|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

#5521 |

|

Zilvia Member

Join Date: Jan 2010

Location: Orlando, Fl

Age: 37

Posts: 191

Trader Rating: (0)

Feedback Score: 0 reviews

|

I don't know what else to tell you. Your welds are under filled and have a large (in my opinion) HAZ. You are probably going too slow and giving the runners time to warp. When a runner warps on me I'm not afraid to lightly tweak the end of the runners to compensate, have you tried that? If you mark the end of the runner touching the collector and shave that side off on a grinder of your choosing and re-bevel the end you can usually gain a lot of fit up back.

__________________

Assistant Fabrication Manager / Welder at Raw Brokerage

|

|

|

|

| Sponsored Links |

|

|

#5522 |

|

Zilvia Junkie

Join Date: Jun 2010

Location: Arizona/LA, California

Posts: 476

Trader Rating: (3)

Feedback Score: 3 reviews

|

Are you welding over your tacks? If you leave the tacks and weld near them first, the metal cant move because of the tacks holding in place, then once the half weld is finished, then weld over the tracks.

Reason is, the tacks are what hold the metal in place so when you decide to weld over them and melt them, they cant hold the pipe where it needs to be. Not sure if this helps but hope it does. I dont do stainless because I have no need for it at the very moment so maybe pointless info. I just run into the same issue from time to time when welding over my tacks and causing the pipe to go out of place :/ Also stupid question but is everything tacked together before you start welding? If so, how much of a gap do you have? If everything is tacked together, shouldnt have an issue.

__________________

S14 KA NA two cylinders, 75whp limper |

|

|

|

|

|

#5523 |

|

Zilvia Member

Join Date: Sep 2007

Location: Kingston

Age: 33

Posts: 252

Trader Rating: (1)

Feedback Score: 1 reviews

|

Build the manifold one runner at a time and fully weld each as you go. That helps.

Tight fit up helps too if your having any gaps. It takes longer but tack everything on each quarter, then check fit up on the manifold. Then weld an inch or two in each quadrant until your done. I normally don't do this but I normally don't have issues with warping like that. Put less heat into it and you will be better off. Less heat doesn't mean less amperage.

__________________

www.facebook.com/HellaFab |

|

|

|

|

|

#5524 |

|

Nissanaholic!

|

bevel to shallow of an angle

passing too slow not enough filler. push/move/push/move/push move, don't tap at it. Stainless will warp and move on you, on long runners I'll weld them in two pieces so i can correct an issue at 3 points instead of one or two. gapping makes penetration easy, but it'll wander around on you way more. so its kinda a trade off, its just about what you want to deal with. Stainless is about welding it as cold as possible while getting complete fusion. if your having to blast heat at it to get a deep weld that isn't cold lapped you'll probably start having cracking issues. also you want a more focused arc. if you're having to run huge point on your tungsten to make up for a shitty machine that lets the arc wander a lot, then you're going to end up with a bigger HAZ. other news.  |

|

|

|

|

|

#5527 |

|

Zilvia Member

|

Ahp alpha tig 200x

60 amps 3/32 2% thoriated .045 308 filler Welded the vibrant t25/28 turbo outlet flange to their transition pipe. Had to crush the pipe some what in the vise to get it to fit. Still had some gaps but worked out. Honestly I'm not that happy with the look, seems like I got enough penetration seems solid but not digging the look. I really got to work on adding filler with stainless. Ran out of gas while welding the inside. Still have to finish it. Then make sure flange is flat don't think it warped at all. Any suggestions are welcomed as always!!!   |

|

|

|

|

|

#5528 |

|

Zilvia Junkie

Join Date: Jun 2010

Location: Arizona/LA, California

Posts: 476

Trader Rating: (3)

Feedback Score: 3 reviews

|

I am most likely wrong since I dont do stainless steel or at least not yet but it seems to me like maybe going too slow.hot. Also did you make sure to clean both metals before starting? What is your gas flow at as well? Trying to figure out why so dark, how far out is your tungsten from the material your welding? Too far out and it will give you that burn look.

again, I am most likely wrong as I haven't done stainless steel yet. Just guesses

__________________

S14 KA NA two cylinders, 75whp limper |

|

|

|

|

|

#5529 |

|

Zilvia Member

|

Did clean but not as much as I should have kin of spaced out tonight. Definitely was moving too slow had/still have a hard time adding filler to the puddle, and getting the puddle to move I get hung up. Also relived my gas meter was super high, I forgot i have to set it every day, relized way to late till I was almost done. I prob should have waited as I just was out of it today

|

|

|

|

|

|

#5530 |

|

Zilvia Junkie

Join Date: Jun 2010

Location: Arizona/LA, California

Posts: 476

Trader Rating: (3)

Feedback Score: 3 reviews

|

Happens, are you Pulsing and if so, manual or auto? With the gas, why do you have to reset it each time? I leave mine at 15cfh and dont adjust it. Only thing I touch on the gas end is to close it or open it.

__________________

S14 KA NA two cylinders, 75whp limper |

|

|

|

|

|

#5531 |

|

Zilvia Member

|

I mean I have to reset the gauge every day not each time, by pushing you mean the way I add filler? I'm dipping I guess not familiar with pushing? Idk I'm being stupid right now lol. Also I'm using pedal and manually changing amps by using pedal position.

|

|

|

|

|

|

#5532 | |

|

Zilvia Junkie

Join Date: Jun 2010

Location: Arizona/LA, California

Posts: 476

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

If so, what I do is only pulse at the end of the puddle each time. Makes it easier to keep a decent rhythm going. For dipping the stick, it depends what you are doing.

__________________

S14 KA NA two cylinders, 75whp limper |

|

|

|

|

|

|

#5533 |

|

Zilvia Member

|

Ok cool I have to mess around with it more, I'm pissed I didn't check my regulator my flow rate was way to high, ridiculously high and made it hard to focus the arc. But hey it's strong and will do the job, justices me want to redo one cause I'm anal about this stuff.

|

|

|

|

|

|

#5534 |

|

Zilvia Member

Join Date: Jan 2010

Location: Orlando, Fl

Age: 37

Posts: 191

Trader Rating: (0)

