|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Builds (and builds only) Got a build thread? It goes here, build threads anywhere else on the forum will be locked and never moved. |

|

|

|

Thread Tools | Display Modes |

|

|

#31 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Some interesting info from that weekend.

Because of how consistent we were and the car remaining reliable, we actually completed the 2nd most laps of any team for the whole weekend. And on top of that, 4 of the top 6 teams for most laps completed weren't BMW's or German! Team Nissan making a serious dent. Total laps completed for the weekend: #41 Team Sahlen Porsche Cayman: 558 #77 Core4 Motorsports Nissan 240sx: 548 #35 Thunder Bunny Racing Nissan 350Z: 544 #133 Busy Guys Racing. Nissan 370Z Nismo: 544 #982 Random Vandals Racing, LLC BMW E46 M3: 543 #23 McParland Motorsport Honda S2000: 542 -------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- The addition of the S15 rear bar was a very worthy one. I didn't notice any less corner exit grip than without one. In fact, because the car rotated better (much better) mid-corner, the car required less steering angle to go where you wanted to go after the apex making for less theatrics by trying to compensate the understeer with the throttle. Still kind of an unfair comparison because I didn't correctly compensate the loss of roll resistance from no rear bar with the right rear spring rate in my previous setup. I will attempt to revisit this one day, but for now the S15 rear bar is staying on to be able to test on my home track. Because we have a gazillion laps there with data, it'll be easier to draw the age old, "my-s-chassis-can't-put-power-down-so-let's-remove-the-rear-ARB" conclusion. --------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- How about some pad taper review on our PFC 11's that we run in the front. Or lack of pad taper is more like it:   Pad wear is higher than ST43 for sure though at the expense of extra torque and modulation it seems. They are also whisper quiet, which for endurance racing when you're in the car for hours, is a huge plus. I may have mentioned this earlier, but the PFC's are the only pads that came with chamfered lead and trailing edges, which according to the knowledge I've been accumulating helps mitigate noise/resonance as well as pad taper in calipers that may be prone to that. If I get other pads that don't chamfers, I will probably end up milling chamfers into them. I will probably give ST43's another go in the future so I will modify them. ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- Also finally managed to get the car on the dyno to see what kind of power she's making and if the AFR's are healthy. Ending up making 240whp/240wtq on a mustang dyno. AFR's are right around 12:1 as well. VQ35DE plot:  Video of dyno pull: https://www.facebook.com/core4motors...3926885879942/ Also dyno'd my brother's E36 with a shrick cammed S52. Our VQ35 plot is solid, and the S52 is dashed. His AFR plot is wacky AF in the low end there. Pretty surprised at how much more torque the VQ makes from 2800-4500 rpm:  Now the discussion is whether or not we go for something like JWT C2 cams and springs. The motor is due for a tear down and inspection over the winter so now would be the time. The 15-20 extra whp that could potentially come from the JWT cams will help us keep up with the S54'd cars on the straights. The main concern is fuel consumption. We're already at the limit with range and adding a fuel cell in an S14 is a huge job. We're just not sure how much more, if any extra fuel will be consumed by being able to get ~500 rpm more of usable powerband with extra power. That extra rev range and power will also make us consider going from the 3.69 to a 3.9 final. Lots to consider with the time ticking down... |

|

|

|

| Sponsored Links |

|

|

#32 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Just wanted to share solution that I'm now offering for BMW E36 (all) and E46 (non-M) cars. Brand new OEM BMW front and rear wheel hubs precision machined to accept and installed with ARP press-in wheels studs. Like most German cars, BMW's come with lug bolts, which are a PITA to deal with when removing/installing wheels often. The ubiquitous thing to do for those who dedicate their cars to HPDE and/or track competition is to use "thread-in" conversion studs, not only for ease of servicing, but to use spacers.

Should be good, right? Not really...almost every single AER event a BMW will at least break one thread-in stud on a random corner of the car during a race and luckily people tend to find them before catastrophe. But, sometimes they don't and you get this (video of Mid-Ohio incident), which I was only seconds behind: Wheel studs breaking and wreck And another one at the Calabogie race in August  As crazy as it seems, it isn't uncommon. Basically every brand (Turner, Bimmerworld, MSI, Apex, etc...) of conversion stud out there has been reported to break. It's a somewhat hotly debated topic (and we can get into here for the sake of keeping the forum active), but it's obviously an inferior interface to that of press-in studs. Typically other components break, like the wheel itself, before an ARP stud will fail. Failures of ARP wheel studs are almost unheard of. So, I want to bring that peace of mind to BMW E36/46 owners with the ability to run up to 12mm to 20mm wheel spacers depending on which wheel stud is chosen. Also peace of mind for us when racing next to these guys!:    https://www.core4motorsports.com/pro...hub-conversion |

