|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

#781 | |

|

Zilvia.net Advertiser

Join Date: Nov 2005

Location: Michigan

Age: 33

Posts: 5,431

Trader Rating: (16)

Feedback Score: 16 reviews

|

Quote:

HOW TO: Ultimate budget front LCAs - Nissan Road Racing Forums

__________________

Build: http://zilvia.net/f/showthread.php?t=643065 Friends don't let friends buy knock-offs. |

|

|

|

|

| Sponsored Links |

|

|

#782 | |

|

Guild of Skullduggerous Intent

|

Quote:

|

|

|

|

|

|

|

#783 |

|

Zilvia FREAK!

|

There when you need them most - SKULLWORKS! AWESOME! I'll be sure to bring you guys something nice

Epic status this Saturday. OH BABY! Epic status this Saturday. OH BABY!

__________________

.25 till 3 |

|

|

|

|

|

#784 |

|

Post Whore!

Join Date: Sep 2007

Location: Westminster

Age: 30

Posts: 2,694

Trader Rating: (14)

Feedback Score: 14 reviews

|

Im not really down to use washers, im going to probably have some spacers made.

and what size bolt do the SPLs use? im guessing if i have to drill the knuckle out im probaby going to have change the heim joint right?

__________________

|

|

|

|

|

|

#785 |

|

Post Whore!

Join Date: Jul 2005

Location: LA

Age: 36

Posts: 3,402

Trader Rating: (19)

Feedback Score: 19 reviews

|

OK, so I was going to go to bed early tonight but I came home and found a package sitting on the table.........................

It was my shock mount spherical bearings!!! I happened to get my uprights back from welding yesterday, so you can bet your ass I was ready to get this crap back together and see how it fits! I had to install the sphericals by drifting it in with a 36mm socket (a 34 would have been better) and hammer, so the very edge of the bearing housing got a little dinged up but the bearing still moved smoothly. I got one in and am going to get the other one pressed in tomorrow - time is a major factor for me in the next 48 hours and I was excited so that's why I didn't wait to get them both pressed in. Here are some pictures, they can do the talking:    The housing is more banged up on the other side, but like I said the bearing moves freely. On the car!    Its a hair closer then I want on one side so I may grind down the misalignment spacer on one side about a mm so the shock mount will shift over just a tad. Overall I definitely thing was well worth the $125 bucks I spend on the welding. I also got my Z33 inner tie rods in and was pleased to find out that they are the same length and offer more adjustability range then the S14 tien inner/outer set. I took some pictures to compare the size differences. Again, the pictures can do the talking:   Threaded all the way down.  Threaded all the way out - I believe the custom outers I put together can thread out a little more and still be safe. For reference, this is how low the car is out back, so you can keep that in mind with the LCA angle and shock mount angle. ~23 inches from the top of the fender arch to the ground.   I can't wait to get the motor in and see how the front sits!

__________________

Instagram - SJKnoop |

|

|

|

|

|

#786 |

|

Zilvia FREAK!

|

I'm hesitant to say if they're either good or bad in fear it'd be a totally awesome, epic, new trend sort of like. Mostly I'd tweak each and ever car differently. A lot of the fast cars out there, especially some of the time attack s14s don't have this sort of mod. BUt that won't stop me from leaving my comment about them

I'm not sure if I can come up to pick up the coils, and do the swap. Work is demanding. I'll update this thread if I get around to it this weekend.

__________________

.25 till 3 |

|

|

|

|

|

#787 | |

|

Post Whore!

|

Quote:

Then figure out what you need from that  |

|

|

|

|

|

|

#788 | |

|

Zilvia.net Advertiser

Join Date: Nov 2005

Location: Michigan

Age: 33

Posts: 5,431

Trader Rating: (16)

Feedback Score: 16 reviews

|

Quote:

Looking forward to it.

__________________

Build: http://zilvia.net/f/showthread.php?t=643065 Friends don't let friends buy knock-offs. |

|

|

|

|

|

|

#789 | |

|

Post Whore!

Join Date: Jul 2007

Location: Simi Valley, CA

Age: 38

Posts: 9,006

Trader Rating: (106)

Feedback Score: 106 reviews

|

Quote:

|

|

|

|

|

|

|

#790 | |

|

Post Whore!

Join Date: Apr 2004

Location: Houston, TX

Posts: 2,701

Trader Rating: (16)

Feedback Score: 16 reviews

|

Quote:

I still wouldn't get an AN bolt - I'm not even sure what those are used on, maybe just regular military hardware like HMMV's and stuff. They're more like an SAE Grade 5 bolt with a grip length specification. What I'd use is a NAS62xx-yy, where xx = your diameter in 16ths(i.e. 08 = 1/2"), and yy = grip length in 16ths. This is a commonly available steel 160 KSI min. shear bolt. They also have a domed head to reduce weight(hence they are not a tension bolt in highly stressed applications).

