|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

#2401 |

|

Zilvia Addict

Join Date: Oct 2006

Location: barrie, ontario, canada

Age: 35

Posts: 997

Trader Rating: (0)

Feedback Score: 0 reviews

|

Slow down a little on your deposition rate. The "dimes" should be tighter.

You can see on the merge collector. There are little eyelets (tiny tiny little pin holes). They're fully sealed, but they will be more prone to cracking. Especially under a 10 or 9 second scenario. Just slow down a bit and add the filler more often. But it still looks good! Keep it up! |

|

|

|

| Sponsored Links |

|

|

#2405 |

|

Nissanaholic!

Join Date: Dec 2008

Location: Upstate NY

Age: 41

Posts: 1,700

Trader Rating: (15)

Feedback Score: 15 reviews

|

Good question, never really thought about that. Although the stock rear balljoint and S14 front spindles are so close to the 7° taper that it didnt take much effort to get them reamed.

|

|

|

|

|

|

#2406 |

|

LAID OUT

Join Date: Mar 2004

Location: LAS VEGAS

Age: 39

Posts: 2,015

Trader Rating: (1)

Feedback Score: 1 reviews

|

Picked up a pair of used Power MIG 215s. Also signed the lease to our 3200sf shop space.. I should have some better contributions to this thread soon. Need to make a materials rack, and a tire/wheel rack and quite a few equipment stands for grinders, bender, etc. Stoked! |

|

|

|

|

|

#2408 | |

|

Nissanaholic!

|

Quote:

|

|

|

|

|

|

|

#2409 |

|

LAID OUT

Join Date: Mar 2004

Location: LAS VEGAS

Age: 39

Posts: 2,015

Trader Rating: (1)

Feedback Score: 1 reviews

|

Thanks fellas. I setup one of the machines and ran some beads on some 1/8 mild square tubing. I was impressed by the power! The PM seems to have a bigger issue with burnback than I have ever had with my MM140. When I look at the gun/cup head on, the mig tip is not in the direct center, it's offset to one side. I might end up replacing the gun + hose + cup assembly and putting the old stuff on the other box. I can rotate the cup a little to re-align it to center but it doesn't stay there long.. Everything I have read says the PM215 is a great machine, a lot of guys seem really happy with them. First Lincoln I have used, my MIG and TIG are miller which I am extremely impressed with...

Either of you guys using a PM215? I was using Voltage "D" and WFS of 200-300, think I settled around 275... The chart on the box says D/240 for 1/8 mild with .035, I started there and fine tuned until it performed how I wanted.. Just adjusted based on sound and bead profile. I also picked up a 5x10 welding table out of 4x4 stock, a 3x5x3 welding table, a 3x5x4 materials cart, a 10 foot chop saw table and chop saw, about a ton (literally) of raw materials, the 2 PM215s, a 4" grinder (can't have too many of those), a small rolling compressor and some other random tables, chairs etc. We pretty much bought out this welding shops equipment and materials... Good thing the lease went thru on the new unit or else I would have nowhere to store all these goodies hahaha |

|

|

|

|

|

#2411 |

|

Zilvia Member

Join Date: Sep 2006

Location: savannah, ga

Age: 41

Posts: 204

Trader Rating: (17)

Feedback Score: 17 reviews

|

well I know most of the stuff on here is welding, so I'll start with a downpipe I made a couple years ago for my s13 KA with a topmount setup. I just went to a muffler shop and picked up some scrap stuff with various bends and cut them and pieced it together to make it fit. Just mig'd it together....not great or pretty, but it fit well and worked great. Someone stole it from my house (along with my turbo and manifold) when my shell was sitting around, so if you've seen it or have it.....I really want it back....

Next is some fiberglass stuff I've done, a lip I made over the past few weeks and a spare radio din I turned into a gauge pod. For the lip, I made a mold from some foam board using the bottom of the bumper cover to mark an outline, laid it up with a few layers of glass and resin. Then added some evercoat fibertech for strength, finished with some polytech putty and rattlecan paint. All in all.....it cost more and took more time than I thought, but doesn't everything.        gauge din    |

|

|

|

|

|

#2414 |

|

Post Whore!

Join Date: Dec 2002

Location: Campbell, Ca

Age: 38

Posts: 5,010

Trader Rating: (3)

Feedback Score: 3 reviews

|

Hi guys and gals. Sorry I haven't been posting much. I have been working 20 hour days building a new Camaro for Sema, and driver Conrad Grunewald for Formula D.