|

|

|

|

|

#33 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

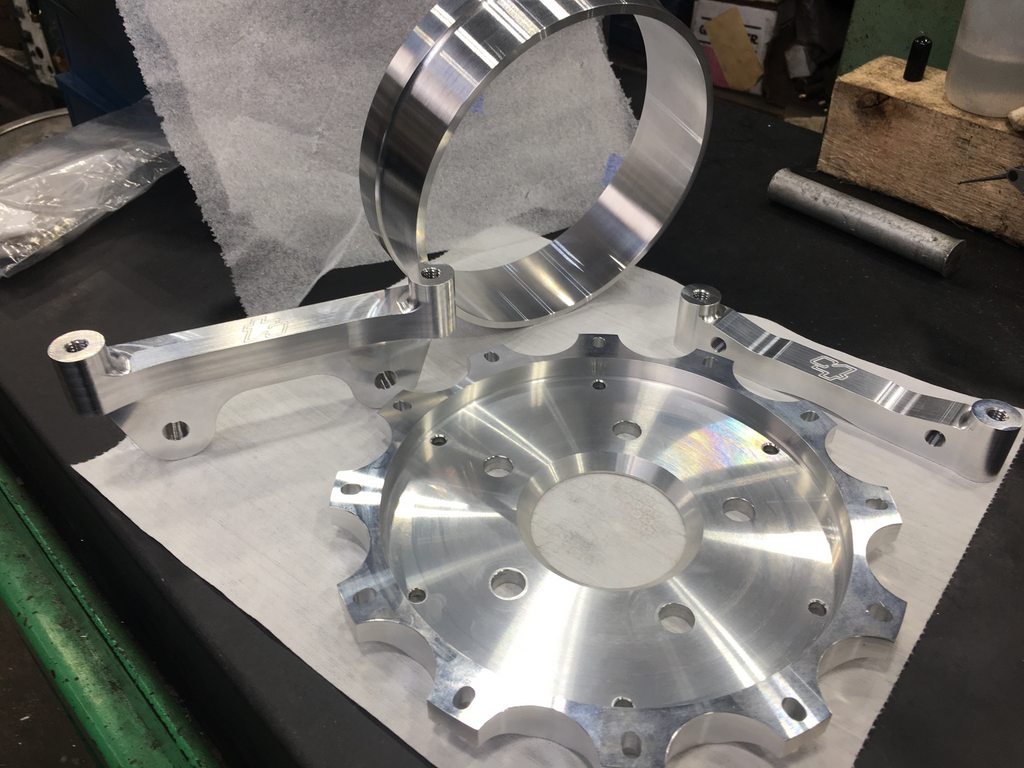

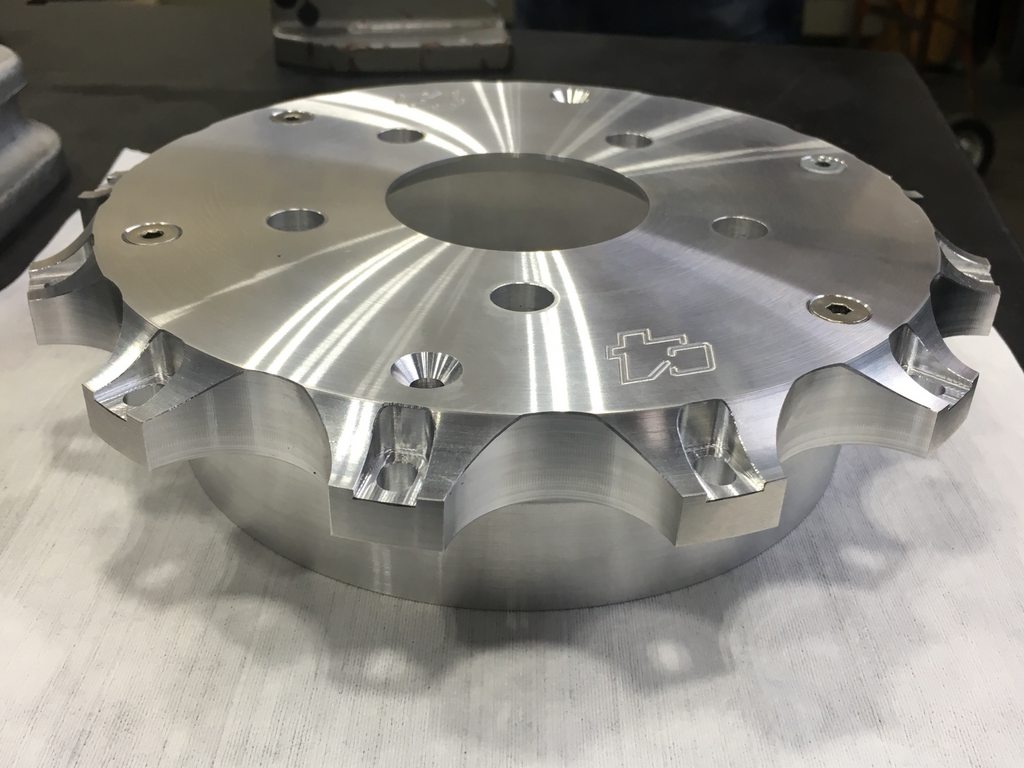

Starting to get ready to tear down. Because I'm getting old and tired, I bit the bullet and decided to give the quickjack a shot. The first lift:

Too early to give it a real verdict, but so far I'm digging it. Car is up ~20" with just using the larger of the rubber blocks the unit comes with and no extra effort to get more height out of it. With a little more effort, I'll easily be able to get it 25"+ out of it. These will be very nice when I do my DIY corner balancing and alignments. Still need to decide on ABS setup as well. That will be made in the next couple of weeks. ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- Also, I've developed a rear BBK that fits aftermarket uprights that will be able to use the Z32 ebrake as an option. Requires no trimming/clearancing on the uprights. I know more than a few of you didn't bite on my previous kit because it didn't work with an ebrake and/or an aftermarket upright (or because no one actually gives a **** about S-chassis?? ) . This one does. It also uses a better, stiffer caliper in the Wilwood FSL4R (relative to my previous rear BBK) which means if you're already running a FSL in the front, it uses the same pad shape and will improve the balance of your braking further than if you're running stock S/Z components. If you're not running an FSL6R front setup, I also have something in the works for that as well, all the way from budget minded to 14" floating rotor baller/high-HP-aero-builds. If you're interested in either, please email me at [email protected] GKTech rear upright:  Z32 rear upright:  Prototype rear rotor hat setup with modular ebrake drum. 12.9"(327mm) x 0.81"(21mm) rotor with floating in hat:  |

|

|

|

|

|

#34 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

OK, that pretty much catches everything up. I'm sorry for throwing it at everyone all at once like that. But, I think this is the better place to be at now anyway. Hope y'all enjoyed and made it through the read....

