|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Builds (and builds only) Got a build thread? It goes here, build threads anywhere else on the forum will be locked and never moved. |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Leaky Injector

|

Need for Speed inspired S13 Welcome to 2005!

Well... I picked this car up yesterday. And yes, people looked at us A LOT on the way home... Guess why

Im really happy that it have the complete interior. Only problem i have is that its leather S14 seats. So i have to find somebody that wants to exchange for some OEM S13 seats. And it have very limited rust. A little bit infront of the rear wheels, and a bit on the frame-rail. The car was imported from UK to Denmark back in 2011. The guy i bought it from picked it up himself, drove it to Denmark and took the engine out to upgrade it with a FMIC, another turbo and to respray the enginebay. Unfortunally he had a lot of other projects, so he never finished the project. And thats where i came into the picture. I saw the car for sale back in 2019 for 50.000DKR (6700?, 7300USD, 5800?) and thought it was a lot of money for a S13 with a rather... uhm.... special paintjob. I didnt think more of it untill i saw it again a month ago. This time the price was dropped down to 23000DKR (3100?, 3400USD, 2700?) I picked up a friend and drove for 3 hours to look at it. It looked decent for the price, but i was NOT a fan of the front bumper, sideskirts and rear bumper were bondo'ed/moulded up. And after all those years in the barn, it was cracking multiple places. Anyway, We agreed on a price lower than 23000DKR (3100?, 3400USD, 2700?) so he could get rid of the car. The engine is fully build with Wiseco pistons and rods from Japengines, and the paintjob did cost over 50.000DKR (6700?, 7300USD, 5800?) But it dont look as good anymore. I am planing to paint it when i get that far. Simply because i cant match all the colors after cutting through the bondo to get the front and rear bumper off. My wife thinks the Dragon is the bomb though, and she wants to keep it           Now i just have to wait a month so i can move into my new 50 m2 (540sq ft) workshop |

|

|

|

| Sponsored Links |

|

|

#2 |

|

Leaky Injector

|

I dont have much of an update as im still waiting to move into my new garage/warehouse. But heres what i have:

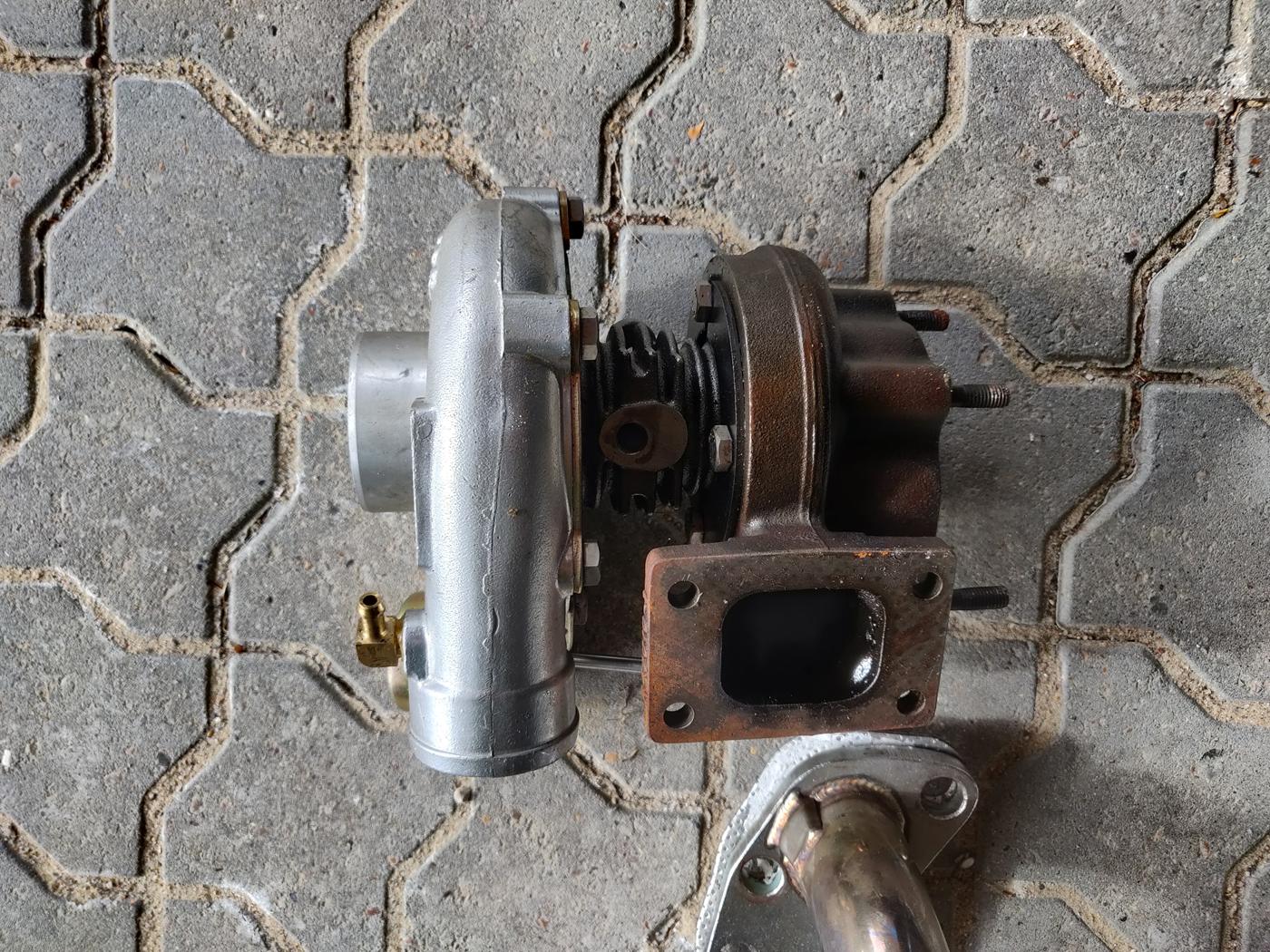

The plan with this car is to keep it cheap. It means i have to do as much as possible myself, and keep all expenses down. This means i only go for stuff thats important to make it run. (except painting the enginebay) The car is still parked in our carport where i cant/am not allowed to work on it. But nobody can deny me to look further into the car.  A previous owner installed a reverse camera - something i would have done a bit different    But i have bought another center piece for cheap (500DKR, 74$, 67?) I got 2 extra exhaust manifolds in the car-deal. But i dont know if i should use them or the original. Any ideas?  Theres also 2 turbos included. the original that have around 1cm play, so its just trash. And another China-turbo that i will use until i find something extremely cheap.    Unfortunally i found some bad parts about the car. First of, i poked a finger through the spare wheel well. But i kinda expected it, so no big deal. Another bag thing is that the whole bodykit is screwed into place, and then moulded. This makes it a LOT harder to remove the sideskirts without damaging it to much. I was hoping to get it of in one piece, so i can sell it to someone who wants the 2005 style.    And bonuspoint. The bodykit is a Veilside C-III http://www.veilsidejpn.com/en/produc...n/180sx_c3.php     The interior is complete, and thats a HUGE plus! But im not a fan of the leather seats. But i guess theyll do for now untill i find something more fitting for this car   I saw some wheels in the other end of the country, and i had a friend who went to pick up a car there. so i asked him if he could pink them up, and he said, no problem. A few days later he dropped them off.  And this was the car he picked up. MK3 supra with turbo and manual gear... and no rust. It was a really good deal!  Anyway. as i wrote earlier, i wanted to keep this build on a tight budget, so i was thinking about painting the car with spraypaint in a desert army theme similar to this one:  but after i ordered 3 different colors from a local army store, i didnt like any of them   So ill end up biting the bullet and painting it with a gun. With also would be a better option in the long run. Btw. does anyone know what this is? My guess is a boost gauge or a boost controller. i dont know for sure as theres no model name on it.   I also have a problem with the wheels. Theres no lock keys, so i cant get the nuts of. Ive ordered some 10 point sockets that might work on 3 of them. But the locking nut might become a problem. Any tricks to get it off that dont include an axe or a welder? I would like to reuse the wheels   And i received new headlights as we are required by law to have correct adjusted ones. And thats not possible with RHD headlights. Luckily they were extremely cheap  |

