|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| S Chassis Technical discussion related to the S Chassis such as the S12, S13, S14, and S15. |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Zilvia Junkie

Join Date: Sep 2012

Location: va beach

Age: 28

Posts: 318

Trader Rating: (3)

Feedback Score: 3 reviews

|

350z Diff and Axle swap info

With the increasing popularity of the a newer Z/G chassis diff swaps into 240s I like to share some knowledge and clear up a common misconception. Threw out this article I will only refer to the 240sx differential as the R200, even though the 350z differential is also a R200. First I'd like to explain all differences between these types of diff you will see if you order or pull complete diffs for the ring and pinion.

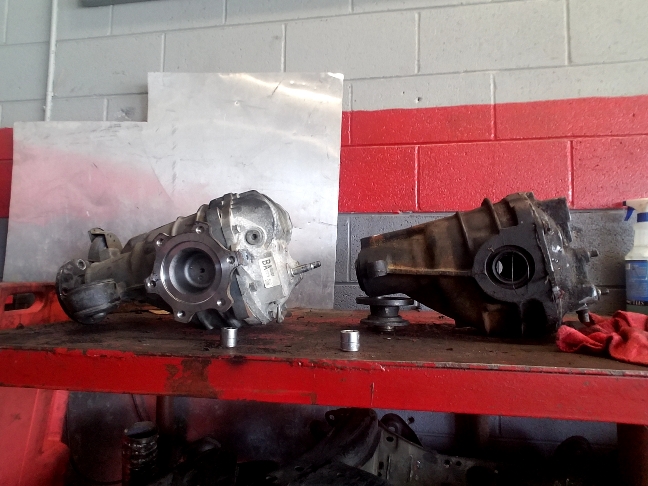

INPUT FLANGES All flanges can be swapped, although using an auto gear set will have a pin that requires removal for any other driveshaft configuration. They are all interchange able provided you may need to knock off the dust ring. While fitting a Z/G flange to an AWD FX35 differential I had to knock it off as the Z/G had a larger OD. Z/G 2WD flange: This flange is simaler to the 240sx diff flange in that in has a negative center bore for the driveshaft of the same diameter. Now the bolt pattern does differ it is larger possibly the same as the Q45 driveshaft pattern and uses larger M12 bolts. This is the flange you want to use you must ether redrill the flange or swap the driveshaft flange. If you don't want to drill your flange you can use a spicer 2-2-2029 on an aftermarket driveshaft with 1310 joints.  AWD flange: A 6 bolt cup for a using a RZEPPA style joint which is becoming more common on modern cars Truck flange: This flange comes on the R51 Pathfinder and Frontier(solid axle). Is it much larger then the 240sx r200 or even the Z/G flange. It has a positive centering step making it not usable for us with out a custom driveshaft or flange/yoke swap.  Auto Flange: This auto G35/G37 flange is a 3 bolt setup meant to use one of those flex donuts, have an extended pin on them the front on the pinion to center the driveshaft. OUTPUT FLANGES Their are only two types of output stubs on the IRS setups for these diffs. First there is the typical 6x1 which will work with the Z32 non-TT, Z32TT, Q45 and GTR axles. Early models have threw hole bolting while later G37/Z34 are threaded. Then there is the much larger R51 6x1 which is also thread. No clue why these are massive but R51 axles are thiccck. All of these output flanges also have a 48 tooth ABS ring perfect for speed pickup when using CD00x transmission. R51 differential next to a bare R200  AXLES Z33 and pre 07 G35 axles are the ones you want to use, as they will fit our standard hubs. The G37 and Z34 axles while stronger, using the larger Z32 TT/GTR output spline, are also 10mm longer. With modified output stubs this would be a cheap and easily obtainable axle upgrade vs the Q45/Z32 TT combo. They also use a threw bolt instead of the output having a male thread. According to Z1 motorsports the 07-08 G35, they are the same but use the normal nut on the output end. R51 Pathfinder axles are out of the question due to length. Fitment and managing length will be discussed later. comparing the output spline: top z33/G35, bottom Z34/G37  UPDATE: pulled a 07 g35x axle whiel getting a replacement g35 axle and confirmed 07-08 axles are same as G37 and Z34. but they have a regular threaded output end. also found output spline to be 32 spline same a Z32 TT and GTR. REAR COVERS There are 2 types of diff covers single stud and dual stud. Dual stud covers come on the R51 Pathfinder (capacity check) some are smooth and some have large cooling fins equivalent to the Nismo Z/G cover with out fins hanging below the bottom of the diff. Rear spacing on the these covers is a bit more narrow then the 240sx varity, requiring both the front a rear mounting points on 240sx subframes to be modified for fitment with special bushings. The Greddy Extended diff cover also features dual rear studs don't know if the spacing is the same.   Every other OEM diff cover is single stud and lacks cooling fins. There are many aftermarket covers adding capacity and cooling to include NISMO (no extra capacity for nismo). A common problem with the these diffs in higher power cars is that the single stud break. This is caused by the flex in the OEM rubber bushings allowing these diffs to move a lot under load. Aftermarket poly or solid bushings solve this issue. CARRIERS Nissan did something kind of weird with these differential and choose 2 different offsets for the ring and pinions in this diff. And the deciding factor with offset you need or the differential with have is the final drive or R&P. 3.357 and lower is the thick ring gear or as many refer to the auto carrier. 