Feedback Score: 0 reviews

|

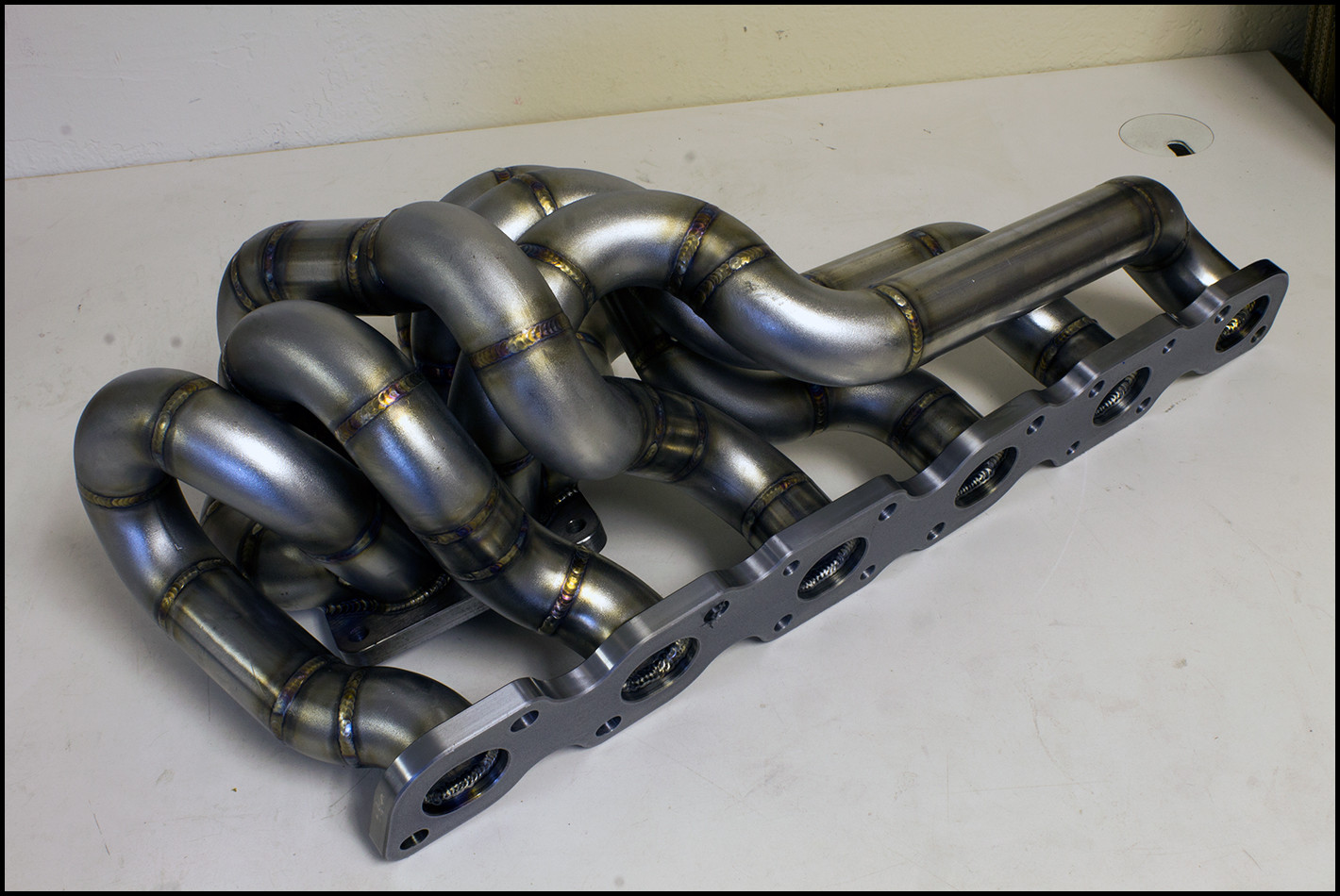

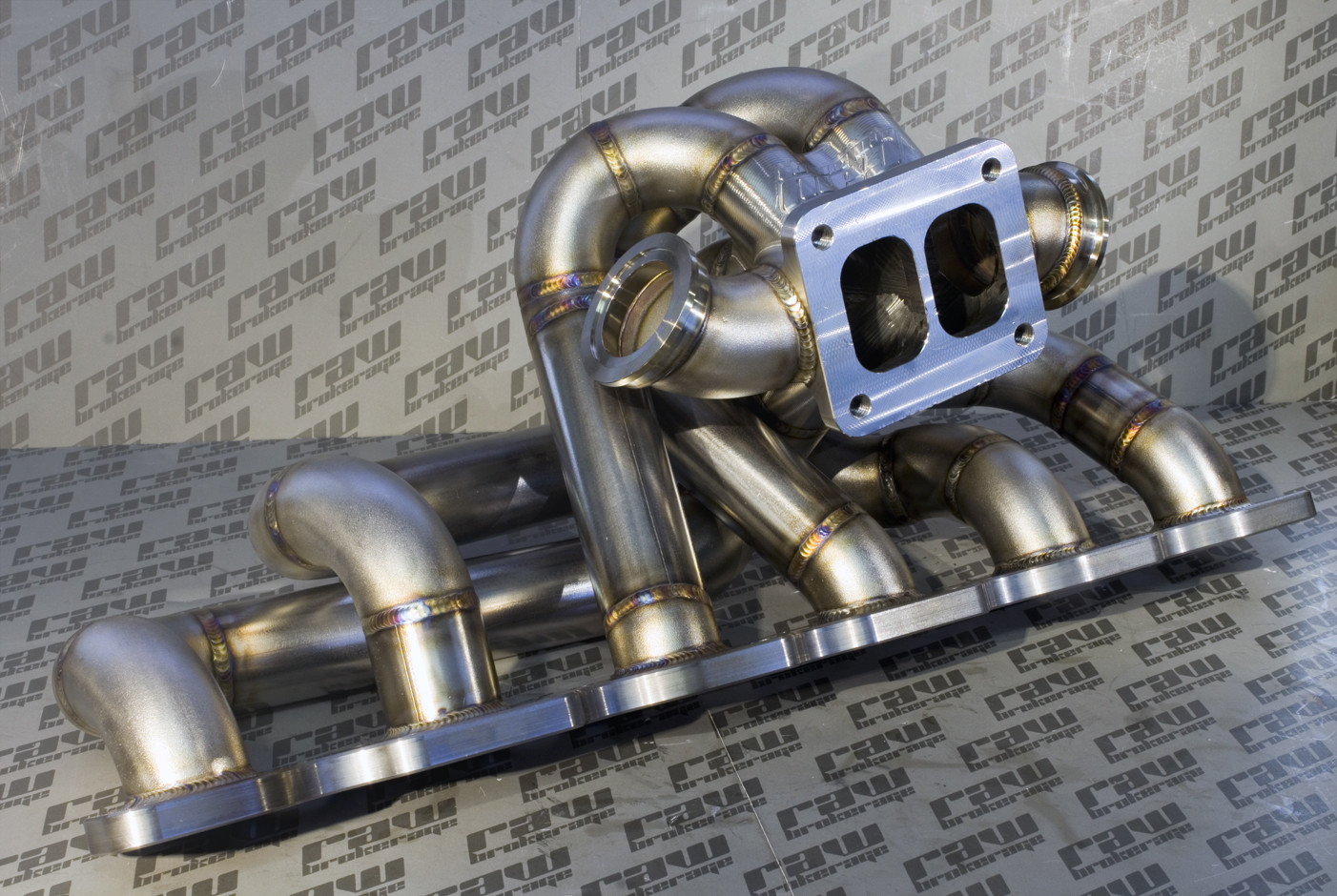

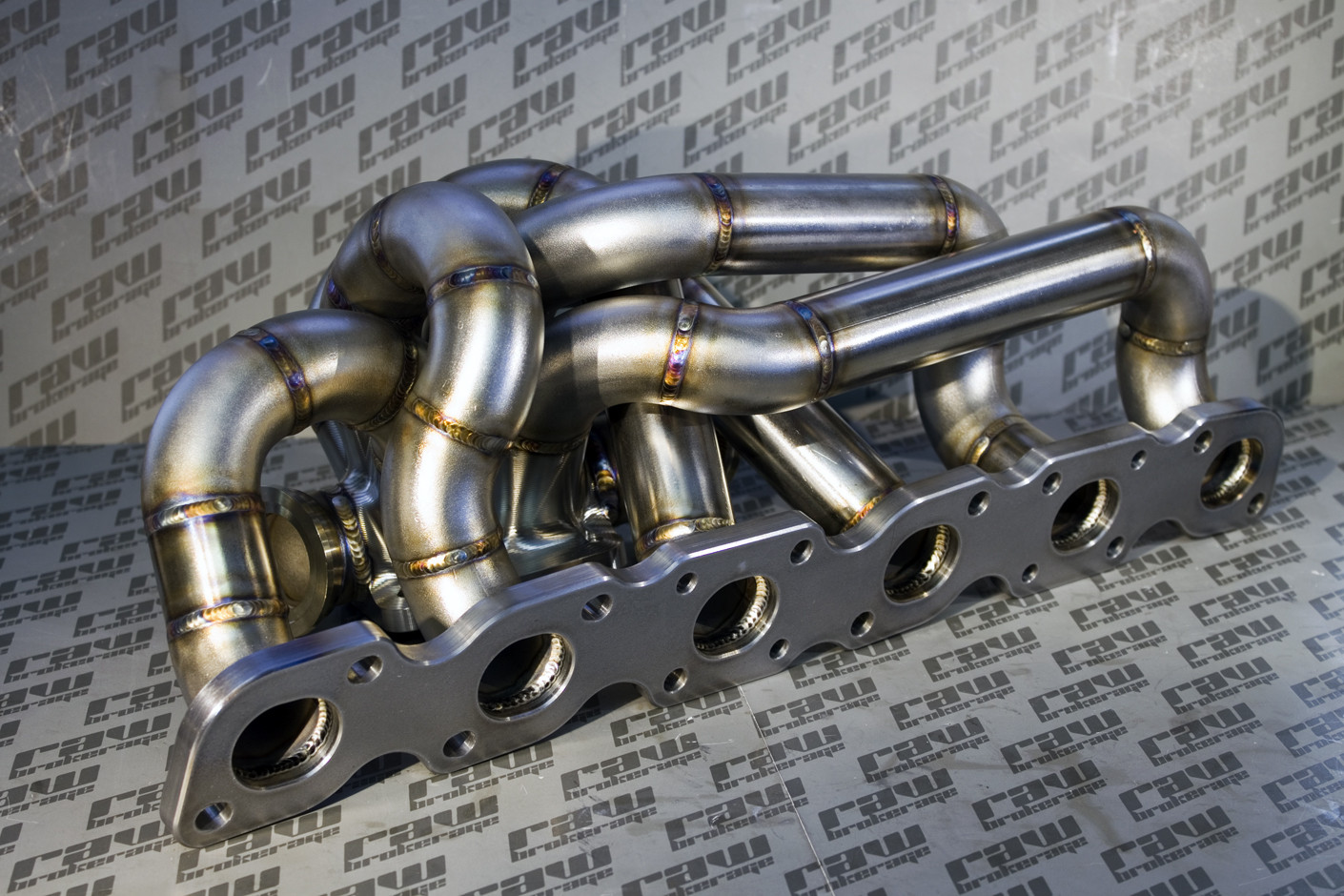

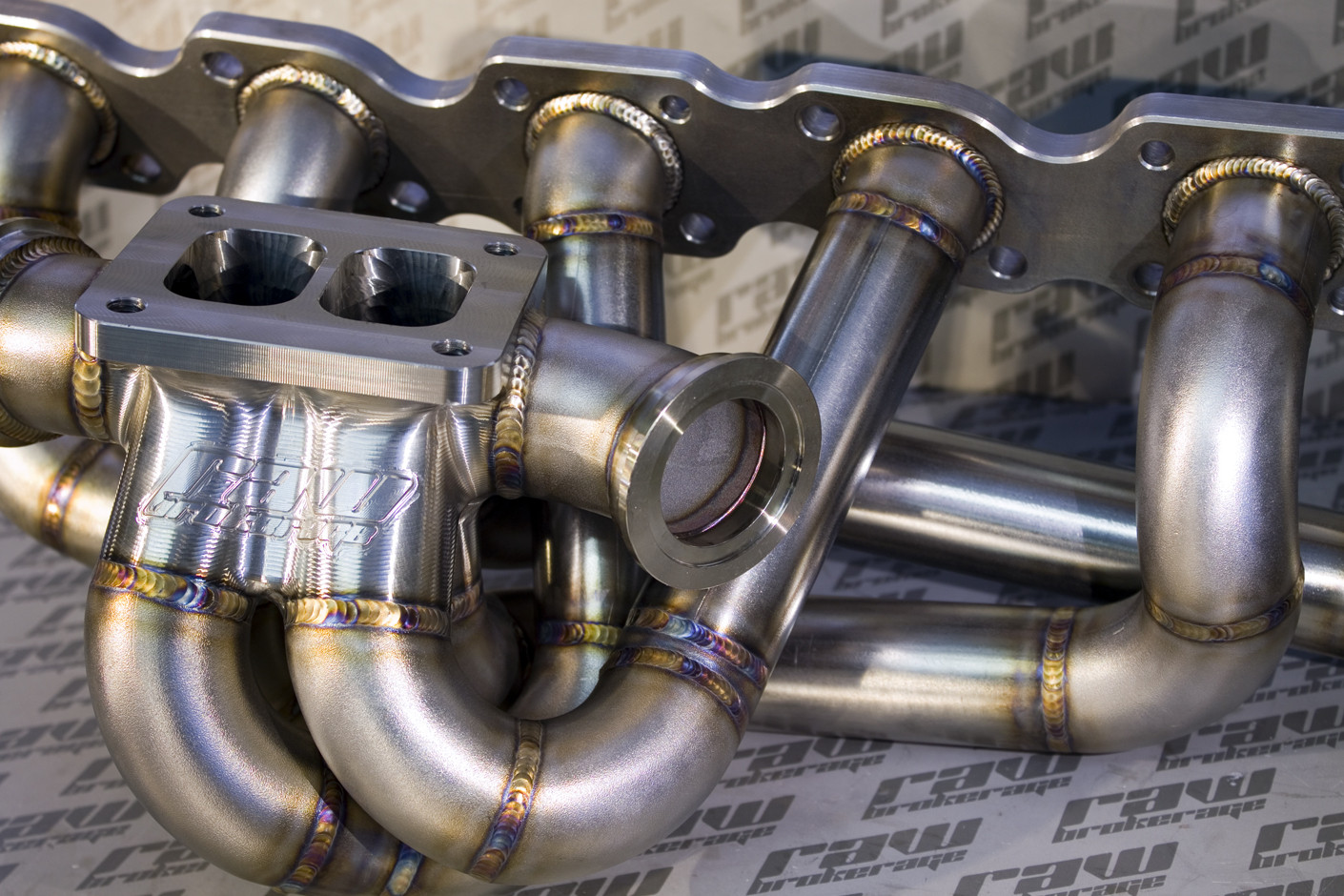

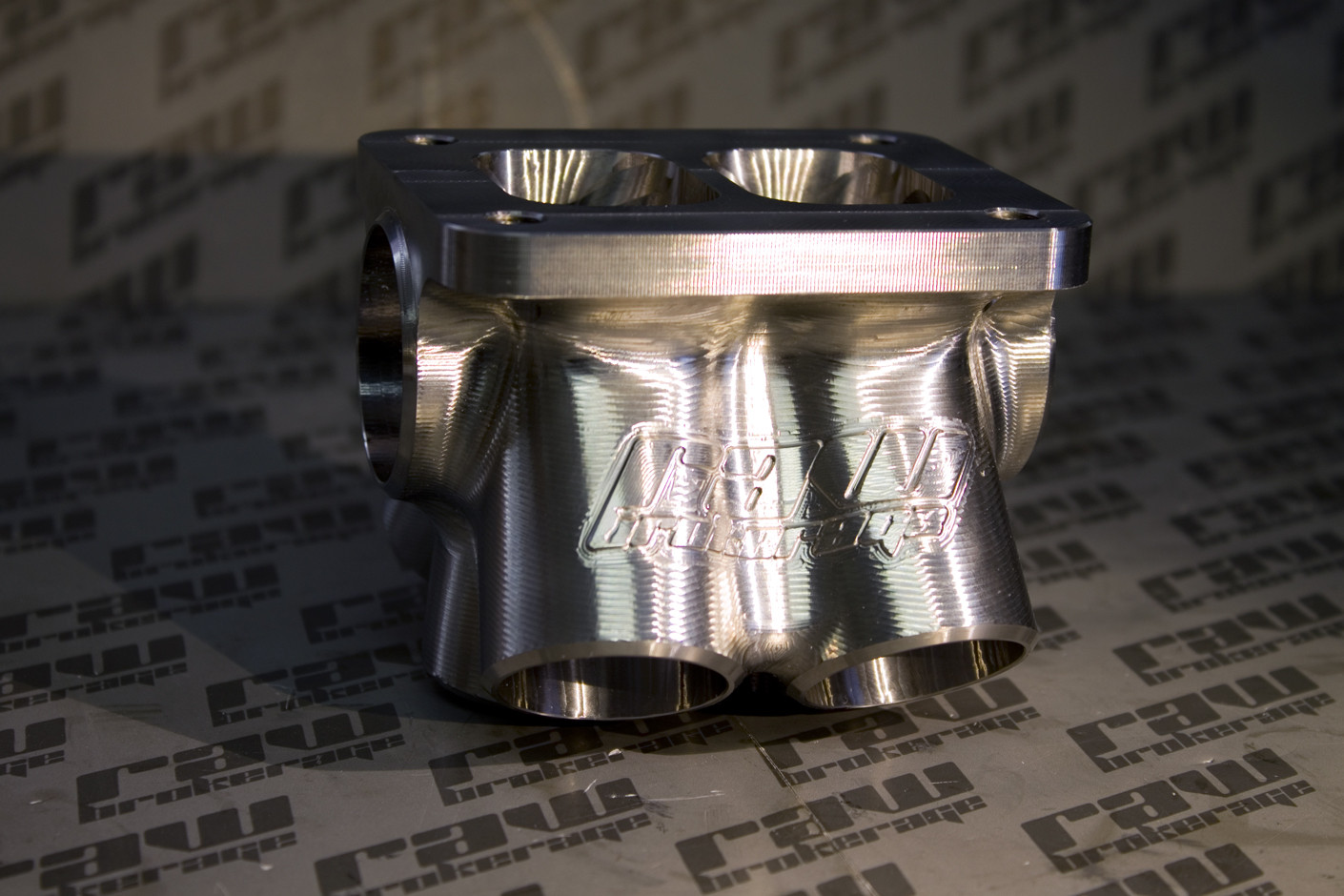

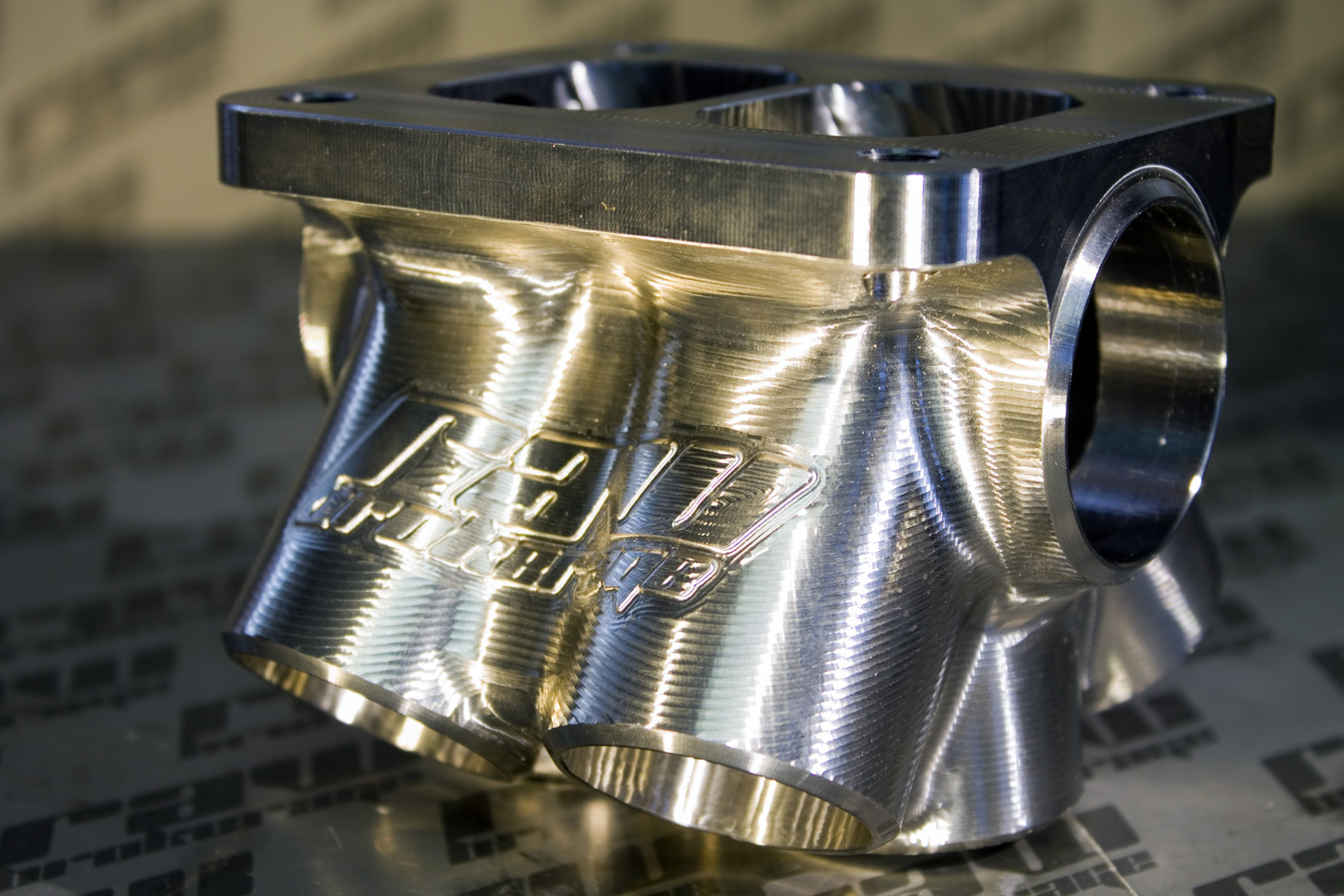

Shipping a custom T6 manifold for a RB30. The car isn't finished yet so the customer will be welding on the wastegate flange after they decide the final location.

__________________

Assistant Fabrication Manager / Welder at Raw Brokerage

|

|

|

|

|

|

#5536 |

|

Zilvia Member

Join Date: Jan 2010

Location: Orlando, Fl

Age: 37

Posts: 191

Trader Rating: (0)

Feedback Score: 0 reviews

|

The problem with a one-off custom manifold is that the second one is always better... only there is no second one!

__________________

Assistant Fabrication Manager / Welder at Raw Brokerage

|

|

|

|

|

|

#5538 |

|

Hey guys so I bought a 240sx sr swapped it's a all stock motor with stock turbo according to the guy I bought it from it is out of tune and I was wondering if anyone has a NIstune ecu for sail or if they knew anyone that did I know this isn't the fit sale forums but this is my project car and I'm just looking for assistance thanks for looking at this.

|

|

|

|

|

|

|

#5539 |

|

Zilvia Member

|

