|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Builds (and builds only) Got a build thread? It goes here, build threads anywhere else on the forum will be locked and never moved. |

|

|

|

Thread Tools | Display Modes |

|

|

#151 | ||||

|

Zilvia Junkie

Join Date: Feb 2008

Location: Carry Water, Chop Wood

Age: 33

Posts: 497

Trader Rating: (0)

Feedback Score: 0 reviews

|

thanks man!! I think as i get older and gain experience/knowledge, things start to beome easier to accomplish!

Thanks dude! excited to see how your coupe comes together as well!! Quote:

Quote:

Quote:

Quote:

I did stop by a small paint supply shop the other day and pick up some seam sealer/undercoating. i will probably go back and get a tube of 2 part seam sealer as well for where some of the corners meet..  |

||||

|

|

|

| Sponsored Links |

|

|

#152 |

|

Premium Member

Join Date: Oct 2006

Location: Carson City, NV

Age: 38

Posts: 307

Trader Rating: (2)

Feedback Score: 2 reviews

|

Quote:

I think the the eastwood welder are great for a hobbyist. I started with an eastwood tig 200 and upgraded to an ahp alphatig 200. I loved both machines. For the seam sealer I brushed all of mine on when it was my final/top coat. I tried to match how it was done in the factory. |

|

|

|

|

|

#154 | |

|

Zilvia Junkie

Join Date: Feb 2008

Location: Carry Water, Chop Wood

Age: 33

Posts: 497

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

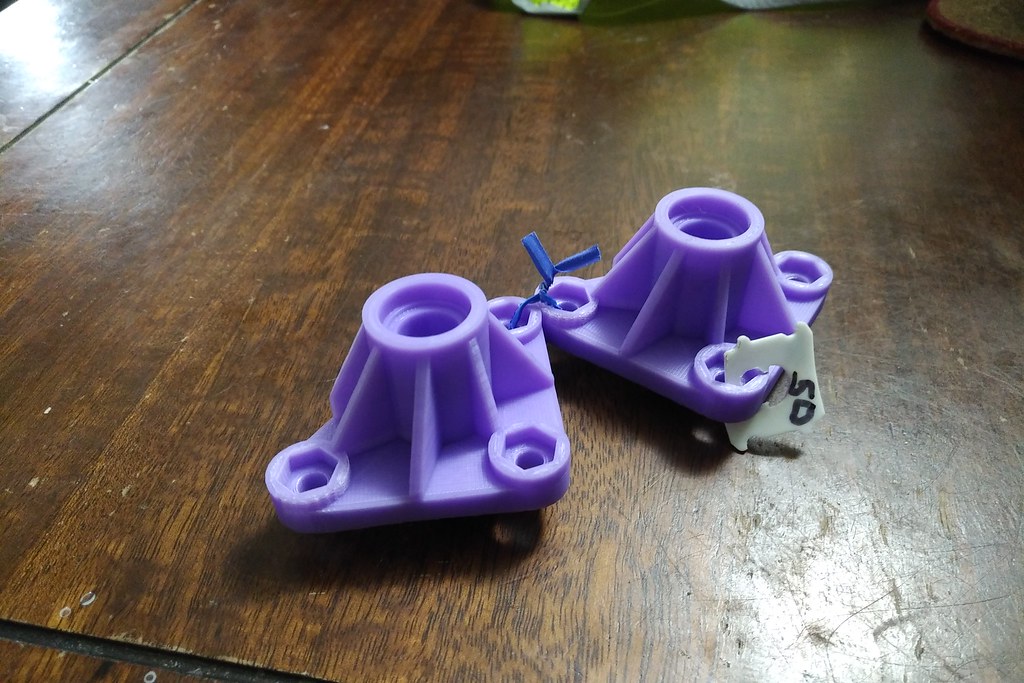

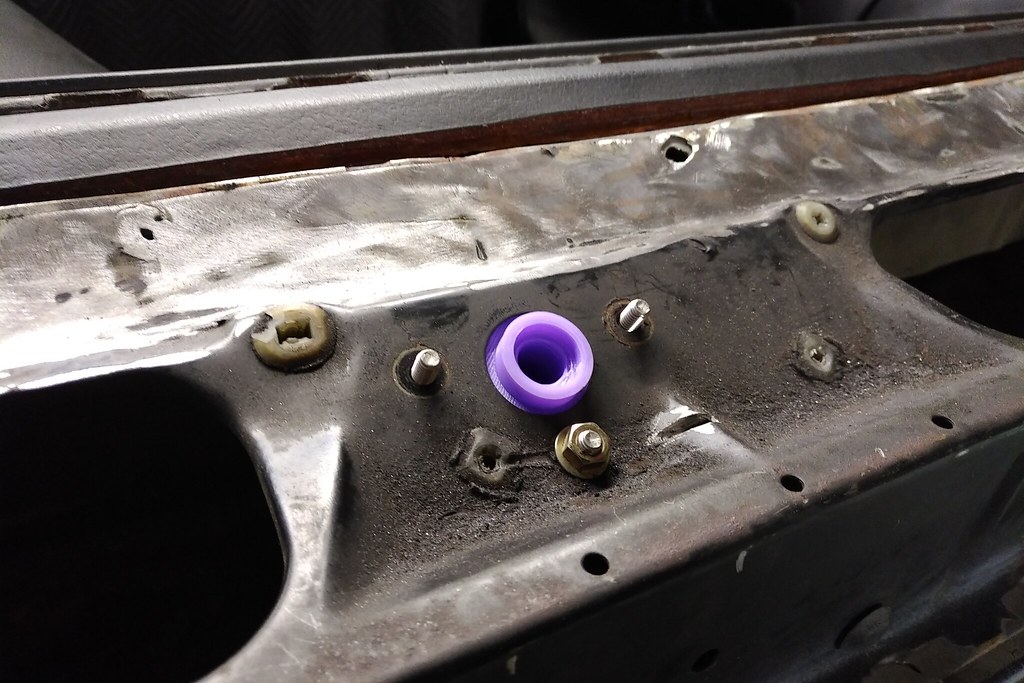

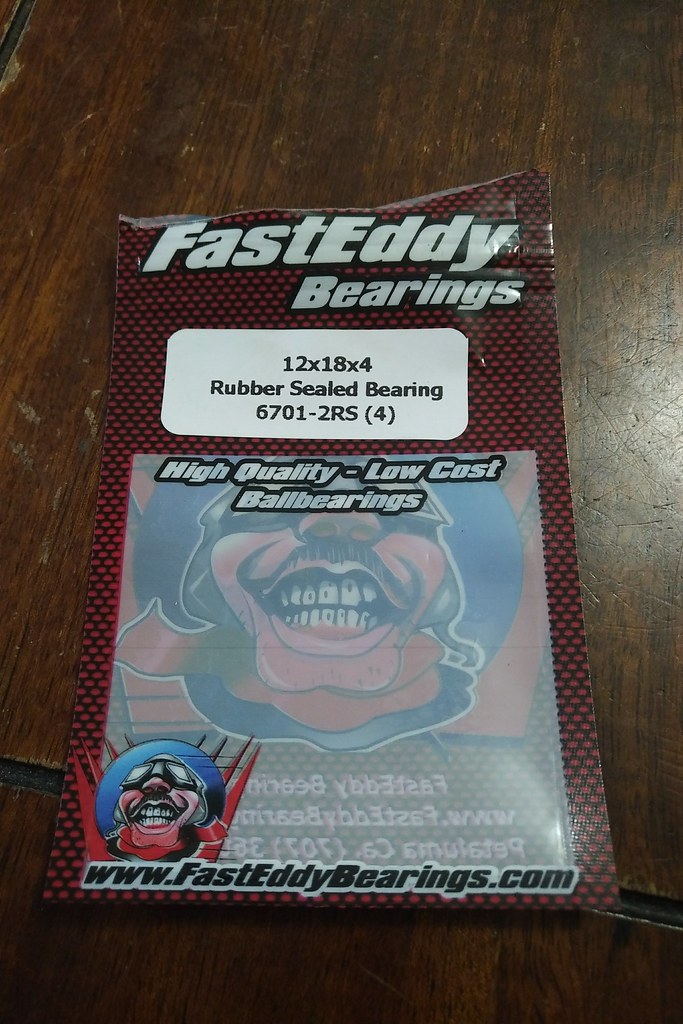

I did make some more progress, I've just been busy with the house interior remodeling and the holidays, to make a post about it. So, HERE GOES!!! I had a couple days to lay some of the seam sealer down.  First wire brushed and sprayed some sealer/primer over the areas that were bare metal.  since its the wheel well, i just smeared it on all over where the panels were welded and very liberally as to seal it as best i could.  Pretty much the last big welding task was to swap the hand-brake bracket to the other side of the trans tunnel. Started by drilling out the spot welds.   After i trimmed the bracket, I bolted the bracket to the hand-brake, set the center console on the dash/over the hand-brake, and made marks about where the bracket should be tacked.  