Planned upgrades for 2019 are:

I'd say the car will easily be 1.5 seconds/minute faster per lap. Stay tuned.... |

|

|

|

|

|

#35 |

|

Zilvia Junkie

|

This is awesome. I’ll read through the entire post when I get home from work. I was following on NRR, but like you said, it’s kind of dead over there which is a shame. Lots of good info there.

|

|

|

|

|

|

#36 |

|

Premium Member

Join Date: Sep 2003

Location: Lake Stevens, WA

Age: 38

Posts: 2,585

Trader Rating: (20)

Feedback Score: 20 reviews

|

Love the build.

I'm interested in which path you take on the ABS. I'm looking to junk the old clunky stock system for something more up to date and fully stand alone. |

|

|

|

|

|

#37 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Thanks, dudes. It is a shame that NRR is so quiet. There's a ton of good info on that site without shenanigans.

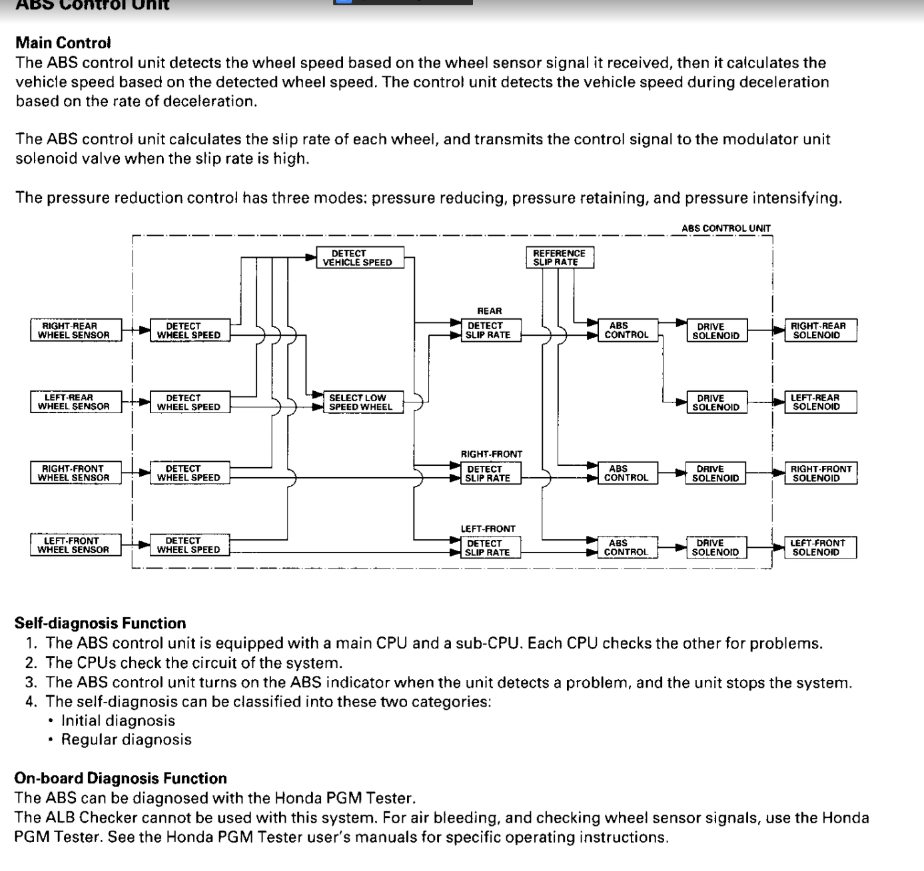

As for ABS, some interesting developments. Firstly, the AP1 ABS is 3-channel, which I incorrectly assumed was 4-channel. It's a much better 3 channel than the stock S chassis or any 90's Nissan stuff, but still 3 channel. Here's the control flow of the AP1:  You can see that the rear corner slip rates are compared and then one chosen that is determined to be slipping then a single control drives both rear corner solenoids simultaneously. Regardless, it's an easy solution to a newer generation ABS that S2000 guys generally really have nothing bad to say about. BUT, because I like to trail blaze and I want EBD in my car, I'm finding out the AP2 (version 2, from 2006-2008. Version 1 AP2 from 2004-2005 is the same as AP1 ABS) is insanely similar to the BMW MK60 system. To the point that they use the same ATE ABS module and control unit. The harness connection on the module is identical. The only difference in their respective wiring diagrams is that the MK60 unit uses two external pressure sensors where the AP2 seems to have them internal to the unit. Everything else from how it handles the stability control inputs to the brake pedal switch and wheel speed sensors seems to be identical, to the point of being on the same pins. These are both CAN based units that have their own brain in the module. The MK60 ABS unit is well documented to be able to work without CAN communication retrofitted in other chassis. Everyone is always quick to say that the AP2 won't work in other chassis because it's CAN based. If MK60 works outside of it's native CAN home, the AP2 ABS will also. There's nothing to suggest that it won't. BMW MK60 ABS module harness connection:  AP2 S2000 AP2 connection:  I'm moving forward on it AP2 stuff. |

|

|

|

|

|

#38 | |

|

Zilvia Junkie

|

Quote:

Please document all the ABS work as I am at this stage next in my build. I purchased everything from a Z32, but I’m up for a better tunable system. Really anything to keep from flat spotting expensive tires is the goal here. I got a couple pretty bad at CMP at the end of 2018. |

|

|

|

|

|

|

#39 |

|

Leaky Injector

Join Date: Jan 2013

Location: connecticut

Age: 30

Posts: 124

Trader Rating: (1)

Feedback Score: 1 reviews

|

wow, so much good info here in this build thread. i had to chuckle a little bit when you beat FCP Euro as i work next door to them and have a friend on their race team.

|

|

|

|

|

|

#40 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Ha! Those FCP guys are seriously well supported. Good guys and they bring a ton of exposure to the series so it's good having them. I also love that they don't run a BMW!