I'd post on the want to buy section or browse the for sale section this is definitely the wrong thread to post in. If not then contact Andy ( I think who it was) at auto Vaughn performance, they sell/instal nistune an were very helpful when I had them install it into my blacktop ecu. They're a vendor on this site too. Google them

|

|

|

|

|

|

#5540 | |

|

Zilvia Junkie

Join Date: Jun 2010

Location: Arizona/LA, California

Posts: 476

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

Post in the WTB section. If you are in Cali or near it, go to suspicious garage. They are one of the Zilvia advertisers and do an amazing job for a good price. @UltimateForce - That is amazing work. By any chance, do you have any tips on welding around the pipe hand wise? I move my hand but not get it to twist enough to keep on the pipe. Any ideas?

__________________

S14 KA NA two cylinders, 75whp limper |

|

|

|

|

|

|

#5541 |

|

Zilvia Member

Join Date: Jan 2010

Location: Orlando, Fl

Age: 37

Posts: 191

Trader Rating: (0)

Feedback Score: 0 reviews

|

My answer to most TIG-related questions: Practice.

Practice on pipe till you can nail it every time on a simple flat position then start getting uncomfortable. Run the torch around the pipe with no voltage, just practice the motions. When I was in welding school I'd roll uncooked spaghetti in my fingers when I went home at night to learn filler control. Take a brake when it stops being fun then try again when you are ready.