We won the coveted GM Design award for Best High Performance Product of SEMA 2009. Pretty excited!

__________________

|

|

|

|

|

|

#2416 | |

|

Zilvia Junkie

|

Quote:

I want to configure my fmic the same way and do the work myself, just want to get a basic idea before I take down my car and start wrenching. what needs to be cut? welded? piping fitment? intercooler size? |

|

|

|

|

|

|

#2417 |

|

Leaky Injector

Join Date: Feb 2009

Location: IRELAND

Age: 35

Posts: 145

Trader Rating: (0)

Feedback Score: 0 reviews

|

This is the full cage i fabricated for our Time Attack CRX race car for next season, its a 11point custom mandrell bent cage, to TA regs. we went for

minimum metal but maximum protection. its defnitly the tightest and best fitting cage ive built to date.

__________________

"Racing is life. Everything else that happens before or after is just waiting." ~Steve McQueen [Le Mans -1970] |

|

|

|

|

|

#2420 | |

|

Post Whore!

|

Quote:

In an event like drifting (or just about any racing), water-to-air is much more efficient way to cool the intake charge than air-to-air. When you add a huge heat exchanger and some airflow to the water, it gets even better. As far as being in the trunk, it's the only place left lol. The car looks stunning in person, I'm lucky to have been a part of it - Luke and Conrad did a fantastic job, and deserve the Best Race Car award! I'll have go get my finished wiring pics up in this thread

__________________

Jordan Innovations has a new web site! www.JordanInnovations.com -- All your favorite FD Pro Drifters love it, trust me -- www.JordanInnovations.com |

|

|

|

|

|

|

#2421 | |

|

Zilvia FREAK!

|

Quote:

compared to the BS roll center adjusters out there, doing what you've done is wayyyyyyy cheaper. also, i FINALLY have something to contribute but didn't take pics yet.. i made my own nismo power brace for my S13. i'll post pics tonight or tomorrow. |

|

|

|

|

|

|

#2422 |

|

Zilvia FREAK!

|

hey nismo014, theres really not all that much to it.

he took the IC and flipped it upside down, and put it in the core support right in front of the radiator. the only custom fab work, is the mounting tabs, and for the piping. just have to either fab it up so the inlet/outlet are going straight back towards the motor, or if u can find a way to rig it with 90 degree couplers. that camero is SICK BTW!!!!!!!!!!!!!!!

__________________

cONtRol FReAkS |

|

|

|

|

|

#2424 | |

|

Zilvia FREAK!

Join Date: May 2003

Location: Augusta, GA

Age: 39

Posts: 1,204

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

How to do it: POWERED BY MAX: Forumsãâ¬â¬Ã£Æâ¢Ã£â©ãƼãÆ©ãÆ* / ãÆâãƼãÆâãâ·ãƧãÆâMAXãÆâ ãÆ*ãÆâ¬Ã£â¯ãÆËãÆâ¢Ã£â©ãƼãÆ ©Ã£Æ*Parts Shop MAX Products Forum / HMIC High Mount InterCooler with short pipe kit *update p.3* |

|

|

|

|

|

|

#2425 |

|

Zilvia Junkie

Join Date: Jan 2005

Location: gloucester, VA

Age: 42

Posts: 517

Trader Rating: (6)

Feedback Score: 6 reviews

|

My first cage build. This car will be getting a lot of work from me.

This car belongs to wishihadasilvia on here and is rocking a set of fortune 500 coilovers. On to the cage. I bought a mitler brothers bender a while back and a miller 211 mig to be able to build my own cages.      I still have to add a few more things to it. We are using the NASA and Formula d rule books to keep it within spec.

__________________

1994 FD3S Drift // 945garage //  sumospeed.com sumospeed.com

|

|

|

|

|

|

#2426 |

|

Zilvia Junkie

|

Quote:

|

|

|

|

|

|

#2427 |

|

Zilvia Junkie

Join Date: Nov 2006

Location: Sacramento California

Posts: 360

Trader Rating: (8)

