|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Builds (and builds only) Got a build thread? It goes here, build threads anywhere else on the forum will be locked and never moved. |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Zilvia Member

|

My S13 Build : LS swap, Corvette transaxle, ITB, Widebody, Do everything car

Sup guys. Figured i had gotten done enough to make a build thread for my s13. Little background on previous cars. Used to have a 2012 Subaru wrx. Bought it when i was 18. Was working full time and decided to splurge on myself. I daily drove it for 3 years while modifying it. Had the typical ringland issue, built motor dropped in. Ended up getting a full varis front end for it, and making another set of varis fenders conforma nd line up with the varis front bumper. That front end is still my favourite to date on any car, such clean aggressive and purposeful lines. I ended up parting it out and selling it to buy the wife a daily. Picked upan 05 wrx as a daily and have had nothing but problems with it, just finished droppin a motor into it, prolly gunna drive it for a bit then sell it off and get a new daily, maybe a truck idk yet.

DSC_0531 by lawrx, on Flickr DSC_0531 by lawrx, on Flickr DSC_0534 by lawrx, on Flickr DSC_0534 by lawrx, on FlickrAnyways enough about the Subarus, (Fucking pains in my ass). So, the plan with the s13 is an all around performer, not built for anything specific and capable of nearly any kinda event i want to attend. Drag, drift, road course, autox, hill climb whatever. From the get go i knew i wanted to do something different. I dont really like following the crowd and love doing custom one off stuff. I knew the 240s already had pretty good weight distribution, so i wanted to capitalize on that and make it even better. did a bunch of figuring, measuring, brainstorming and a slight bit of obsession, but i finally settled on a corvette transaxle with an ls motor. I considered other motors to run with the corvette transaxle but none of them met my goals better than the ls did. So, picked upa local shell, and got it home. Thing was in rough shape. I knew i didnt want to buy a mint car as it will be getting cut up and everything and i wouldnt be using majority of the stock ext. panels. This is the shape i got it home in and basically my starting base (if you want to call it that)  untitled (1 of 29) by lawrx, on Flickr untitled (1 of 29) by lawrx, on Flickr untitled (2 of 29) by lawrx, on Flickr untitled (2 of 29) by lawrx, on Flickr untitled (3 of 29) by lawrx, on Flickr untitled (3 of 29) by lawrx, on Flickr untitled (4 of 29) by lawrx, on Flickr untitled (4 of 29) by lawrx, on Flickr untitled (5 of 29) by lawrx, on Flickr untitled (5 of 29) by lawrx, on FlickrI didnt waste any time starting to gut it of virtually every part on it as evberything will be either changed or modified.  untitled (7 of 29) by lawrx, on Flickr untitled (7 of 29) by lawrx, on Flickr untitled (8 of 29) by lawrx, on Flickr untitled (8 of 29) by lawrx, on Flickr untitled (9 of 29) by lawrx, on Flickr untitled (9 of 29) by lawrx, on Flickr untitled (10 of 29) by lawrx, on Flickr untitled (10 of 29) by lawrx, on Flickr untitled (11 of 29) by lawrx, on Flickr untitled (11 of 29) by lawrx, on FlickrOnce mostly gutted. I pulled the rear subframe in lieu of the transaxle currently being in route. Once out i test the the rear diff which i already had in my possession.  untitled (12 of 29) by lawrx, on Flickr untitled (12 of 29) by lawrx, on Flickr untitled (13 of 29) by lawrx, on Flickr untitled (13 of 29) by lawrx, on Flickr |

|

|

|

| Sponsored Links |

|

|

#2 |

|

Zilvia Member

|

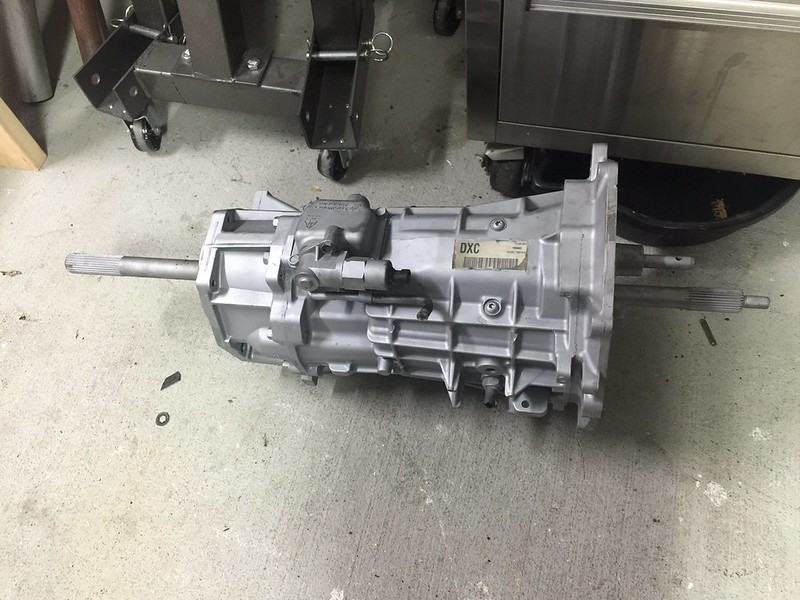

After mocking up the diff the I could see where the rear crossmember needs to be cut so that it could fit up into the chassis. About this time my trans and torque tube were arriving. Had to find some spare bolts in my bolt collection to get them bolted up for mock up. Ill get some quality arp hardware once I'm ready to really bolt them. Excuse the sub par pictures, had to take some with my iPhone 6, had just sold my camera and was still waiting on the new upgraded one to come in.

