|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Engine Tech Technical discussion related to all relevant engines such as KA, SR, RB, CA, 2JZ , L24/26/28, VG, VQ, and LSx series. |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Zilvia Junkie

Join Date: Aug 2008

Location: MT, AZ, Seoul, Bangkok

Posts: 335

Trader Rating: (0)

Feedback Score: 0 reviews

|

Fuel Pressure and engine safety

While tuning engines I often times have people ask me what they can do to ensure their engine remains reliable and making good power for as long as possible.

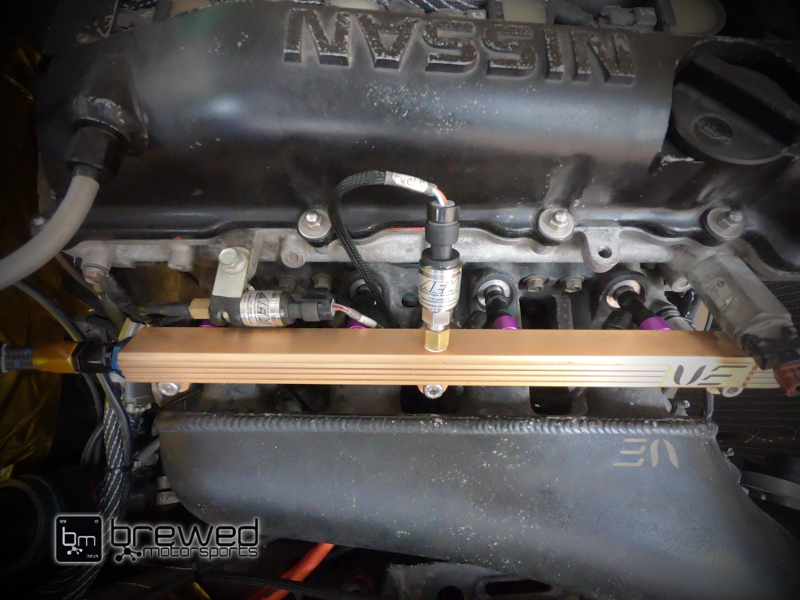

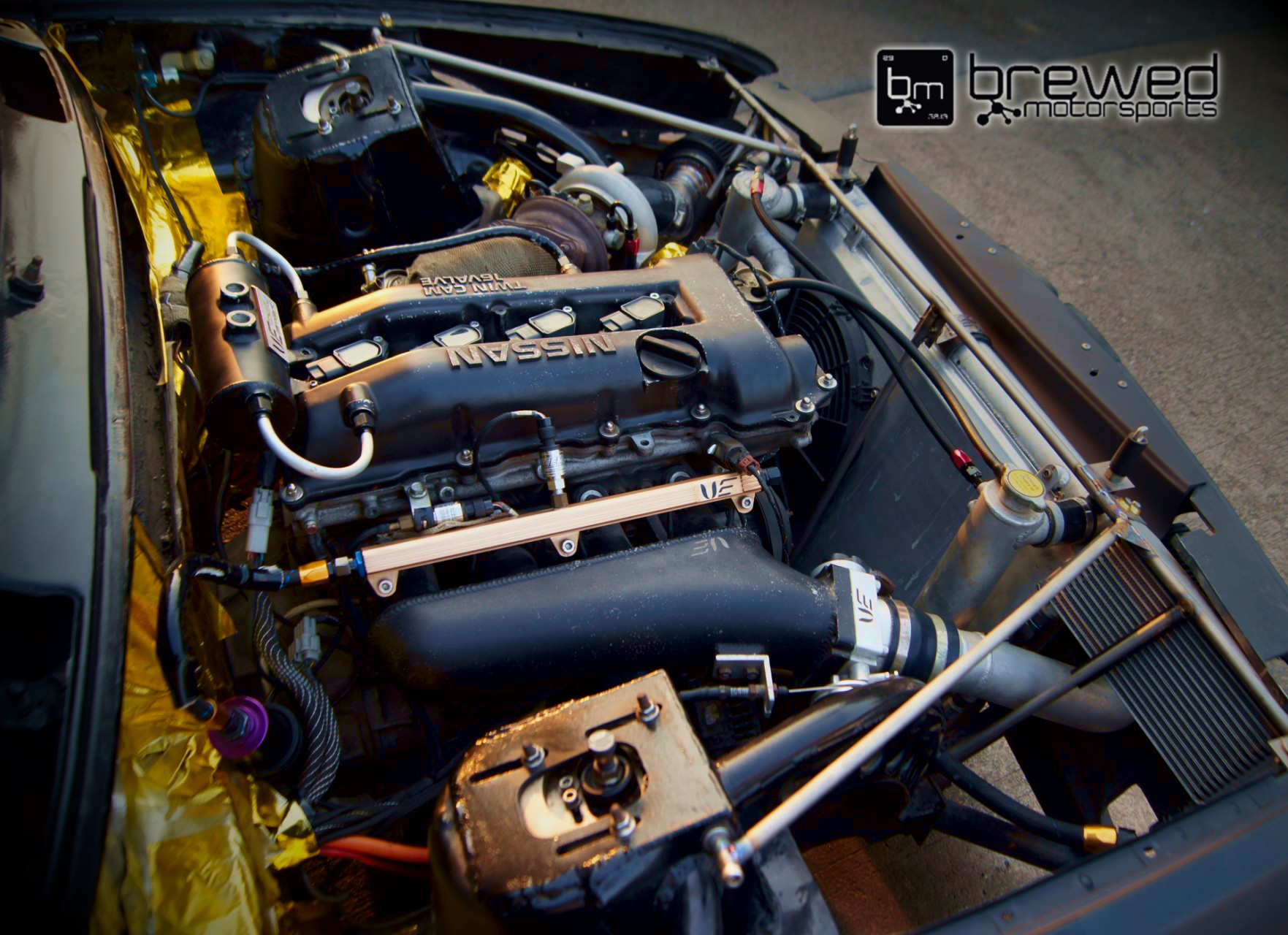

Besides the obvious hardware requirements/clearances and general maintenance there are a few key sensors that can be incorporated into the ECU and calibration/tune that can not only increase engine performance but also save an engines life if there is something as simple and common as a fuel pump failure. This little article goes into detail about the Fuel Pressure sensor and how it can be incorporated into a calibration by the tuner to not only help your engine run efficiently but also keep it safe and healthy. This little read is HIGHLY recommended for anyone that "pushes" an engine on the track or the street. Fuel pressure sensors, gauges and engine safety explained  Explanation: Fuel injectors flow a given amount at a set fuel pressure; more pressure - more flow, less pressure - less flow (for the same given injector open time). If your engine has been tuned with 50psi fuel pressure/injector pressure and 6 months later your dirty fuel pump starts to die fuel pressure will fall off first at high RPM/high engine load. This is where the pump needs to flow the most fuel, this is also the most vulnerable operating range for an engine so any loss in fuel will quickly cause a