|

|

|

|

|

#3 |

|

Leaky Injector

|

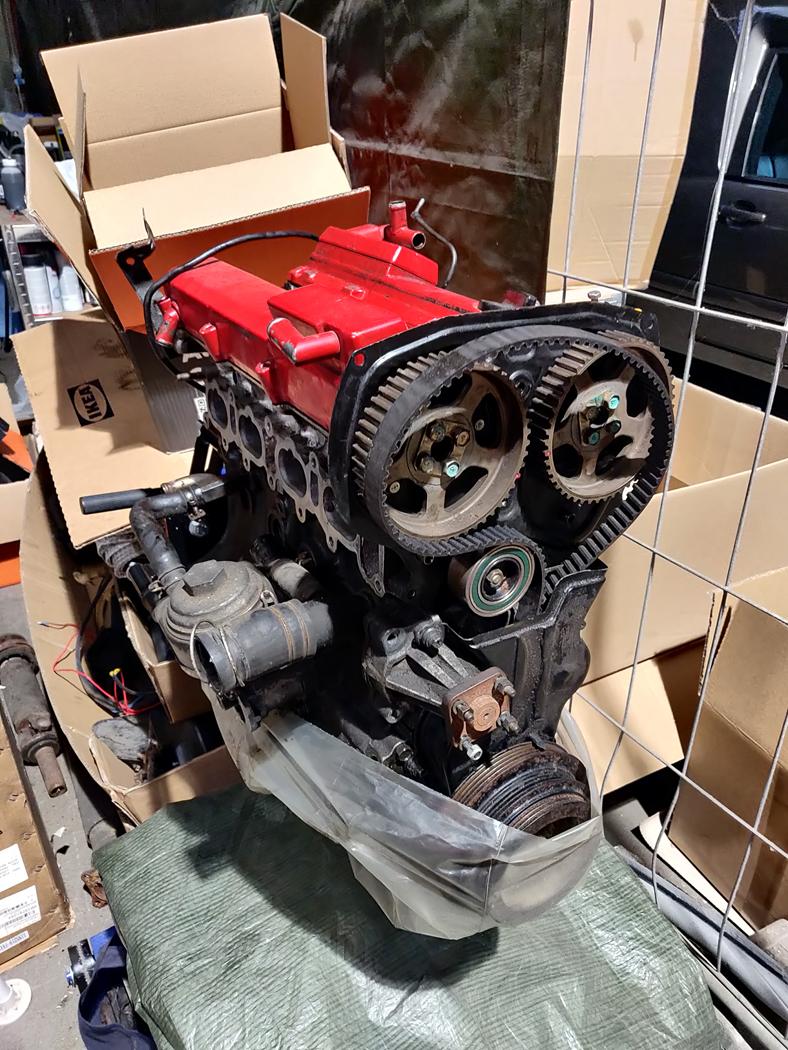

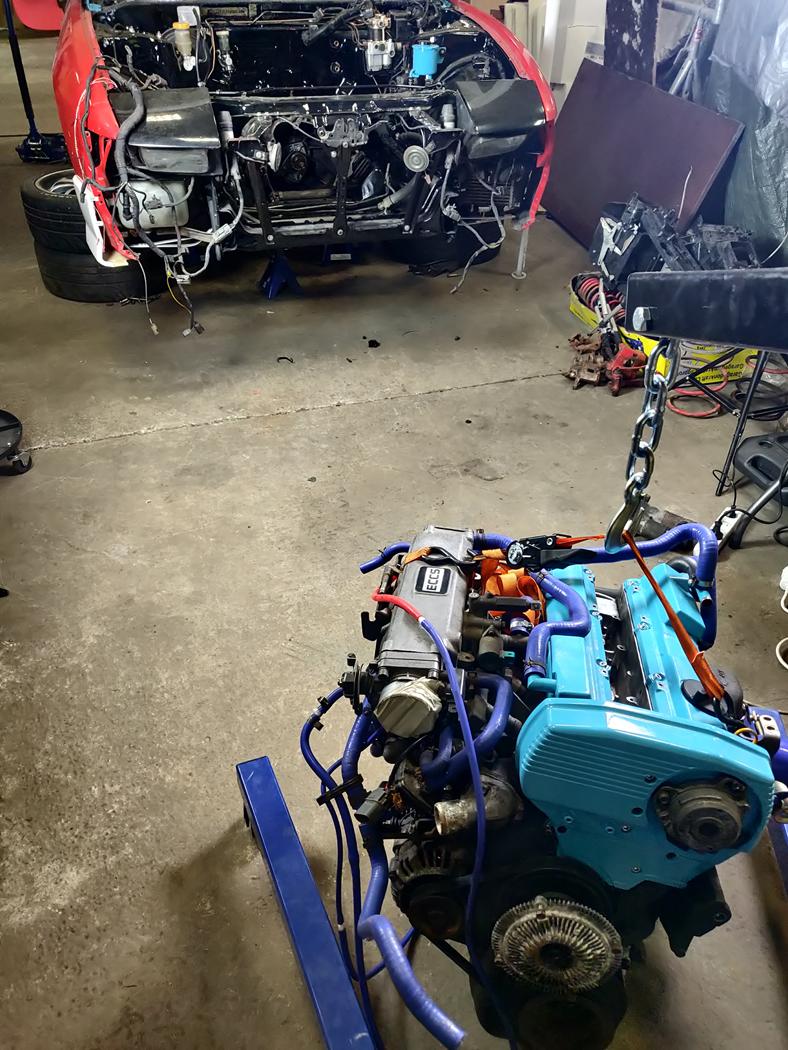

Finally i got the car into my small workshop. Its been some crazy days trying to get all the tools needed. Im still lacking a lot, but at least i have enough to keep me going for some time now.

My friend, Peter falk from Peter Falk Photofactory came by to shoot the car before i was going to rip the Veilside bodykit of of it.          And a few pictures of the new place and a good friend whos helping me. Even though he have no knowledge of cars, he's willing to help and learn. Gotta love that positivity!    After some work, we got the front bumper off. It was only held in place with 8 selftapping screws and bondo... If you are thinging about installing a bodykit with bondo, PLEASE DONT!!! - Good news though. Those front fenders are rustfree! Super rare in this part of the world!     Also the side skirt are screwed in with selftappers. I accidentally pulled out the first one as i didnt know there was a screw. But after looking close, i can see theres about 10 screws holding each sideskirt. So i have to get a small wirewheel to be able to screw the screws out.  As a last thing, i got the engine out of the bay. I dont have any plans to the engine as it should be pretty upgraded already. I might paint the valvecover, though. But i dont know what color yet.    |

|

|

|

|

|

#4 |

|

Leaky Injector

|

I think its time for a small update.

As i propably mentioned earlier, this car is going to be a budget build as i have another where i spend all my money... that i dont have! Anyway. i bought a palletshelf to get more storagespace. And bought ton of parts. They could barely fit in my daily driver (chevrolet cruze) And i found a few bad rustspots. But nothing some new metal cant fix.                                   |

|

|

|

|

|

#5 |

|

Leaky Injector

|

Well... After ive been listening to the Need for speed 2 Underground soundtrack for a month straight, i figured out it was time to go crazy on this.