IMG_2485 by lawrx, on Flickr IMG_2485 by lawrx, on Flickr IMG_2399 by lawrx, on Flickr IMG_2399 by lawrx, on Flickr IMG_2457 by lawrx, on Flickr IMG_2457 by lawrx, on Flickr untitled (14 of 29) by lawrx, on Flickr untitled (14 of 29) by lawrx, on FlickrOnce i had the trans, diff, and torque tube in and bolted together, it was time to cut a giant hole in the rear floor to make room. I knew there was going to have to be a substantial hole, needless to say it was still larger than i expected. This was the turn that if i took it i couldn't turn back once done. I did it without blinking an eye haha. I also had to cut up the rear subframe for room as well. I cut out both center sections which turned it into a two piece rear subframe. While the subframe was out i installed Gkteck solid bushings. Once final position of the rear diff and trans are found, a mount tieing the two separate subframe pieces will be made. the rear subframe won't be staying two separate pieces.  IMG_2528 by lawrx, on Flickr IMG_2528 by lawrx, on Flickr IMG_2540 by lawrx, on Flickr IMG_2540 by lawrx, on Flickr IMG_2519 by lawrx, on Flickr IMG_2519 by lawrx, on Flickr IMG_2463 by lawrx, on Flickr IMG_2463 by lawrx, on Flickr IMG_2482 by lawrx, on Flickr IMG_2482 by lawrx, on Flickr IMG_2476 by lawrx, on Flickr IMG_2476 by lawrx, on Flickr IMG_2418 by lawrx, on Flickr IMG_2418 by lawrx, on Flickr IMG_2541 by lawrx, on Flickr IMG_2541 by lawrx, on Flickr |

|

|

|

|

|

#4 |

|

Zilvia Member

|

After cutting up the rear floor i had a beautiful day here so i decided to pull her out the garage and clean up the underside and engine bay. This thing was FULL of grease and grime as if it had leaked from day one and never fixed. Got it much cleaner but still has a long way to go. I also mockup up one of my Varis side skirts from my gr wry, may just have to incorporate that into the build....

IMG_2567 by lawrx, on Flickr IMG_2567 by lawrx, on Flickr IMG_2546 by lawrx, on Flickr IMG_2546 by lawrx, on Flickr untitled (17 of 29) by lawrx, on Flickr untitled (17 of 29) by lawrx, on Flickr untitled (15 of 29) by lawrx, on Flickr untitled (15 of 29) by lawrx, on FlickrAt this point progress slowed a bit as i had to do a trans,hug,brake and suspension swap on a friends 03 wrx wagon. Talk about a sleeper. Hell of a fun car and room for the family. At this point the 240 had been sitting in the driveway as pictured above for 2.5 weeks.Got a letter from the HOA, luckily i was planning on moving it back inside the next day or so anyway. Damn HOA, can't wait to move somewhere with 1-2acres and no HOA lol  untitled (18 of 29) by lawrx, on Flickr untitled (18 of 29) by lawrx, on Flickr untitled (16 of 29) by lawrx, on Flickr untitled (16 of 29) by lawrx, on FlickrAfter finishing the trans swap on my buddies car and getting the 240 back in the garage, i made a el cheapo crude strut tower brace to make sure everything is square once i start to cut up the front. traced out some lines of rough cuts for the front and i will finalize them later once i have a better idea of how much i actually want to take off.  untitled (19 of 29) by lawrx, on Flickr untitled (19 of 29) by lawrx, on Flickr untitled (21 of 29) by lawrx, on Flickr untitled (21 of 29) by lawrx, on Flickr untitled (22 of 29) by lawrx, on Flickr untitled (22 of 29) by lawrx, on Flickr untitled (23 of 29) by lawrx, on Flickr untitled (23 of 29) by lawrx, on Flickr untitled (24 of 29) by lawrx, on Flickr untitled (24 of 29) by lawrx, on Flickr |