lean condition leading to damage. Solution: Assuming your car is using a proper motorsports ECU such as; Motec M1, AEM Infinity, Haltech, Bosch, Pectel, etc we would incorporate a 3 wire fuel pressure sensor into your calibration aka “ecu tune” in a number of helpful ways listed below. Full article Fuel pressure sensors, gauges and ECU support  |

|

|

|

| Sponsored Links |

|

|

#3 |

|

Zilvia FREAK!

Join Date: Jun 2010

Location: North Dakota

Age: 30

Posts: 1,066

Trader Rating: (4)

Feedback Score: 4 reviews

|

More of tuning advice is needed around here! I've been self learning the AEM v2 for the past 4 years and it sucks haha.

This is awesome!

__________________

|

|

|

|

|

|

#4 | |

|

Zilvia Junkie

Join Date: Aug 2008

Location: MT, AZ, Seoul, Bangkok

Posts: 335

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

|

|

|

|

|

|

|

#7 | ||

|

Zilvia FREAK!

Join Date: Jun 2010

Location: North Dakota

Age: 30

Posts: 1,066

Trader Rating: (4)

Feedback Score: 4 reviews

|

Quote:

Quote:

I could probably upgrade to the infinity and it sounds like its more user friendly to tune with plus all the extra failsafes(I think AEM added some for the V2 but I 'm not sure on that.)

__________________

|

||

|

|

|

|

|

#8 | |

|

Zilvia Junkie

Join Date: Aug 2008

Location: MT, AZ, Seoul, Bangkok

Posts: 335

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

|

|

|

|

|

|

|

#9 |

|

Zilvia Junkie

Join Date: Aug 2008

Location: MT, AZ, Seoul, Bangkok

Posts: 335

Trader Rating: (0)

Feedback Score: 0 reviews

|

Recently had the MAP reference going to the fuel pressure regulator hose split on me. Didn't notice AFR change but did notice boost was a bit low on WOT (boost trim to lower boost when injector pressure drops) and fuel pressure was a bit high at idle (full vacuum).