I skipped the process during welding/pictures, but after the bracket was positioned and welded, This morning, i wire brushed it and threw some primer on this morning and taking pics. It snowed a little bit this past weekend. The G35X is stupid in the snow. I hate it (and all the electronic bullshit assists    ) and I think i want a Kouki to daily and maybe another D21 pickup to get supplies for the house and what not... ) and I think i want a Kouki to daily and maybe another D21 pickup to get supplies for the house and what not...     welds are probably over kill but i know if i add something like a small extender piece on the handle i know it can hold yanking it!!  This is how it sits right now.   All thats really left is more seam sealer on the interior side, filling in spots on the firewall/cowl seams with the welder, more seam sealer, and wait till the weather breaks to start body work and re-finish the engine bay.   ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------- **SUPER**EXTRA** After reading TSSS22 build. I PM'd about some special parts that were re-designed. hopefully they will hold up (I think they will) since the bearings will take the load instead of the plastic wearing out like from factory.  My Uncle that lives in New Hampshire has a 3D Printer and he printed this for me in 2 different fill %. One is 15% which is VERY light and i don't think it'll handle the heat nor have the strength for the loads to stay put and break/wear out. But the other pair is 50% infill and SIGNIFICANTLY stronger/solid.  Ordered the bearings it was designed around and they were a perfect press fit. I was suprised on the hold and shape/tolerances on the PLA. Rubber sealed ball bearings to keep the water and dust out the best it can.  Also picked up some stainless hardware for them. M6-1.0-16mm long seemed to be the best length without cutting to length. I'll probably put some jb weld/epoxy on 2 sides of the bolt heads before i assemble them so they don't rotate/strip the hex out in the mounts.  heres the link for the mount on thinsverse. https://www.thingiverse.com/thing:2961561 link for the bearings i used. https://www.amazon.com/gp/product/B0...?ie=UTF8&psc=1 All the credit for design goes to TSSS22. |

|

|

|

|

|

|

#155 |

|

Post Whore!

Join Date: Oct 2008

Location: MI

Age: 35

Posts: 3,913

Trader Rating: (131)

Feedback Score: 131 reviews

|

Very cool stuff!

