  For oiling reliability we installed a Cosworth oil pan baffle kit and AAM oil pan spacer. Oil capacity now at 6+ quarts:   Also installed a new VQ35 rev-up oil pump to handle the sustained high rpm use. This VQ motor makes excellent oil pressure using 30wt Redline Race oil. About 80-85psi in the upper rev range under WOT with oil temps at 240-255F.  I scored a great deal on a used AiM MXL PISTA datalogging dash with a GPS05 sensor (10Hz). This is one of the best things I’ve purchased yet for the race car. It’s expensive, but for good reason. This allows complete driver analysis and enough resolution to monitor oil pressure in turns. Needed a solution to mount it in my bare interior and came up with this to mount directly on my steering column (I can make this for anyone wanting a solution to mount their AiM/Motec dashes):     In AER, there’s a minimum pit stop time of 3 minutes, which is plenty of time to re-fuel, change drivers, and go over vitals on the car. It also prevents fueling rig cost creep for all teams so we’re not forced to use dry-break systems to be competitive. Ironically, there’s no pit time restriction in 24HoL (5 minutes in Chump/Champ) and there are some top teams with fuel fill systems that are more expensive than the car. I just drill out the flappy door thing from the OEM filler neck and use Hunsaker quick fill fuel jugs. Takes about 20-25 seconds for 5.5 gallons of fuel with OEM venting.  Also removed and replaced the existing wiring harness and power distribution box with a more robust kit from Painless Peformance. The existing power distribution box had only 2 relays for all the circuits in the car and suspicious wire sizing. We ended up using the 10 circuit race only chassis harness as the replacement. I would’ve like to have gone with a solid state power distribution box/harness, but they are more than double the price: Old:  New:  Wiring is the best!!:  Did our own version of the Pathfinder coolant tube bypass mod on the rear coolant pipe by the firewall instead of piecing together OEM parts which adds $$$ up quickly. Whether this actually improves cooling efficiency or not is debatable. I like the idea of it at least so I figured it wouldn’t hurt and *should* provide an additional exit for coolant at the back cylinders.   While having everything out we also discovered the transmission front cover shaft the TO bearing slides on was completely broken off. Not sure why this is yet or how long it was like that for, but it at least functioned that way. I’m hoping that it was just too much clutch pedal movement so I adjusted the clutch pedal stop to provide the minimum amount of travel required to disengage the clutch. The verdict is still out if this worked. We’ll find out next time trans is pulled. Broken clean off:   Cleaned up and TIG’d back on:  There was an ACT unsprung 6 puck clutch disc with HD pressure plate in the car already, but it was unanimously agreed upon that we all couldn’t stand it and it needed to be removed. Surprisingly, the 6 puck disc is no lighter than the an ACT SS sprung full clutch disc so that solidified my decision. The main negative is that the springs in the disc add another point of failure that can screw us in a race. My fingers are crossed.  A Cosworth intake manifold came with the car and is gorgeous. Based on all the research I’ve done it seemed that it was best suited to be used on FI applications and actually hindered performance in the low-end to mid-range and negligible gains in top-end on NA cars. Unfortunately, I never got it on a dyno to actually prove that out. I ended up selling it and installed an OEM manifold with a ½” Motordyne plenum spacer kit. I regret it sometimes because 1) it was gorgeous and 2) it was very space efficient. I ended up having to space the hood a bit more to clear the OEM IM setup. The hood spacing is one of my biggest peeves aesthetically on the car (in addition to the fender vents) so spacing it higher ticked me off. But, I sold it for a pretty penny and function >>> form, BRUH!  Motordyne:  Engine all buttoned up and going back in. Engine install # 5,173:  Mr. KA24DE isn’t happy about being replaced and eventually sold off  Lastly, fire system, communications, and center net installed. Want to also mention that we use a Schroth Enduro 6 point safety harness. It is by far the smoothest, and easiest adjusting safety harness I’ve ever used. Driver changes are incredibly easy with it.  Ended up borrowing a load cell from work to have fun weighing engines and transmissions because these were all sitting in my garage at the same time and why the hell not!: KA24 stuff (484 lbs w/o PS and AC):   VQ35DE stuff (521 lbs):   And for sh!ts and giggles, arch nemesis BMW S52 on the scale (377lbs + 82lbs ZF trans = 459lbs w/o plastic IM) :  Unfortunately don’t have a pic of the ZF 5 speed, but it only weighed a feathery 82 lbs. Is it a surprise that the KA being an I4 is the heaviest of the bunch? Cast iron block, sure, but so is the S52. It treated us well even when we didn’t (unfiltered oil ), but good riddance. Maybe one day I’ll mate the VQ to a ZF… Last edited by gills; 02-01-2019 at 08:34 AM.. |

|

|

|

|

|

#4 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

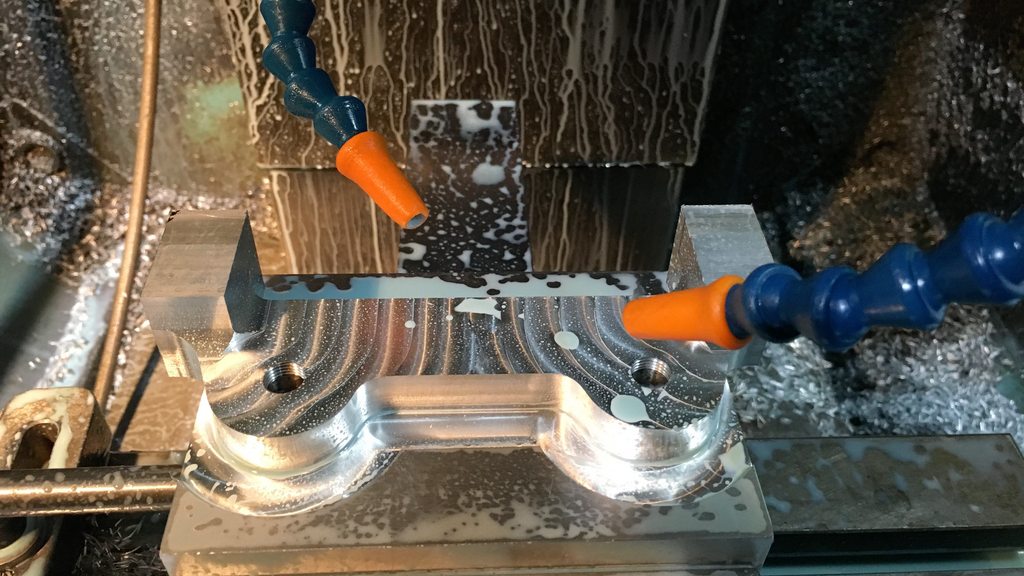

4/2017 AER Watkins Glen race

Goal was to just finish the race incident free. We were all unsure as to where the car would class since there’s a large disparity in lap time potential between driver pairs. We all really wanted to be in class 4 with this car, but after Friday’s qualifying session we put the car into class 5 with the 7th fastest lap time. 2 of the 4 drivers are in the 2:10.xxx range and the other 2 are 5-7 seconds slower per lap. It’s something we need to work on. The car is essentially a class “4.5” car in this race. Heading out:  Green flag! There we are on the right...  Crazy race start with one of Team Sahlen’s Cayman’s wrecking right at the drop of the green flag and almost causing a huge pile up. My first 2 wide rolling start also. If you have extra time, the first 12 laps or so there’s some good battling: https://youtu.be/si_yyScV4Vk We were about mid-pack in class 5 and 7th place overall with the 3rd driver in the car when divine intervention came down upon him/us and prevented a giant wreck. Nothing like starting a spin at 106mph and not touch a single piece of armco at a track where it’s only feet off the asphalt (must watch!): https://youtu.be/zhCCTJzI7Ec That essentially parked us for the rest of the day as we went over the car to make sure everything was all right. We lost a tire from dirt packing into the wheel from going slideways in the grass and coincidentally (or not) one of the lower front coilover locking collars worked loose so that was clunking around. We also put in some fresh Redline 75w-110 diff fluid because it was starting to get noisy and extra clunky. The PO used Redline “NS” gear oil that had no friction modifier so it was always very noisy. We went back out on track for a few more laps at the end of the day to make sure everything was ok for Sunday. We found that the 6th gear synchro was also starting to take a sh!t. Sunday: The cooling system was gradually getting more and more heat soaked as we cycled through drivers. Driver 2 was the first to report higher water temps vs Saturday. By the time I got in as 4th driver the water temp was dangerously high to run for extended period. Within 5 laps I started seeing temp spikes to 240*F. Once I realized I couldn’t get them to come down by farting around I parked it. The rest of the day was trying to bleed the coolant system and trying to determine if we had a slight head gasket leak. VQ’s are notorious for finicky coolant systems to bleed. Subpar results for our first race. Positives are that we ran as high as 5th overall for awhile and we had the 7th fastest lap overall for the weekend. Oh, and the car came out unscathed in that spin!! A few things that needed addressing before the next race 1) the 4.08 final with a 6800rpm rev limit is too short, especially for the Glen. 2) the car couldn’t brake as well as the BMW’s. 3) the CD009 6th gear synchro was toast. 4) the 4 piston Wilwood superlites with equal piston sizing have serious pad taper issues. Here’s what was a brand new set of Hawk DTC-60 at the start of the weekend after 14ish hours of track time. Maybe this is why braking felt ‘meh’ over the course of the weekend?:  It had to be addressed for the next race, which was 4 weeks later at New Jersey Motorsports Park (NJMP) so onto prep time. First thing was testing if the head gasket was leaking. Compression and leak down tests were good. Just to be certain we used this nifty little tool that “sniffs” the gas in the radiator for CO2 and changes color if it does, which indicates a leak of combustion gases. Luckily it tested negative: https://www.amazon.com/UVIEW-560000-.../dp/B000NPDL76 It was air in the system that came to ruin our Sunday at Watkins Glen. VQ’s are notoriously a PITA to bleed. Most VQ swaps do away with the OEM bleeder that ties into a line that runs from behind the T-stat to the heater core circuit. This is a problem. Also a problem that the top of the radiator in a S-chassis is far below the high points of the VQ cooling system. We T’d in a generic bleeder in the highest line of the system that runs from the radiator return to behind the t-stat.  Then bought this vacuum coolant refill tool to help evacuate much of the air in the system: https://www.amazon.com/Robinair-7526...nt+refill+tool And lastly, a giant funnel with the nose of the car way up in the air. https://www.amazon.com/EPAuto-Radiat...ill+tool&psc=1 It all worked and we haven’t had bleeding/overheating problems since. After chatting with Def on here about the brake situation, I went all in on making radial mount brackets for the Wilwood FSL6R’s based on his design. I changed a few things for manufacturability and also made them so they will fit 12.2” rotors as is and 12.8” rotors with a spacer: Machining:  Ready for testing:  Perfect:    Also changed the final drive to an S15 3.69 ring and pinion. Many people just swap ring and pinions using existing pinion height shims and side bearing spacers, etc. Definitely couldn’t get away with that here. Look at how different the pinons are: 4.08 on left, 3.69 on right:  I ended up having to grind down the pinion height shim that came with the 3.69 substantially. See/read more detail in this thread if you’d like: http://www.nissanroadracing.com/show...?t=5069&page=3 I also decided to move away from Hawk pads and try a different brake pad compounds. Ended up going with Porterfield/Raybestos ST-43 compound for the front and rear after talking with many endurance guys. They had to make the rear Z32 pad shape custom (more on this next). Last edited by gills; 02-01-2019 at 08:29 AM.. |