Upon inspection found and replaced the split vacuum line and things are back to normal. It was great to see the ECU calculating the correct fueling needs and holding target AFR even with the lack of MAP reference for the FPR.  |

|

|

|

|

|

#10 |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,648

Trader Rating: (17)

Feedback Score: 17 reviews

|

I dont see a breather on the crankcase

what the hell is up with the pcv youve got no crankcase oil control, that will pollute the engine oil, facilitate engine oil leaking, eventually the seals will dribble. Also it increases blow-by during cruise and idle there must be something I am not seeing |

|

|

|

|

|

#11 | |

|

Zilvia Junkie

Join Date: Aug 2008

Location: MT, AZ, Seoul, Bangkok

Posts: 335

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

|

|

|

|

|

|

|

#13 |

|

Zilvia Junkie

Join Date: Aug 2008

Location: MT, AZ, Seoul, Bangkok

Posts: 335

Trader Rating: (0)

Feedback Score: 0 reviews

|

Vent to atmosphere is extremely common set up you haven?t ever seen something?s like that before? Very easy way to keep crank case pressure low while keeping all blow by fumes out of the engines combustion cycles. Only time I?d ever recirculate to intake would be for emissions inspection.

|

|

|

|

|

|

#14 | |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,648

Trader Rating: (17)

Feedback Score: 17 reviews

|

Quote:

You are not keeping the crank case pressure low if you don't have pcv lol When you run an engine, any engine, it creates blow by, which raises crankcase pressure above atmospheric So say atmosphere is sea level 103KPA When the engine starts there, with no pcv, the crankcase pressure will be higher than 103KPA for the entire time it runs. This puts additional pressure on oil seals (creates oil leaks) and reduces the ring-seal (increased blow-by). This also allows combustion byproduct easy access to engine oil which quickly becomes contaminated and broken down as partially combusted hydrocarbon fragments dissolve You should never run an engine like that. -Daily drivers use active manifold suction (for simplicity and low maintenance) -Race cars use a vacuum pump Sometimes these are combined with an active-exhaust venturi driver or electric pump but that is rare and adds complexity heres a picture, pay close attention to the exact pressure numbers KPA, and the bottom where it shows with and without pcv in terms of KPA You want to be below the yellow line (at sea level, 101.xKPA) at all times, typically 1 to 2.2" Hg or roughly 12-25" of water (its easier to set pcv using inches of water as a measurement) |

|

|

|

|

|

|

#15 | |

|

Zilvia Junkie

Join Date: Aug 2008

Location: MT, AZ, Seoul, Bangkok

Posts: 335

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

I don?t think think your picking on me I just see you are confused about crank case ventilation options. Venting all crank case ports including adding more vents (an fittings you see welded into valve covers) is a very common and efficient way to keep crank case pressure low. Recirculating to the intake (pre turbo) is also common but allows dirty blow by gas into the combustion cycle. Oem PCv set up using a check valve/connected to intake manifold is also ok but limited flow for releasing pressure from crank case when the engine is under load and check valve is closed. Keeping doing your research my friend and you?ll find loads of information out there including data logs of people testing all types of catch can/crank case ventilation plumbing options. The key to any wet sump oil system is keeping crank case pressure as close to atmospheric as possible while the engine is under the highest loads (most blow by). Only when you get into dry sump oiling systems are you able to create a vacuum condition in the crank case under high engine loads thanks to multiple scavenging pumps. Using a vacuum pump to apply negative pressure to the crank case is something you’ll see to help emissions on newer vehicles during low engine loads. These small pumps can not keep up with crank case pressure during high engine loads and you will see crank case pressure climb as blow by/cylinder pressure increase dramatically. L |

|

|

|

|

|

|

#16 |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,648

Trader Rating: (17)