I'm curious, did you happen to notice if the e-brake assemblies are identical between LHD and RHD? Everything I have seen has led me to believe they are, they just changed the mounting position on the chassis itself. I have been studying photos but can't tell for sure. Just wondered if you happened to notice this or not. |

|

|

|

|

|

#156 | |

|

Zilvia Junkie

Join Date: Feb 2008

Location: Carry Water, Chop Wood

Age: 33

Posts: 497

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

Last edited by Super_OK_S13; 01-14-2019 at 07:05 PM.. |

|

|

|

|

|

|

#158 |

|

Leaky Injector

Join Date: Feb 2014

Location: Slovakia

Age: 29

Posts: 83

Trader Rating: (0)

Feedback Score: 0 reviews

|

Hey, nice work man

Thanks for trying my design, when you start using them please share your experience with us, maybe leave a comment on Thingiverse. If you saw my build, you know I can't test it now  Anyway the PLA has low heat resistance so if it softens or start deforming, maybe try ABS or NYLON. |

|

|

|

|

|

#160 |

|

Nissanaholic!

Join Date: Jan 2010

Location: location X

Posts: 1,807

Trader Rating: (10)

Feedback Score: 10 reviews

|

effing crazy. so if I used the 3m body panel cement, do I need that seam sealer? like this for example?

do these spots need that sealer?    I then sprayed primer on it

__________________

http://www.240sxforums.com/forums/rb...ject-s-rb.html |

|

|

|

|

|

#161 | ||

|

Zilvia Junkie

Join Date: Feb 2008

Location: Carry Water, Chop Wood

Age: 33

Posts: 497

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

I wanted the part made in nylon, since that is what factory looked like. But my uncle's printer is set up for pla right now. I will definetly share when the wipers are functional!! I wanted the part made in nylon, since that is what factory looked like. But my uncle's printer is set up for pla right now. I will definetly share when the wipers are functional!!thanks!  Quote:

little update.  It's been pretty cold in PA/north east in late Jan/early Feb. so, I haven't been outside in the garage other than to fire up the snow blower or do a quick small job for on some friends cars.. Found a good deal on an RSX *base model* a friend was selling and since my girl was looking for a new car, we test drove it and pretty much ended up with it ASAP.. It has solid engine mounts  , custom intake, dc sports header, some kind of exhaust,(it's too loud, and that shows my age , custom intake, dc sports header, some kind of exhaust,(it's too loud, and that shows my age  ) godspeed coilovers, type-s wheels/spoiler, new exedy clutch and new tires. ) godspeed coilovers, type-s wheels/spoiler, new exedy clutch and new tires.  I ended up getting rid of that wood stove, found time and a warm(er) day and piped in that forced hot air furnace that was beside the compressor. I got a couple gallons of diesel and fired it up on a 20* day. Surprisingly enough, it warmed up the garage (25x40x10ft ceiling) with open rafters and WELL vented at the ridge vent/sides to about 45-50* in about an hour of it turning the blower fan on/off, with no thermostat and just blowing out of the top of the furnace/no plenum to direct the air. I'll be getting foam board for a ceiling this week, and build/buy a new plenum to sit on top and direct air to where i need it to blow. Having a ceiling will help heat loss SIGNIFICANTLY, eventually ill add some blow-in insulation on top.  Anyway.... I did some work on the car and it's pretty much onto the next step of re-finishing the bay since the firewall is completely welded in place, and just needs sealed up. sprayed a little primer on to prevent surface rust.   I'll be smoothing out the sections of old seam sealer, and making the sections where the fender/tube front bolts to more presentable. Removing the seam sealer and cleaning up for more welding.  Hopefully another update soon!! -Jimmy  |

||

|

|

|

|

|

#162 |

|

Premium Member

Join Date: Jun 2012

Location: Lancaster county, PA

Age: 30

Posts: 465

Trader Rating: (4)

Feedback Score: 4 reviews

|

Keep us posted on the printed wiper pivot results. I just don't think the PLA will survive the engine bay heat. PLA has been known to deform if it's used even for something in the interior like a shift knob. ABS is the recommended automotive plastic material.

Congrats on the RSX! The Honda K series engines are incredible. You know Honda is doing something right when a 2liter Honda engine makes as much horsepower naturally aspirated as a 2liter Nissan does with a turbo! |

|

|

|

|

|

#163 |

|

Nissanaholic!

Join Date: Oct 2013

Location: Western Mass.

Posts: 2,254

Trader Rating: (3)

Feedback Score: 3 reviews

|

I used some seam sealer in my bay, and its almost impossible to make it look "great". Its so fucking spongey and flexible. My tubs in my bay are done with bondo, it takes tons of time, but the smooth finish is worth it. You'll thank me later.

|

|

|

|

|

|

#164 |

|

Leaky Injector

|

in for ceiling updates! my garage needs the same

__________________

https://www.youtube.com/bennyobscene |

|

|

|

|

|

#165 | ||

|

Zilvia Junkie

Join Date: Feb 2008

Location: Carry Water, Chop Wood

Age: 33

Posts: 497

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

Quote:

I completed the ceiling. i used, 1/2" poly iso foam board. i paid 6.50$ a sheet!!! (vs home depot/lowes- $13.50ish) i got it from a surplus supplier near me.. All thats left is to foil tape the seams. It made the garage feel a little smaller and i now have 2 dark spots around the middle of the back wall which dont show up well in the picture but to the right of the Japanese flag and left of PLANK. i will be getting some 8ft led lights from amazon most likely, to add more light to the garage.  IMG_20190312_1920215-panorama by Jimmy Acri II, on Flickr IMG_20190312_1920215-panorama by Jimmy Acri II, on Flickr |

||

|

|

|

|

|

#166 |

|

Leaky Injector

Join Date: Nov 2018

Location: Winnipeg, Manitoba, Canada

Posts: 55

Trader Rating: (0)

Feedback Score: 0 reviews

|

Enjoyed reading up on your build. You have a good taste in modifying your 240 which makes this super entertaining to follow!