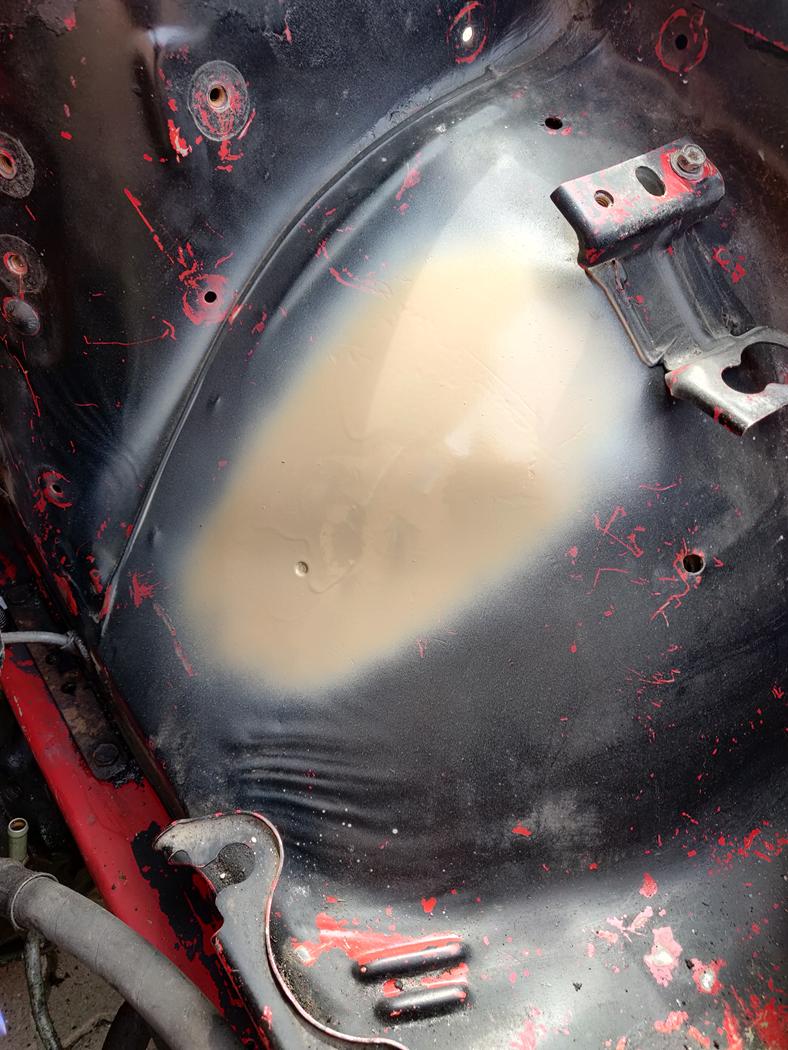

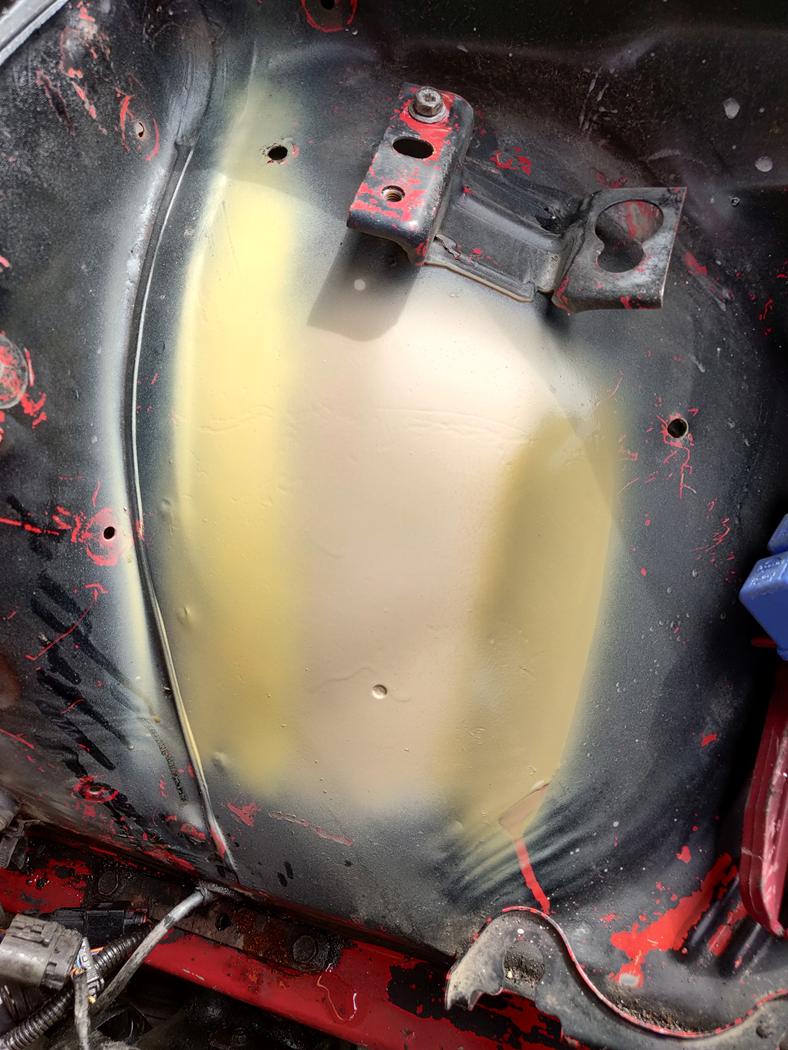

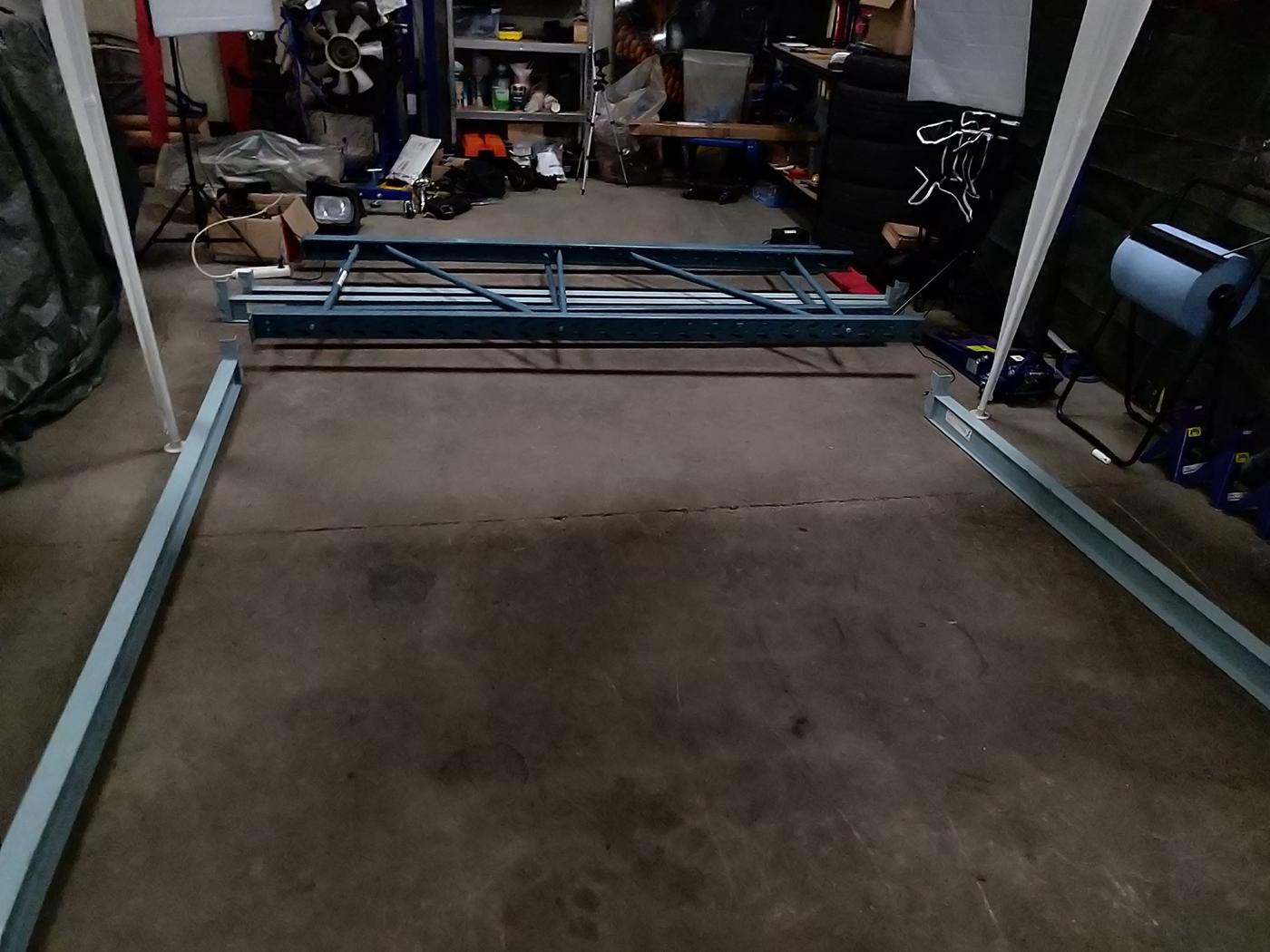

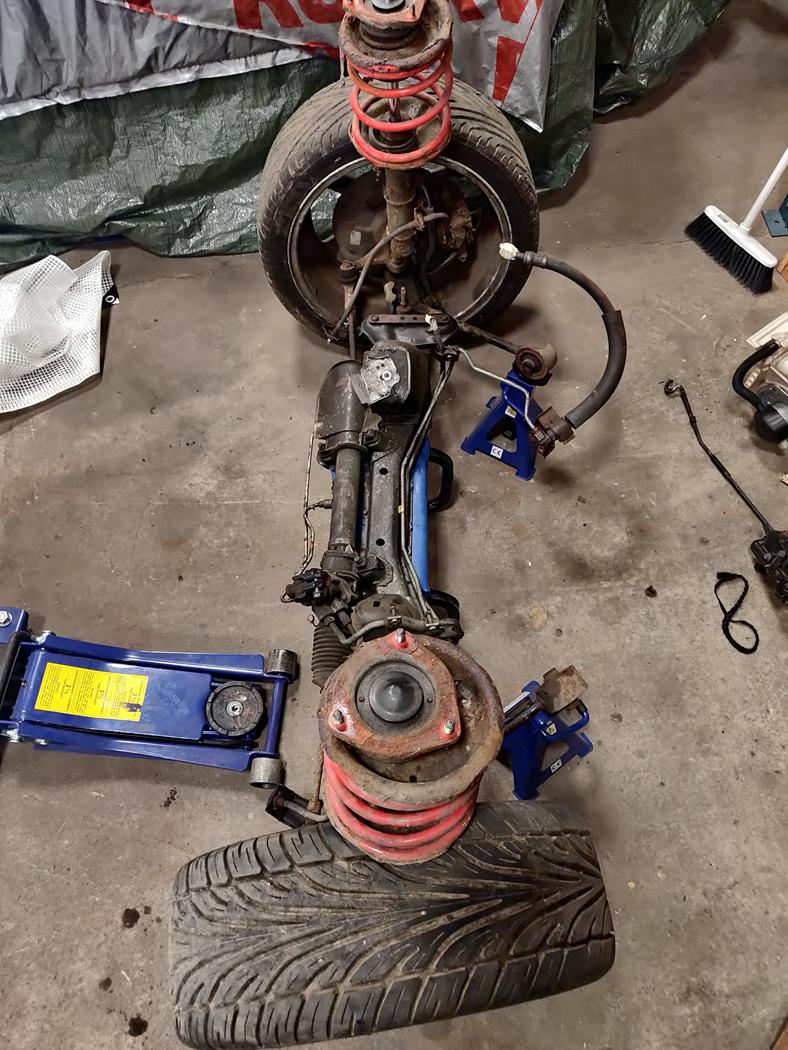

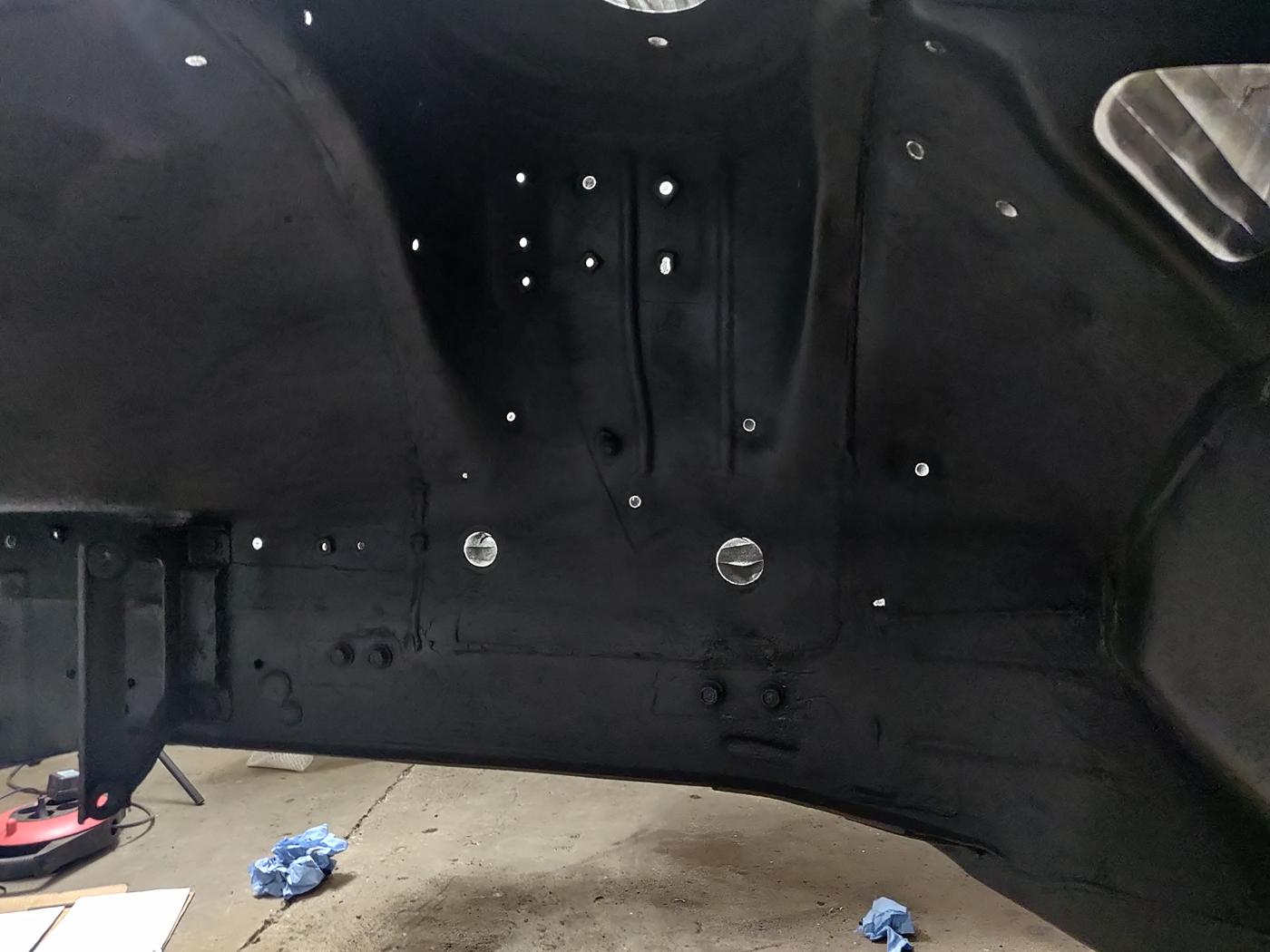

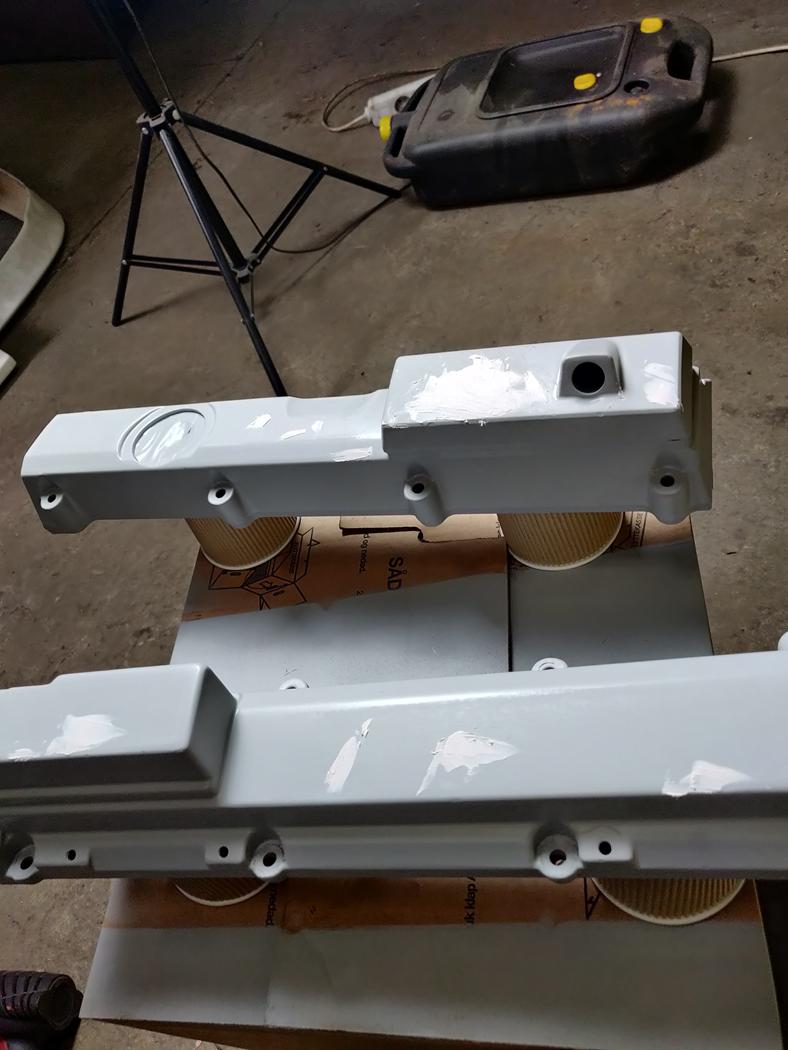

Ive been working evenings and weekends to get as far as i am now. As mentioned multiple times, its a budget build, and thats why ill be doing as much as possible myself. Including painting it! So in the last month ive been prepping the enginebay. So everything had to go. As ive had problems with a locknut on the wheels, i desided to take the whole front subframe off in one go. It went great and a lot easier as we could just roll it out under the car.    Then it was time for some Wash primer / Epoxy primer. This protects the bare metal from rust.   The wheelwells were in really good conditiion, so i just scraped all the loose debris of and gave it a few layers of anti-gravel to protect it a bit better. Before:  After:  And the enginebay got somehigh build primer. My "paintbooth" is only 3x3 meters (around 9x9 feet) so i cant paint all parts at once which sucks!    After hours of sanding to get it down to an acceptable surface, it was time for the color. I used a "Super-black" from Autolakhandel.dk. It was really easy to use and gave a really nice finish. Only problem is me and my primitive paintbooth       And its back to fill out the enginebay again...   All the suspension are getting cleaned up and painted.    |