|

|

|

|

|

#5 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

5/2017 NJMP AER race

Friday Qualy/Practice: new final drive ratio is excellent and much less frantic. Started having issues with the rear brakes locking once heat got into them under even the slightest amount of brake pressure. SOB… Porterfield’s pad shape template turned out to be a bit off. When the rotor would expand from proper heat, the very top portion of the pad was getting caught up on the circumference/edge of the rotor and created way too much friction. Nothing a good ol’ 4.5” angle grinder flapper disc wheel couldn’t deal with though. I hit the top of the pad so it wasn’t overhanging on the rotor edge anymore. They probably don’t sell many Z32 rear applications at all so as irritating as it is, it was an easy fix. They’ve updated their template now. Dealing with that ate up a couple of hours so we didn’t get a ton of laps in for qualy. We ended up qualifying in class 4, 11th overall behind some impressive hardware. Saturday starting grid in front of us:  Another Nissan in a sea of BMW’s:  And another!:  Y’all remember ‘CodyAce’ on this forum? Here he is wishing he still drove his S14 and had radial mount FSL6R’s! lol:  Saturday was the best day of racing yet for this car. We finished 3rd overall (58 cars) and 2nd in class. We got pushed into Class 5 once the slightly faster of the faster driver pair (hopefully he reads this ) got into his groove 30ish minutes in at the start. Good, clean driving all around. Brakes felt the best yet, even though there’s definitely less initial bite on the ST43 vs. DTC-60, but longevity isn’t even close (pics below). They are also just as loud though. Big negative; 5th gear synchro now took a sh!t also. The Saturday results determines starting grid for Sunday so we were P2 next to some proper hardware. We are the only car at the front that runs basically zero aero. Comical. Now it’s a pride thing being aero-less : Sunday P1, 2, and 3:  Green!:  Sunday was going great until our exhaust decided to partially fall off toward the end :embarrassing: Someone forgot to fully tighten some exhaust flange bolts in the muffler (me). That caused us to finish mid-pack for Sunday. Passing 2 modern Nissan machines at the beginning and end of the same lap: https://youtu.be/PQVwbcpIsik?t=46m41s Because class 5 is typically the class of attrition, we actually finished P2 overall in class for the weekend. Great result for the team. Core4 podium:  About those brakes, check out wear of the ST43 pads inside the FSL6R after 15 hours of racing:  I didn’t believe we raced when I saw how much they wore. Zero taper issues and what looks to be multiple race weekends on a single set of pads. Amazing consumable efficiency. I also don’t run any brake ducting at all. Alignment and setup also seems to work ok. Maybe squeeze more camber out in front. Here’s a Falken RT615K+ after 14 hours of track time. Outside edge facing up:  Unfortunately, that was the end of our 2017 AER campaign. We really wanted to hit Summit Point and Mid-Ohio, but life/family and tow rig issues prevented that from happening. Last edited by gills; 02-01-2019 at 08:28 AM.. |

|

|

|

|

|

#6 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

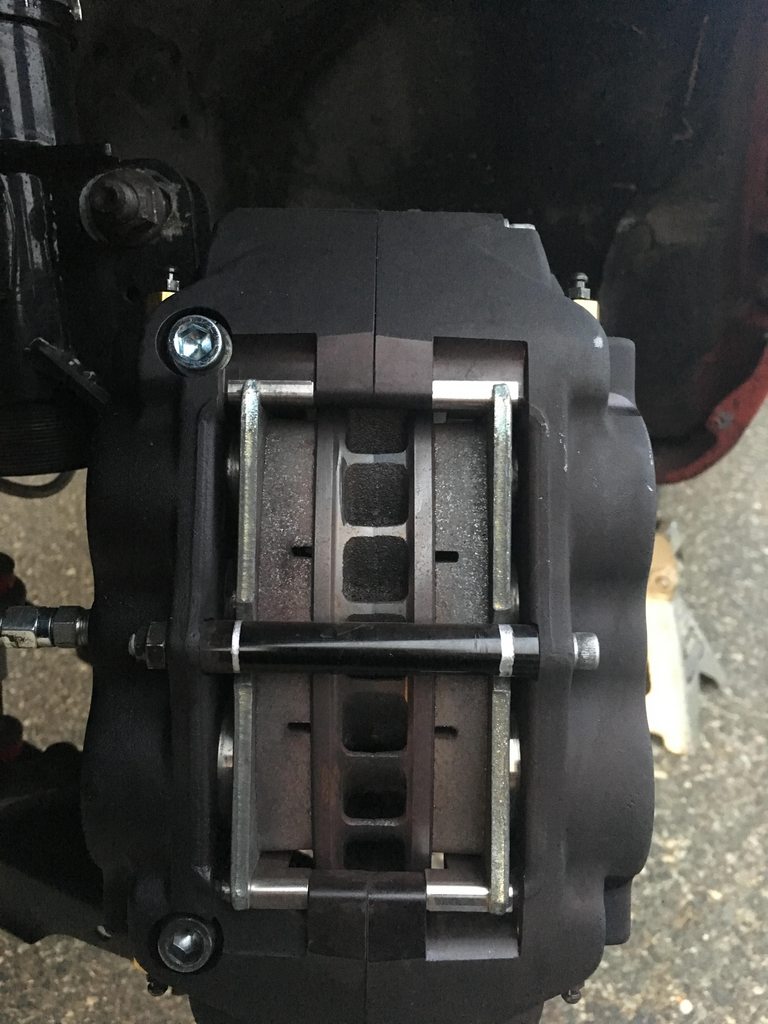

That didn’t mean the rest of 2017 sucked!

First, we managed to get into a partnership with Motion Control Suspension (www.motioncontrolsuspension.com) and are now running their 2-Way remote reservoir dampers.  [lap comparo video of initial damper settings vs final damper settings: https://youtu.be/vw3EJLwz_6c Second, I designed, machined and tested a rear Wilwood BBK that doesn’t require cutting off the OEM caliper mounting tabs/ears. The kit uses Wilwoods Forged Dynalite Narrow caliper and 12.2 x 0.81 2 piece rotors (8x7” hat bolt circle). The benefits mirror Defsport’s front BBK. The kit weighs about 3.6lbs per corner less than a Z32 rear setup (not including the e-brake mechanism), moves more bias to the rear (can be even more if you choose to go with the larger piston size caliper), larger pad volume, more pad choices, and way cheaper than Z32 pads! They will last way longer than Z32’s as well. Bracket:    Rotor Hats:  Installed:   Inside wheel clearance (17x10 +18 RPF1), no spacer:  WW Pad vs Z32:  Paired with Defsport front BBK (new Greddy Zenki lip too):  If you have any interest at all in this kit and/or the front radial mount brackets, please PM me. I’ve made 4 kits so far that will be sent out in hopefully the next two weeks. I will also be creating a FS thread soon for these items to pre-order. 2018 plans will be four AER races, Watkins Glen, NJMP, Calabogie or Summit Point, and Mid-Ohio. Changes in the pipeline are making a flush mounted hood, which we already started experimenting with:  We’re going to attempt to graft a 2005 Dodge Ram hood buldge onto the Zenki hood. Ideally I would use it as a plug to make a fiberglass mold and a nice lightweight hood. The hood is a big place to lose a few lbs. OEM Ram hood stock photo:  Also will be incorporating trackspec hood vents/louvers (http://trackspecmotorsports.com/) for venting the engine compartment instead of custom reverse scoop things.  We bought a brand new Nissan CD00A (supersedes CD009 now) transmission for a killer price from our hookup at a local Nissan dealership. Going this route vs dealing with unknown used CD009’s that still develop synchro issues was a no brainer. I want to eat sushi off of it:   A big change and one I’m very much looking forward to will be real-time telemetry from a soon to be released unit from Autosportlabs called PodiumConnect (same guys that make RaceCapturePro). This unit is filling a large void in the market that allows you to tie into existing DAQ systems (AiM, Motec, etc.) and stream their data live, instead of having to get another complete DAQ system like RaceCapturePro to use for telemetry.  www.autosportlabs.com We will also be live streaming in-car video for all races this year. I will be sharing telemetry and video streams during race weekends in here so stay tuned! And lastly, fine tune the MCS dampers, spring rates, and ARB’s. I just jumped from 500 lbs/in front to 600 and 335 lbs/in rear to 500 lbs/in with no rear sway bar. Already tested this setup and did manage to post our fastest lap yet at our home track (NJMP) on street tire that is nowhere near the fastest of the current crop (original Falken RT615K), but not in a good feeling manner. Needs more work for sure. I’m confident Wyatt at MCS can help us get these dampers dialed in just right. We are still not going to add any wings or significant aero. I want to maximize the mechanical grip first and it’s not like we’re slow in this configuration. At the most, I will put on a very small front splitter to tie into the Greddy lip. Last edited by gills; 02-01-2019 at 08:58 AM.. |

|

|

|

|

|

#7 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

I've contacted Liberty Gear about face-plating a CD009 to circumvent the weak point of these transmissions (more info here: http://libertysgears.com/services/fa...modifications/). They've never face-plated a CD00x transmission. It can be done, but they would require 2 transmissions from me; one sacrificial for engineering and one to build. It would be a minimum 6 month lead time as well.