Keep up the good work.  |

|

|

|

|

|

#167 |

|

Join Date: Feb 2019

Location: San Clemente Ca

Age: 36

Posts: 4

Trader Rating: (0)

Feedback Score: 0 reviews

|

Hey man awsome watching your build. Makes me wish i documented my build as well as yours so i could post it. Very professional work. I lived in the Delaware county area prior to moving out to California wish i would have seen this back then. I dont know many other s13 guys.

|

|

|

|

|

|

#168 | ||

|

Zilvia Junkie

Join Date: Feb 2008

Location: Carry Water, Chop Wood

Age: 33

Posts: 497

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

Quote:

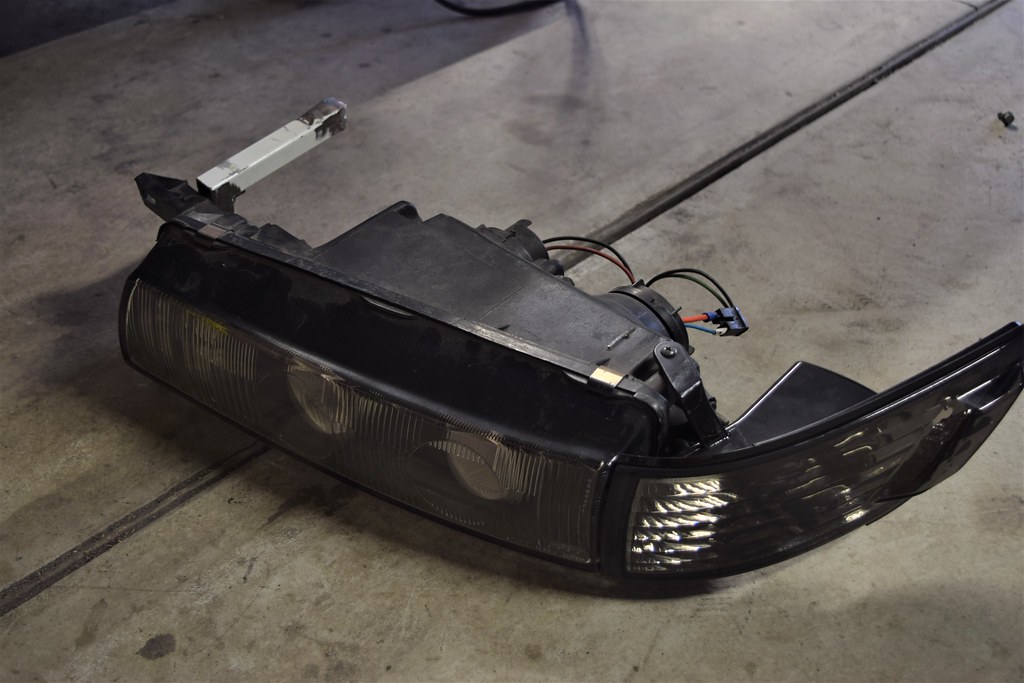

ONTO my semi-annual update.....   So, after getting the car to the point of he firewall welded in, i put the car on the back burner for a bit to get some much needed house/yard work done!  I started with a small patio made from old railroad ties and some stone. this area was really bugging me the way it looked before, so i finally did this..   Finished up with some 3/4" pearl pebbles. Put a small table and a bench me and Ericka restored with new planks, stain, and paint.  Next project  First off, I dont mind my neighbors at all, they can live however they want, but i was really disgusted seeing all the trash, dead leaves/sticks, 2ft tall grass/weeds, disgusting (probably mosquito infested) baby pool in their yard  So! i decided that it was time to put up a fence. I really like to be the cool car guy neighbor and if ANY of them need help they can come to me and ill help!! But i just wanted a little more privacy and put a 6ft fence up instead of 4ft height, Stinging it out to make sure its a straight line.  Had a couple people from my job(s) come by to help out! Post holes dug and posts in!   My dad moving a couple bags with the tractor.   Had to let the posts setup over night even though it was "fast-setting" concrete.  Started about 930-10am, and finished about 430pm putting up the stringers AND the pickets by myself.    Just sitting there, waiting patiently to go out.... Or for me to work on the damn car...  Speaking of the car. I started by finishing up welding the rest of the area around the tubs/frame. Adding some pieces so when i re-finish with filler its will be smooth with minimal hard corners/edges/angles. Since i've had a little more time with the welder, (i think) my welds/technique have improved a tiny bit. I still need MUCH more time with it though!!   After those areas were done, i added some more material to the edges.     Had to make a new bracket for the front of the fender to bolt to, and added some more material to smooth out/straighten/follow the edges under/along the fender.   Welded in some washers and nuts for the hardware to screw into.  Core support back on for new headlight brackets!!!!   CHOP CHOP!!!  GRIND GRIND!!!  Also made a piece to support the bumper while i re-fit the lights as a semi-guide.  Bought some cheap smoked corners off ebay. I'm going to add an amber tint to make them look semi-factory, since i like that look of having the different colors on the car.  I've definitely missed seeing the front end kind of together.  Tabs made and held in place.   after measuring and measuring a bunch of times i tacked, then took off to weld the top sections in place.  To hold the tabs for the outside of the lights, an idea that Auto Collect Storm inspired me to use. Made some paper templates for each side.  Traced them to some metal.    This thing landed on the vise as i was grinding, grabbed the closest thing to smack it with, and hit it!!  Anyone know what it was? Looked like it had a needle between the eyes, and was acting like it was stinging the vise with its butt when it landed... Anyone know what it was? Looked like it had a needle between the eyes, and was acting like it was stinging the vise with its butt when it landed...  Setup and welded the inside.    Continued in next post |

||

|

|

|

|

|

#169 |

|

Zilvia Junkie

Join Date: Feb 2008

Location: Carry Water, Chop Wood

Age: 33

Posts: 497

Trader Rating: (0)

