|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

#2431 |

|

Post Whore!

|

Finally got some work done on the JefeS14 today... started with a XS Power (SS Auto Chrome) RB25 turbo elbow that hit the steering column hardcore. Sectioned it, and was able to get it welded back up nicely with my trusty wire-feed. I was really worried I wouldn't be able to weld up the stainless with the flux-core, but it worked nicely, minus the mess.

Sectioned  Tacked   Testing clearance, bingo!  Welded up - not bad!   Nice and even penetration!  Was way easier to weld than I thought. Next step is chopping the flange, welding in a couple mild steel pie cuts, the mild steel flex section, and then the wastegate tube with it's flex section. Anyone see any problems welding mild to stainless with flux core?

__________________

Jordan Innovations has a new web site! www.JordanInnovations.com -- All your favorite FD Pro Drifters love it, trust me -- www.JordanInnovations.com |

|

|

|

| Sponsored Links |

|

|

#2433 |

|

Zilvia Junkie

|

wow does it fit that close to the steering colum cause of where the rb motor sits in the S14? i have a rb turbo that i plan on using for my ka and after looking at your picture i am kinda scared. think i might run into that issue?

|

|

|

|

|

|

#2435 | |

|

Post Whore!

|

Quote:

The other option to clear it is to find a non-divorced elbow and just weld in a couple inches of 3" tubing, to bring the exit closer to the firewall ~ that's how the Syko elbows were, and they cleared the LHD steering column. It would all depend on your manifold placement in the end though.

__________________

Jordan Innovations has a new web site! www.JordanInnovations.com -- All your favorite FD Pro Drifters love it, trust me -- www.JordanInnovations.com |

|

|

|

|

|

|

#2437 |

|

Post Whore!

|

Fuck, that's what I'm afraid of lol - it looked so good and sturdy though!

Good thing it's all temporary, just has to last until I take it up there for twin-scroll action!

__________________

Jordan Innovations has a new web site! www.JordanInnovations.com -- All your favorite FD Pro Drifters love it, trust me -- www.JordanInnovations.com |

|

|

|

|

|

#2439 |

|

Premium Member

Join Date: Jan 2005

Location: Cali

Age: 53

Posts: 1,371

Trader Rating: (29)

Feedback Score: 29 reviews

|

Thanks! Luke got to sit in it on Sunday....He looked like a little kid behind the wheel...lol. Seriously I sat in his seat and there is a foot of clearance between my head and the roof.

|

|

|

|

|

|

#2441 | |

|

Post Whore!

|

Lol this isnt one of my crazy schemes, there's actually a decent amount of text online saying that for automotive applications (no pressure), flux core is alright for welding stainless to mild steel. If it made a huge difference, I'd go buy a bottle of 70/30 and use my MIG wire, but I've heard that it doesn't.

Quote:

Hopefully only a month or so. Hopefully only a month or so.

__________________

Jordan Innovations has a new web site! www.JordanInnovations.com -- All your favorite FD Pro Drifters love it, trust me -- www.JordanInnovations.com |

|

|

|

|

|

|

#2445 | |

|

Post Whore!

|

Quote:

What's the consensus on grabbing a bottle of 70/30 and using my MIG wire? Better than flux core?

__________________

Jordan Innovations has a new web site! www.JordanInnovations.com -- All your favorite FD Pro Drifters love it, trust me -- www.JordanInnovations.com |

|

|

|

|

|

|

#2446 |

|

Post Whore!

Join Date: Dec 2002

Location: Campbell, Ca

Age: 38

Posts: 5,010

Trader Rating: (3)

Feedback Score: 3 reviews

|

Shielded will almost always be better than fluxcore. Fluxcore is better in outdoor applications where your shielding gas would get blown away by the wind.

If you used shielded setup with stainless wire then it should work. The problem with mig welding stainless (and 4130) is that you will tend to put too much heat into the metal and it will result in cracking. Stainless develops a condition called sugaring. If you look at the picture you posted of your penetration, all those weld marks inside the pipe are all considered to be sugaring. One way of telling is by looking at it closely. If it looks hella pourous then you have likely sugared the work piece.

__________________

|

|

|

|

|

|

#2447 | |

|

Post Whore!

|

Quote:

Thoughts?