In all fairness to them, their car is in class 3, which is a slower class. Thing moves damn good though. |

|

|

|

|

|

#41 | |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Quote:

A couple of us are continuing the conversation in there that plan to try the more complex route with 4 channel AP2. But, to keep it in here also, here's my latest: Some rear wheel speed sensor testing. I've got my hands on an E46 M3 rear sensor and Z33 rear sensors. The clearance between the sensor housings on the Z32 diff cover and the stock 240 3x2 bolt pattern output shaft diameters where an ABS tone ring would sit is about 3/8". My plan is to use extra front S14 tone rings I have laying around installed on machined output flanges. The OD on those ABS tone rings is 97mm. That leaves about 1mm clearance between the tone ring and the sensor housing, which is a perfect air gap. The E46 M3 rear wheel speed sensors work surprisingly well. Their depth seems just about perfect with the end of the sensor flush with the housing, which would leave that 1mm air gap. They don't have the 90 degree wire output, more like 45 degree, but it still will clear the subframe. Of course the mounting hole doesn't line up. It's pretty close, but this would be the "hardest" thing to deal with (besides turning down the diameter of the output shaft to accept the ABS tone ring): E46 M3 sensor inside diff cover sensor housing:   Mounting hole alignment:  The Z33 sensor is basically the opposite. The mounting hole lines up perfectly, but the depth is a bit too much. These have 90 degree wire outputs like Z32 sensors and the two rear sensors are tied into one harness plug. Definitely clears the subframe as well. Z33 sensor inside housing:  Alignment with mounting hole is exact:  As for the front sensors, it seems that active sensors (have an IC built inside that generates a square wave vs analog sine wave of older style sensors) that have their pickup 90 degrees from normal, or read from the side (which is what will mimic S-chassis uprights/spindles wheel sensor mounting provisions) are uncommon. Most seem to read dead on/at the tip. The E46 M3 front wheel speed sensor may actually be the right solution. My modified OEM uprights are non-ABS so I still need to drill them to test this. But,nonetheless, here's a E46 M3 front wheel speed sensor: Reads from side here:  Most sensors I've come across read from tip like this, which would require custom bracketry on the upright (using E46 M3 sensor just as an example):  |

|

|

|

|

|

|

#42 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

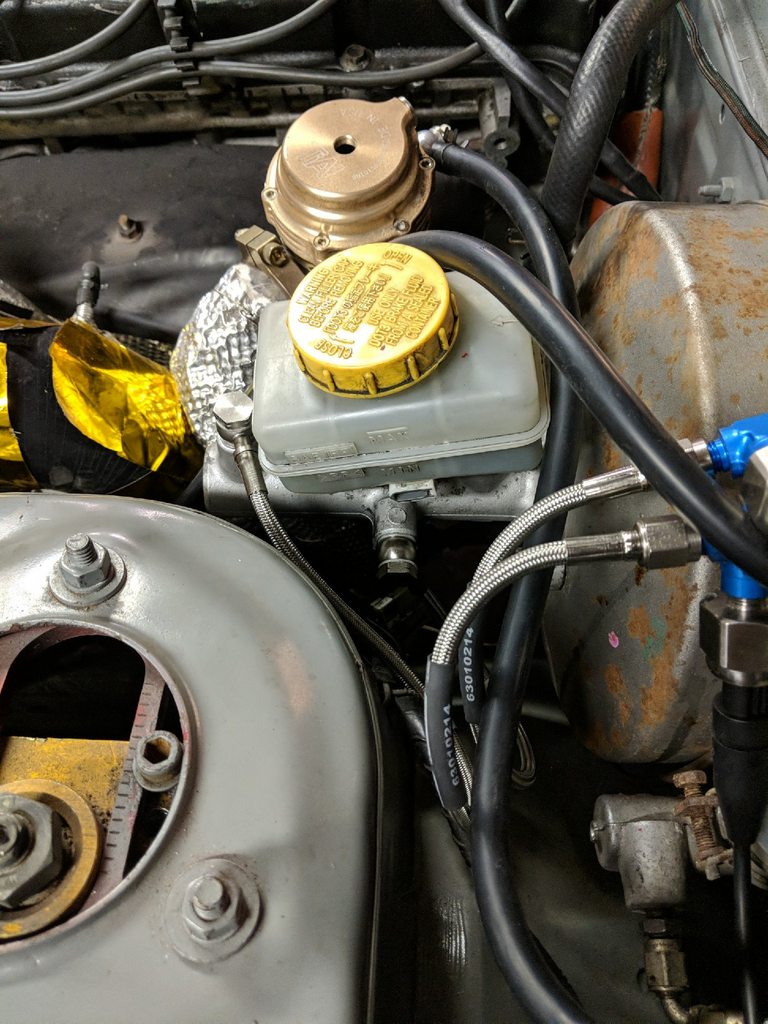

So because these 4-channel systems use EBD - Electronic Brake Distribution cycles solenoids pertaining to the rear circuit in the ABS modulator in closed loop control to proportion the rear circuit, you don't want mechanical proportioning devices in your system at all.