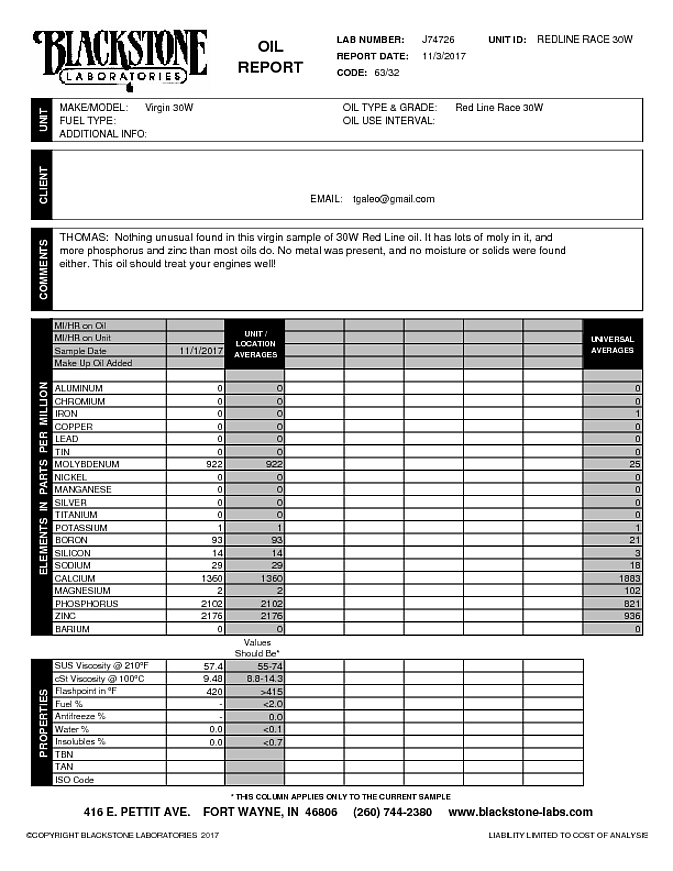

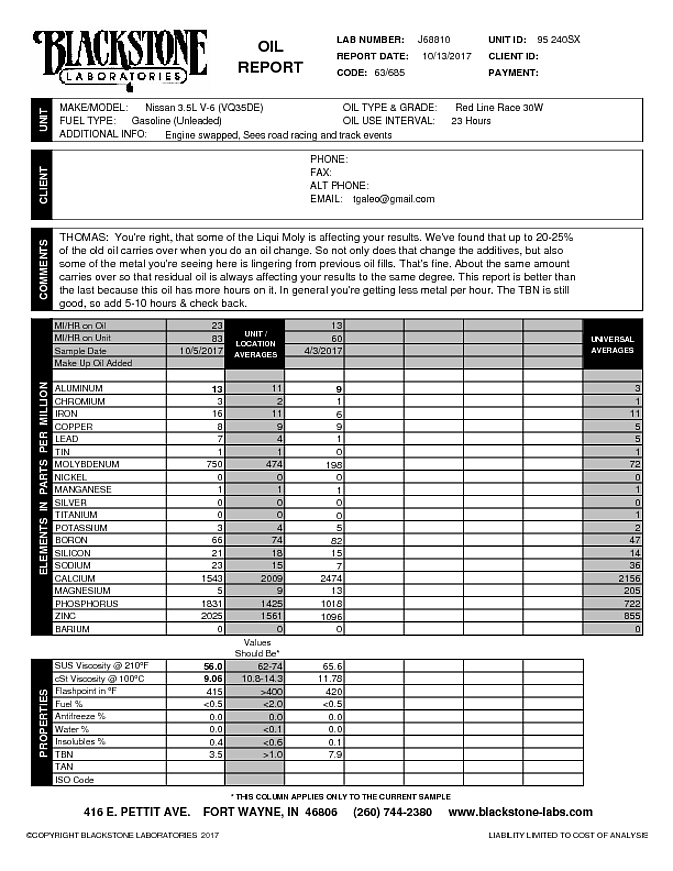

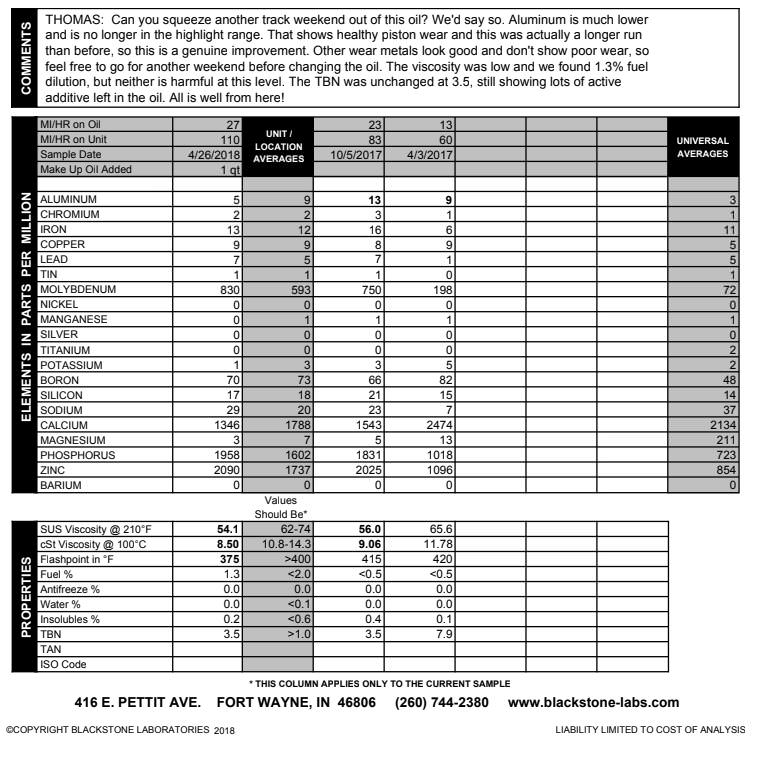

I'm going to ride out the new CD00A and see how it goes. If it becomes and issue again, I'll wait until then to determine a solution. ----------------------------------------------------------------------------------------------------- I started doing engine oil analysis on the VQ in 2017 with Blackstone labs. It's a great preventative tool to monitor engine and bearing wear, how much the oil has sheared down, and contamination. It also will establish a concrete oil change interval (i.e.-$$ in my pocket). Redline oil isn't cheap and just assuming when it was time to change always bugged me. Like throwing money in the garbage. I sent it virgin Redline 30WT Race Oil to establish a baseline on additives and viscosity. Typical high amounts of "race" oil type additives like Zinc, Molybdenum, and phosphorous:  The analysis below shows two tests, one from 4/3/2017 and one from 10/5/2017. The 4/3 test was actually on standard Redline 5W/30 High Performance oil and 10/5 was on the 30WT Race oil (a short interval of Liqui-Moly was used in between). You can see the 5W/30 oil has less zinc, phosphorous and Molybdenum vs the Race Oil, which are anti-wear and friction modifiers. The 5W/30 does contain more calcium, which I believe is used as a detergent for standard street car use. The viscosity numbers of the 10/5 analysis showed that the oil sheared down when comparing to the 4/3 test. I ended up doing a change after that 23 hour interval, but in hindsight I should've done 5-10 more hours like they suggested in the comments. If you look at the viscosity numbers on the virgin 30WT report above, they are basically identical to my 10/5 report. I should've done the virgin report first and foremost. All the wear numbers are within limits, except aluminum is a hair on the high side when compared to their universal averages. I'm expecting higher metals since I'm only racing.  |

|

|

|

|

|

#8 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

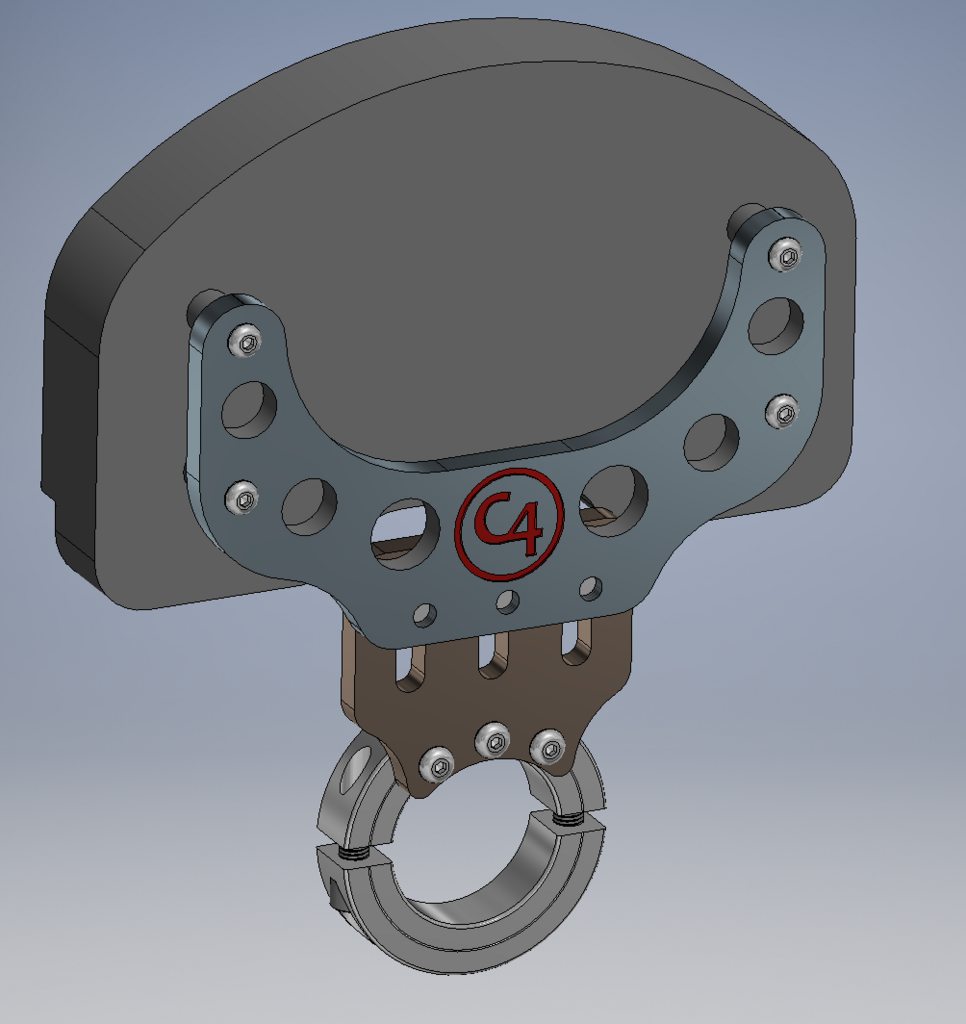

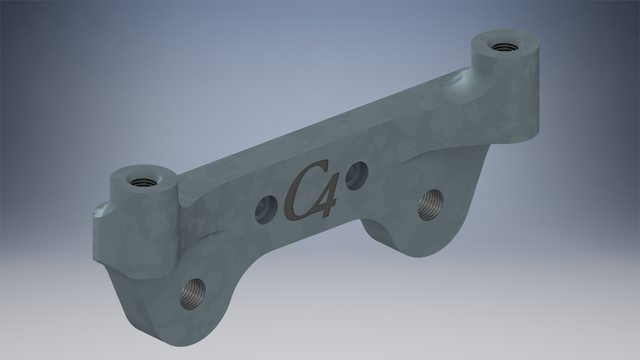

I'm going to start production on the radial mount front brackets to be used with Defsports rotor hats/offset. I will likely be starting up a group buy for these (as well as the rear brake kit I made) in the next week or two.