Feedback Score: 17 reviews

|

lets try this again

factory engines from all manufacturers of every engine in the world use PCV. Factory wet sump engines use PCV to generate a BELOW atmospheric pressure drop inside the crankcase AT ALL TIMES. Including cruise, and WOT. If you disable this feature by venting to the atmosphere, you no longer have a positive crankcase ventilation "PCV" the main benefits of PCV are: -Improved ring seal character & reduced blow-by -Reduced hydrocarbon fragment contamination of engine oil and parts (the black sticky goo and hard diamond-like crust that forms on various surfaces) -Lower pressure on oil retaining side(inside the crankcase) reduces the passage of engine oil through every seal (try putting a small leak of viscous fluid as water or oil in a sealed cup then applying a low pressure to the inside of the cup, the leak is reduced or entirely prevented) preserves oil seals and prevents leaks, high crankcase pressure is known to blow out seals i.e. front main, rear main, valve cover, dipstick, etc.. You throw all of that away when you vent to the atmosphere as you are doing This atmospheric venting technique is employed on budget short term racing equipment, i.e. if you are wagering the entire vehicle in a pinks race, and just need max power for that one race, and you don't care about any of the parts in the car, you would do this sort of thing. It gives max power at the expense of reduced engine service life expectancy. I've examined and cleaned around 1000 engines imported from Japan from say 2004 to 2012, and installed many into cars. Without launching into a dissertation suffice to say that engines where the owners had disabled their PCV functions were significantly worse, to the point where I stopped accepting engines with modified air filters and will only accept engines with intact air box, factory filter and pcv systems (no modifications) for swaps in any car (including local V8 engines sourced) to this day PCV is often overlooked yet its part of the oil system and one of the most critical functions on an engine if you care about the engine Last edited by Kingtal0n; 04-09-2020 at 02:14 PM.. |

|

|

|

|

|

#18 | |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,648

Trader Rating: (17)

Feedback Score: 17 reviews

|

Quote:

Most of the time I never see them again lol. Some people don't want to do it right, they just want to copy how everybody else is doing it |

|

|

|

|

|

|

#19 | |

|

Zilvia Junkie

Join Date: Aug 2008

Location: MT, AZ, Seoul, Bangkok

Posts: 335

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

Record setting Teams like Mazworx and T1 among many others both use and sell this type of catch can as it is the most efficient way to lower crank case pressure under high load/high RPM/high cylinder pressures when the most blow by is created. **for a wet sump oiling system, as mentioned above dry sump oiling can be set up much more efficiently do to the multiple high volume belt driven scavenging pumps. I do regularly get cars in for tuning or that i Etune that do NOT have their catch can or PCV system set up correctly and in many cases for cars running a pre turbo MAF not only is their PCV set up wrong but it can also cause a bypass of un-metered air into the engine (under vacuum conditions when the OEM PCV check valve is pulled open). This is all an easy fix though and i regularly have to walk Subi and Nissan guys through this before tuning can start. If you still don't believe throw a MAP sensor in your valve cover and do some logging with the PCV system set up different ways at high engine load/RPM. You'll find the 2 most effective methods for PCV system is: catch can that is either vented to atmosphere or routed to pre turbo intake. Either option will get net you the same crank case pressures under high load BUT the vent to atmosphere option will keep the dirty blow by fumes out of the combustion cycle. An engine is MUCH happier running 100% on clean fresh air VS having to digest/combust it's own dirty blow by gasses. This is also why you will always see every OEM use a recirculated PCV system (usually with check valve to post throttle body), it creates a closed loop system with low emissions ALL of which can be measured at the tail pipe un like a vented system. |

|

|

|

|

|

|

#20 |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,648

Trader Rating: (17)

Feedback Score: 17 reviews

|

the picture I posted is a measurement of pcv system with and without atmospheric venting.

Here is the data so you can see it easily from one example random engine out of a sample size of around 100 Measurement taken from random engine with Atmospheric Vent: At idle: 104KPA At 2000rpm cruise: 106KPA At 3000rpm cruise: 107KPA At WOT: 112KPA Measurement taken from random engine with PCV: At idle: 89KPA At 2000rpm cruise: 87KPA At 3000rpm cruise: 92KPA At WOT: 93KPA Reference centerline atmospheric pressure: 103KPA Anything over 100KPA is undesirable and unachievable without PCV |

|

|

|

|

|

#23 |

|

Premium Member

Join Date: Feb 2020

Location: Omaha, Nebraska

Posts: 80

Trader Rating: (1)

Feedback Score: 1 reviews

|

Tunermt's claim that it is wrong because of unmetered/dirty air. I figured it'd be compensated for in the tune, but I've only done a base tune on a DSM so I'm definitely not the most knowledgable.