|

|

|

|

|

#5 |

|

Zilvia Member

|

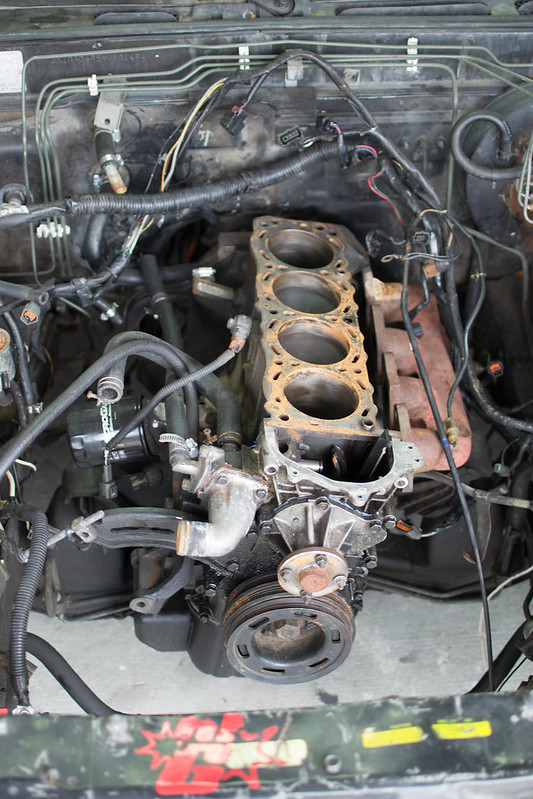

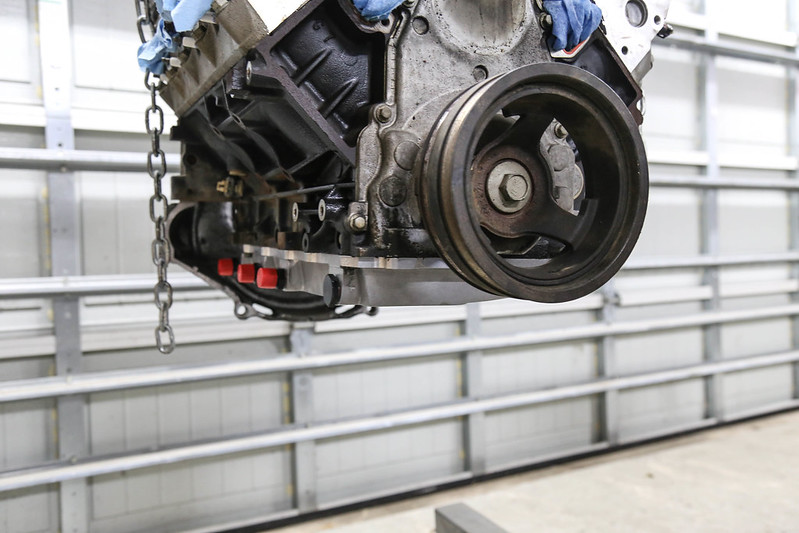

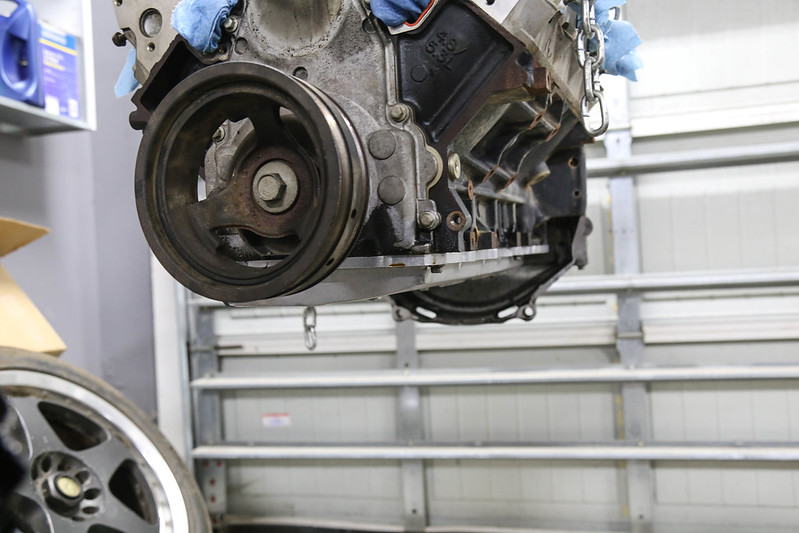

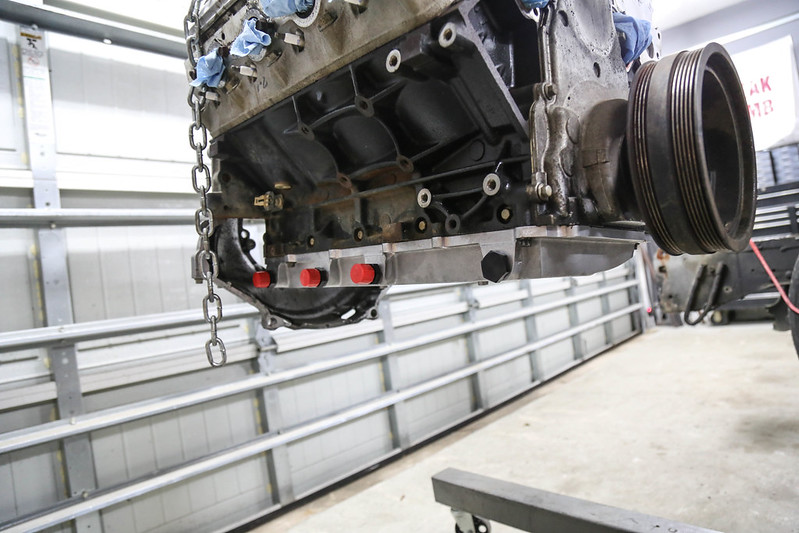

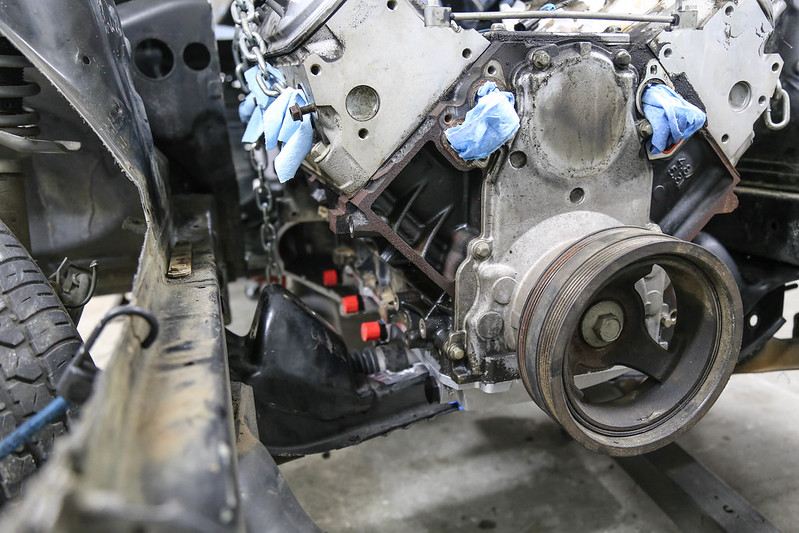

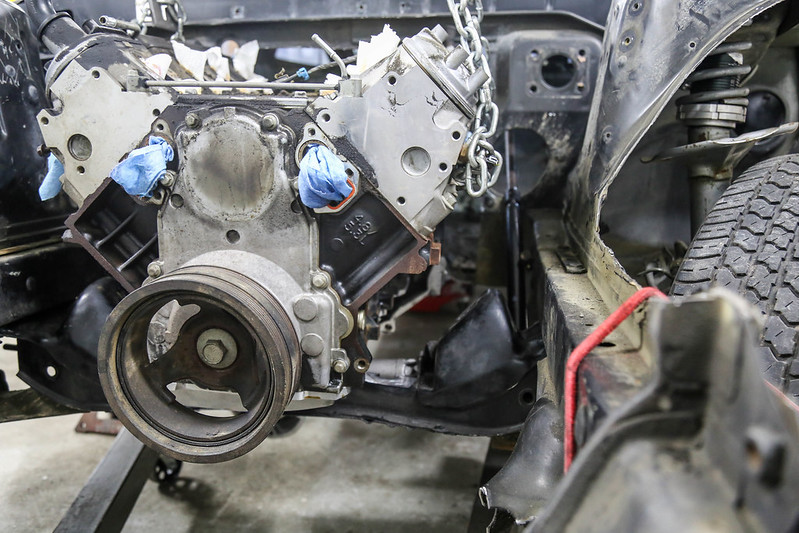

Finally got my motor. For now its a LR4 4.8 from a silverado. iron block. Plan is build the it setup for it, get the dry sump up and fitted to it and all the quirks figured out, add a decent cam, some better flowing heads and i will also be building a 180 degree header for it as well to give it a unique sound. Should def be a unique ls swap for a 240.