__________________

S13 Hatch - Goes around tracks quickly DEFSPORT |

|

|

|

|

|

|

#791 |

|

Post Whore!

Join Date: Apr 2004

Location: Houston, TX

Posts: 2,701

Trader Rating: (16)

Feedback Score: 16 reviews

|

Looking good there.

It looks like you might have pressed it in a little bit farther on the side that has more clearance. Might want to just press the housing in a little bit farther to the side that's tighter. I wouldn't recommend grinding on the misalignment bushings, as I doubt you'll get the face perpendicular to the bolt axis, and you'll remove the zinc dichromate coating(those are chromoly, so they will rust without a coating).

__________________

S13 Hatch - Goes around tracks quickly DEFSPORT |

|

|

|

|

|

#792 | ||

|

Nissanaholic!

Join Date: Feb 2007

Location: Memphis

Age: 29

Posts: 1,907

Trader Rating: (6)

Feedback Score: 6 reviews

|

Lookie what I found.

Quote:

And also looks like they also offer a camber adjustment setup. Quote:

__________________

Nagasaki Motors Nagasaki Motors Friends help you move. Real friends help you move bodies. |

||

|

|

|

|

|

#795 | |

|

Post Whore!

Join Date: Jul 2005

Location: LA

Age: 36

Posts: 3,402

Trader Rating: (19)

Feedback Score: 19 reviews

|

Quote:

Just trying to think of a way to not completely reassemble the rear end again - but if need be I will, haha.

__________________

Instagram - SJKnoop |

|

|

|

|

|

|

#796 |

|

Zilvia FREAK!

|

I was finally able to installt he Driftworks spindles. But first off, a big thanks to Skullworks for lending me their coilovers to use in the meanwhile as my AST coilovers will be modified. Without them I'd still be looking for a set to do the swap. And secondly for my parents for understanding what my car means to me and not threatening to kick my ass out as I spend a few whole days installing these things.

Now, the Driftwork spindles are a bit of a crude product. They aren't exactly bolt up. I mean, they intended them to be, but it's their lack of quality and control that let them down. I found myself massaging the product to fit correctly (ie sanding down the front hub, doing a bit of grinding on my rear caliper mount to have them fit, grinding down the rear traction rod to allow full suspension articulation). That doesn't make me too excited, nor happy. It's hard for me to recommend this product to someone who isn't handy with a wrench and grinder (wtf). Actually, I wouldn't. I'd say 99% of you will not be using this for the street as it takes a bit of ingenuity on someone else's part (thanks Skullworks again) to get the ebrake lines to fit correct, let alone having someone make additional ebrake lines (pending), and yes you would need an ebrake if you live in San Diego, it has a lot of hills. Is it Track worthy? Maybe. For Street usage? Most likely not. I know it states for offroad usage so don't bother calling me out on that  With that said here's some pix... With that said here's some pix...The DW knuckles are in addition with the Moonface Roll center adjusters btw... Prior to the installment of the rear spindles, and with only the fronts installed, the car felt great. The car changed direction quickly and abrutly. If you thought of where you wanted to go you where there. The steering ratio is much faster which makes the car funner to drive and gives it a darty feel, almost like a go-kart. One draw back I felt, was the difference in roll center height - front vs rear. I've read a few online publications saying if the front roll center is too high, there's oversteer on corner exit. I believe this to be because as the fronts are heavily loaded (thanks to the higher roll center) versuses the rear of the car, the moment the weight sitting on the front is basically "dumped" on the rear wheels causing a sudden overload of rear traction... but maybe someone could confirm/clarify this better. Now with the addition of the rear spindles... wow. The authors were right. As I punched my car around town, on occasion I anticipated countersteering where the car would normally break, but as I gave it more gas there was nothing. It was just grip and go. Now, I have a g meter in my car, and on average I'd hit .7g's through corners and kicking out there rear here and there for fun. But again, nothing. The car just grips and goes. I ended up hitting more than .8g's, and I wasn't sliding out the rear of my car - nice! I'm prety excited to try these out on the circuit and find the newer, higher limits of my car *fingers crossed* So for the average user/daily driver/show car setup, this might not be for you. It's a pain in the ass to install, the parts aren't cheap, and your hands will hurt. For someone who's pushing the car's limits and want to get every bit out of your car then I would definitely recommend looking into something like this, or better yet bother Def and Skullworks to get something like this made. Don't assume you'll be getting them "cheap". The engineering it takes to develop something like this will take a lot of time and money. The next track event I head out to, with the folks over at Skullworks, is Fon-tucky's (aka AAA speedway's) roval. I'll also definitely take the car out to Malibu canyon to get a better feel of the balance of the car. I'll post reviews as I progress.