Feedback Score: 0 reviews

|

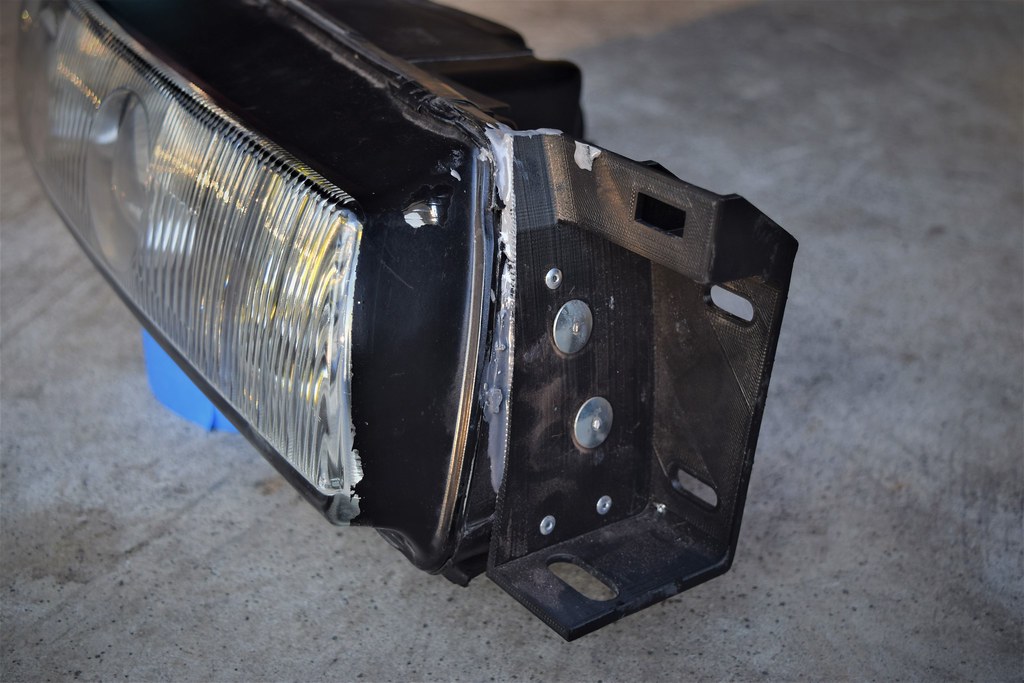

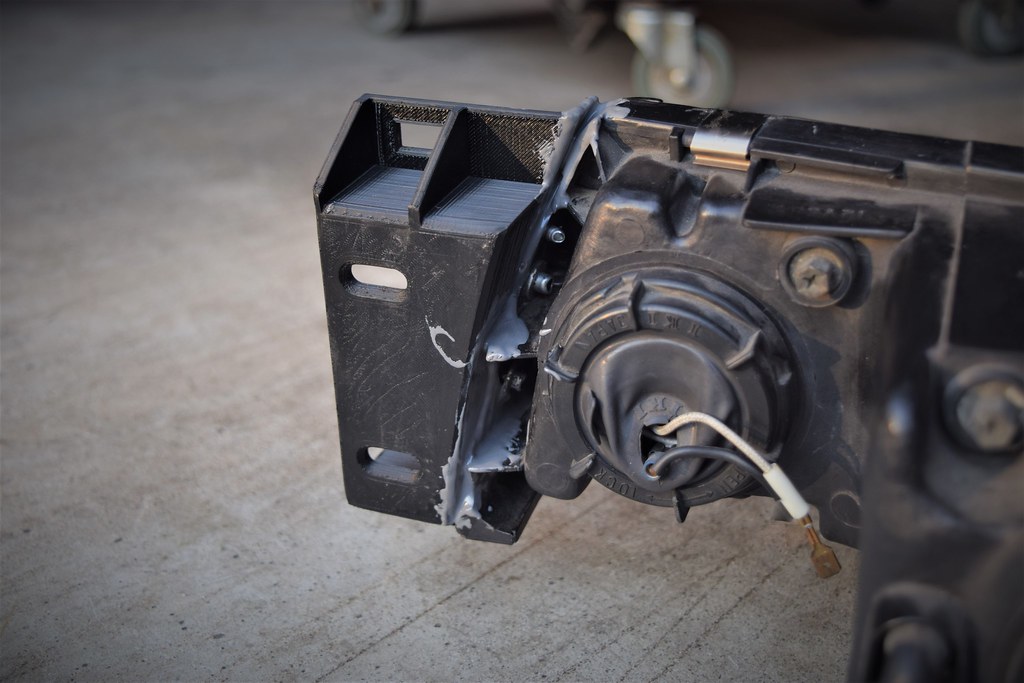

ONTO the inside bracket on the right side light.... It had a makeshift piece of metal riveted onto the not-yet-completely-broken plastic and held up good for time it was on there! but i wanted something better and more aesthetic looking and i knew with 3d printing there HAD to be something out there... Low and behold, GARAGE EMPEROR Headlight brackets! You can buy single side or both!!!! It is made of ABS and feels pretty sturdy!