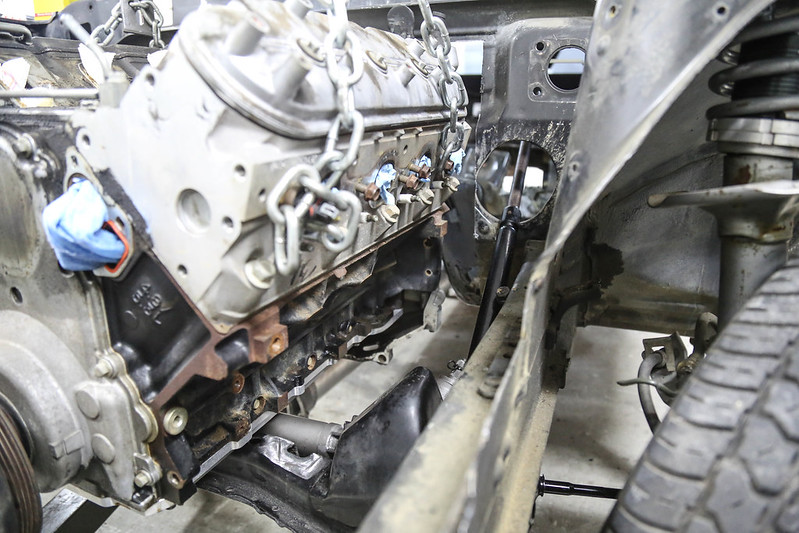

untitled (25 of 29) by lawrx, on Flickr untitled (25 of 29) by lawrx, on Flickr untitled (12 of 18) by lawrx, on Flickr untitled (12 of 18) by lawrx, on Flickr untitled (26 of 29) by lawrx, on Flickr untitled (26 of 29) by lawrx, on Flickr untitled (27 of 29) by lawrx, on Flickr untitled (27 of 29) by lawrx, on FlickrAfter initial mockup of the motor i knew i wanted it to sit further back in it was, so i did what insane person would, i cut a giant hole in my firewall. I also removed some of the double layer metal as well, ill clean the hard glue shit up later on. Now the motor is sitting a good 2'' further back, with the center of the motor in line/slightly aft of the front strut tower center line, great for weight distribution.  untitled (16 of 18) by lawrx, on Flickr untitled (16 of 18) by lawrx, on Flickr untitled (6 of 18) by lawrx, on Flickr untitled (6 of 18) by lawrx, on Flickr untitled (14 of 18) by lawrx, on Flickr untitled (14 of 18) by lawrx, on Flickr untitled (9 of 18) by lawrx, on Flickr untitled (9 of 18) by lawrx, on Flickr untitled (10 of 18) by lawrx, on Flickr untitled (10 of 18) by lawrx, on Flickr untitled (8 of 18) by lawrx, on Flickr untitled (8 of 18) by lawrx, on Flickr untitled (4 of 18) by lawrx, on Flickr untitled (4 of 18) by lawrx, on FlickrPup decided he wanted to help today. He's not too keen on the loud noises tho lol. When i pulled the intake manifold i was created with a lovely sight. Some fabulous grimy build up in the intake ports on the heads. Good thing these will be replaced with some higher flowing units before she fires up. These will work great as mock up test fit set up tho. After the initial mockup i decided i need to trim a bit more, just to make future access a bit easier, and so i could make a slightly shallower incline once i fabb up the firewall back. Id ask accumulated a decent amount of parts I'm not going to use. Need to figure out somehting cool to make out of it all in the future.  untitled (2 of 18) by lawrx, on Flickr untitled (2 of 18) by lawrx, on Flickr untitled (1 of 18) by lawrx, on Flickr untitled (1 of 18) by lawrx, on Flickr untitled (13 of 18) by lawrx, on Flickr untitled (13 of 18) by lawrx, on Flickr untitled (5 of 18) by lawrx, on Flickr untitled (5 of 18) by lawrx, on Flickr untitled (8 of 18) by lawrx, on Flickr untitled (8 of 18) by lawrx, on Flickr |

|

|

|

|

|

#6 |

|

Zilvia Member

Join Date: Oct 2011

Location: So Cal

Age: 34

Posts: 268

Trader Rating: (1)

Feedback Score: 1 reviews

|

I like this, really like this!

Very interested to see what you do with the body- hopefully something custom

__________________

S13 Silvia Lip's f/s :www.codycasale.com

|

|

|

|

|

|

#10 | |||

|

Zilvia Member

|

Quote:

Quote:

Quote:

|

|||

|

|

|

|

|

#11 |

|

Zilvia Member

|

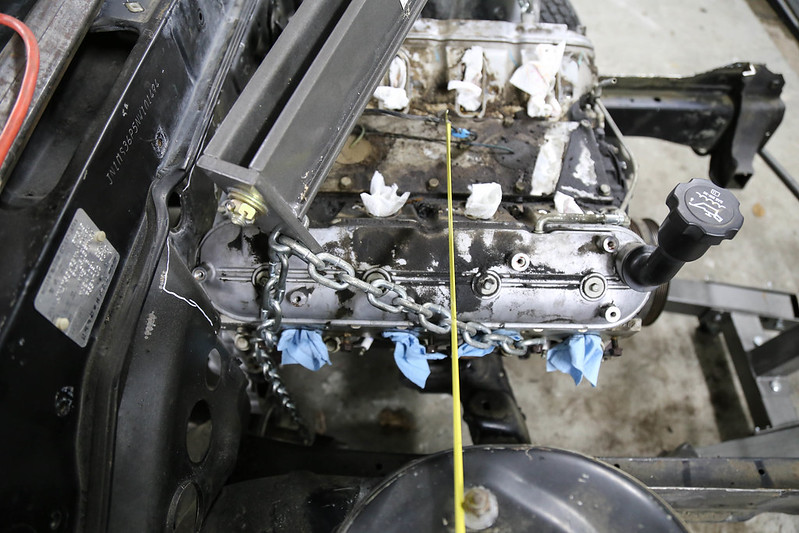

After getting the rough idea of where the motor was going to sit, pulled the front subframe to get it cleaned up and to cut off the steering rack mounts, as I'm going to modify it to get it to sit as low as i can get it so that i can get the motor as low as possible.