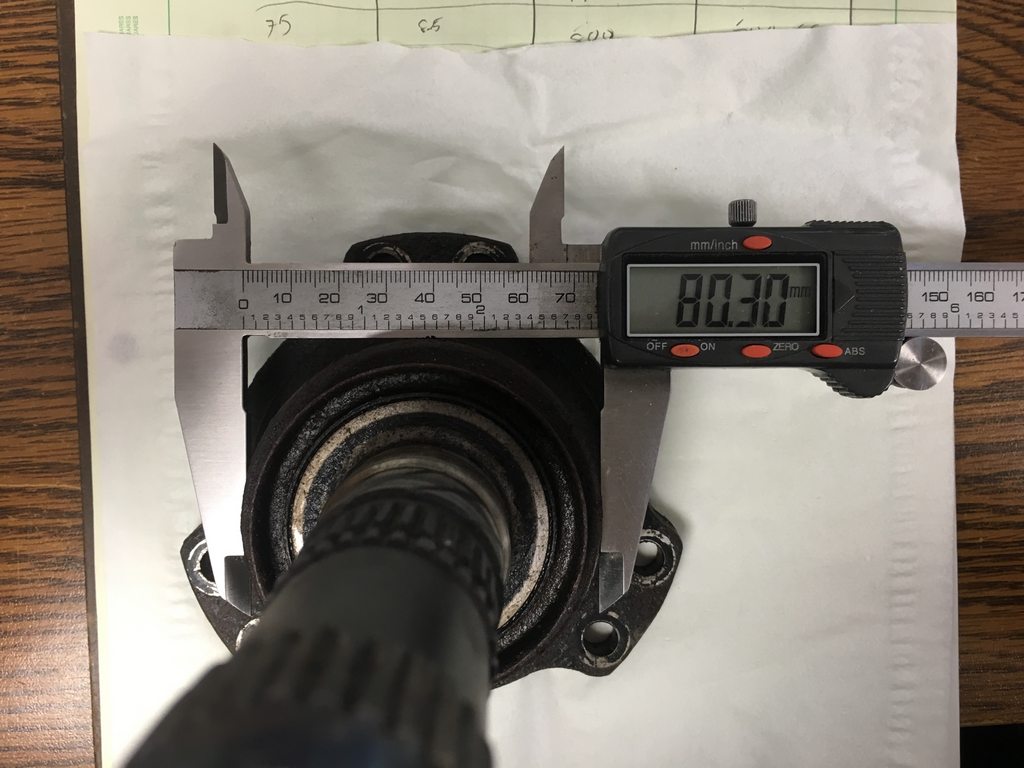

All Nissan BMC's of the S-chassis era that are worth using have built in proportioning valves. Hoping that I could get away with using my Z32 BMC, I removed the internal prop valve and tested to see if rear proportioning would be removed. Surprisingly, nothing changed. I checked this by measuring caliper clamping force, not pressure, with these nifty scales: Front:  Rear:  Someone in that NRR thread I shared in my previous post ended up using a 2001 Pathfinder BMC that doesn't have internal proportioning. It also has oddball output locations on the top of the MC and the other on the driver side/left side, which is nice for people wanting to keep their lines away from turbo/exhaust heat. The inclination of the reservoir is also greater than the Z32. 2001 pathfinder BMC (pictures from "Scores240" on NRR):    Here's a Z32 BMC for reference to show you the difference in the reservoir inclination:  Because I don't care for the specialized outputs of the pathfinder and want to keep the same sizing as what's in the car now (17/16"), I'm eyeing the Z33 BMC. The inclination on the Z33 looks the same as the pathfinder. BTW, it seems that Nissan has been using 80mm as their standard for BMC hole mounting through at least Z33:   Just eyeing the pictures, the center-center spacing of the reservoir inlet ports looks the same as the Z32. The height offset between the ports also looks the same. I wouldn't be surprised if the Z32 reservoir could just pop right in the Z33/pathfinder. I do like the reservoir and cap better that's on the Z33/pathfinder though. The Z32 always leaks some during races. I just don't like that inclination when mounted in an S. Here's some more info and pictures on the output shaft and front ABS tone ring:    Output shaft just needs a couple mm's removed. Should work perfectly. |

|

|

|

|

|

#44 |

|

Premium Member

Join Date: Sep 2003

Location: Lake Stevens, WA

Age: 38

Posts: 2,585

Trader Rating: (20)

Feedback Score: 20 reviews

|

Love the progress so far.

Is it possible to use the factory 2X3 output shafts that already have the tone rings on them? It would save the step of having to turn down the stock output shaft.  |

|

|

|

|

|

#45 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

@tacotacotaco, thanks man. I'm glad to read that because there's definitely times where I ask myself do people actually give two F's about reading this

@Agamemnon, definitely. I'm doing it this way because I have front tone rings laying around and a lathe/machine tools at my finger tips. I'm assuming those are S15 output shafts? You could also use 300zx ones, but then you need new axles. Trying to be frugal going this route. |

|

|

|

|

|

#47 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Thanks, Battery.

