|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Builds (and builds only) Got a build thread? It goes here, build threads anywhere else on the forum will be locked and never moved. |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Zilvia Junkie

Join Date: Sep 2012

Location: va beach

Age: 28

Posts: 318

Trader Rating: (3)

Feedback Score: 3 reviews

|

K24-T hold the A

I'm finally ready to share this build now that able to get back to working on it come next month. Anyways, last year i decided to ditch my ~325whp KA24DE-T after blowing the rings off a stock block for the second time (too lazy to open up the ring gap) and upgrade to K24A2. At time the i didn't really have much going on other then Riding Unemployment. The auto shop i was working for fired me for enlisting. Illegal I know but the common wealth of VA is a "right to work state". So while waiting in DEP to go to Navy Boot Camp, all i did was work on this swap, sidework and replace the body on my fathers 73' spitfire. so i I parted out my KA-T and started getting ordering the first wave of parts.

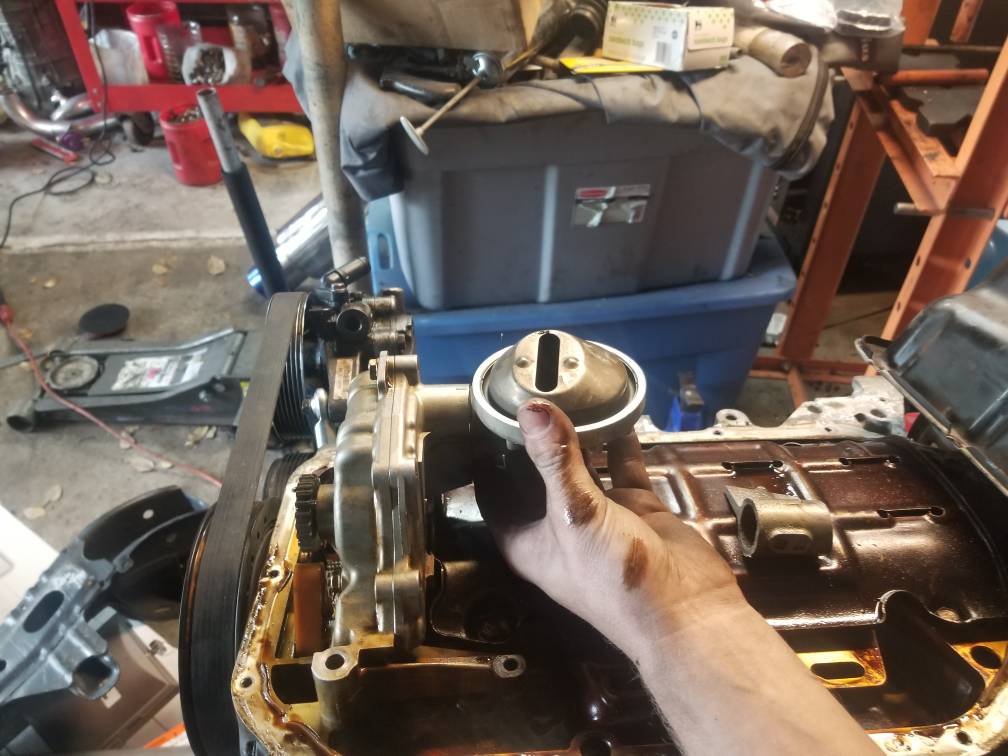

I started out with making the oil pan fit while I waited on the tranny adapter. fitting the oil pan and oil pump is a big placement problem as with how far back i wanted it, the pick up would be in the subframe. I cut and welded the pickup shorter to get it in about the same location as a KA/SR would be.     Sometime in the build I found the perfect turbo for 500$ to kick off this build, a Borg Warner S257SX-E twin scroll 1.0 A/R. Here it is next to a RB25DET NEO on the left and the T3/T04e off my KA-T in the middle.  Next came relocating the PS pump and finding a new way to tension the serp belt as the PS pump and tensioner would be in the way of the intake i wanted to run.  Mounted a S2000 radiator with S2000 silicone hoses. The radiator fill cap is a little tall for the 240, but I'm going to relocate the fill port later.  Did a Timing upgrade with a skunk2 tensioner, type-s oil pump, oil pump guides, timing chain gaurd, and the revised upper chain guide while installing a 45degree VTC gear. To get some more low end torque out of the Honda.  After getting all this sorted out, I moved on to wiring. As I still had not received my transmission adapter from Collins yet. So I began to do wiring for a Haltech 1500 in my final weeks before boot camp. I wish I could of keep my MS3X from the KA-T, but I wanted to use my J35 DBW TB i got from work a while back swapping out a Honda Pilot engine.  May 2018 With only a few days left before I leaving for an undetermined amount of time I pushed s13 outside, and set about locking up all my tools. November 2018 After finishing A school I got a chance to go home and take 14 days leave. A few weeks prior my tranny adapter kit finally came in, but collins never sent me the clutch. So I focused on getting the motor mounted and plumbed. I came home to this pile of boxes  Tranny fitted and dropped in to make mounts. Fit just as planned, although the valve cover sit a bit higher then when i was building the oil pan. I have a plan for later so I don't have an ugly ass hole in the hood.  My dad lending me a hand droping it in.    Mounts made using poly leaf spring bushings.   Once mounted I set about making the turbo manifold for the BW S257SX-E. Never making a turbo manifold before, this was a challenge, but atleast I already had a equal length manifold planned out using autodesk Inventor. using FSMs and pictures i mocked up a K24 in an S13 engine bay.   