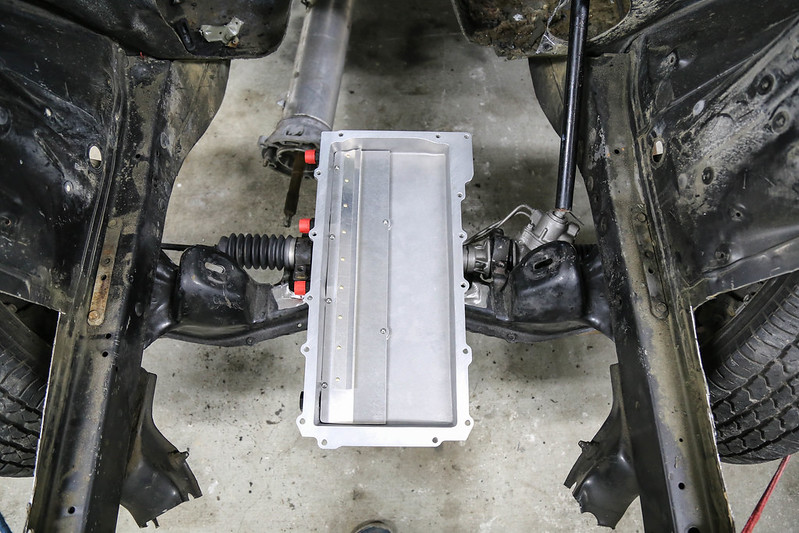

untitled (11 of 18) by lawrx, on Flickr untitled (11 of 18) by lawrx, on Flickr untitled (17 of 18) by lawrx, on Flickr untitled (17 of 18) by lawrx, on Flickr untitled (7 of 8) by lawrx, on Flickr untitled (7 of 8) by lawrx, on Flickr untitled (8 of 8) by lawrx, on Flickr untitled (8 of 8) by lawrx, on Flickr untitled (18 of 18) by lawrx, on Flickr untitled (18 of 18) by lawrx, on FlickrAlso had some shiny parts come in today. As i mentioned before my shell i purchased didn't come with a steering rack or any of the brackets or bushings. So i had to source some separately. Today i received the factory mount brackets, which btw weigh a TON for what they are. Gong to drill some holes in them and lighten them up bit. Also got in some energy suspension steering rack bushings. These are just for mock up and test fit duties. Ill be getting a set of aluminum solid bushings for the final install. Also received the ARE dry sump oil pan. Currently only ordered the pan as thats all i need right now to mock up the motor and get it mounted. Ill ordered the rest of the kit later down the road when i need the additional parts and when i can afford it lol  untitled (2 of 8) by lawrx, on Flickr untitled (2 of 8) by lawrx, on Flickr untitled (3 of 8) by lawrx, on Flickr untitled (3 of 8) by lawrx, on Flickr untitled (4 of 8) by lawrx, on Flickr untitled (4 of 8) by lawrx, on Flickr untitled (5 of 8) by lawrx, on Flickr untitled (5 of 8) by lawrx, on Flickr untitled (6 of 8) by lawrx, on Flickr untitled (6 of 8) by lawrx, on Flickr

__________________

My S13 Build http://zilvia.net/f/showthread.php?p=6005967#post6005967 |

|

|

|

|

|

#12 |

|

Zilvia Member

|

So with this post brings us up to date of where I'm at on the build. Today has been a whirlwind to say the least. I hit an animal (still never figured out wtf it was i actually hit) in my daily driver 05 wry, my wife nearly ran over a body on the interstate (something had just happened and no one was on the scene yet, cops were right behind her). And then a little bit of good happened. The last few weeks i have been searching for a set of Nismo Lmgt2's to buy. Ill be rebuilding them and converting them to 3 piece wheels so i wasn't looking for a mint set. My biggest stipulation was i wanted all 4 correct center caps in decent condition with the wheels. Turns out as rare as these wheels are i happned upon a set 10 minutes away from my house. I couldn't believe after searching for weeks with multiple dead ends i was able to find a quality set with all 4 center caps right down the road from my house.

untitled (1 of 8) by lawrx, on Flickr untitled (1 of 8) by lawrx, on Flickr untitled (1 of 4) by lawrx, on Flickr untitled (1 of 4) by lawrx, on Flickr untitled (2 of 4) by lawrx, on Flickr untitled (2 of 4) by lawrx, on Flickr untitled (3 of 4) by lawrx, on Flickr untitled (3 of 4) by lawrx, on Flickr untitled (4 of 4) by lawrx, on Flickr untitled (4 of 4) by lawrx, on Flickr