i drilled out the old one, sanded both parts with some rough sand paper so the epoxy would stick. mocked everything back up, drilled for the new rivet holes, mixed up some epoxy to put in between the light and new bracket, and put the rivets in!  since there were some gaps, i mixed up some more quick, and let it gravity feed itself into the cracks and spaces for a bit.    As of right now, I am letting the epoxy cure for a day or 2 before i put it all back together and then i'll end up tweaking the headlights. Then i'll need to get some metal tubing to make a bash bar to hold up the bumper. it will slip into the front tubes on the frame rails, and bolt in place. I'll try to make a small parts post that i've gathered on friday!!  |

|

|

|

|

|

#171 | |

|

Zilvia Junkie

Join Date: Feb 2008

Location: Carry Water, Chop Wood

Age: 33

Posts: 497

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

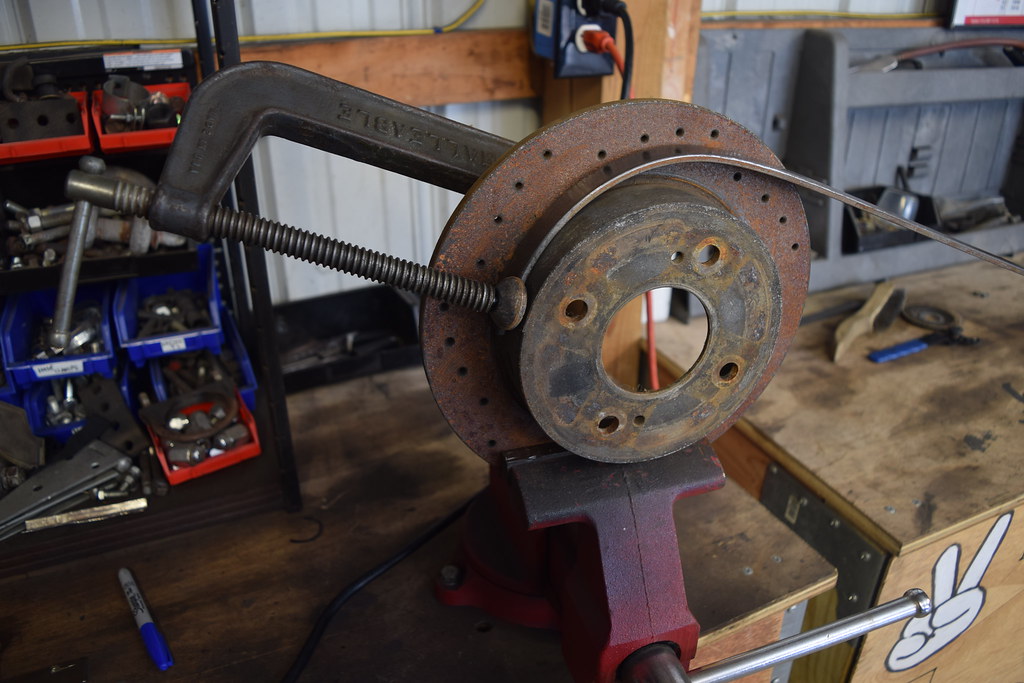

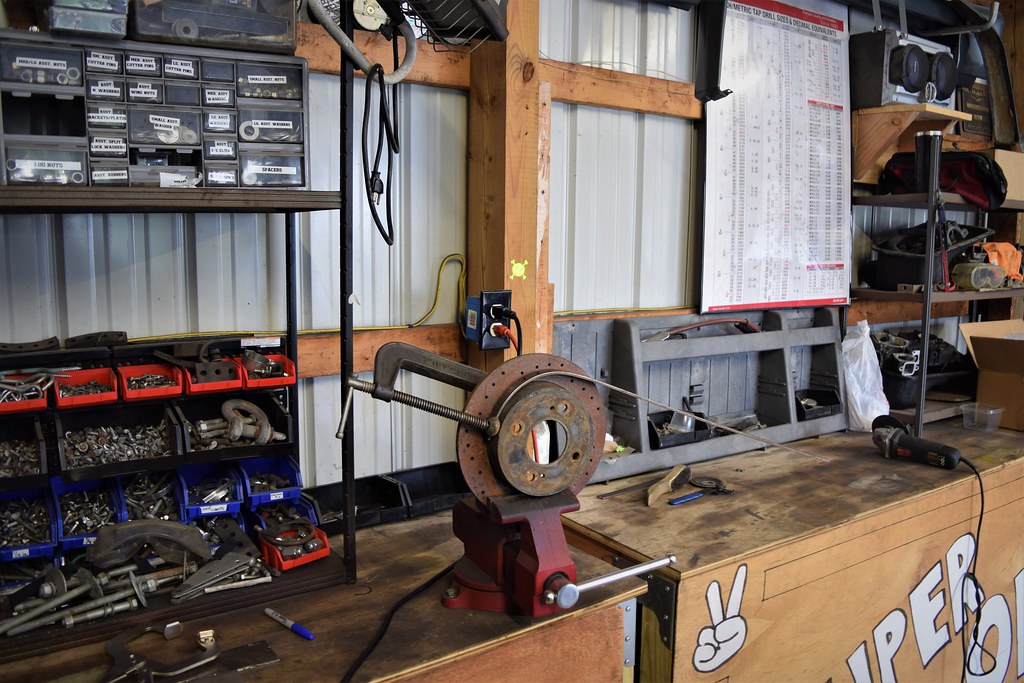

After the epoxy cured for a couple days, i started to put the front end back together.  Started by making the backside of the inner brackets. Some flat stock bent around an old 4 lug rotor did the trick.   Next up was the bottom tabs.  Test Fit and adjust the hood and fenders a little bit.   As you can see, there is a bigger gap under the headlights than on top...  So, onto a bumper support.  ALSO made some pieces for the headlight brackets to keep them stiff. Added a MUCH needed cutout to make them fancy (and dedicate the build to my 3 dogs!).  After cutting the notches and bending it to the shape of the bumper, for the most part anyway. I welded the notched sections to hold its shape.  Held up in place for the next step, how i'l attaching it to the car.  Similar to how the factory bumper mounts, i made these (one for each side) since i cut off where the factory support mounted when i re-did the front end the first time.  welded on the first plate to the sides of the frame next to the factory locations.   I had some steel pipe laying around and decided it will do the job of holding up some plastic. using my bender made 2 pieces and welded them to the plates that bolt to the ones welded to the frame.   All i can say, is my front end looks 10000000000000X better than when i had the other support bar beinnd the bumper.  I am Extremely happy with how it's coming together!  Next on the list is, to start grinding down all the welds on the pieces to make them presentable. The welds around the tubs need it too and then the body work can start in the bay!!!  thanks for looking  -Jimmy |