--------------------------------------------------------- Moving along with ABS stuff. Threw a spare output shaft on the lathe to test. Measuring up the front hub diameter the ABS ring came off of and the ID of the ABS ring, Nissan wants a 0.002" interference fit:  Here it is in the diff with the BMW sensor. Perfect clearance (about 1mm) so this method is a go for me:   Still waiting on my contact to see if he can communicate with the S2000 AP2 ABS unit to see if it can be used as a standalone unit. He's in possession of it and hopes to bench test it this weekend. ------------------------------------------------------------------------- Since I have the diff out, it is time to rebuild/refresh since I'm going to a 3.9 and also explore playing around with the Mfactory clutch lsd in there. At the last race the driveline started to develop a very distinct whine proportional to road speed, which is indicative of a diff. You can hear it in my in-car video here: https://youtu.be/4o8RcV68MtE?t=29857 Lo and behold, it was most likely was the diff. We were worried for a minute that it was something on the output side of the CD00A (bought new in 1/2018). Here is the inner pinion bearing cup showing typical fatigue failure of a tapered roller bearing: Cup:   Cone/rollers:   I've ordered all new bearings and seals for the carrier. I believe this is an R200 carrier, not R200V. There are differences between the two and you will see different sized pinion seals and I believe pinions bearings when you search parts sites for 240sx. Here's what I measured and noted on my diff:

So, because the bearings in this carrier were original from the factory, I got the same ones as that's proof to me. The carrier had 100k miles on it before it started living the race car life that has a couple hundred hours of track time now on top of that 100k. ----------------------------------------------------------------------------------------------------- That brings us to my 1.5 way M-Factory clutch diff setting change. I have a theory with the S-chassis when it comes to track/grip racing. Almost everyone who tracks these cars complains about excessive corner exit oversteer. And, almost everyone who tracks these cars extensively has a clutch/salisbury type LSD. The kicker is that the diffs that everyone gets for these cars come by default with 100% lock under acceleration. I know for sure that Cusco and MFactory diffs come with 100% lock. Why would you put 100% lock on a track car that has difficulty putting the power down to the ground? 100% lock is a recipe for oversteer when coming back onto the throttle. Great for drifting and rallying, not great for grip driving. There has to be more of a balance. How the lock builds or comes on with the throttle is dependent on ramp angles, preload on clutch discs, and how many clutch discs there are. My belief that all of it is too aggressive on units that come out of the box for these cars. So, I'm going to experiment with less preload and at the very least 80% lock arrangement on the discs. I may even try 60% based on my research into what top BMW E46 M3 and E36 M3 cars run. I will be measuring preload also so there's no second guessing. Just need to come up with something to measure it. Some pictures of the M-factory LSD. There are 10 clutch discs per side. Looks basically identical to a Cusco RS.  Here you can see there's a choice to run it as a 1 way also:  The coil springs that you can add or remove to control preload (or the minimum torque it takes to de-couple the sides):  Spring pockets to have up to 12 preload springs (I believe minimum is 4):  Closer look at 1.5 way ramp:  1.0 way ramp:  clutch discs:  |

|

|

|

|

|

#48 |

|

Premium Member

Join Date: Mar 2009

Location: Maricopa, AZ

Age: 30

Posts: 7,679

Trader Rating: (10)

Feedback Score: 10 reviews

|

I've heard of Evo 8/9 guys adjusting their oem rear differential lockup by swapping the clutch plates around in different configurations as some are slotted and some are smooth etc.

|

|

|

|

|

|

#49 | |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Quote:

Here's a good tech article from Cusco, which covers most clutch type diffs: https://www.cusco.co.jp/en/pdf/LSD%20Guide%20Final.pdf |

|

|

|

|

|

|

#51 |

|

Zilvia Member

|

Awesome build. Nice to see you guys doing so many events with it.

If you ever need an extra hand at the track for 2019 let me know. I've been wanting to crew some events while my own car is getting a bit of an overhaul.

__________________

'95 240 | @SleepySteve72 |

|

|

|

|

|

#52 | |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Quote:

Thanks! We typically always could use a hand here and there. We'll be at Watkins Glen 4/13 weekend, NJMP 5/18, Palmer 6/15, Summit Point 9/14, and Mid Ohio 10/19. You are more than welcome to come by. ---------------------------------------------------------------------------------------------------------- Checking preload, here's my little bench testing rig I came up with using the output shafts. Not pictured is a digital torque gauge that's inline between the socket and the ratchet to measure the breakaway torque.  With 6 preload springs and the clutch discs in "100% lock" arrangement, it was about ~55ft-lbs breakaway torque. That is basically the range MFactory said it would be with 6 springs, so that's good. What isn't ever really mentioned (but should be pretty obvious) is that this breakaway torque decreases with lower lock % disc arrangements with the same number of preload springs. Preloads are just stated without any consideration for disc arrangement. For shits and giggles, I lowered to what is stated to be 20% lock arrangement (the minimum possible) and the breakaway torque was 10ft-lbs. So, not surprisingly, if you want to make the lock less aggressive, but keep the same preload/break-away, you need to add more coil springs. Then of course ramp angles in conjunction with disc arrangement come into play here with how much lock you can actually achieve. |

|

|

|

|

|

|

#53 |

|

Zilvia Member

|

That seems like significantly more precise control over break-away torque than what you get out of the cone-spring based preload setup on a Kaaz / Tomei diff. I don't think they had all the different ramp angle options either.

__________________

'95 240 | @SleepySteve72 |

|

|

|

|

|

#54 | |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Quote:

Yea, that is one of the advantages/traits of a preloading with coil springs instead of cone disc springs. They can maintain more consistent preload over a longer period of time as discs wear. Cone disc springs have very little displacement so they fall off exceptionally quick as the system gets more clearance. |

|

|

|

|

|

|

#55 |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

So diff is all closed up. Ended up with "60%" clutch disc lock arrangement and 8 preload coil springs (up from 6) for about 40-45 lbs.ft of breakaway torque. Adding/removing a pair of springs seems to be good for 10 lbs.ft jumps. The car should be smoother when transitioning from on and off the throttle and be less snappy when back on the throttle. Really looking forward to testing this difference (hopefully April 1st test day).