__________________

Assistant Fabrication Manager / Welder at Raw Brokerage

|

|

|

|

|

|

#5542 |

|

Zilvia Junkie

Join Date: Jun 2010

Location: Arizona/LA, California

Posts: 476

Trader Rating: (3)

Feedback Score: 3 reviews

|

I do practice and practice, just was wondering if you had any tips. Before I try, I make sure I can do it without welding but when welding, for some reason my hand doesnt want to do the same movement and once it does, already too late.

Was just wondering if you had any tips to try. Being able to weld 4 times around is something I can do so far, but most of the stuff like harley arms adn what not cant exactly be picked up and turned 90 degrees each time. Thats what gets me, only being able to weld from the top and bottom. :/

__________________

S14 KA NA two cylinders, 75whp limper |

|

|

|

|

|

#5543 |

|

Zilvia Member

Join Date: Jan 2010

Location: Orlando, Fl

Age: 37

Posts: 191

Trader Rating: (0)

Feedback Score: 0 reviews

|

Try holding the torch differently. Most of the time I hold my torch in a way someone could easily pull it from my hand, but some times you gotta get weird with it. I sit for low stuff and stand for high stuff on my table. I can get a lot more angles standing and leaning over the table.

__________________

Assistant Fabrication Manager / Welder at Raw Brokerage

|

|

|

|

|

|

#5544 |

|

Zilvia Junkie