Edit: Thanks for the clarification guys. Good stuff Last edited by AndrewS13; 05-16-2020 at 03:19 AM.. |

|

|

|

|

|

#24 | |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,648

Trader Rating: (17)

Feedback Score: 17 reviews

|

Quote:

The factory produced 100,000's (or whatever) of these cars (Sr20de/sr20det) all the same with crankcase that rely on the post air filter duct for their pressure drops (the post air filter tube feeds the crankcase during vacuum and visca versa at wot) hundreds of thousands of them like that. They did this because it was shown in the computer modelling that without such a pressure drop, any engine would become a leaking smoking dripping pile of shit in so few miles And now you want to remove it because somebody on the internet says its 'dirty air' lol - I Don't blame you. It does sound like dirty air and the whole appearance of emissions can seem misleading in this case. But lets clear it up clear sentence: the dirty air inside the crankcase is below the pistons (with the engine oil and oil system) whereas it NEEDS to be above the pistons (where it can't harm the engine oil) and by removing or deleting that tube(any pcv tubes) you allow it to propagate and persist inside the crankcase with the oil system where it does the most damage. In other words, the 'dirty air' that gets below the piston was accidentally released there, that is called 'blow by'. If we could, we would use a 100% perfect seal piston ring to avoid that from happening. But we can't. Where that air(its really a mixture of hydrocarbon fragments suspended in fluid) should have stayed, is inside the combustion chamber, but it leaked out, see? So we need to put it back into the combustion chamber somehow, and fast. Either that or find another way to suction it out somehow (vacuum pump). [size=3]But under absolutely no circumstances should you ever simply open a vent to the atmosphere from the crankcase and allow the pressure to build and force its own way out over time 'delete pcv' That gives the filthy air time to circulate and literally bounce from every conceivable surface, as gas molecules are want to do at very high rate. Especially hot, energetic, fragments of carbon compounds displaying reactive radical species of all manner shape and size! By deleting PCV, you prevent the engine from moving that dirty air back into the combustion chamber. So where does it go instead? It contaminates the engine oil, sticks to engine parts, lowers the life expectancy of the engine. It isn't air; its full of partially combusted hydrocarbon fragments which form that black tar, sticky gooey substance, and diamond-like crust on engine parts. By the way, have you seen the size of the orifice that feeds an sr20 cam oil squirter? Oh and the unmetered air argument, I love that. Did you know, everytime you step on a brake pedal you feed an engine unmetered air? Unmetered air is only a concern when the mass is high enough to throw the air fuel ratio off far enough during a troubling time, i.e. when the engine pressure in the intake manifold is higher than 50KPA and we are talking greater than say 2lb/min worth of airflow that is 'slipping by'. The trifle amount that should be leaving a fully sealed crankcase with healthy piston ring/wall character under acceptable operating conditions is negligible, probably closer to 0.2lb/min (about 1% of the flow required to trigger a 'unmetered air' issue) or less. Last edited by Kingtal0n; 04-14-2020 at 01:23 PM.. |

|

|

|

|

|

|

#25 | |

|

Zilvia Junkie

Join Date: Aug 2008

Location: MT, AZ, Seoul, Bangkok

Posts: 335

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

OEM set up is ok and clearly works fine for most applications. If emissions inspection is not an issue I prefer not to use the OEM PCV design for the following reasons: -low flow at high crank case pressure do to limited outlets/size on valve cover and crank case. -The PCV 1 way valve between intake manifold and valve cover is prone to leaking which can lead to a boost leak directly into the PCV system. -Venting to atmosphere keeps the crank case fumes out of the intake/turbo/intercooler. Over time this just keeps everything a bit cleaner and oil free. The problem i mentioned of un metered air only comes into play when someone installs a catch can into the PCV system incorrectly which is something i see some what often and have to address before tuning. |

|

|

|

|

|

|

#26 |

|

Zilvia Junkie

Join Date: Aug 2008

Location: MT, AZ, Seoul, Bangkok

Posts: 335

Trader Rating: (0)

Feedback Score: 0 reviews

|

** meant to add, shall we make a new thread to discuss crank ventilation options and set up so we can keep this thread on topic regarding the ECU/fuel pressure sensor reference and related trims/tuning?

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|