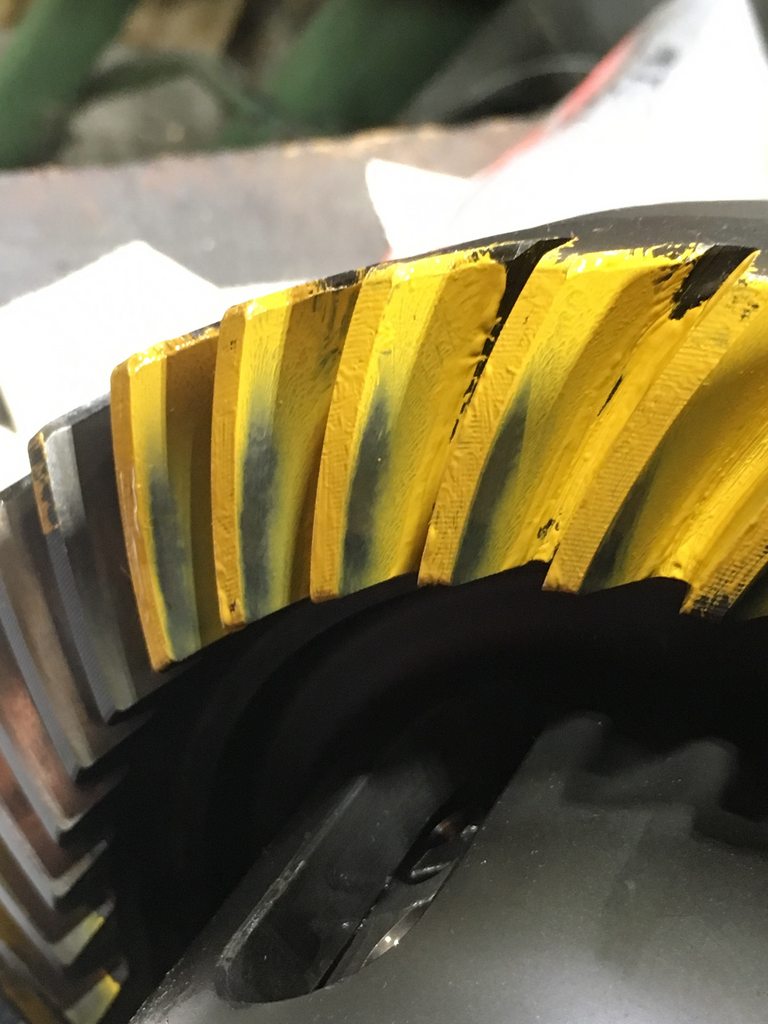

Speaking of diffs, just want to share how changing shim thicknesses so little changes things so much for those that may be curious. I personally haven't had luck yet re-using pinion height shims that were already in my carrier when swapping used ring and pinion sets. Or maybe because I'm anal due to the nature the car is being used, I need it to be as perfect as I can get it. Setting the pinion preload is very sensitive to thickness changes in the preload washer/shim. It went from too loose to just right with 0.0005" (0.0127mm) difference with the preload shim. For reference a basic sheet of paper is 8x thicker than that. After setting pinion preload, you work the gear pattern by adjusting the pinion height with a shim that's sandwiched in between the pinion head and inner tapered roller bearing. Here's what I started off with: "Drive" side is close. A touch high toward the "face" (top of the gear tooth), and biased toward the "heel" (outside diameter of ring gear) :  "Coast" side is also high toward the face, and is very much toward the "toe" (inside diameter of ring gear):  The drive side is obviously the more important pattern to pay attention to, but that pattern is pretty close. Increasing pinion height will bring the pattern lower toward the "root" and also move the coast side toward the heel and drive side toward the toe. Here's the pattern raising the pinion height 0.005" (0.127mm) from the above: Drive side. Too deep/close to the root now, and biased more toward the toe  Coast side also too deep, but centered up more nicely  Here's splitting the difference at 0.0025"(0.064mm). This is also with 0.007" backlash taken at the center of the ring gear. This is what I'll be sending it with for this race season: Drive side is nicely centered  Coast side still biased toward the toe, but is centered between the root and the face. Not perfect, but the drive side is pretty close to being spot on that I'm not concerned with this  ------------------------------------------------------------------------------------------------------------------------------------------------ ABS My contact at Race Harness Technologies confirmed that diagnostic information can't be communicated over the K-line on the OBD2 port on the MK60e1 AP2 S2000 unit like he can on the MK60 BMW unit. That means diags is over CAN, or CAN is still active in stand-alone mode, where that isn't the case with the MK60 unit. Now, that doesn't confirm that the unit can't be used as stand alone. It just means if you are to retrofit an AP2 unit, you won't be able to tell if there's anything wrong or errors being thrown the same way you can on the MK60. You also run the modulator through a bleed routine through the K-line. HOWEVER, he still has some steps to go through to for him to be able to access the diags over CAN so there's still a possibility that the MK60e1 can be used in a similar fashion, and not just blindly. With all that said, I had to abort the AP2 mission because of time and his inability to promise that he can get something working by my Watkins Glen race (4/13). I ended up just ordering the BMW MK60 stuff for now as it's all a known quantity. Out of the sake of trailblazing, I'm having him keep the AP2 unit so he can continue to progress as he's just as interested in getting it to work as I am. Another very important discovery of the AP2 S2000 vs the BMW MK60 is that the BMW unit doesn't split the inputs from the master cylinder across diagonals on the car where the AP2 (and AP1) unit does, as shown here:  So input1 = FL/RR, input2 = FR/RL, where the MK60 splits inputs Front to Rear. The diagonal split is very common on modern road cars. This means that if you have any rear mechanical biasing/balancing/proportioning upstream of the MK60e1 module, you'll be doing it across the diagonal of the car, which = bad. That leaves all proportioning up to the EBD algorithms stored for S2000 parameters. The MK60 you can mechanically proportion and balance however you want on top of the EBD for E46 M3 parameters. I *think* this is especially important for retrofits where weight distribution, wheel base, etc, can potentially be very different than the E46 M3. For the most part, the stock M3 parameters cover many of cars most of us race/drive give or take a few % points here and there. And, I believe the stock S2000 would probably cover many bases as well. So, I was about to change out my MC for the Z33 unit, but that is no longer necessary. I hope that keeping the Z32 BMC with the internal prop valve is a decent fail-safe in case the ABS faults as I'll still have proportioning in that case. Got the rear wheel speed sensors situated. Ended up using E46 M3 sensors instead of the Z33 ones. Ended up slotting the mounting holes on the sensor instead of messing with the diff cover. That brass insert molded into the plastic so it'll be sturdy. I mean, it was sturdy enough for me to mill it, should be good. The mounting hole for the BMW sensor is for an M6 and the Nissan is M8, so the hole also needed to be enlarged as well:     Next up, getting my custom non-ABS OEM front spindles to work with E46 M3 front sensors. A local S-chassis friend was nice enough to lend me his spare ABS uprights that I could map out to get exact dimensions. The sensor tips can't be more than a mm away from the tone ring, so this is a huge help. Backside of OEM ABS S14 spindle in vice for probing:   I've got the measurements I need now. Time to drill/mill! ------------------------------------------------------------------------------------------------------------------------------------------- Also, my V2 front and rear big brake parts arrived. Floating, modular Z32 e-brake compatibilty, front rotor options from stock Z33 brembo track rotor to 355mm x 32mm baller setup....    Last edited by gills; 03-21-2019 at 08:04 AM.. |