PM me if you want more info now. Obligatory CAD render...  |

|

|

|

|

|

#9 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

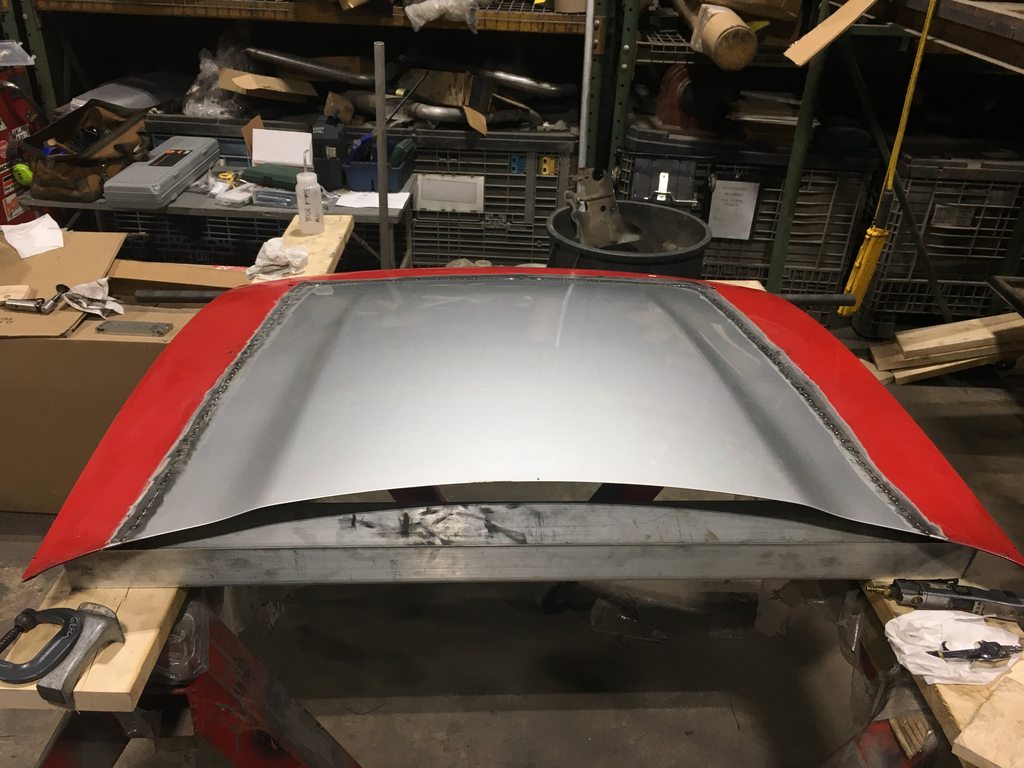

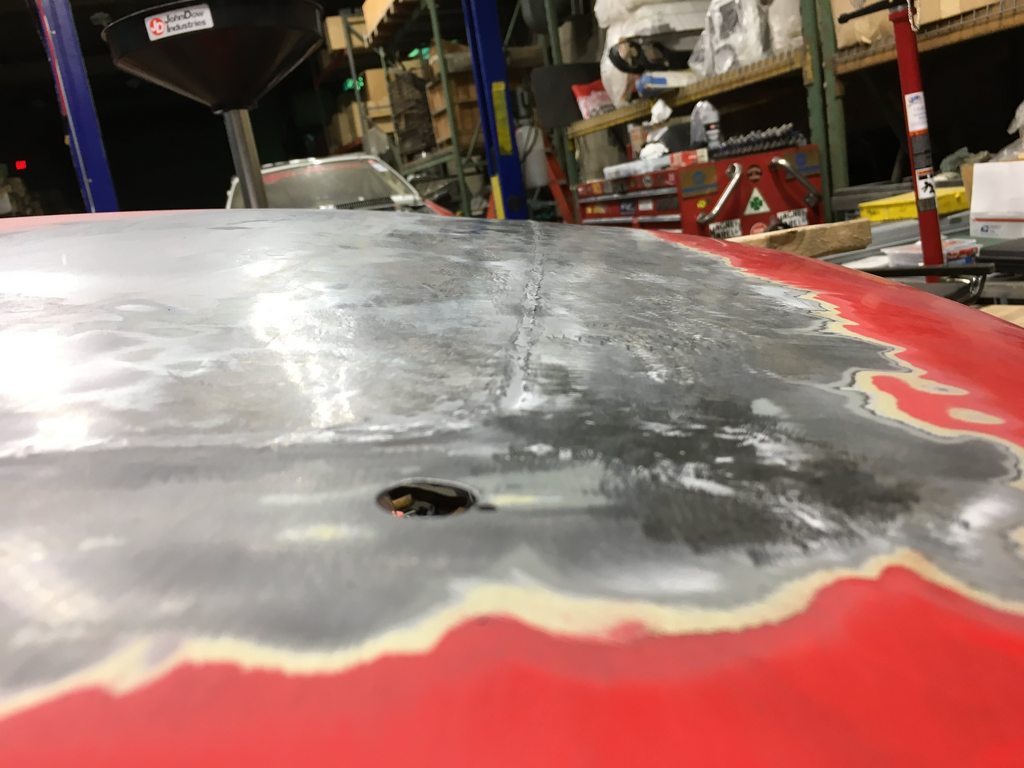

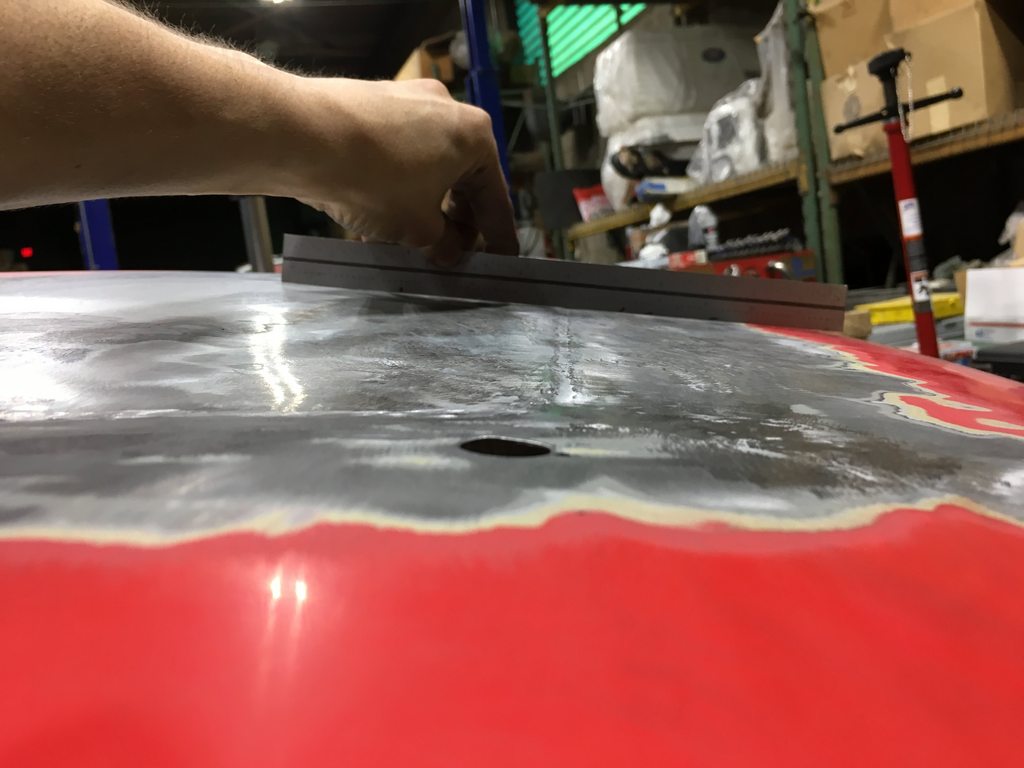

Production Core4 radial mount bracket proved out:

NOT ONLY FOR DEFSPORT 2-PIECE ROTOR KIT...One of the best things about this bracket is that it can also run off-the-shelf Z33 track rotors (12.8" x 1.18") with the simple use of shims/spacers. You can get Centric Ctek Z33 track rotors for $30 a piece! Not sure you can get a cheaper, more effective big brake upgrade out there without worrying about chucking rotors after a few events. Z33 track rotor with Core4 radial mount bracket:   ------------------------------------------------------------------------------------------------------------------------------- Started working on grafting the 05 Dodge Ram hood bulge on the S14 hood. I don't want to get ahead of myself here, but it's laying up on the S14 hood REALLY nicely. Better than expected. It should definitely provide adequate clearance for the VQ IM with a 1/2" manifold spacer and the friggin hood should finally sit flush and not ghetto raised. Here's the first cutout and lay up:  More to come shortly. Last edited by gills; 02-01-2019 at 08:59 AM.. |

|

|

|

|

|

#10 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Moving along with the hood.

Fixtured up the hood with some angle where it mounts to the chassis to prevent excessive sloppiness once we cut out the area of interest.  Ended up going with a butt weld joint instead of using a flange tool and making a lap. It seems that butt weld joints are the preferred method for sheet metal fab guys even though it's a bit more work to get it just right. Got the skin graft fully tacked in. Surprising how well the RAM cowl curvature matches the S14's:     Next up is fully welding, grinding welds down flush, and working the sheet metal where it'll shrink from the welding to get it as smooth as possible before going body filler crazy. Last edited by gills; 02-01-2019 at 08:00 AM.. |

|

|

|

|

|

#11 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Getting ready for a 4/9 test day. I took the risk of running no tender springs with my new, stiffer rates at my last test day in November and this is the result on a rear corner:

Did not expect that to happen to that extreme. Going through video you can actually hear the spring re-seat at about the 21-22 second and 26 second marks: Click for video That ushered the order of some tender springs. Getting tender springs setup piece meal is a more expensive journey than I had anticipated, but then I stumbled on these from the land of Miata: https://supermiata.com/dual-spring-kit-xida.aspx  Two tender springs (150 lbs/in), two needle thrust bearings, and HPDE spring couplers for $115 + shipping. It's a great deal. The only caveat is that they're 2.25" ID, which not many S-chassis people run. Luckily, I had just switched to 2.25" to gain a bit more tire/wheel clearance. 'Murica....kinda:  -------------------------------------------------------------------------------------------------------------------------- Still got some forward momentum with the hood project also. It's fully welded and I've been hammering and dollying away on the metal near the weld seams to relieve stress and stretched metal relative to the heat affected weld zone. I've also been using a "shrinking disc" in between H & D'ing which has been nothing short of amazing for working the sheet metal and removing oil canning (sheet metal popping up and and down) and waviness. (Click here for what shrinking discs are and do). Again, I'm doing this to minimize the amount of filler that needs to be used. A heat cycled hood isn't ideal for filler by any means. Fully welded up:  Passenger side weld seam after working it. Hard to tell how smooth it is in pictures, but it's night and day difference from how it was:  Here's the front seam area prior to me working it. Notice how different the crowns are between the Ram hood and S14:  After spending some time shrinking the metal adjacent to the seam to flatten it out, I then used a "slapper spoon" with some crown and hit from underneath and arrived here:   Worlds better. There's some slight oil canning going on after shaping it up so I'll need to do one more round of shrinking and and light slapping and it should be good to go. On to filler it goes after that. Last edited by gills; 02-01-2019 at 07:59 AM.. |

|

|

|

|

|

#12 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

So Watkins Glen AER event is coming up fast next weekend. Of course some of the line items I wanted to complete need to be put on the back burner. One of them is NOT the hood project though I will most definitely be streaming video and car telemetry for this race so STAY TUNED...

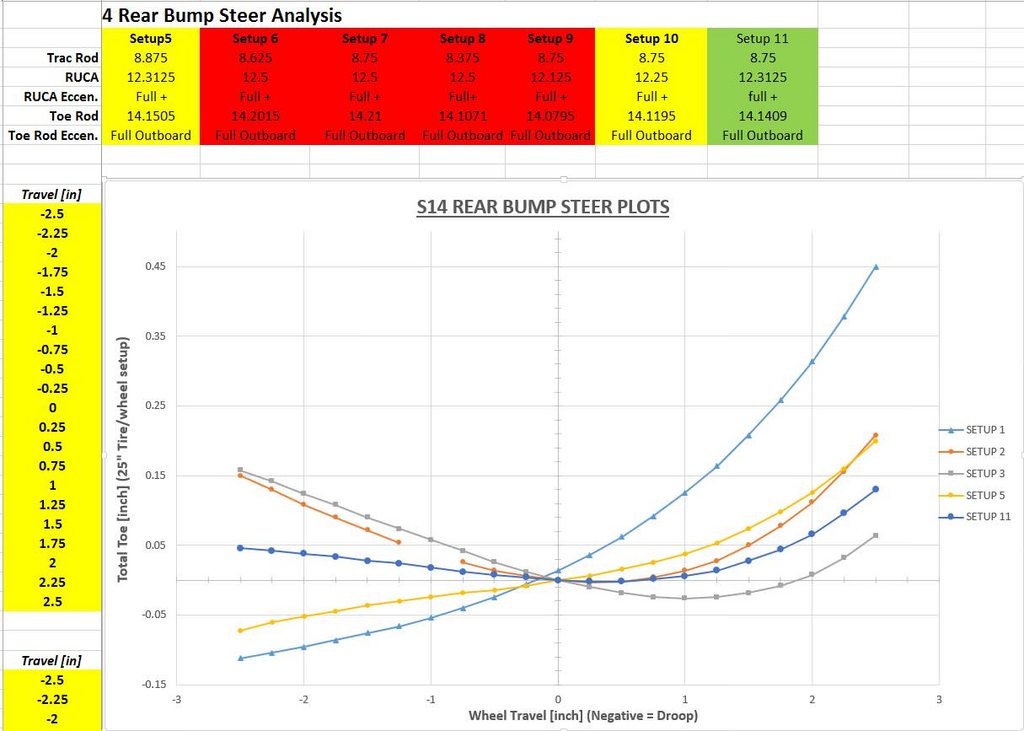

But, I had a test day on 4/9 at NJMP with the tender springs and the alignment/setup gone through with a fine tooth comb in an effort to make the car less frantic and more planted. Oh, and the brand new CD00A installed. Transmission felt great as expected and the tenders did their job. Crossweight: 50.2% with 200lbs driver, 1/4 tank of gas (not intentional) Increased ride height about 10mm front and rear from previous setup. Front Castor: 7.5* Camber -3.8* Toe: 1/16" out Rear Camber: -1.4* Toe: touch less than 1/8" in Toe Thrust/thrust angle less than 1/16" difference between front and rear axle. So, the biggest difference from my last setup is the the fact that I dialed in the thrust angle to basically nothing, reduced rear camber from -1.8*, and lengthened the rear trac/tension rods, and shortened the toe rods to be the shortest possible. Camber gain in the rear is about 0.25-0.3*/in of travel from static ride height. I changed the link lengths based on analysis from a CAD assembly that I put together with a s14 subframe pivot points someone had modeled and also a Z32 upright someone else scanned in an effort to minimize bump steer (see thread here). Here's a little snippet from the spreadsheet. Setup #11 was my ultimate target to induce stability for the rear. I'm setting ride height by choosing a toe rod angle above horizontal based on my own observations/experience:  Of course once I went onto the final alignment, I had to dial in the rear camber to get it symmetric because the manufacturing world isn't perfect. What I didn't get a chance to do yet was measure this physically to see if at the very least the trends match. I will touch more on this later once I'm not in full race prep mode (2 races within 4 weeks). Regardless, the rear of the car was notably more stable. I also pipped my personal best at this track by 0.6 seconds in low to mid 40F overcast weather. The lower rear camber works well based on my tire temp spread and I may also be able to pull some front camber out based on temps as well. 255 performance on a 10" wheel so far has been excellent. So the HOOD....Finally test fit before moving onto final touches and paint. Clears everything and looks 10000x better even not painted.     Last edited by gills; 02-01-2019 at 08:01 AM.. |

|

|

|

|

|

#13 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

The hood project was completed and run in last weekend's race. The car turns a lot of heads in a field with 55% BMW's.