__________________

My S13 Build http://zilvia.net/f/showthread.php?p=6005967#post6005967 |

|

|

|

|

|

#17 |

|

Zilvia Member

|

It was quite the sight during the first mock up lol

__________________

My S13 Build http://zilvia.net/f/showthread.php?p=6005967#post6005967 |

|

|

|

|

|

#18 |

|

Zilvia Member

|

Got my steering rack in today. This allowed me to mock it up along with the dry sump pan to see how low i could get the motor.

untitled (1 of 22) by lawrx, on Flickr untitled (1 of 22) by lawrx, on FlickrAfter setting the steering rack in place of where it goes stock, I was able to see how far i could move it over to gain more clearance for the driver side header. The downside of this is now one inner tie rod is too long and one is too short. In the future i will measure exactly how far over i moved the rack, cut that much out of the longer tie rod and add it to the other side. Ill probably have to add a bit of small tuning reinforcement, kinda like a sleeve, over the modified areas that get back welded together  untitled (2 of 22) by lawrx, on Flickr untitled (2 of 22) by lawrx, on Flickr untitled (3 of 22) by lawrx, on Flickr untitled (3 of 22) by lawrx, on Flickr untitled (5 of 22) by lawrx, on Flickr untitled (5 of 22) by lawrx, on Flickr untitled (4 of 22) by lawrx, on Flickr untitled (4 of 22) by lawrx, on Flickr untitled (6 of 22) by lawrx, on Flickr untitled (6 of 22) by lawrx, on Flickr untitled (7 of 22) by lawrx, on Flickr untitled (7 of 22) by lawrx, on Flickr untitled (9 of 22) by lawrx, on Flickr untitled (9 of 22) by lawrx, on FlickrWith the modified distance for the steering rack confirmed, i mounted up the dry sump oil pan and lowered the motor in to see how low i could get it and what would be in the way of getting it lower.  untitled (8 of 22) by lawrx, on Flickr untitled (8 of 22) by lawrx, on Flickr untitled (10 of 22) by lawrx, on Flickr untitled (10 of 22) by lawrx, on Flickr untitled (11 of 22) by lawrx, on Flickr untitled (11 of 22) by lawrx, on Flickr untitled (12 of 22) by lawrx, on Flickr untitled (12 of 22) by lawrx, on Flickr untitled (13 of 22) by lawrx, on Flickr untitled (13 of 22) by lawrx, on FlickrWith the motor dropped into the engine bay i was amazed how much more room i had with the steering rack over. Def a helpful modification in the space department. Also got a bit of a visual of where the Altenator, Ac compressor, and Dry sump pump will be. Plan is to mount the oil gear pump on one side of the motor and low near level with the motor mount under the head, and the alternator and ac compressor on the other side in the same position, all below the head. Ill be running a electric power steering pump from a vauxhall astra so there won't be a mechanical pump mounted on the motor. With the few accessories i have being mounted so low and out of the way and running an electric water pump, the front of the motor will be extremely clean and simplistic.  untitled (14 of 22) by lawrx, on Flickr untitled (14 of 22) by lawrx, on Flickr untitled (15 of 22) by lawrx, on Flickr untitled (15 of 22) by lawrx, on Flickr untitled (16 of 22) by lawrx, on Flickr untitled (16 of 22) by lawrx, on Flickr untitled (17 of 22) by lawrx, on Flickr untitled (17 of 22) by lawrx, on FlickrI realized after setting the motor in roughly where it is going to sit that there is going to be a monumental amount of space for the radiator and condenser, which both will be mounted on a roughly 45* forward angle, with the air coming through the from bumper, passing through the radiator/condensor and then up and out a duct through a center vent in the hood, more than likely a koguchi power item.  untitled (18 of 22) by lawrx, on Flickr untitled (18 of 22) by lawrx, on Flickr untitled (19 of 22) by lawrx, on Flickr untitled (19 of 22) by lawrx, on FlickrI also took a minute to mock up one of the rear wheels. I know its not anywhere near what its gong to look like, between missing about 6" of lip and a massively wonder qtr, but you get the idea. And who can't give in to the temptation to mock up a new set of wheels on the project car?!  untitled (20 of 22) by lawrx, on Flickr untitled (20 of 22) by lawrx, on Flickr untitled (21 of 22) by lawrx, on Flickr untitled (21 of 22) by lawrx, on Flickr untitled (22 of 22) by lawrx, on Flickr untitled (22 of 22) by lawrx, on Flickr

__________________

My S13 Build http://zilvia.net/f/showthread.php?p=6005967#post6005967 |

|

|

|

|

|

#19 |

|

Zilvia FREAK!

Join Date: Feb 2007

Location: Southern CA

Posts: 1,190

Trader Rating: (66)

Feedback Score: 66 reviews

|

What is your reason for running an electric water pump aside from parasitic loss? It's my understanding that most electric pumps are meant for a drag racing application where the car is ran for short periods of time and then turned off. Pump keeps working while car is shut down, cooling between runs. I've heard they arent good for extended run time, i.e. track events, etc. due to not having the capacity of a manual pump.