Mounting twin MVRs with dump pipes, the space on the passenger side is getting very cramped.   bumming 220v at a friends body shop to TIG weld the manifold, and new exhaust.    It was looking so close, but so many little things left to do.  ran out welding gas 4 days before i had to leave and airgas was closed cause of thanksgiving and black friday, so i focused on wiring and packing the garage back up. pulled the motor, set it down on a dolly and rolled the S13 back outside  And here we are now march 31st Ill be home back in VA, with orders a ship in Norfolk. I'll have almost 4 weeks to work on the car before I go on me first deployment. I don't know when I'll be back yet. Guessing late summer early fall tho as ill be joining in mid deployment. The very last of the parts have been ordered to finish the swap plus some extra goodies I've picked up while waiting. just recently ordered a walbro E85 450l and all the plumbing to convert to flex fuel. Also my clutch and flywheel came in back in January. Last edited by foreverdeath; 03-20-2019 at 04:25 PM.. |

|

|

|

| Sponsored Links |

|

|

#3 |

|

Zilvia Junkie

Join Date: Nov 2016

Location: Los Angeles

Age: 30

Posts: 489

Trader Rating: (3)

Feedback Score: 3 reviews

|

Nice start to the build thread man, good luck getting it finished . If I may ask tho, why did you choose to go with a k24 ?

Sent from my iPhone using Tapatalk |

|

|

|

|

|

#5 |

|

Premium Member

Join Date: Jun 2003

Location: torrance, ca

Age: 39

Posts: 12,407

Trader Rating: (129)

Feedback Score: 129 reviews

|

1: thank you for your service

2: this Is the first new build thread I've seen here in quite a while that actually has me stoked! looks like you're doing some rad shit! def keep us posted!!! |

|

|

|

|

|

#7 | ||

|

Zilvia Junkie

Join Date: Sep 2012

Location: va beach

Age: 28

Posts: 318

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

I wanted something different some thing challenging. yeah I could scrape up the cash to drop in an LS but everyone and their mother has done it now. one of the motors I've always wanted as a 13B or 20B but thats a bit to exotic and my pockets don't go that deep yet. But K24 fits the bill. As far a I know this will be the 5th one to be completed, the 3rd turbo K series, and the 1st to run a CD trans (I got collins first kit which explains all the delays). stone motorsport has their turbo k24 in ireland and TNTgarage in Austraila has a turbo K20. I've actully talked to the owner of the TNTgarage s13 on facebook and hes a cool dude. theres also the speed academy S14, and an s13 with a K20 that was up forsale in New Jersey last year. But I've always loved Hondas. I still miss my 91 DOHC ZC EF hatch. the K series is a great engine its much motor modern then any other 4cyl or 6cyl we drop into 240s. shit its still in production and I can go get replacement engines at picknpull for 250$ all day long. the stock block will hold 500whp with E85  or racegas. its been fairly costly to get it in but once its in its dirty cheap to fix just like an LS. or racegas. its been fairly costly to get it in but once its in its dirty cheap to fix just like an LS.Quote:

Thank you. There was a Kswap thread on here before? |

||

|

|

|

|

|

#8 |

|

Zilvia FREAK!