__________________

.25 till 3 Last edited by mmdb; 05-16-2010 at 01:52 PM.. |

|

|

|

|

|

#797 | |

|

Post Whore!

Join Date: Apr 2004

Location: Houston, TX

Posts: 2,701

Trader Rating: (16)

Feedback Score: 16 reviews

|

Quote:

You could shave down a misalignment bushing and use some washers to move things over some, but like I said, they're chromoly, so don't be surprised if you get some surface rust over time. Not a huge deal, but I get irritated when I see ANY parts rusting on my car. Paint also doesn't work very well when it's bolted up against something, but might be better than nothing.

__________________

S13 Hatch - Goes around tracks quickly DEFSPORT |

|

|

|

|

|

|

#798 |

|

Post Whore!

Join Date: Jul 2005

Location: LA

Age: 36

Posts: 3,402

Trader Rating: (19)

Feedback Score: 19 reviews

|

mmdb - are you planning on getting any actual measurements done one your roll center? To actually find out where your sitting and where it "should" be. I know the way a car handles is subjective, but I am just curious.

I can definitely say my rear control arms point way more up then yours, but my car is probably a solid 2 inches lower then yours. My front control arms are nearly flat, so I am excited about seeing how it handles. I was watching it on the trailer and it wasn't rolling even a little bit on exit/on ramps - obviously it was traveling at truck + trailer speed, not actually moving, and was strapped down, but in the past I could still see the body roll on the trailer.

__________________

Instagram - SJKnoop |

|

|

|

|

|

#799 |

|

Post Whore!

|

So the front suspension on both sides are buttoned back up on my end.

The rack is sort of centered, but for some reason it seems that I have more toe out on the passenger side than the driver's side, and I get just a tad more steering wheel turn towards the driver's side before it stops versus the passenger side. Now here is where I am having a little bit of issue. I am guessing that the FLCAs are not sitting in an optimal length, and is causing the spacers on the spherical bearings to bind on the bearing mounting cups on the arms when I turn the wheels. The knuckles can move backwards (which causes the wheels to point outward) easily until the tie rods hit the rack, but there seem to be binding going on when the knuckle moves the other direction (which points the wheels in towards the wheel well). I'm going to try to remember to take pics of what I am talking about, along with taking some pics after I adjust the FLCAs to show what they need to look like for binding-free operation. BTW, 140 ft-lbs is no joke lol Tightened the 3/4" nut to 140 ft-lbs lubricated, and the 5/8" nuts to 120 ft-lbs lubricated. |

|

|

|

|

|

#800 |

|

Zilvia Addict

Join Date: Nov 2009

Location: Canada

Age: 36

Posts: 685

Trader Rating: (0)

Feedback Score: 0 reviews

|

mmdb that's great news im glad you love the car now more

I really hope def/skullworks gets this going I really hope def/skullworks gets this going  Tearlesssjj, whats up with that subframe, link, more info |

|

|

|

|

|

#801 |

|

Post Whore!

Join Date: Apr 2004

Location: Houston, TX

Posts: 2,701

Trader Rating: (16)

Feedback Score: 16 reviews

|

SoSideways, did you enlarge the top hold in the bearing holder? I thought the overhang was excessive when I first got the arms, so I drilled mine out probably 3/16-1/4"(just used a 1-3/8" step drill and went one size from max IIRC).

__________________

S13 Hatch - Goes around tracks quickly DEFSPORT |

|

|

|

|

|

#802 |

|

Post Whore!

|

Yeah we reamed it out pretty good.

IIRC we had the same stepped drill, and on your suggestion I had my arms' bearing cups reamed out with the last step of the drill, which is like you said, somewhere in the 1-3/8" range. I think I just need to extend the arms out a little so the spacers are sitting in a more centered location, so when the knuckles start to pivot, they have more room to move around. I have a bit of room to extend the FLCA before it actually starts to push the track width out, so I should be OK. I'll take pics later tonight if I feel up to it.... it's been raining all day here and rainy days make me tired and lazy lol |

|

|

|

|

|

#803 | |

|

Zilvia FREAK!

|

Quote:

__________________

.25 till 3 |

|

|

|

|

|

|

#804 |

|

Post Whore!

|

I figured out what the problem was.