I'm the welder/sheet metal-er, here's the filler:  Ready for paint:  Back from paint:  Ready for action (Trackspec hood vent for BMW Z4):   And, yes, there was snow on the ground morning of practice/qualy day:  Last edited by gills; 02-01-2019 at 08:02 AM.. |

|

|

|

|

|

#14 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

WATKINS GLEN AER 2018 RECAP

Backstreet's Back, ALL RIGHT!! lollll  We once again qualified in the fastest class, with the likes of ex continental tire BOSS 302R Mustang, Porsche Cayman's, M235iR's fresh from BMW, E36 S54 swaps, etc, etc. 95 total cars for the weekend, qualified 17th overall without trying too hard. We should've pushed harder during practice/qualifying. We really would've liked to be in the next lower class, but sand bagging sucks and it's the last thing we want to do (can't say the same for all teams). After the practice/qualifying day we were blessed with one of the front brake pads looking like this:   Now I don't run brake ducting because I never measured the need to. And, if I did run ducting, this may have been worse because there was literally snow on the ground the morning off. I'm thinking this was an environmental factor with the ambient temperature and going hard on the brakes in the first few practice laps or so. Good ol' race start:   Saturday we were running as high as 2nd place overall when 1st driver came in. With 2nd driver out toward the end of his stint, the fuel pump inertia safety switch we installed was tripped over rumble strips exiting "the heel" of "the boot." Driver immediately thought he ran out of gas as we were in the window for a pit stop. It was very close to pit-in so he tried to use starter to crawl into pit, but that ended up tripping the main 100A circuit breaker. Had to get a tow. We were P7 overall when that happened. That killed most hope for the day. video of the moment he thought he ran out of fuel (please excuse the NY accent cussing lol): https://youtu.be/sd2RKMF7SRI?t=4h29m38s Sunday's 9 hour race was a much better result. We had zero issues all day and managed to finish 4th overall (and in class), 2 laps back on the lead cars (the nutty 302R Mustang broke a spindle.....an aftermarket one), which finished with only 1.8 seconds between them after 9 hours. The #395 E36 (S54 swap) was driven by Randy Pobst and not surprisingly scored the fastest lap of the weekend (2:03.393).   The car looking planted:  Pit stop:  With that said, notes to take away from the weekend are that we need to further work on driver coaching to narrow the lap time deltas between drivers. If this gap is narrowed, we would've likely podiumed based on brief analysis. A biggie is that the car topped last years best lap by 1.5 seconds (2:10.003 vs 2:08.559) without any power adders and less sticky tires. Differences from last year:

Also, my live streaming setup worked basically flawlessly. I hope some of you caught it when it was live. I ended up going a more expensive route, but it was 100% worth it. I was able to monitor video from the pit all weekend long with a 10-15 second maximum delay. The difference maker I believe is the enterprise level modem and antenna. The antenna is the black fire alarm looking thing on top of the roof. That's my biggest complaint, but the trade off is worth it. My system:

The autosport labs podium connect module for engine and GPS data telemetry did not work unfortunately. I'm working with Autosport Labs in troubleshooting. So STAY TUNED for the New Jersey Motorsport Park race coming up on the weekend of 5/18. I will be live streaming again. Changes in the pipeline are going to a 12.72" rotor in the front instead of 12.2" and I'm giving PFC brake pads a shot. Going with 11 compound in the front and 97 in the rear.  I may also throw a factory rear bar on. Will test with it on practice day. Last edited by gills; 02-01-2019 at 07:58 AM.. |

|

|

|

|

|

#15 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

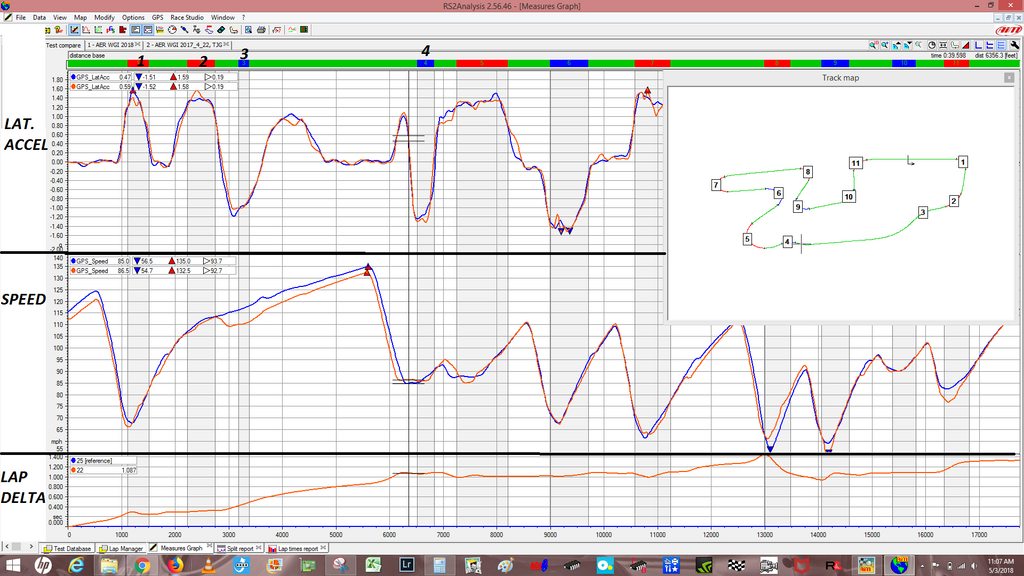

Digging into the data a bit to see where and how the 1.5 seconds was gained when compared to last year.

So again, here are the changes to the car when compared to last years WGI race: 10" vs 9" wide wheel RT615K vs RT615K+ no synchro issues with new transmission 3.69 vs 4.08 FD stiffer spring rates with no rear bar (600/500 vs 500/335) MCS 2 way remote dampers vs Feal 441 Below is an image from AiM analysis software (RaceStudio) showing my personal best laps from last year (2:10.6xx {red line} and this year 2:09.3.xx {blue line}). My co-driver is the one who usually sets the fastest laps, but unfortunately I don't have his data from last years 2:10.0xx to compare to his 2:08.5xx. But, it's basically the same difference between our bests; 1.3 seconds for me, 1.5 for him. So, 80% of the time gained this year from last year is from the final drive ratio and butter smooth new transmission. The bottom most row line graph is the lap time delta. You can see from start/finish all the way up to the entry to turn 4 ("bus stop") the line just keeps climbing steadily. I don't have the TPS shown there, but from the exit of turn 1 up to turn 4 is full throttle the whole way and it's significantly uphill through very high speed turns, called "the esses." A good ball tester. Look how brutal the 5-6 gear shift from last year was on the speed graph in between turns 2 and 3 With that said, lateral accelerations and speeds through the turns are basically the same on a less sticky tire this year. Perhaps a testament to the new dampers and spring rates.  Last edited by gills; 02-01-2019 at 08:02 AM.. |

|

|

|

|

|

#16 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Before getting into the results of the NJMP race, a bit of pre-race prep:

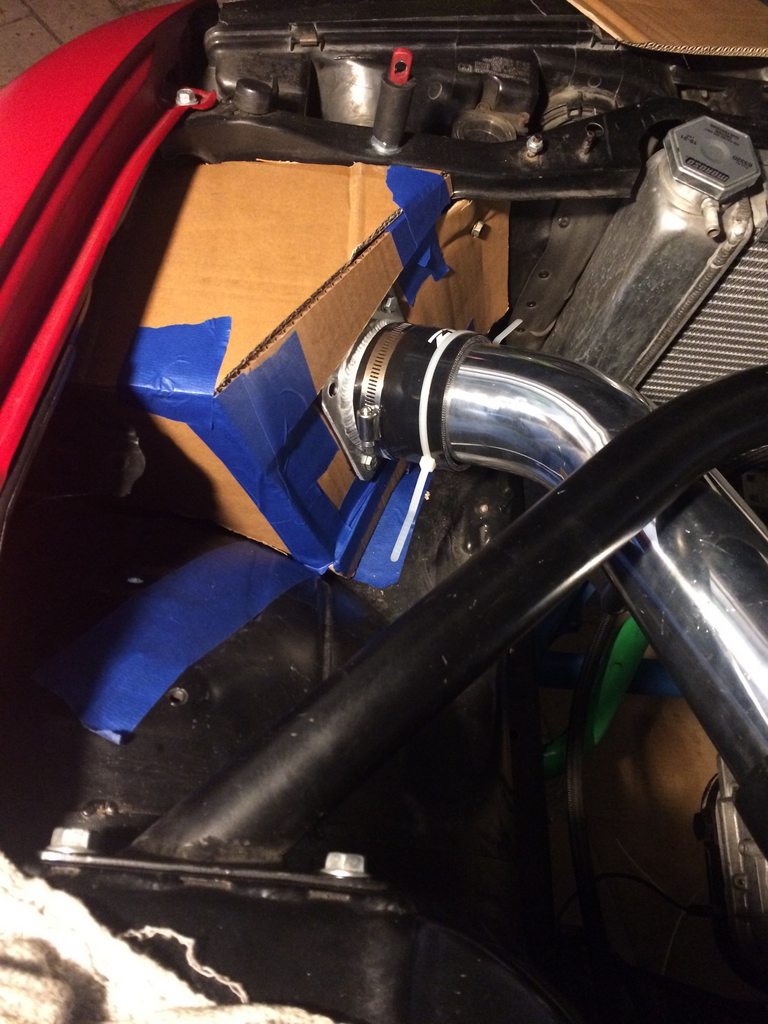

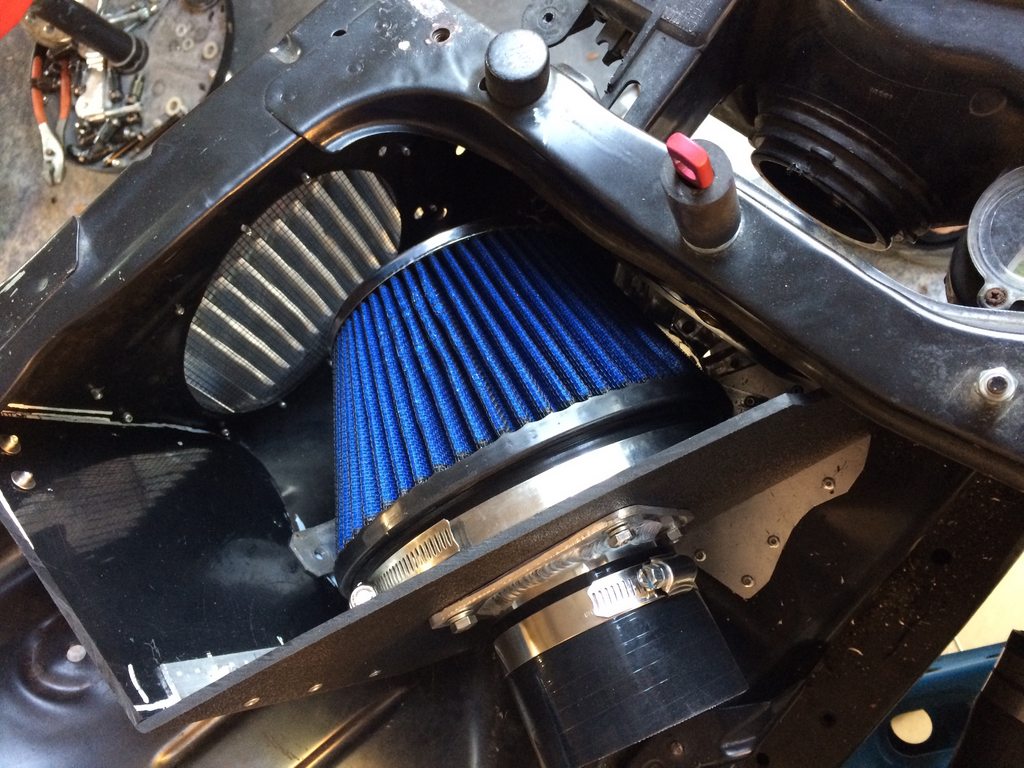

At Watkins Glen while following a very well driven and setup E36 M3 (while I set my fastest lap time), I noted that he would lightly tap the brake pedal a couple of times on every straight away prior to a heavy braking. A lot of guys do this as an "inspection" so they know they'll have (or won't have) brakes prior to the braking zone. Many drivers do it to return the brake pads as close to the rotor as possible because of flexing in the wheel hub/bearing. The system under racing loads causes the rotor to push the caliper pistons back into the caliper a bit. This is called "pad knockback" as I'm sure most of you know. A few companies sell knockback springs to install inside the caliper to combat this. It is something that I experienced very much in my old 2004 STi that had the older 5x100 wheel hub and bearing assemblies. I never thought I'd need to do it on the S14 because it is fairly light car and things seem to be robust. But, I figured I'd test it out while following this guy as he was giving me a constant reminder. Much to my surprise, the pedal travel reduced notably vs when I didn't do it. The hubs/bearings on the car have been on it since the beginning so I figured it was probably best to the change them anyway and inspect them. So I procured new OEM hub/bearing assemblies all around, new ARP extended wheel studs (M12x1.25 all around ....more on this later), and new Muteki SR48 lug nuts, just to cover all bases. And to top it off, I purchased some of that fancy NEO Synthetic wheel bearing grease that I'm sure most of you read about in the ubiquitous MotoIQ article. Since I'm endurance racing, I figured that this is probably can't hurt.  The process that the MotoIQ article goes through is pretty accurate, although he doesn't make mention of the outer seal on the inboard side that needs to be removed in order to pull the balls out. It's not difficult, but you need to take care with a small flathead screw driver slowly working your way around to pry it up and out. Only then, can you remove the inboard balls. This is probably the "hardest" part. Anyway, here's a brand new OEM bearing. Same yellowish, waxy grease is still used. You can see the seal that needs to be removed that I referred to:  Practice run on spare hubs I had on the shelf:  And here's a hub/bearing that was on the car since I've had it:  I still have yet to pop the balls out of those bearings, but at the very least the inner races and the balls look fine. I have yet to fully inspect the outer races. I was also expecting to see the OEM grease not be yellow, but rather cooked, greyed, and darkened. As you can see, that certainly isn't the case. There's significant racing and track time hours on those bearings. To top it off, I don't run any brake ducting either so these aren't getting cooled off much at all. And if you're wondering about re-greasing the rear bearings, I didn't, but the process will be nearly identical. I just ran out of time. Ready to go. Now I have full spares for hubs/bearings, wheels studs, and lug nuts:  About those ARP extended studs. Apparently you used to not be able to get ARP M12x1.25 studs all around for S-chassis, only M12x1.5. If you want M12x1.25 all around, for S14 you get Subaru WRX ARP kit 100-7716 for the front, and for the rear you get these from ConceptZ, which they had ARP custom make a few years back: click here (use these all around for S13). I really wanted to go with ARP vs. the other random brands you can get off of ebay. Other big-ish changes were with the brakes. After a conversation with a PFC engineer, we went with 11 compound front, 97 compound rear and as per his suggestion, we tried a 15/16" BMC (from a 1"). Also moved to slotted rotors all around, and bumped up the rotor diameter in the front to 12.72" (from 12.2); the max diameter available with a 8 x 7" rotor bolt circle from Wilwood. The slots can potentially help combat squeal/noisy brakes.  Rocking Defsport:  Threw some temperature indicating paint all over stuff also. Was curious if things were reaching dangerous temperatures:  My teammate was determined to get rid of the hot-air intake we had. Definitely cost some power in the middle of a hot 9 hour race. Used some HDPE sheet we had sitting in the garage forever to construct an airbox of sorts, and some G35/Z33 tubing/adapters from Z1performance to extend the intake. Considering the time crunch, he did an awesome job. Although not measured, it must be an improvement for IAT. "CAD template" (if you haven't yet, go watch the "Project Binky" video series. If you appreciate fabrication and car stuff, you will most likely love this: Bad Obsession Motorsports:      Lastly, had another oil analysis done after Watkins Glen to see if things were healthy and if the oil could go another weekend. After 27 hours of racing, going to give this batch another go:  Also trying a different tire out. Went with a set of the Hankook RS4 as this race's fresh tire. Still have Falken RT615K's as backup. Race update coming next.... Last edited by gills; 02-01-2019 at 07:56 AM.. |

|

|

|

|

|

#17 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

New Jersey Motorsports Park, 5/2018

Saturday's 9 Hour Race "Please don't rain, mommy" The one picture that basically describes this entire day:  We qualified 17th overall with a 1:59.8xx which was FINALLY good for class 4 (Reminder, we don't want to be in class 5, which is the fastest class and what we always end up in). All it took was a sh!t ton of rain! That lap time is basically 30 seconds slower than a proper dry lap in our car. So all this time we've been gambling on the weather and just hoping that it would never rain on us. Well, the hope finally wore off. With no 'real' rain setup, our car was a handful in the wet stuff. And by handful, I mean scary AF. By the time we realized we'd be screwed with rain, it was too late to make any significant setup changes (softer springs, small tire, better tire, etc..). Combine that with human foot ABS and traction control (unlike some of the fancy teams that are gracing AER with their presence) and it's a recipe of butt puckering. The only thing we did was add lighting to make sure people would see us. I took out front camber (down to -2.5), removed gas pressure from the shock reservoirs, and went to almost max soft on compression and rebound damping. It was also somewhat cool out so I took out some tire pressure in an effort to get the tire to squirm some more heat into the carcass. To top it off, RS4's are not good in cool, wet conditions, which we can definitely confirm! The track was insanely slick on the dry line, to the point where it literally felt like driving on ice when crossing over it then finally getting grip in the rain line. Heading out for the parade laps through monster puddles:  In hindsight, not so sure that was the best idea (low tire pressure) in the type of rain on this day. It was a lot, and hence there was a bunch of standing water. Higher tire pressures are better for hydroplaning resistance, which became the more important factor in many parts of the track. Green Flag! Hey look, at least the lights are working well...  So the goal of this day was not to crash and not get crashed into, and we were successful. 2 drivers had significant off road excursions and luckily were able to come back on track. We were also almost successful scoring a 3rd place podium finish as well. But, the Race Gods just weren't having it. Using a window squeegee to defog the windshield while going 100mph down the straight just wasn't enough for the Race Gods. (some video from the live stream to give you a moving pictures idea of the poor visibility) About 30 minutes out from the finish, in 3rd place with no more stops to go, I got a flat tire. Looks like a rivet from a piece of body work that was ripped off from the deep puddles did us in:  Would've been an amazing ending to a terrifyingly fun day. Not surprisingly, a turbocharged FWD car (Chevy Cobalt) won class 4 for the day.  Team fastest lap: 2:03.2 Overall fastest lap: 1:53.7 (IMSA driver Al Carter in a worked E46 M3) (Some good "racing in the rain" reading material from Grassroots Motorsports Magazine: https://grassrootsmotorsports.com/ar...ing-race-rain/) Last edited by gills; 02-01-2019 at 08:27 AM.. |

|

|

|

|

|

#18 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Sunday's 9 Hour Race

In the back of our minds we were all thinking about Sunday as the radar and forecasts were showing a drier and warmer, more humid day. I set the car back up with dry front camber settings, rechecked toe and reverted back to typical dry tire pressures and damping settings Saturday night. We obviously also had to switch back to our set of Falken RT615K tires due to the RS4 flat. We know them well... Beginning of the day, the track started off wet from the previous day's rain. Took about an hour to get within 4-5 seconds of the car's/track's typical dry pace. The car may be terrible in the rain, but it can certainly haul ass in the dry. Green Flag (need to build out some fences/fenders for the front tires, eh?):  Midway through the day it was apparent that we were a favorite to win class 4. We focused on being strategic with pitstops, i.e.-pitting during full course yellows/safety car laps. So much so, that we gambled on bringing in our 3rd driver about 15 minutes earlier than normal to take advantage of a fairly lengthy full course yellow. Based on what we knew of fuel consumption of the car at the time, it seemed like a winning decision. That certainly came to bite us in the ass later.... Dry weather, WOOHOO!:  BUT, not without something else coming to bite us in the ass first. During the 3rd pitstop, my brother (who was getting in the car to drive) forgot to lower his visor once over the pit wall. All visors must be down and no work can be done on the car during fueling. The stewards saw the violation and handed us a drive through penalty. Even with that drive through penalty, we were still 1st in class. We thought that perhaps the organizers had something against us since we were handing many BMW's their asses. Then we checked the vid.....caught red handed:  So as much as that sucked, one really cool thing about AER is that they send out team specific and mass text messages throughout the weekend giving you information about violations, pit stop times, number of pit stops, the current driver in the car, general race updates, other teams needing parts, etc. Information about the race is shared instantly in real time and direct. It's very efficient. They are definitely ahead of the game in this regard. Fast forward to my stint, which started at 2:54pm. Race was ending at 6pm with one required pit stop remaining to do in that time span. With the knowledge that we can squeeze out 1.5 hours per tank, it was cutting it close on paper. I usually do a double stint to finish the day, although it typically ends up being more like ~1.75 stints most races. But, we were being more aggressive with the earlier pit stops this time around. We obviously wanted to max out my first stint, so fast forward about 1:10 and I'm communicating with pit about when to come in. One curveball that we weren't ready for was that I was starting to get heat exhaustion in the car. I regrettably didn't drink as much water/liquid as I usually do before getting in the car this time around in an effort to not have to piss like a race horse during my stint like I always do. Probably wasn't a good decision. I was also having an issue accessing the camelback during my stint so I also didn't drink enough in the car also. (Video of me struggling to find camelback) We've survived all this time without a rain setup and we've also survived without a Coolsuit setup. But, this time, there was no way I was going to be able to do a double stint without one. There wasn't a single yellow flag during my stint and I was in it to win it almost the whole time. Hot and humid southern Jersey that started getting to me this day. I let the team know that someone else needs to get suited up to go in for me. (I managed not to put 4-off on the previous day's ice rink of a track. But, the heat got to me, and of course, it was while getting pointed by a team that we are very friendly with: Heat Exhaustion 4-off video clip) The Volvo team that we always pit next to at New Jersey and who pointed me by in the video:  Inevitably it turned into a scramble in the pits. The driver I wanted to go in wasn't suited up yet as we all thought I had another 15 minutes of fuel in the car and I was ok with going that much more time. As I was insisting on them to all be ready ASAP because I was overheating, I got fuel cut a little before pit in. I immediately made the decision to pit so I didn't run out of fuel on track, which happened to me on Friday practice very shortly after hitting fuel cut. I informed the pit. They were barely ready. I was out on track for a total of 1:24. Not a single full course yellow contributed to this shortened stint. We were in 3rd overall, 1st in class at this point by a comfortable margin. During the scramble, the driver going in wasn't able to get his ear buds for communications in on time. He informed me of the situation and we were relegated to using pit boards to communicate with him. He went out and we still had 1st in class, dropped down to 4th overall. We had about just under a lap lead over P2 still after this. Because of my surprise early pit stop, it meant we had to bring the last driver in for an extra pit stop for a splash of fuel. He went out at 4:22, which left 1:38 left on a tank of fuel...not going to happen. What took place from that moment on was riddled with indecision. We had the win in the bag, but it was our race to lose. It should've been simple, but only in hindsight is it ever. The second place car behind us was a 'detuned' E36 S54 swap (#955 Just For Fun Racing) with basically no aero like our car. These guys have been a juggernaut with winning Class 4 for consecutive races. Where we screwed up was not letting our driver know to push as hard as he can to build a larger gap. He was in a more conservative mode to try and stretch the fuel out. That's all he wanted to know when he was out there, whether to push or conserve. We failed at parlaying that information to him. The next failure was when we pulled him in for the "splash" of fuel. We ended up putting in about 1.5 jugs of fuel where we could've easily have gotten away with 1 jug. Filling that extra 1/2 of jug of fuel eats up about a good 15-20 seconds. Far too long in the instance we were in. While he was going down to pit exit, #955 passed us. We were released back on track about 16 seconds adrift at 5:27.  At that point it was no holds barred. Our driver managed to cut the gap to 7 seconds. He was steadily gaining on #955 and would've passed them...until the unthinkable with about 15 minutes left in the race....RAIN. The heavens opened up with a sporadic downpour that basically vaporized our chance of winning. #955 was already setup with softer springs and smaller tire for the rain from Saturday. There was no chance in catching them at that point. Unfortunately I have no good pictures of that moment when it started down pouring. #955 took P1.  Core4 Motorsports took P2:  Team Fastest Lap: 1:32.8 Overall Race Fastest Lap: 1:28.7 (Nelson Canache, Mustang BOSS 302R) ------------------------------------------------------------------------------------------------------------------------------------------ Last edited by gills; 02-01-2019 at 08:27 AM.. |

