|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| S Chassis Technical discussion related to the S Chassis such as the S12, S13, S14, and S15. |

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,649

Trader Rating: (17)

Feedback Score: 17 reviews

|

differential flange "falling out" of rear end

I put a 3.69 ratio differential from Q45 into my nissan 240sx s14. After approx 100 miles, the front of it started falling out. It started as more and more slack in the drivetrain. then I took out the differential and I can pull the flange out about an inch.

I am not sure how to even start fixing this... the previous owner put a 240sx flange into it and took out the q45 flange. so i assume this is what failed. I dont know what parts are involved to even try this |

|

|

|

| Sponsored Links |

|

|

#2 |

|

Zilvia FREAK!

Join Date: Jun 2010

Location: North Dakota

Age: 30

Posts: 1,066

Trader Rating: (4)

Feedback Score: 4 reviews

|

I'm assuming you're talking about the pinion nut/driveshaft plate? I'd figure the pinion gear is shot but you never know. Pull the cover and have a look. The pinion nut is a crushed nut and should be replaced after removing and the PO probably used the same nut.

That being said I have seen guys reuse the nut with locktight and had great success.

__________________

|

|

|

|

|

|

#3 |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,649

Trader Rating: (17)

Feedback Score: 17 reviews

|

So I have to go in through the rear, to get to the front? You make it sounds pretty easy...

So i just goto nissan parts and buy a "pinion nut" and crush it on is best case scenario? (I usually go for worst though) |

|

|

|

|

|

#4 | |

|

Zilvia FREAK!

Join Date: Jun 2010

Location: North Dakota

Age: 30

Posts: 1,066

Trader Rating: (4)

Feedback Score: 4 reviews

|

Quote:

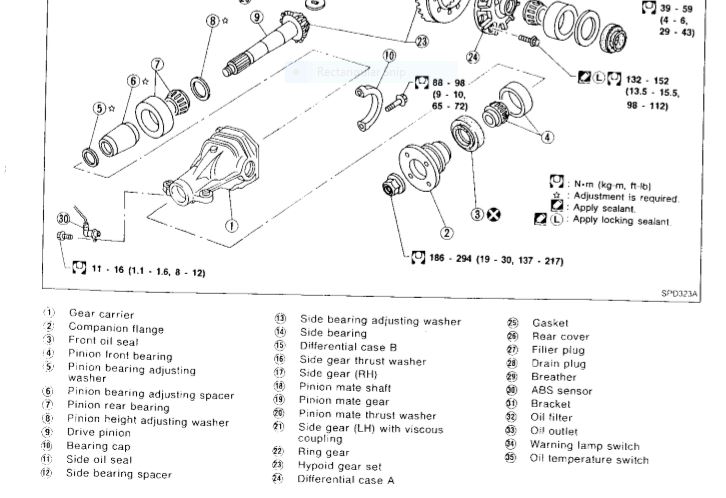

It shows a pinion adjuster on that diagram but i'm nut sure if its a crush sleeve. I, myself have never pulled the pinion gear out so I can't say. I would think it would be described as a crush sleeve but i'm not sure.

__________________

|

|

|

|

|

|

|

#5 |

|

Zilvia Addict

|

__________________

|

|

|

|

|

|

#6 |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,649

Trader Rating: (17)

Feedback Score: 17 reviews

|

thanks, I took it to a friend (with big tools) and he says that number 2 should pull right out of it when you take off the nut in front of it. We took off the nut but #2 is stuck in the diff. The oil plug has a LOT of metal on it also. Something went turribly wrong with this diff....

|

|

|

|

|

|

#7 |

|

Zilvia Member

|

its common for the front flange to be 'stuck on' you want to use a puller to pull if off, or smack it with a soft hammer.

I bet who ever swapped the flange over wound the new one on with an impact gun till it went tight (2 ugga dugga's on the gun) which has ruined the crush washer #6 in your picture. I cant recall the exact terminology but you set the amount of crownwheel and pinion contact/how it contacts by tightening on the crush washer to crush it till its in spec. I cant remember on these diffs if you can resuse the washer (straighten it out in the vice/press) on say an AE86 axle you would set it up with the crush washer then strip it out and machine a solid one then rebuild. if you didn't want it to go noisy again. be a nice little project for you. im sure it says how to do it in the workshop manual. probably need some engineers blue. try not to ruin the seals as they cost loads. heating the flange so it expands makes them easier to get on and off. |

|

|

|

|

|

#8 |

|

Nissanaholic!

|

I found specs for rebuilding the diff on google a long time ago when I put my 2 way in...ill try to remember to look at it when I get home and update this I think It was on there...

|

|

|

|

|

|

#9 |

|

Nissanaholic!

Join Date: Feb 2012

Location: Oxnard, CA

Age: 28

Posts: 1,876

Trader Rating: (31)

Feedback Score: 31 reviews

|

The pinion height adjusting washer is not a crush washer, it's meant to space out the pinion gear to the ring gear, along with the shims on the sides of the diff itself, known as backlash adjustment. You can get different thickness washers depending on your measurements. When said you put a 3.69 diff, you swapped the pinion in too right? You can't just swap the ring gear itself, the gear and pinion are matched to each other, not to mention wear in together as well. You could take a 4.08 ring and attach it to a different 4.08 pinion and it will most likely fail. Setting backlash is not the easiest thing to do. I'm just asking as it seems like the pinion wasn't also swapped since you're saying the input flange is stuck.

Sent from my SM-G955U using Tapatalk |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|