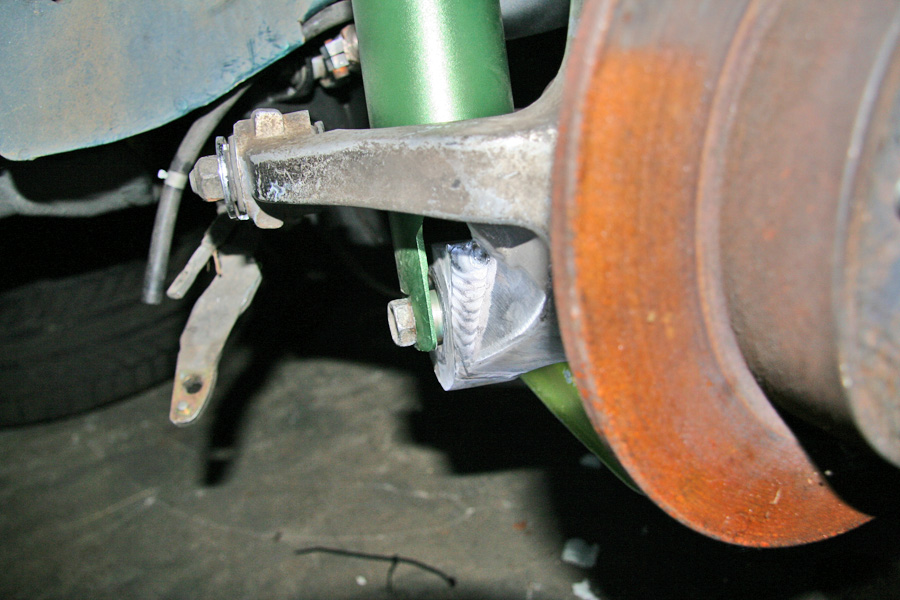

It wasn't because the spacers on the FLCAs binding on the bearing cup, it was because of how long the stock knuckles' steering arms are, and the problem was compounded by the long spacing from the tie rod ends. Basically, to push the knuckles OUT to turn the wheel into the wheel well (picture the passenger side suspension when you turn the steering wheel to the left), the tie rod has to push the steering arm on the knuckle out and BACK. That's right, BACK, because that arm is bent inwards stock, when you push it out, it goes through an arc that brings it back as well. Here are a couple of pics to show you what I'm talking about. Here are some pics of the other side. Notice how much more angle this side has due to the bend in the stock knuckles's steering arms already. The rod end is actually getting caught up on that bracket on the FLCA where the end link would bolt up to. I am going to try to put the brackets that come with the FLCAs that were supposed to be used as the steering stoppers on there, that way maybe the rod end will hit that bracket and then just slide over the the end link bracket, allowing me to get that last half an inch of space between the tie rod and the rack. Yes, the tie rods aren't even bottomed out on the rack yet. Hopefully, someone can help me out with how to figure this out, because I really really REALLY need to get my car back on the road, and this is preventing me from buttoning everything back up in the front there... |

|

|

|

|

|

#805 |

|

Nissanaholic!

Join Date: Feb 2007

Location: Memphis

Age: 29

Posts: 1,907

Trader Rating: (6)

Feedback Score: 6 reviews

|

Is there anything I need to know before I get my knuckles welded?

What I plan to do, Preheat with torch Weld Slowly cool down with sand. The welder is rated for 3/8" metal. I am having a friend that welds for a living weld it. PBM adapters btw.

__________________

Nagasaki Motors Nagasaki Motors Friends help you move. Real friends help you move bodies. |

|

|

|

|

|

#806 |

|

Post Whore!

|

I don't know, but I think I am way too involved in this project and am now into the "tunnel vision" state, and I cannot see anything else that might be able to fix my problems.

So if any of you have any ideas that I could try to fix my issues, please post up here. |

|

|

|

|

|

#807 |

|

Premium Member

Join Date: Jan 2005

Location: Cali

Age: 53

Posts: 1,371

Trader Rating: (29)

Feedback Score: 29 reviews

|

We ran into this issue when were modding knuckles on my buddies drift car. The angle of the steering arm causes the tie rod to hit very soon when using bump steer correction. The only two options I see are run less correction, or cut and weld your knuckles.

|

|

|

|

|

|

#808 |

|

Post Whore!

|

Damnit! You're the second person to give me the bad news about modifying the knuckles Jonnie!!

I have spent so much time and money on the front suspension that I just kinda want to get it to work without spending more time and money on it ya know? Grrrr....... this is really pissing me off.... |

|

|

|

|

|

#809 | |

|

Premium Member

Join Date: Jan 2005

Location: Cali

Age: 53

Posts: 1,371

Trader Rating: (29)

Feedback Score: 29 reviews

|

Quote:

|

|

|

|

|

|

|

#810 |

|

Post Whore!

|

I was thinking about the PBMs, but the fact is, I just dumped a bunch of money into my tie rod ends, so I'd rather seem them put to good use.

Argh... we'll see what's up later on... |

|

|

|

|

| Bookmarks |

| Tags |

| anti-squat, best thread ever, kpi, roll center, steering angle, suspension |

| Thread Tools | |

| Display Modes | |

|

|