|

|

|

|

|

#19 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

So, about them brakes....

We've gone through a few combinations of calipers, pad compounds, and rotors. But, the one thing that has remained constant is the brake master cylinder size. For the Waktins race this year (and all prior races) we were on a 1" BMC (shimmed, not shimmed, and kinda shimmed...). Even with the caliper upgrades, rotor sizes increasing, etc, the biggest complaint (if we are to split hairs) has been about feel and modulation. So, we decided to [subjectively] test the old argument of whether a larger or smaller BMC will aid with feel and modulation. The general consensus is that usually a smaller BMC aids in modulation because it makes for longer pedal travel with a smaller amount of pedal force for a given system pressure. That longer pedal travel gives you more 'resolution' of sorts through the pedal stroke. Vice versa for a larger BMC. I've always been in the "you don't modulate your brakes based on pedal travel" camp so I've been skeptical of going smaller. But, after conversations with PFC and a few others, I decided to try the 15/16" BMC for the NJMP race. The result was just 'meh.' I could definitely feel the longer pedal travel when compared to the 1" BMC, but the modulation and feel was similar to the 1" BMC to me. My co-driver thought it was worse. Next up was the 17/16" BMC that we just ran at an open test day last Friday. No other changes on the car except for that. It was a unanimous decision; we have a winner! Everything about the change was positive. Higher pedal force threshold to lock up the brakes, shorter travel, easier to modulate. It really addressed most of our complaints (until we get bored and try to find more) about our Frankenstein braking system. Not only that, it also confirmed my suspicion about the smaller BMC provides more feel/modulation mantra. At least in my case. My current setup which is the best the brakes have felt yet all around. And to top it off, they don't squeal. Huge fan of the PFC compounds so far:

If this was a track day only/TT type car running R-compounds or slicks, I'd get more aggressive PFC compounds. Last edited by gills; 02-01-2019 at 07:36 AM.. |

|

|

|

|

|

#20 |

|

Premium Member

Join Date: Mar 2009

Location: Maricopa, AZ

Age: 30

Posts: 7,679

Trader Rating: (10)

Feedback Score: 10 reviews

|

Loving all of this thread! I have a vq35hr in my own drift car and would love to try my hand at time attack events some day. Definitely been wanting to start the oil analysis myself as well. Also sent you a PM about that strut bar!

|

|

|

|

|

|

#21 | |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Quote:

The S with a VQ engine is an amazing setup for any track event. I like to call it the Japanese E36/46 M3. Where I am on the east coast, almost no one tracks them (road racing/grip) so when I rip passed people they're always like  It's a very underrated and capable chassis. It's a very underrated and capable chassis.Will respond to your PM shortly. |

|

|

|

|

|

|

#22 | |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Some good info that someone shared in my thread that is worth putting here also:

Quote:

|

|

|

|

|

|

|

#23 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Here's my Sim racing rig I built to practice for the Mid-Ohio race in 10/2018. My end goal is to have a decent DIY motion simulator. I just built the PC and got the VR goggles. I had everything else already.

PC I built is bare bones just for gaming and video/photo editing and CAD:

Then an Oculus Rift for the VR goggles. Pedals are Fanatec Clubsport V2 pedals with load cell brake pedal. Steering wheel is basic Logitech Driving Force GT. Shifter is a Thrustmaster TR500(?). The rig is an Obutto Ozone. |

|

|

|

|

|

#24 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

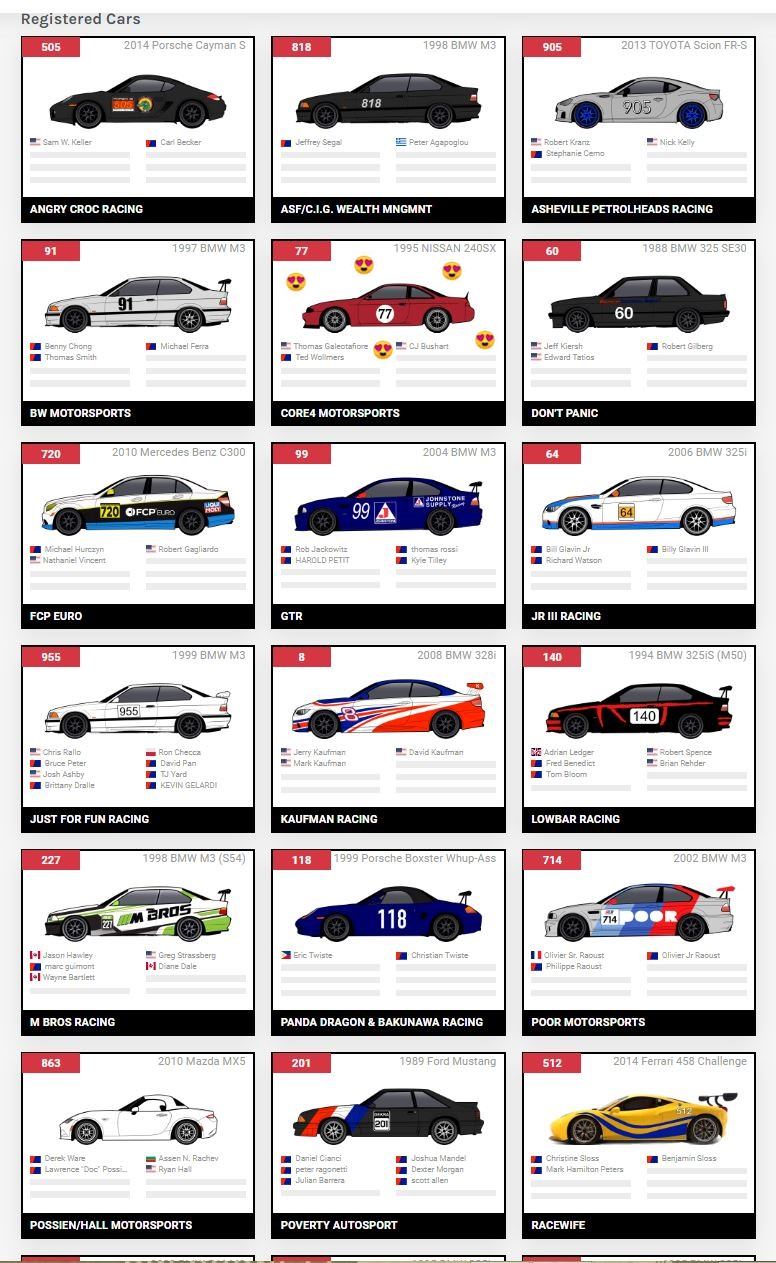

We're officially registered for Mid-Ohio for the weekend of 10/19! We're a man down for the weekend. If anyone lives near Mid-Ohio that's reading this would be willing to help out for the weekend, or even a single day, it would be very helpful! Even better if you have race gear to assist during pit-stops.

Some of the entry list that I can capture in a screen shot (all german except us, FRS, and Miata....no surprise):  Interesting tidbit, yes, that's a Ferrari 458 Challenge car that "Racewife" team is running on the bottom right. Car is owned and driven by Ben and Christine Sloss. Ben Sloss is the Vice President of Engineering for Google, hence the ability to choose and field a Ferrari 458 Challenge meant to sprint race and race it for 18 hours in a weekend. Next year they'll be campaigning a Mustang built by Multimatic specifically to endurance race. Must be nice, eh? Hopefully it gives everyone even more insight as to why we don't want to be in the top class (5). I mean, I would, but need sponsors. Any takers???? Anywho, it'll be the teams first time racing at Mid-Ohio so we're very pumped. So, in conjunction to practicing on my new VR sim racing rig, it's good to watch some video. How about some oldish, but still good video from long time NRR/Zilvia member "240sxTTC" in his S13 LS swapped TT car (now sold and bought a Camaro....bah!): |

|

|

|

|

|

#25 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Finally got some green flag only video up from our 4/2018 Watkins Glen Sunday race. I've put some time stamps in the description to get you to some interesting parts and fast laps for each driver. The start of the race is also a good laugh. First time that driver ever did a two wide rolling race start. Nerves got the best of him, but he came around and ultimately only lost 1 position by the time he came in to pit.

https://youtu.be/j_ZzOjFbEuo |

|

|

|

|

|

#26 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Hmmm, probably the only time they'll look this clean I'm sure. But, regardless, we've wanted white wheels for awhile now especially with a red car. Powder-coated Honda Championship White. Trying to stand out from the sea of BMW's.

|

|

|

|

|

|

#27 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Mid-Ohio race prep is moving along. As mentioned before, I really wanted to do a spring rate change. Either drop the front rate about 100 lbs/in or increase the rear rate 50 lbs/in to dial out some of the mid-corner understeer the car has at the moment.