Join Date: Jun 2010

Location: Arizona/LA, California

Posts: 476

Trader Rating: (3)

Feedback Score: 3 reviews

|

Ill try sitting lower. Normally my table is pretty low so I am always way higher. Trying to save up to buy a nice welding table.

Heres some welds from a few nights ago. 1/16 tungsten 3/32 ER70s-2 filler 1 1/4" piping with .120 wall (easy to work with but its all I have currently because its normally the only piping I work with. In this photo, there is some blue on the weld which caught me off guard. These photos were taken by the end of the day so a lot of times I was trying to figure out how I got the blue in the weld but couldn't replicate it. Couldn't find anything online either, there isn't much information online for tig welding without everything going off subject or covering a hint of something. At the beginning of this one, forgot to turn on gas and started with too much angle on accident. Clumsy.

__________________

S14 KA NA two cylinders, 75whp limper |

|

|

|

|

|

#5545 |

|

Zilvia Member

Join Date: Jan 2010

Location: Orlando, Fl

Age: 37

Posts: 191

Trader Rating: (0)

Feedback Score: 0 reviews

|

Go to the scrap yard and buy some rusty (but flat) sheet to make a table. Grind the rust off and you are good to go. Make the table top as thick as possible, mine is an inch thick piece of mild steel. Total over kill, 3/32" is a great thickness for a table.