|

|

|

|

|

|

#173 |

|

Zilvia Junkie

Join Date: Feb 2008

Location: Carry Water, Chop Wood

Age: 33

Posts: 497

Trader Rating: (0)

Feedback Score: 0 reviews

|

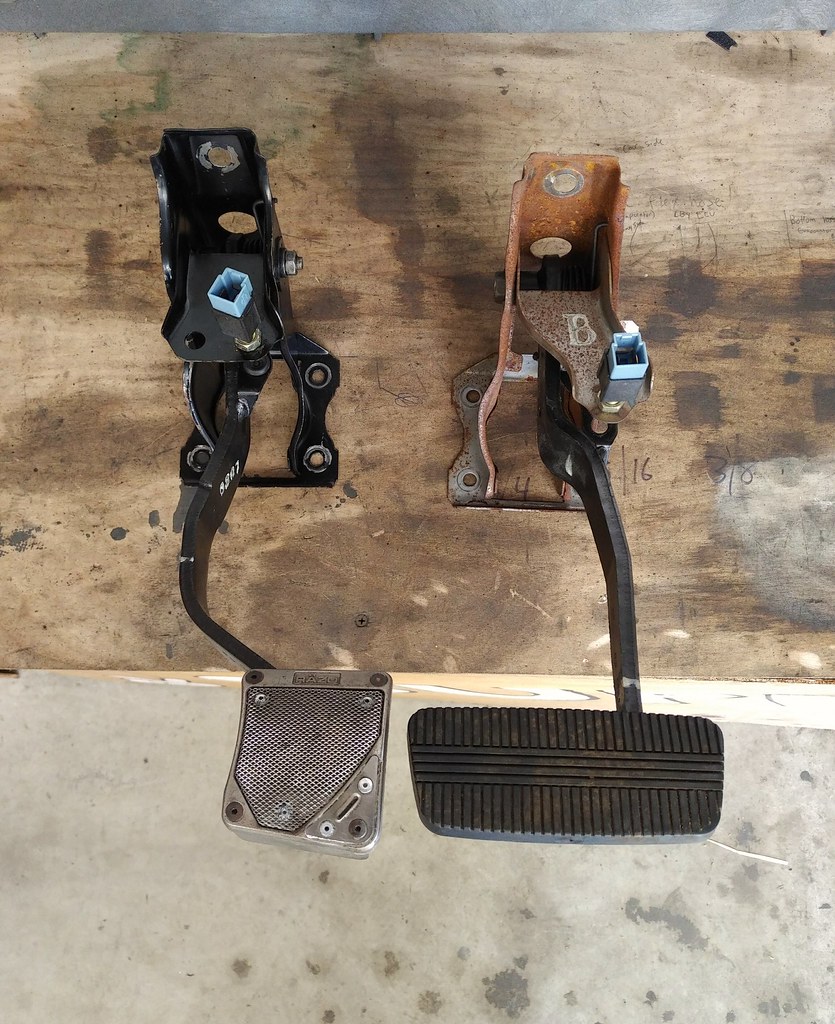

thanks ! !!!

Update time!! After Fitting the front end and staring at it for a while, i started looking at other detail things to do before i make a huge mess of body dust/paint in the garage. I started with new headlight covers that extend a little bit more/up to the fender bolt.  I made a bracket that attaches to the headlight bracket and supports the backside of the cover. Held on with a plastic removable rivet giving the look of it coming from factory that way.   I dont think ill make a middle piece since i want the filler piece of the headlight brackets to show.  after they were done, I started assembling the interior to see how the pedals mounted.  I noticed there are differences in USDM/JDM for the brake pedal and how it bends around/next to the steering column, not knowing i couldnt use the USDM one. Since my clip was an auto model i had to cut the pedal on it and swapped my pedal cover over afterwards.  After this, i took it all back out and started working on the engine bay. Adding some corner pieces at the shocktowers.  While adding them, i decided to go over the couple welds on the plates.  started grinding, and using flap discs on the grinder to strip the bay to get rid of some old filler, and smooth the welds out to apply filler over them.  I was sure that i'd be working on it but not for a couple days and wanted to get the epoxy primer on. i sanded most if it smooth with 80/100 grit. mixed up the epoxy primer and started spraying.  Next on the list after the epoxy cured, was to start the sanding/filler process. First was Duraglas, Short hair fiberglass in body filler. Mixed and started laying it down. After it sits for a bit, sanding/more filler/sanding. You get the process....   after the duraglass is "regular" filler.  Then some glaze to fill in some pin hole/low spots...  after filler and some SEM high build primer, more sanding and filler to find some low/high spots and block them, then some more primer.  Taped off areas for 3m "controlled flow" seam sealer... all it did was level out and seep into the cracks and run down the section on the firewall/back of the wheel wells, which turned out AWESOME!!!    Final spray from the paint gun will include. basecoat/mid coat/poly-urethane clear coat. White Nova - 083 is the paint code. 2012-present Lexus color.  |

|

|

|

|

|

#174 |

|

Nissanaholic!