|

|

|

|

|

#56 |

|

Premium Member

Join Date: Mar 2005

Location: Arizona

Age: 37

Posts: 798

Trader Rating: (28)

Feedback Score: 28 reviews

|

You have a price figured out for the new brake setup? Build looking awesome as always man.

__________________

96 S14: Grip Track Car 90 R32: Bucket List Car 92 S13: Just for Fun Car Instagram: @SS.Maxey |

|

|

|

|

|

#57 | |

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Quote:

I will have concrete pricing in the next week or two. The front will use the Wilwood FSL6R caliper and the rear uses the Wilwood FSL4R. These newer radial mount Forged Super Lite calipers are definitely stiffer than the old lug mount FSL that came on Defsports kits. I've measured the difference. Hope to share the comparison eventually. |

|

|

|

|

|

|

#58 |

|

Post Whore!

Join Date: Apr 2004

Location: Houston, TX

Posts: 2,701

Trader Rating: (16)

Feedback Score: 16 reviews

|

One the Cusco Diff - I always wondered if maybe a 1 way operation with a tad more preload would make the car turn in a hair better off throttle than set up for 1.5 way.

I had mine at 80% clutch engagement and 6 springs. It felt great on throttle, but definitely fought turning in off throttle on corner entry. It was nice and stable under braking, so I was thinking maybe it could do with less biasing under braking than on 1.5 way.

__________________

S13 Hatch - Goes around tracks quickly DEFSPORT |

|

|

|

|

|

#59 |

|

Premium Member

Join Date: Jun 2003

Location: torrance, ca

Age: 39

Posts: 12,407

Trader Rating: (129)

Feedback Score: 129 reviews

|

THIS THREAD DELIVERS!!!!

Very cool to see your efforts paying off. People tend to forget that s-chassis is a potent chassis for more than just skid racing. I don't know if you've considered it, but theres also a 1" pathfinder master cylinder that has the lines attached to the other side (further away from the engine, less exposure to heat) but obv you'll either have to bend new lines or switch to stainless braided lines https://suspicious-garage.myshopify....ine-relocation |

|

|

|

|

|

#60 | ||

|

Zilvia Junkie

Join Date: Dec 2012

Location: Long Island, NY

Posts: 449

Trader Rating: (13)

Feedback Score: 13 reviews

|

Quote:

Did you ever drive your car with the LSD setup @100% lock? It's definitely a bit over the top. It's also a PITA in the paddock. I mean it's fun AF, but a bit too binary. It really does have a significant stabilizing effect when threshold braking though. Like a poor mans stability control. I was initially going to go 80% like you, but after picking some brains of people who setup racing BMW diffs I chose 60%. I think it'll help free up the car off-throttle/under braking just enough, but still have no problem putting down the power I'm making. Might need to make a rear sway bar and/or shock adjustments, but I'm also banking on the fact the MK60 ABS will come into play for stability. As for the 1-way, I personally loved the hLSD in my S13 even though it only had a KA which was very free off throttle. I'd love to try the 1-way setting in the future. Quote:

I did not know about that pathfinder one. I just knew about the one that I shared above that has 1 outlet coming out of the top and the other coming out of the left side. It says in the description of that link that it will interfere with the S14 strut tower. I guess it would require some "massaging" to get it to fit on my car. I've decided to stick with the Z32 for the time being out of simplicity. I still have to make new lines for the ABS system no matter what. |

||

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|