Feedback Score: 8 reviews

|

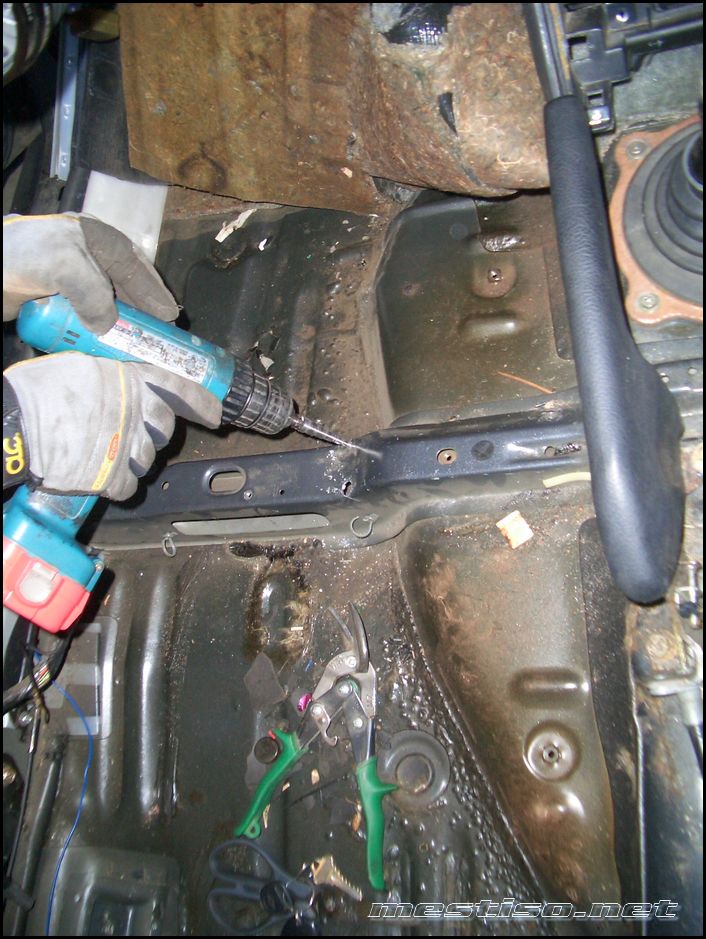

Ok I guess it's time to throw a few pics of my car in here.

Jonnie Fraz did all of this work for me, we lowered my seat and made a harness bar for this Sunday's Thunderhill track day. This is just the latest work that Jonnie has done to my car, there is a lot more in my build thread. Removing the stock seat mount.  Then we used a plasma cutter to slice the cat hump, next was a hammer to knock it down til it was just above the exhaust.   New seat mount partially finished.   Front seat mount all finished and the cat hump welded back together.  Then he made a fixed mount bracket for the seat so I could get the lowest seating position possible.   Just to give you an idea of what my seating position is now... I am 6'7", 285lbs and now I have about 6 inches of room above my head. My head actually touched the roof prior to this.  I got rid of my auto belts finally so Jon made me a harness bar, hopefully soon we can get a bender so we can cage the car.   |

|

|

|

|

|

#2428 |

|

Zilvia Junkie

Join Date: Sep 2006

Location: culpeper/richmond

Posts: 370

Trader Rating: (10)

Feedback Score: 10 reviews

|

I love this thread, keep up the good work guys.

Heres my contribution: After last event it blistered the tires from rubbing the inner fenders and around, on the 9J with a 215: And I wanted to run much larger tires and wheels and go lower than that. SO, while the motor was out I went and tubbed it, 16 gauge, about $30 in sheet metal. Near end result: The ends tuck in for the IC pipes. NEXT, was the oil cooler I picked up for cheap by Yamato Garage. But because it was large it wouldnt fit quite where I hoped up front where the stock fogs go. And I didnt want to bury it inbetween the rad and front mount because of over heating and I still have AC so I didnt want to stack four coolers on top of each other and suffer down the road. My front mount is way too large but I couldnt afford to buy anything new and the one piece custom IC piping was to hard to part with. Because of that it used to look like this with cut bumper support, pretty weak. So in attempt to do the two birds with one stone thing I made a bash bar with some seamless tubing that was lying around the shop. I had to rewire the blinkers up front to my body lights beside the headlights to pass inspection and this, athough ugly, gives lots of function by direct air from where the blinkers once were to the cooler. I used the stock mounts so it can be bolted on and off, and can still go back to stock if I ever want. This last week I also went to the junkyard and happened to stumble across a Mistu Montero SUV with a lovley PS cooler, so I yanked it for nine bucks and its going on the otherside of the front mount once I make some brackets. All major final welding is done by my brother, I just make it and tack it together. The car should leave the shop this week if I get all the little things worked out next weekend. Sorry for the long, mistake filled post.

__________________

http://buildmakecreate.tumblr.com/ |

|

|

|

|

|

#2430 |

|

Zilvia Junkie

|

dude wow your tubs look really good and amazing job with lowering the seat too!

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|