Join Date: Jan 2010

Location: SHOW ME WHAT YOU GOT

Posts: 1,115

Trader Rating: (1)

Feedback Score: 1 reviews

|

i believe he is referring to Max's car:

https://zilvia.net/f/showthread.php?t=532923 |

|

|

|

|

|

#9 | ||

|

Zilvia Addict

|

Quote:

Quote:

|

||

|

|

|

|

|

#10 | |

|

Zilvia Junkie

Join Date: Nov 2016

Location: Los Angeles

Age: 30

Posts: 489

Trader Rating: (3)

Feedback Score: 3 reviews

|

Yea man I’ve seen a few people interested in this swap, I can def understand the availability of the Motor as well as being able to hit 500whp and all the aftermarket parts available as well haha

What I don’t understand is why someone would want to go from a 2.4 to a 2.4 with so much customization to make it work. But hey at least you will have some variable valve timing and definitely have something different. Good luck man, will be following the progress Quote:

Sent from my iPhone using Tapatalk |

|

|

|

|

|

|

#12 | |

|

Post Whore!

Join Date: Mar 2007

Location: Sacramento, CA

Age: 32

Posts: 4,573

Trader Rating: (13)

Feedback Score: 13 reviews

|

tight! curious to see how you'll like it compared to the ka.

why did you decide to go with haltech instead of hondata or ktuner? Quote:

one day i'll stop getting distracted one day i'll stop getting distracted

__________________

|

|

|

|

|

|

|

#14 | |

|

Zilvia FREAK!

Join Date: Jan 2010

Location: SHOW ME WHAT YOU GOT

Posts: 1,115

Trader Rating: (1)

Feedback Score: 1 reviews

|

Quote:

i would much rather see these threads than a ls or a sr swap. its entertaining and refreshing to see something new. another cool thing about swaps like this is it encourages others to think outside the box. more options for the s chassis community is always better than less. |

|

|

|

|

|

|

#15 | |

|

Zilvia Junkie

Join Date: Nov 2016

Location: Los Angeles

Age: 30

Posts: 489

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

Oh no I completely understand what he meant. What I’m saying is, at least my way of thinking is, if ima swap something, and go through all the hassle, it’s going to be for more displacement. That’s just me tho, all the power to OP and others with the swaps they choose Sent from my iPhone using Tapatalk |

|

|

|

|

|

|

#16 | |

|

Zilvia Junkie

Join Date: Sep 2012

Location: va beach

Age: 28

Posts: 318

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

2.4 to 2.4 isnt a fair argument. The kseries is much more efficient of a motor. The max anyone has made out a NA KA other then the CORR trucks, is what 220 whp. OEM part combo K24s can make mid to high 200s whp and built motors have made 500hp at the crank. With that efficiency it's more comparable to 90s I6 or V6 even v8s of larger displacement. Sent from my SM-G960U using Tapatalk Last edited by foreverdeath; 03-14-2019 at 04:36 PM.. |

|

|

|

|

|

|

#17 | |

|

Zilvia Junkie

Join Date: Sep 2012

Location: va beach

Age: 28

Posts: 318

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

Sent from my SM-G960U using Tapatalk |

|

|

|

|

|

|

#23 |

|

Zilvia Junkie

Join Date: Sep 2012

Location: va beach

Age: 28

Posts: 318

Trader Rating: (3)

Feedback Score: 3 reviews

|

Thank you I cant wait to get back. This last 3 weeks on corry station has been killing me nothing to do in holding and almost all my friends have gone on to their new duty stations.

Do have some news tho. Today I sold my old 93 Dakota 3.9 2wd beater truck and got a 01 F250 7.3 superduty 4x4 crew cab. Now I can tow myself and my whole gang to summit raceway and Shenandoah. Next Tuesday I got a 1033 mile road trip to Norfolk stopping in TN. Gona be a much better ride on the way back.   Sent from my SM-G960U using Tapatalk Last edited by foreverdeath; 03-18-2019 at 05:05 PM.. |

|

|

|

|

|

#24 | |

|

Super Moderator

Join Date: Jun 2004

Location: SF Bay Area

Posts: 16,761

Trader Rating: (73)

Feedback Score: 73 reviews

|

Quote:

__________________

Best way to do business with me? Make your best offer FIRST. |

|

|

|

|

|

|

#26 |

|

Leaky Injector

|

This is awesome man.