Every time you sit down pre-flow your torch against the back of your hand or something. I have developed this as a habit. The blue is where the pipe caught the argon and the weld was properly shielded. The rest of the gray welds are from lack of shielding. Stop practicing on random places on pipe and go get some flat steel and run welds across that to practice. I don't see how anyone expects to learn anything by randomly welding on metal they had laying around doing something different every time. Fun fact: You can buy something called BOOKS to learn about something! welding | Barnes & Noble

__________________

Assistant Fabrication Manager / Welder at Raw Brokerage

|

|

|

|

|

|

#5547 | |

|

Nissanaholic!

|

Quote:

Tungsten too small Filler too big using a filler thats too big will cause all sorts of issues. plus you can't get your tungsten close enough to get any good arc focus so your haz will be huge and zero penetration. Like the idea of that Tee fitting on the wastegate tube, looks pretty good, wonder if it'll flow enough to keep that turbo in check. |

|

|

|

|

|

|

#5548 |

|

Zilvia Junkie

Join Date: Mar 2013

Location: Athens, Greece

Age: 43

Posts: 580

Trader Rating: (0)

Feedback Score: 0 reviews

|

here's my fabrication: making a vented FRP bonnet

mould ready top part out of the mold welding nuts on laser cut plates for the mounting points aligning the bottom part and attaching the mounting plates and glueing on the top part added aerocatch and windshield washers, and opened up the front 2 vents before i decide what im gonna do about rainwater total cost: as much as a store-bought one, but i have the mold left. total weight: i havent weighed it, but my arms say half the weight of the oem one.

__________________

My Build |

|

|

|

|

|

#5549 |

|

a little custom work from russia we working on my personal drift car

link to full build http://zilvia.net/f/builds-builds-on...-ls2-drft.html |

|

|

|

|

|

|

#5550 |

|

Zilvia Member

Join Date: Jan 2010

Location: Orlando, Fl

Age: 37

Posts: 191

Trader Rating: (0)