How excited I'm getting about this build!  |

|

|

|

|

|

#20 | |

|

Zilvia Member

|

Quote:

Im really not too concerned with how efficeint the cooling system will be as i will have very good airflow to and from the radiator, so i doubt 20% less coolant flow at the upper end of the rev range where i may only spend 10-15% of the time driving the car will make that big of a difference. Thanks for the support on the build tho

__________________

My S13 Build http://zilvia.net/f/showthread.php?p=6005967#post6005967 |

|

|

|

|

|

|

#21 |

|

Zilvia Addict

Join Date: Jan 2011

Location: In my house

Age: 29

Posts: 755

Trader Rating: (3)

Feedback Score: 3 reviews

|

I am lovin this build man. Sucks to hear about your Subaru woes. My gc8 hasn't really given me issues and I spy a black one.

I wasn't aware even the new wrxs had issues on them. |

|

|

|

|

|

#22 |

|

Zilvia Member

|

Yeah thats a buddy of mines gc8 I'm doing some rust repair and body work on. And yeah the wry and sti have always had ring land issues. Up until 2015 where the wry got the new fa20, although the sti still has the 1989 based j25 lol Sad part is Subaru has known about the ring land issue since the GD chassis but have yet to fix it.

__________________

My S13 Build http://zilvia.net/f/showthread.php?p=6005967#post6005967 |

|

|

|

|

|

#23 |

|

Zilvia Member

|

Got a bit more work done the other night. Borrowed my dads plasma cutter (thing is AWESOME) to start cutting some sheet for the motor mounts. At this point for the mounts thats about all i can do for now until i pick up a welder and a drill press, which should be soon.

untitled (2 of 9) by lawrx, on Flickr untitled (2 of 9) by lawrx, on Flickr untitled (1 of 9) by lawrx, on Flickr untitled (1 of 9) by lawrx, on Flickr untitled (4 of 9) by lawrx, on Flickr untitled (4 of 9) by lawrx, on Flickr untitled (3 of 9) by lawrx, on Flickr untitled (3 of 9) by lawrx, on Flickr untitled (5 of 9) by lawrx, on Flickr untitled (5 of 9) by lawrx, on FlickrAlso was able to mount the trans, torque tube and motor all up as one. This allowed me to see about where the diff will sit in relation to how far back the motor will sit. I ran into a bit of a clearance issue, probably have about another inch back the diff could go before the motor sits where i want it. Just have to do some minor trimming on the rear subframe for some more clearance. I also have to grind off the stock corvette shift box mounts to allow the trans axle/ rear diff to be mounted higher as at this current point they are contacting the trans tunnel in the middle. So the rear diff will probably sit .5-.75" higher and 1-1.25" farther back than this. Should have plenty of ground clearance, cooling air space, and hopefully SOMEWHERE to run the exhaust...  untitled (6 of 9) by lawrx, on Flickr untitled (6 of 9) by lawrx, on Flickr untitled (7 of 9) by lawrx, on Flickr untitled (7 of 9) by lawrx, on Flickr untitled (8 of 9) by lawrx, on Flickr untitled (8 of 9) by lawrx, on Flickr untitled (9 of 9) by lawrx, on Flickr untitled (9 of 9) by lawrx, on Flickr

__________________

My S13 Build http://zilvia.net/f/showthread.php?p=6005967#post6005967 |

|

|

|

|

|

#25 |

|

Zilvia Member

|

Any of yall have any experience on casting aluminum? Like making a mold and all? Will be making my own itb setup for the 240 and thinking casting aluminum runners for each itb will be the best way to have each runner as close to each other spec wise as possible.

__________________

My S13 Build http://zilvia.net/f/showthread.php?p=6005967#post6005967 |

|

|

|

|

|

#26 | |

|

Post Whore!

|

Quote:

Yes, but only in manufacturing. |

|

|

|

|

|

|

#27 |

|

Zilvia Member

|

Any trade secrets?? haha Any knowledge is helpful, dos, donts. Currently acquiring knowledge and know how so see if im really up for it.

__________________

My S13 Build http://zilvia.net/f/showthread.php?p=6005967#post6005967 |

|

|

|

|

|

#29 | |

|

Post Whore!

|

Quote:

There are software programs to calculate the metal flow to make sure you have even heat and material dispersion. Its likely far cheaper and easier to buy and existing ITB setup or convert some motorcycle units and machine adapters. |

|

|

|

|

|

|

#30 |

|

Post Whore!

|

My S13 Build : LS swap, Corvette transaxle, ITB, Widebody, Do everything car

He can prolly take his stock outer and corvettes inner with an axel measurement and have a axle/drive shaft shop make him a hybrid set. Last edited by Corbic; 01-26-2016 at 03:11 PM.. |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|