3.538 and up is the thin or manual carrier. Both can be factory VLSD depending on the vehicle and options. Output shafts for all open diffs are interchangeable, like wise with VLSD output shafts. When ordering an aftermarket LSD for a particular gear set can be tricky as they don't list whether they are meant for a thick or thin ring gear, they'll list what model and trim what differential fits. FINAL DRIVE RATIOS I'm not going list every where you can find a particular gear set as the Frontier comes pretty much any ratio (not the 3.538 weird) if you juggle around the year, engine, drive train and trim levels. I'll just list the most common spots to get it. All of this Info was pulled from the FSMs, along with a nice chart from Z1 motorsports going over the Z/G Chassis Ratios 2.937 06 Q45, 05+ Frontier VK KING CAB, 05-15 Xterra 3.133 03-04 M, 03-05 Q45, 07-13 EX, 05-07 Pathfinder 2WD, 05-15 Xterra 3.357 06-08 M VK, FX 2WD, 05-07 Pathfinder 4WD, 05-08 Xterra, Frontier 4WD 3.538 06-08 M VQ 3.692 06-08 M AWD VQ, FX AWD, 05+ Frontier QR A/T 3.916 2009+ Frontier QR A/T 4.083 2005+ Frontier QR M/T 4.363 2009+ Frontier QR M/T SV or QR M/T optional For those running a CD00x transmission conversion on a SR/KA or really any USDM 240sx, the 3.692 aligns 1-5 with OEM the 5spd and 4.08, accounting for the smaller tires on the 240sx. Installing Theres 2 things to overcome when wanting to install a ether a 350Z differential and axles. Mounting the differential is one of the more interesting challenges on one hand you can use aftermarket bushings to mount then in a S14 subframe, the other modify a S13/S14 subframe. Using offset bushings in the S14 subframe mounts the differential ~2? lower then the factory R200 mounting. This increases driveshaft and axles angles which increases joint stress and drivetrain drag. Another option is to modify a S14 or S13 subframe. Modifying a S14 subframe is much easier then a S13 due to the taller arch where the differential mounts and already having rear stud lined up. If using the R51 or Greddy cover the second stud does not line up with the other hole as the spacing is more narrow. When modifing a S13 subframe arch where the front of the differential mounts must be cut out as it nears the edge once cut. Area to cut on a S13 subframe   Finished S13 350Z differential with R51 cover subframe  S14 subframe modified for 350z differential S14 subframe with conversion bushings. In the second photo you can see how much lower the differential is then the subframe   AXLE FITMENT Fitting these axles into a 240sx subframe can be a challenge due to their increased length. With a longer compressed lentgh and 1/2? wider differential, we are trying to squeeze a 1-7/8? wider axles assembly into our cars. Good news is from the factory the stock axles have a good bit off plunge, and when lowered we need longer axles. Bad news is being low and running 0 camber is not quite enough and axles will bust the inner joints at full droop. S13 left - 23" compressed, 25" relaxed S14 left - 23" compressed, 25" relaxed 350Z left - 23-7/8" compressed, 24-3/4" relaxed S13 right - 25" compressed, 26-1/2" relaxed S14 right - 25" compressed, 26-1/2" relaxed 350Z right - 25-1/2" compressed, 26-3/8" relaxed Plunge is checked by removing the coilover and axle nut with the car on jacks. Then seeing how much freeplay, or how far you can push outer axles spline in through out the suspensions operating range. The tighest spot is going to be droop or the lowest point of suspension travel A couple of solutions exist: shortening the output stub, spacing out the wheel hub, and extending the rear LCAs. The simplest way to make the axles fit is to space out the rear wheel bearings. This can be achived by making a spacer or buying a dual rear caliper kit that bolts behind the hub bearing. They all vary in spacing and caliper rotor options and will space out your hub 6-12mm. GKTechs kits is good option with a spacing of 7mm, while allowing you to use OEM rotors and keep the Z/R chassis parking brake.  Running Extended LCAs gives more room for the longer axles while providing suspension performance benefits. GKTech makes rear LCAs that are adjustable from -15m to +15mm width. Im currently in the process of doing my swap with a S13 subframe and with +9mm I'm seeing 4mm of plunge at full droop. This was at stock width no point at installing the other arms as the knuckle would not square up  Additionally the output stubs can be shortened. By having a machine shop shorten them then welding. If you just looking to run Z33 axle this is an easy route as a few companys offer modified stubs.  Last edited by foreverdeath; 04-12-2020 at 04:43 PM.. Reason: Update |

|

|

|

| Sponsored Links |

|

|

#5 |

|

Join Date: Apr 2019

Location: Hazel green alabama

Age: 30

Posts: 5

Trader Rating: (0)

Feedback Score: 0 reviews

|

They are the same six bolt patterns I have a s13 with a auto 350Z diff and axles you do not have to space the wheel bearings out if you use the 350Z diff as wellthe flange two flange difference between the s13 diff and the 350z diff allows the 350Z diff to work with no issues with stock 350Z axles have been running this setup at over 700 horsepower for over 2 years

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|