__________________

Jordan Innovations has a new web site! www.JordanInnovations.com -- All your favorite FD Pro Drifters love it, trust me -- www.JordanInnovations.com |

|

|

|

|

|

|

#2448 |

|

Leaky Injector

|

You will probably be ok on that weld but I would put in a flex pipe for sure. I have fluxed and mig'ed 304ss to mild and ss to ss with mixed but generally acceptable results. TIG is prefered and is necessary on headers or manifolds but for exhaust flux or mig will often work. If you use flux or mild wire you will also get rust on the joint over time where as ss filler will keep the whole deal shiny as the alloy is pure throughout. To prevent sugaring you need less heat and you should backpurge all SS joints when possible. You can make a simple rig to do this by using small foam balls and a hose. Just jam the foam balls into the two ends of the pipe (away from the joint lol) and stick a rubber hose in alongside one ball, hook the other end to a tee and hook the tee inline with the gas line on you regulator. The gas flows behind the joint, stays between the balls for the most part and keeps oxygen from contaminating the reverse side of the weld.

|

|

|

|

|

|

#2449 |

|

Post Whore!

Join Date: Apr 2007

Location: Covina

Age: 33

Posts: 2,844

Trader Rating: (8)

Feedback Score: 8 reviews

|

Question about welders. I'm looking into buying myself a TIG machine and for the price I cannot afford the dynasty series welders, so I was looking at getting a Diversion 165 which are about 1200$ or a Syncrowave 180SD used. Reading up on the reviews the Diversion seems to be a legit TIG but what are your opinions between choosing one or the other. I realize the Diversion is lighter and more compact but I would still have to purchase the tank and regulator.

The syncrowave I'm looking at comes with the foot pedal,torch, ground, tank, and cart for 1400$ |

|

|

|

|

|

#2450 |

|

Leaky Injector

|

Go for the syncrowave. That price is killer with a pedal and bottle. You really want a pedal IMHO I can't control heat worth shit with the finger control although it works well for welding upside down. If you really need that though just have a friend work the pedal while you lay down, crude but works. For upright welding the pedal is boss.

|

|

|

|

|

|

#2451 | |

|

Zilvia Addict

|

Quote:

|

|

|

|

|

|

|

#2453 |

|

Zilvia Addict

|

I forgot to mention that I mig'd that not tig'd

|

|

|

|

|

|

#2454 |

|

LAID OUT

Join Date: Mar 2004

Location: LAS VEGAS

Age: 39

Posts: 2,015

Trader Rating: (1)

Feedback Score: 1 reviews

|

You might want to look for a Sync 250 or at least a Sync 200 for around the same price. You'll have more amps and can weld thicker material. But they are all good machines.

|

|

|

|

|

|

#2455 |

|

LAID OUT

Join Date: Mar 2004

Location: LAS VEGAS

Age: 39

Posts: 2,015

Trader Rating: (1)

Feedback Score: 1 reviews

|

Got my little collection of welders moved to the new shop:

^ PM215, PM215, Syncrowave 200, Millermatic 140 Ran a couple beads on the new PowerMIG 215 on a bracket for a window cage:  I really like the PM215 so far compared to my MM..  ^ Also bought an upgrade Bernard Q-Gun for the PM, with a 15 lead, new liner, centerfire tip. And scored a Tweco copper ground clamp... Everybody loves upgradings! Anyone else using one of these Bernard guns? |

|

|

|

|

|

#2457 |

|

Zilvia Junkie

Join Date: Jan 2005

Location: gloucester, VA

Age: 42

Posts: 517

Trader Rating: (6)

Feedback Score: 6 reviews

|

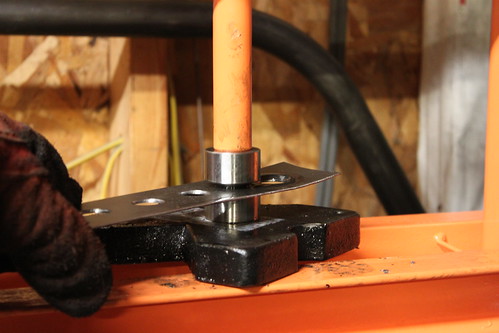

Drill press on special from Harbor freight $59  Harbor freight hydraulic press $129 Ebay 4140 .75 dimple die $40   = Dope Status Dimples

__________________

1994 FD3S Drift // 945garage //  sumospeed.com sumospeed.com

|

|

|

|

|

|

#2459 |

|

Zilvia Junkie

Join Date: Jan 2005

Location: gloucester, VA

Age: 42

Posts: 517

Trader Rating: (6)

Feedback Score: 6 reviews

|

Not at all. make sure to buy some cutting oil and then go to town. I think I drilled about 50 holes with that harbor freight step drill bit and it still cuts awesome. Im building 3 more cages to compete in USdrift events and hopefully it will hold up. I took it easy on the drill press. Its built really cheap, but it does the job if you take your time.

__________________

1994 FD3S Drift // 945garage //  sumospeed.com sumospeed.com

|

|

|

|

|

|

#2460 |

|

Not my work, i just wanted to share this. Ti turbo manifold=badass

http://http://s565.photobucket.com/a...rx1/?start=320 |

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|