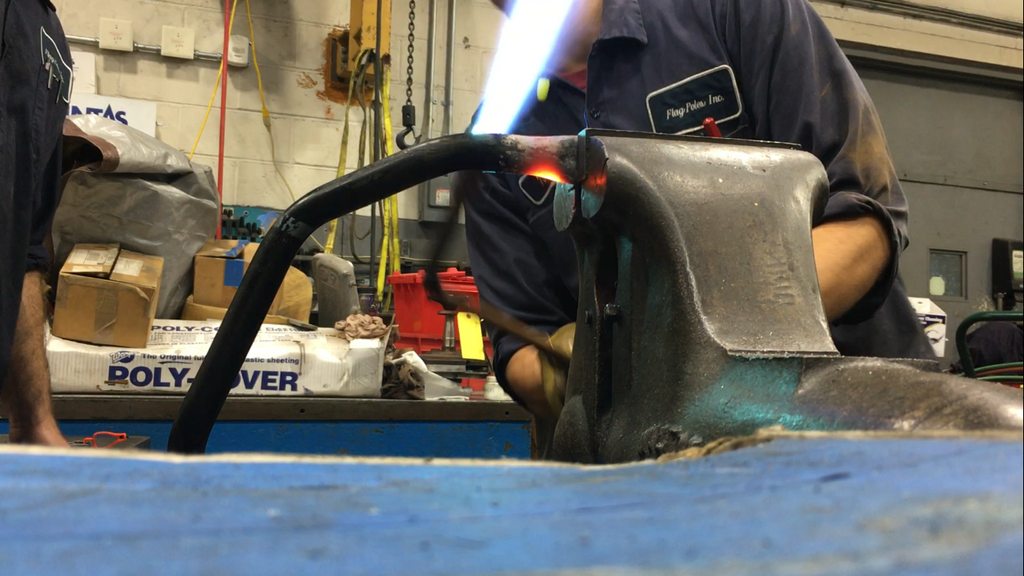

Since a spring change is a semi-PITA, I was initially going to throw in a stock S14 rear bar to move the roll couple rearward out of simplicity. After messing with my suspension spreadsheet a bit it probably wouldn't have been enough of a shift. I then stumbled upon an S15 OEM 21mm rear bar on ebay. It's a diameter that falls right in the middle of OEM bars and aftermarket ones and it's tubular. Weighs nothing vs aftermarket ones which are almost always solid. Made a low-ball offer and the guy accepted.  I just wanted to use the existing brackets, but the bushings were taller:  The bar also needs to be spaced down from the subframe since the subframe is raised and there's potential for the bar to hit the gas tank on an S14. So, I machined some stepped aluminum spacers to use the new bushing and space it down:  I also wanted some adjustability. So I flattened the end more on a press and drilled another hole. stock:  Flattened and drilled:  I then realized that I didn't want to use the OEM style end-links and still had the nice adjustable spherical end-links from the 24mm Progress bar I used to have on the car. But, OEM bar end-link mounting look like the above pictures. Need the mounting holes rotated 90 degrees. So? My overkill solution; I made up some aluminum clevis' with 3 different lever arm positions to mount to the two holes now on the sway bar:  But, my first test install revealed that there was too much mis-alignment with the spherical. Using some washers to rotate the clevis into a position that would work to get an idea of how much I need to move:  Nothing a little oxy-acetylene heat can't fix! Probably partially annealed that area, but it's not of concern:  Voila. My 21mm adjustable tubular adjustable rear sway bar:  Should be interesting to see how it helps at Mid-Ohio, which is very technical and undulating and will destroy the front tires if the car is understeering a lot. Will obviously report back on the change. |

|

|

|

|

|

#29 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

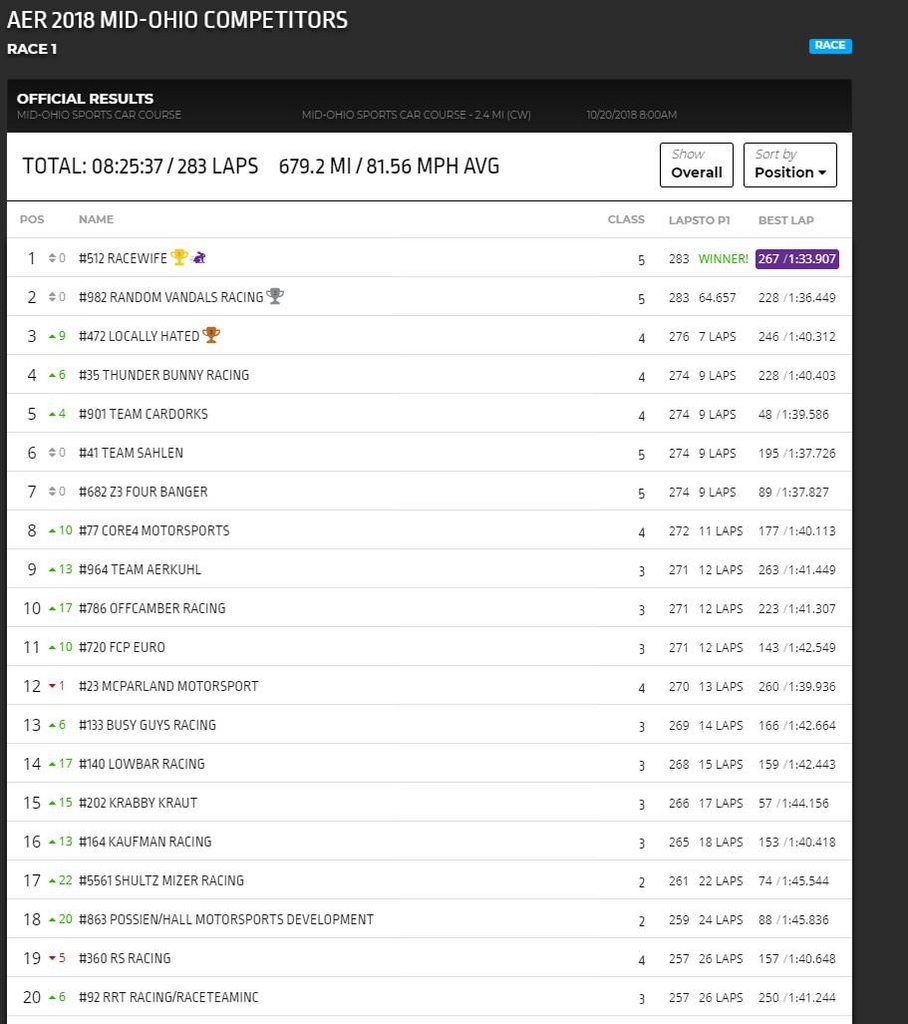

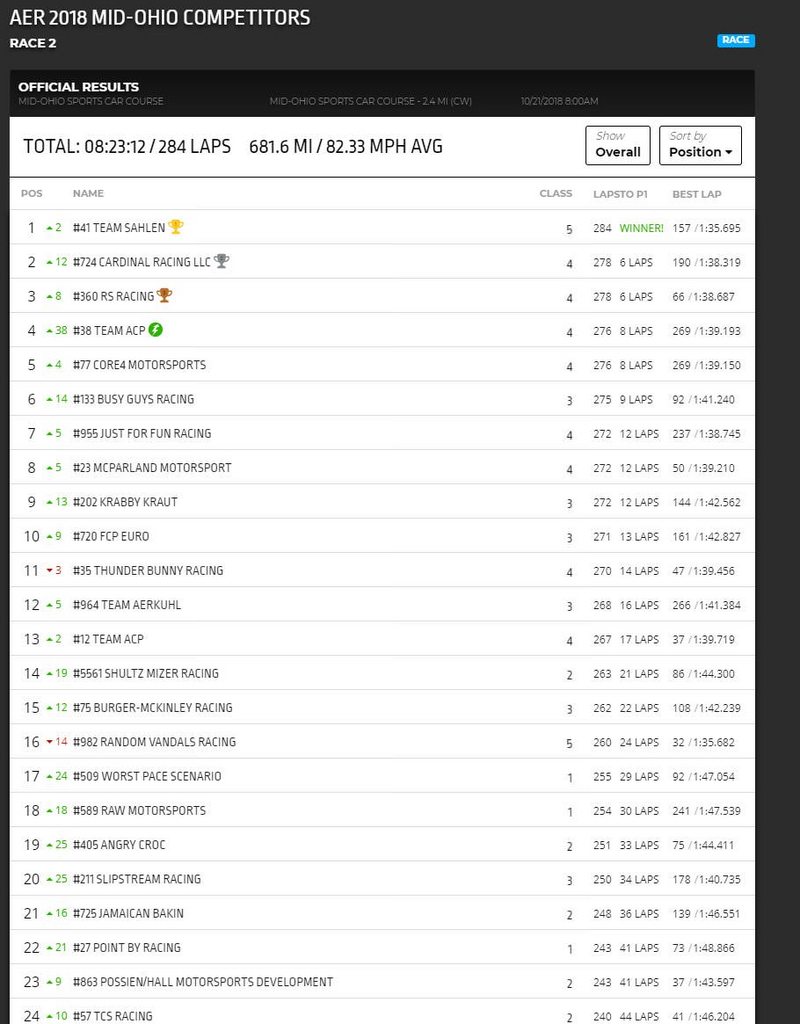

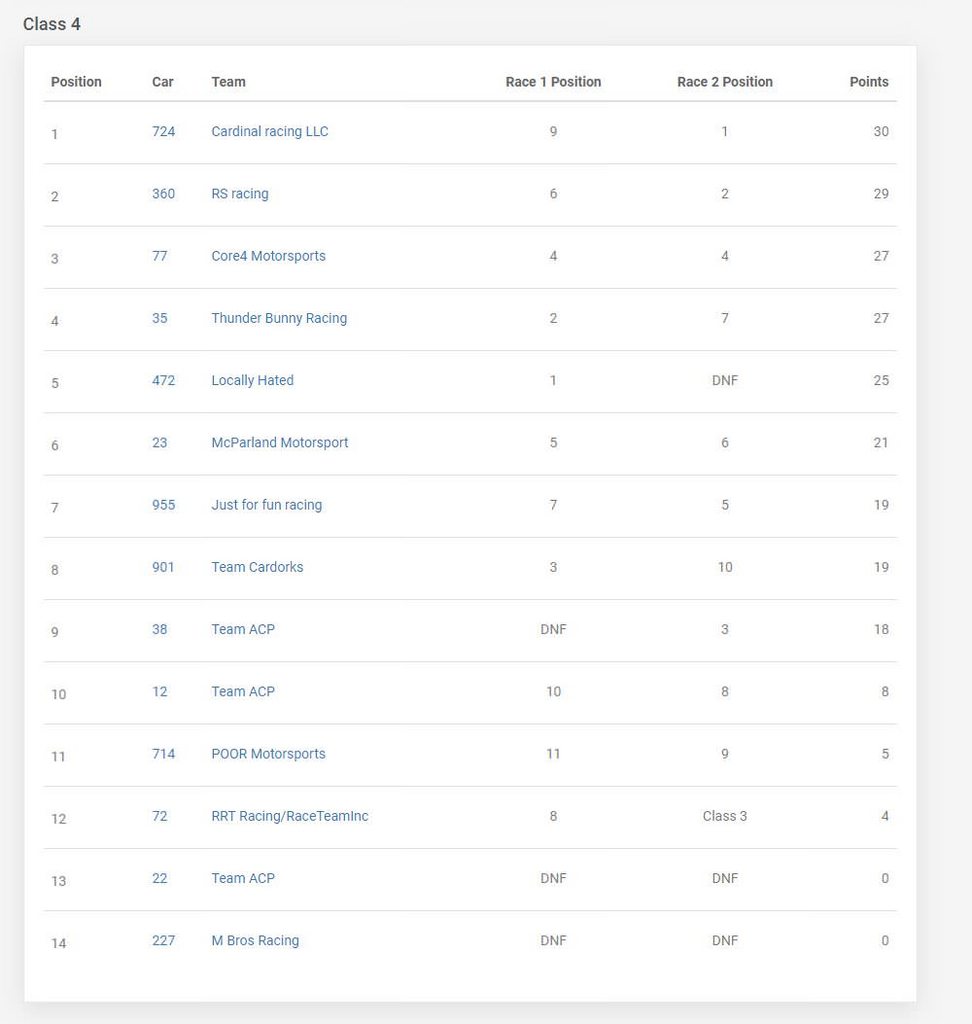

Mid-Ohio 10/2018