Join Date: Oct 2013

Location: Western Mass.

Posts: 2,254

Trader Rating: (3)

Feedback Score: 3 reviews

|

Awesome progress and work.

Grind down the welds for the gusset plates and lightly smooth that area over to look flat and shaved. Seems like your attention to detail is similar to mine end result wise, and someday it'll bother you having those be the only visable welds. |

|

|

|

|

|

#175 | |

|

Zilvia Junkie

Join Date: Feb 2008

Location: Carry Water, Chop Wood

Age: 33

Posts: 497

Trader Rating: (0)

Feedback Score: 0 reviews

|

testing for posting error....

Quote:

|

|

|

|

|

|

|

#176 |

|

Zilvia Junkie

Join Date: Feb 2008

Location: Carry Water, Chop Wood

Age: 33

Posts: 497

Trader Rating: (0)

Feedback Score: 0 reviews

|

UPDATE!

So, after using the SEM high build primer. I smoothed out the gusset plates and complete the shave bay look like tuzzio mentioned...  IMG_20190826_1139416 by Jimmy Acri II, on Flickr IMG_20190826_1139416 by Jimmy Acri II, on FlickrLater, Burnsauto from here on zilvia, came by and did a little more body filler work on the wheel tubs and REALY made them nice and straight. They do look awesome!!! After that, I wiped down the bay with pre-paint prep, and sprayed the 2k Filler primer. 3 Coats and i let it sit a couple days to cure.  DSC_9105edit by Jimmy Acri II, on Flickr DSC_9105edit by Jimmy Acri II, on Flickr DSC_9106edit by Jimmy Acri II, on Flickr DSC_9106edit by Jimmy Acri II, on FlickrAlso sprayed the core support with 2k filler primer (in the background)  DSC_9109edit by Jimmy Acri II, on Flickr DSC_9109edit by Jimmy Acri II, on FlickrLoving her car!! she says she wants some mesh wheels for it... maybe some vs-xx or bbs wide(r) meshies?  DSC_9113edit by Jimmy Acri II, on Flickr DSC_9113edit by Jimmy Acri II, on FlickrUsing this stuff helps keep the panels you sand straight!  DSC_9121edit by Jimmy Acri II, on Flickr DSC_9121edit by Jimmy Acri II, on FlickrWet sand- 400grit, wet sand- 600grit  DSC_9119edit by Jimmy Acri II, on Flickr DSC_9119edit by Jimmy Acri II, on Flickrmaking sure everything is ready to go when i sprayed it the day after.  DSC_9122 by Jimmy Acri II, on Flickr DSC_9122 by Jimmy Acri II, on FlickrBasecoat on the core support and engine bay!!  DSC_9131edit by Jimmy Acri II, on Flickr DSC_9131edit by Jimmy Acri II, on Flickr DSC_9133edit by Jimmy Acri II, on Flickr DSC_9133edit by Jimmy Acri II, on Flickr DSC_9136edit by Jimmy Acri II, on Flickr DSC_9136edit by Jimmy Acri II, on FlickrI didn't take any photos of the mid-coat And I ALMOST didn't spray it since I liked the look of the basecoat/metallic in it...But i'm glad i did because it adds just the right amount of pearl/flakes on top of the base-coat. I put 2 coats of clear on.  DSC_9138edit by Jimmy Acri II, on Flickr DSC_9138edit by Jimmy Acri II, on Flickr DSC_9139edit by Jimmy Acri II, on Flickr DSC_9139edit by Jimmy Acri II, on Flickr DSC_9141edit by Jimmy Acri II, on Flickr DSC_9141edit by Jimmy Acri II, on Flickr DSC_9148edit by Jimmy Acri II, on Flickr DSC_9148edit by Jimmy Acri II, on Flickr |

|

|

|

|

|

#178 |

|

Leaky Injector

Join Date: Nov 2018

Location: Winnipeg, Manitoba, Canada

Posts: 55

Trader Rating: (0)

Feedback Score: 0 reviews

|

White bays are so clean but super annoying to clean after every 10 minute cruise haha

As for the RSX, I vote for some clean BBS. Something along the lines of the LM-series I think would look nice. |

|

|

|

|

|

#180 | |

|

Zilvia Junkie

Join Date: Feb 2008

Location: Carry Water, Chop Wood

Age: 33

Posts: 497

Trader Rating: (0)

Feedback Score: 0 reviews

|

i cant wait to just drive it!

Quote:

thank you!! im an amature at best. i'm just happy to have gained the knowledge and experiences!  ------------------------------------------------------------------------------------- I put the car semi-back-together. Enough to roll around and clean up the garage some in the next few weeks. It does't have brakes yet  DSC_9213edit by Jimmy Acri II, on Flickr] DSC_9213edit by Jimmy Acri II, on Flickr] DSC_9219edit by Jimmy Acri II, on Flickr DSC_9219edit by Jimmy Acri II, on FlickrAfter i let the jack down all the way, it reminded me how low s-chassis can be... Blackberry keyone for reference...  DSC_9215edit by Jimmy Acri II, on Flickr DSC_9215edit by Jimmy Acri II, on FlickrI bought front and rear z32 calipers a while ago and the conversion fender-well lines, also a front re-build/seal kit. I still need the rear seal kit, and to re-paint them. I will most likely be adding the drum setup for them in favor of a hydro. I dont plan to slide the car and really only need to hold the car in place parked, so the drum setup will suffice!  2019-09-06_04-41-01 by Jimmy Acri II, on Flickr 2019-09-06_04-41-01 by Jimmy Acri II, on Flickr |

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|