I'm looking into doing this swap myself. Do you have any more pictures of how you modified the oil pickup? I have a different idea altogether but it would be a lot of work, so it's good to keep my options open! |

|

|

|

|

|

#27 |

|

Zilvia Junkie

Join Date: Sep 2012

Location: va beach

Age: 28

Posts: 318

Trader Rating: (3)

Feedback Score: 3 reviews

|

I just got home to Virginia last nite. Idk how you modify the pan different but you can try. Speed academy did less cutting by lowering and notching the front subframe but affect geometry. I notched the front subframe a little but not much cause my rack has been relocated

Sent from my SM-G960U using Tapatalk |

|

|

|

|

|

#28 |

|

Zilvia Junkie

Join Date: Sep 2012

Location: va beach

Age: 28

Posts: 318

Trader Rating: (3)

Feedback Score: 3 reviews

|

Opened up the garage today and looked over all the parts I've been piling up. Sorry I dont have many pictures I was mainly tryn to figure out if everything was there. At first the amount of boxs wasnt right but they were scattered around the house. I did mess up and forgot to order more AN10 hose for the remote oil filter setup I have. And the Canton remote filter adapter I got used for a deal was the wrong thread pitch.

I didnt spend to much time today cause I had to help a friend move and I was wiped out. I got the motor on the stand to get ready to fit bungs on the oil pan and move some coolant fittings around. Moved the wastegate coolant feed to the top of the rear coolant adapter for firewall clearance will pulling and installing the motor. And the coolant temp sensor for my innovative gauge to the thermostat housing, but I need to open the hole for the sensor as the 1/8 npt port is ressed and the sensor wont fit. Tommorrow I got check in on base and move into the barracks. But I'll try put some work in this weekend. Cant do any welding till next week tho cause I didnt get a chance to refill my argon bottle today.     Sent from my SM-G960U using Tapatalk |

|

|

|

|

|

#29 |

|

Zilvia Junkie

Join Date: Sep 2012

Location: va beach

Age: 28

Posts: 318

Trader Rating: (3)

Feedback Score: 3 reviews

|

Did a good bit of plumbing work today. But first here's all the extra bits I acquired while in Florida to add to the build. Got a walbro E85 450lph pump, turbo speed sensor for my borgwarner, parts to remote mount the oil filter, and a fuel pump controller out of a range rover. This fuel pump controller is the same module out of Aston Martins with supercharged V8s and handles big single fuel pumps. NZEFI has tested this unit up to 18amps continuous load and it takes a simple 100hz PWM signal from a standalone ECU. They sell this unit with a bracket for over 300$ but I got mine on ebay for 60$ with the pigtail.

Started off with the fuel lines, fuel filter and flex fuel sensor. Riv-nutted the fuel filter to base of the shock tower. I didn't spring for the PTFE hoses as want to later rerun the hard lines down the drivers side away from the exhaust with -8 feed and -6 return. Later I'll add a heat shield to the passenger rear side of the engine bay to protect the fuel lines and body harness.  Next I moved to the oil system. Mount up the remote oil filter to the frame rail to make more room around the exhaust manifold. Haven't started running lines as I'm still waiting to get into contact will Canton racing about ordering just a the banjo bolt so I can use mount the adapter.  Originally I wanted to run -10 for the crankcase scavenger with a fitting made for these motors. But, flipping the Skunk2 Ultra intake doesn't allow for it. So I used some left over -6 from the old fuel system which just barely clears the intake, alternator and alternator cable. This will work till later modify a pre 09 water housing to fit a post 09 alternator. Which I can mount with a turnbuckle, making belt tightening much easier then squeezing a turnbuckle behind the water pump pulley to move the power steering pump.  Also started some welding prep. Fitted up the fitting for the wastegate coolant feed by cutting a S2000 oil cooler barb fitting for a -4 bung.  Hopefully tomorrow I get out of class early enough to refill my argon bottle and start finishing up the oil pan. |

|

|

|

|

|

#30 |

|

Zilvia Junkie

Join Date: Sep 2012

Location: va beach

Age: 28

Posts: 318

Trader Rating: (3)

Feedback Score: 3 reviews

|

New class schedule gives me a good bit of time to work on the project in the afternoons. Today I got cracking on finishing the oil pan. added bungs for the turbo drain, temp sensor and a -6 for oil drain. Used some hinges and 16ga to make the baffles for the pan. At this point only 2 more things are holding me up from putting the motor in for the last time. Hammering the transmission tunnel on the drivers side of the tranny bracket on the body to clear the CD009 and final welding of the motor mounts on the subframe.

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|