Feedback Score: 0 reviews

|

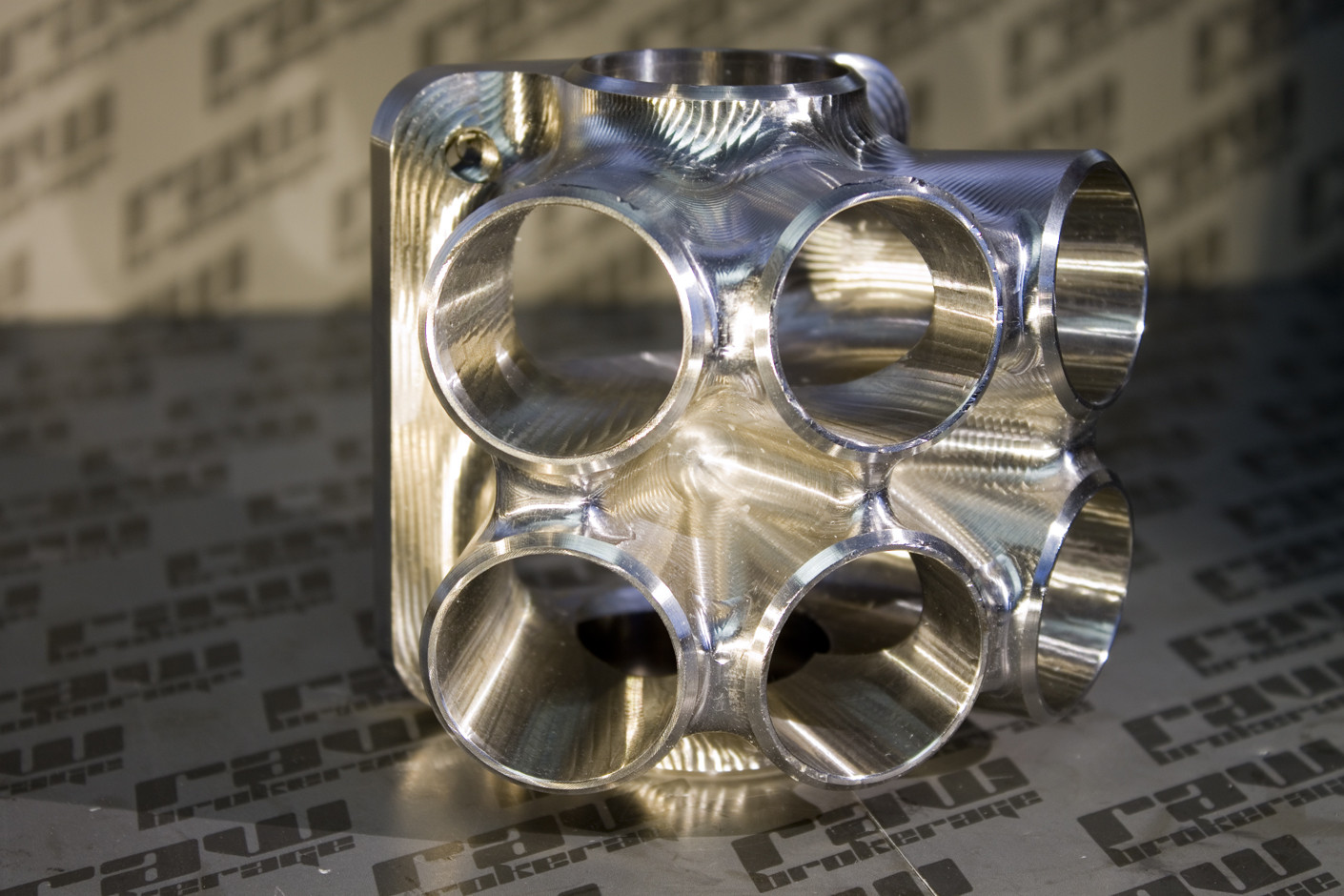

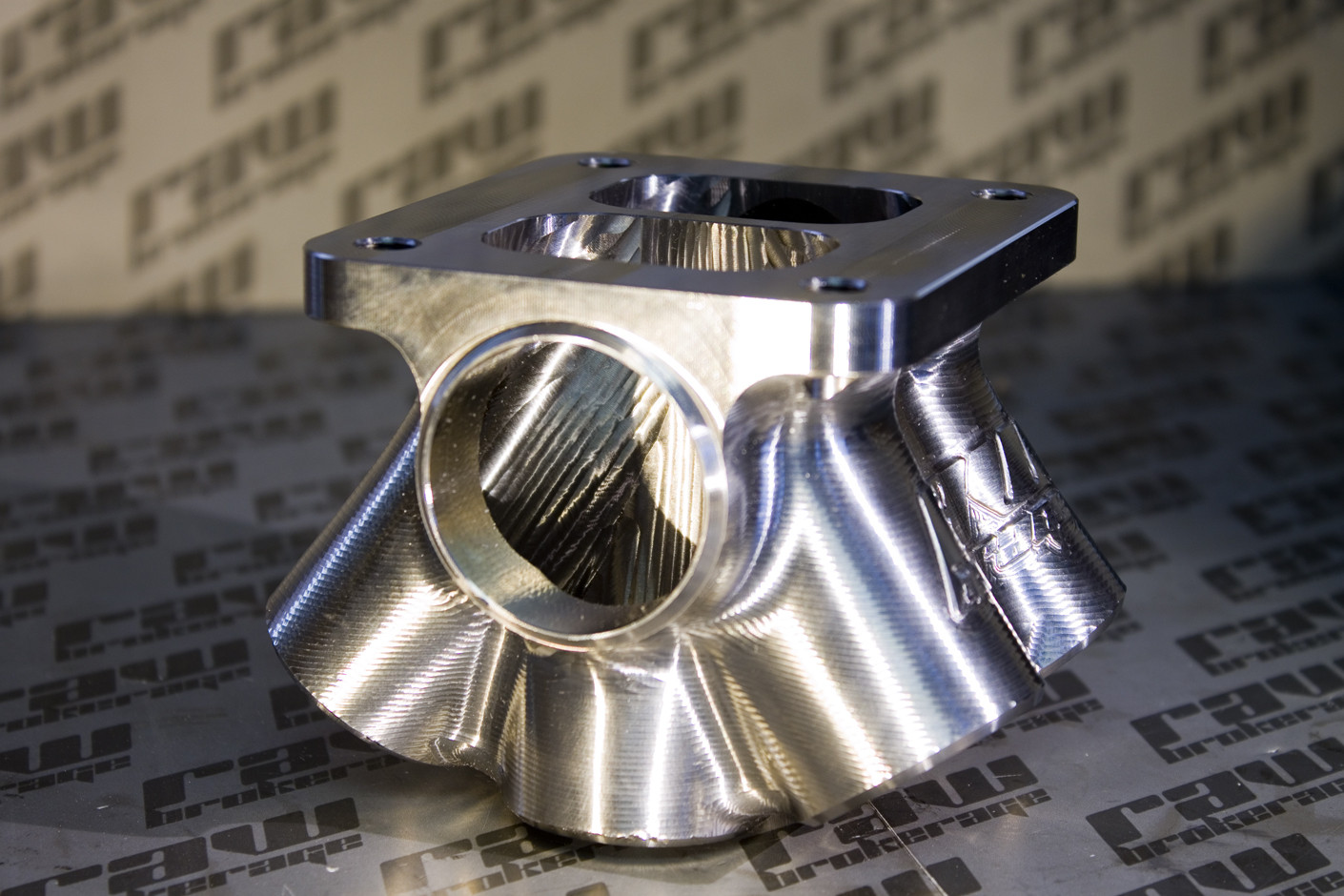

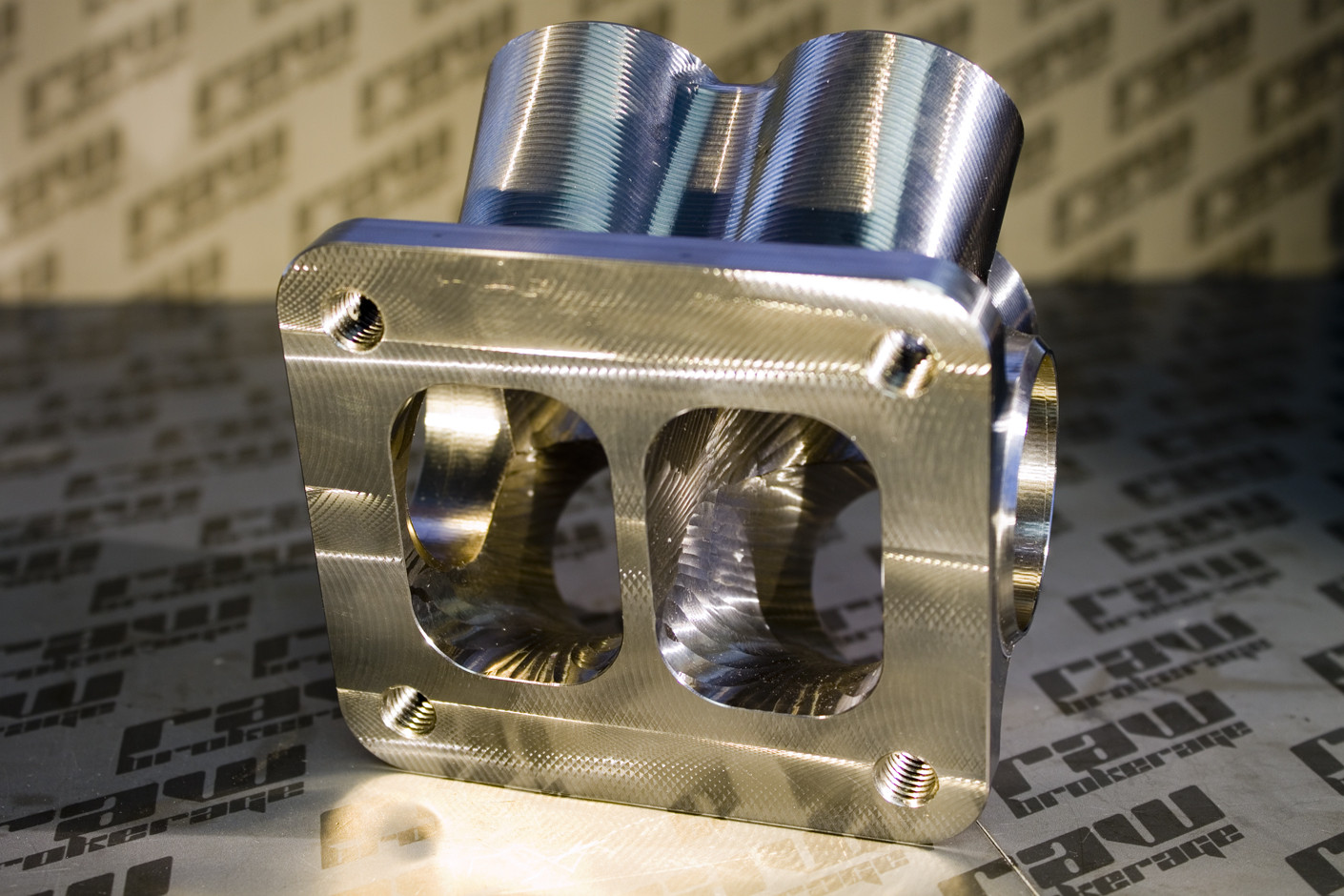

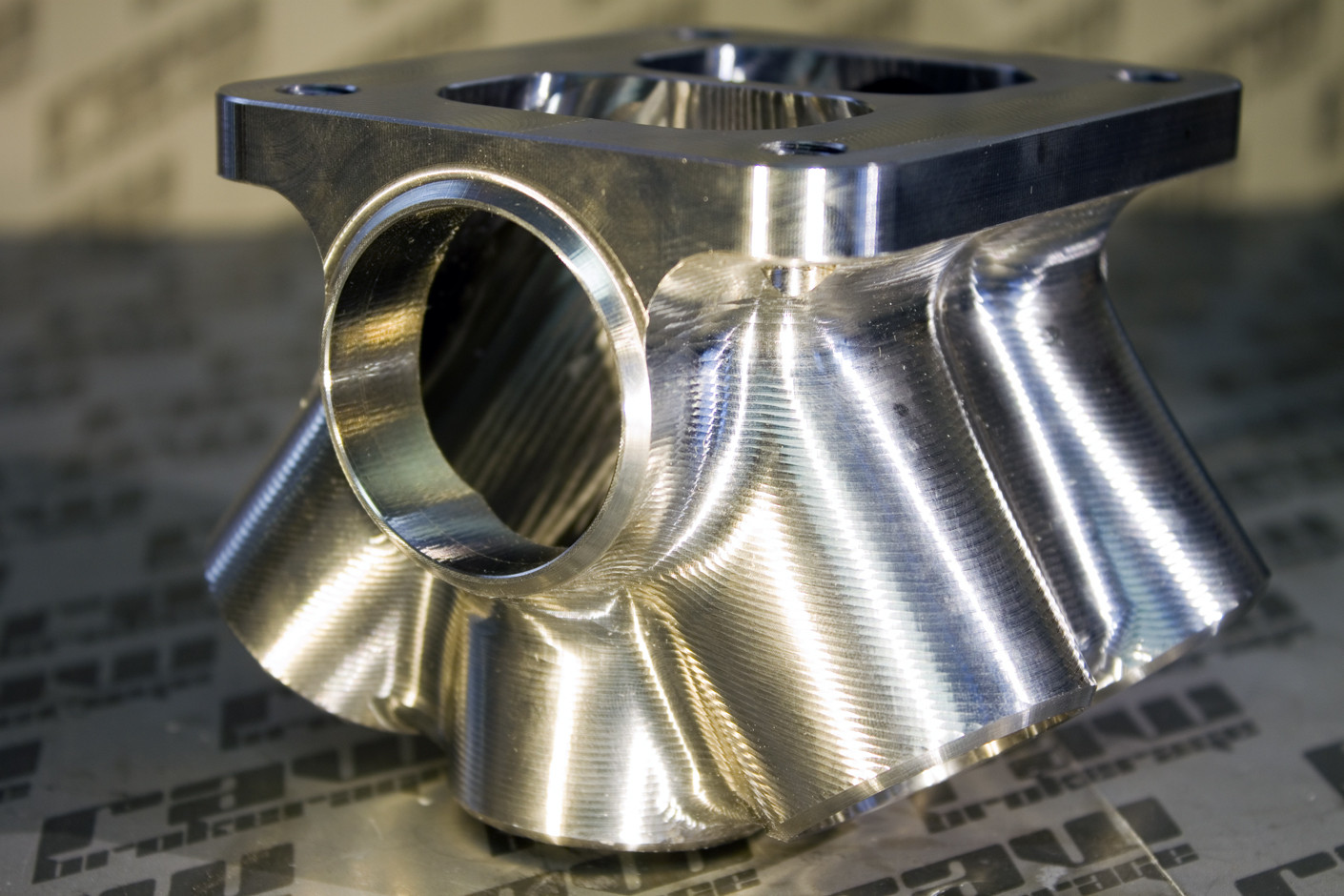

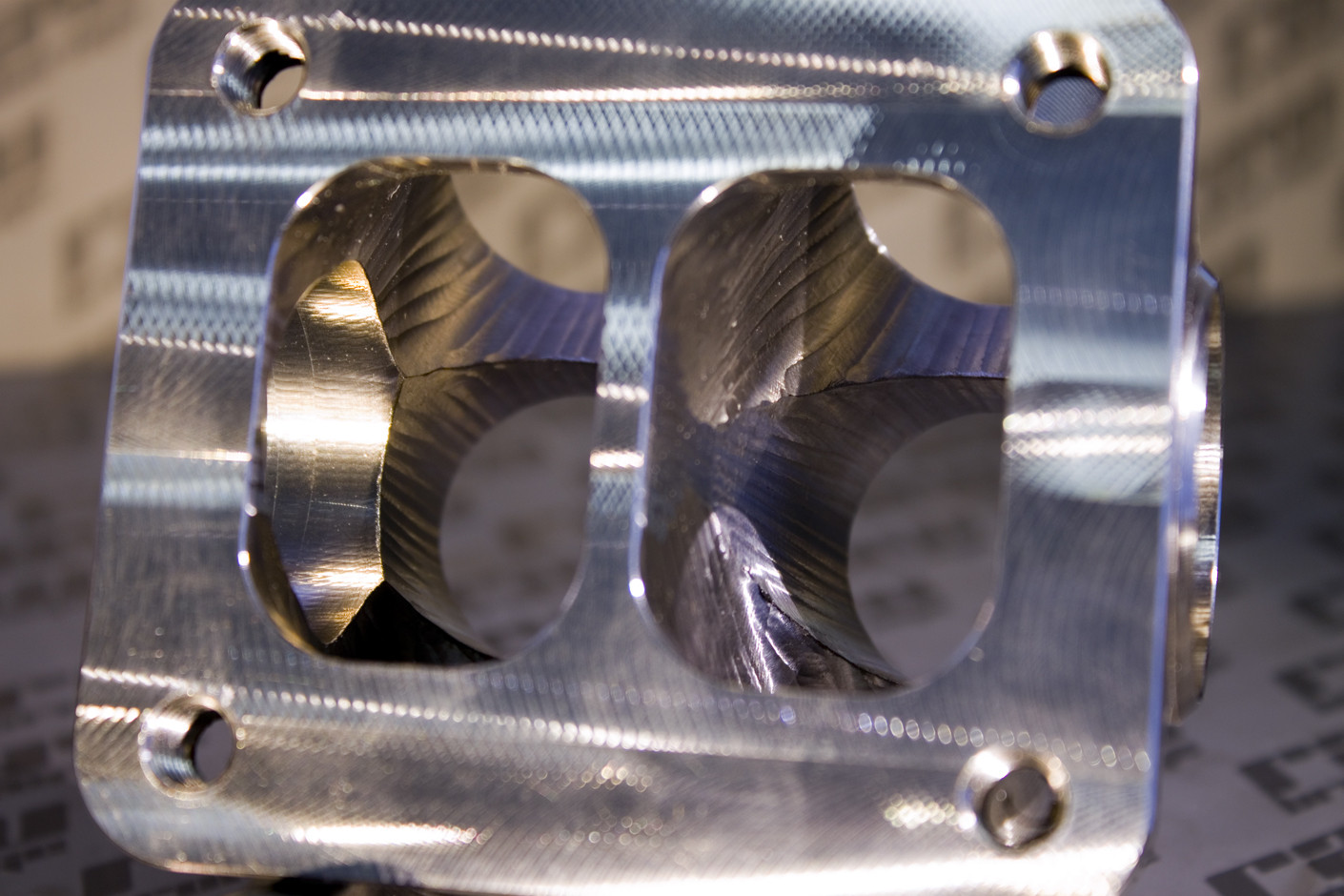

Took some quick product photos for the website today.

Professional photo booth.  Billet collectors.

__________________

Assistant Fabrication Manager / Welder at Raw Brokerage

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|