|

|

|

|

|

#8 |

|

Leaky Injector

|

|

|

|

|

|

|

#11 |

|

Leaky Injector

|

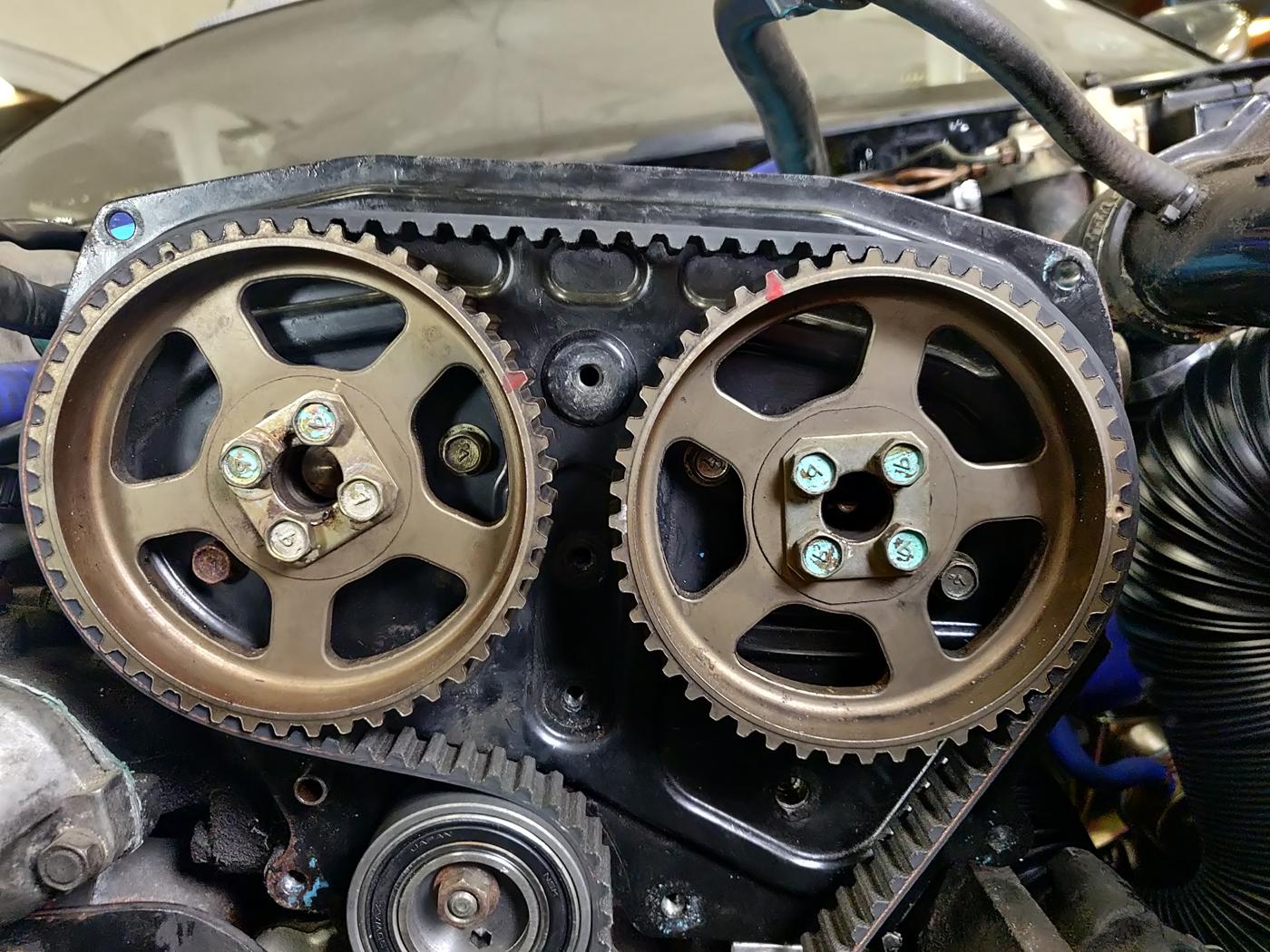

Well. I guess its time for a small update

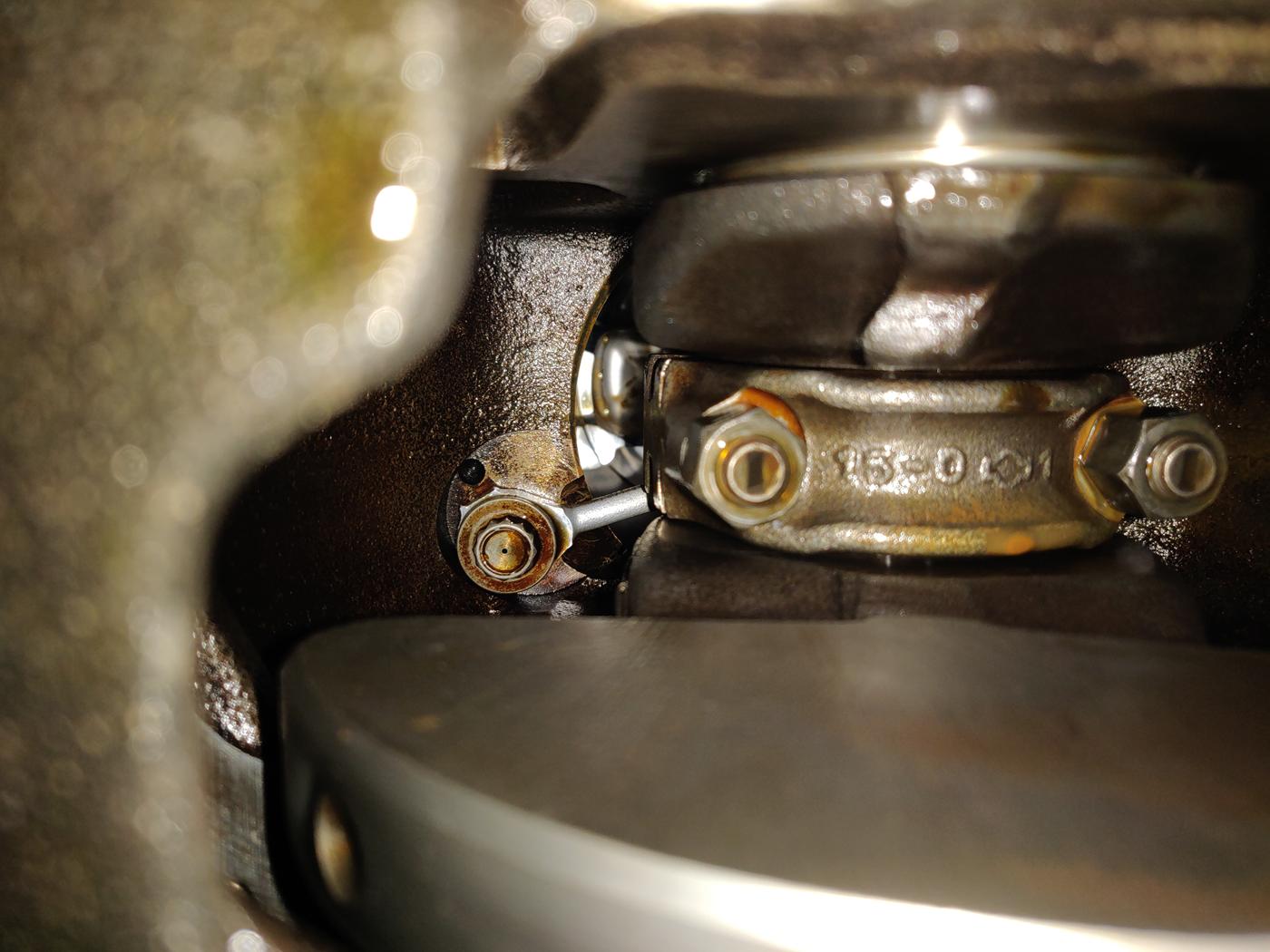

I finished the front suspension and got the car rolling again.       I also did my first brakeline in over 10 years, pretty proud of the result. I might have to redo it all some other time to get a more clean look. But for now its fine.  And a quick picture of the engine :P  I need to change the timing belt before the engine is going back into the car, but havent been in the mood. Im propably asking a friend to do is as i have no idea how to do it. But theres is guides to do it, so i might have a go at it at some point :P  As the car is RHD, i thought the only right bodykit for this car is the TypeX. Luckily i had a complete set laying around from my other build :P  We rolled the car out so we could clean my workshop. So why note take a few pictures?  I was tired of always using a ratchet for all bolts and nuts. So i spoiled myself and got myself one of these 400NM bastards.  Last thing, the caliper was rusted so much i couldnt save it, so i found some other OEM ones and gave them some paint. Now im just waiting for a rebuild kit so they can go back into the car. And then the suspension in the front of the car official done   |

|

|

|

|

|

#12 |

|

Zilvia.net Advertiser

Join Date: Nov 2005

Location: Michigan

Age: 33

Posts: 5,430

Trader Rating: (16)

Feedback Score: 16 reviews

|

Nice progress!

__________________

Build: http://zilvia.net/f/showthread.php?t=643065 Friends don't let friends buy knock-offs. |

|

|

|

|

|

#13 |

|

Leaky Injector

|

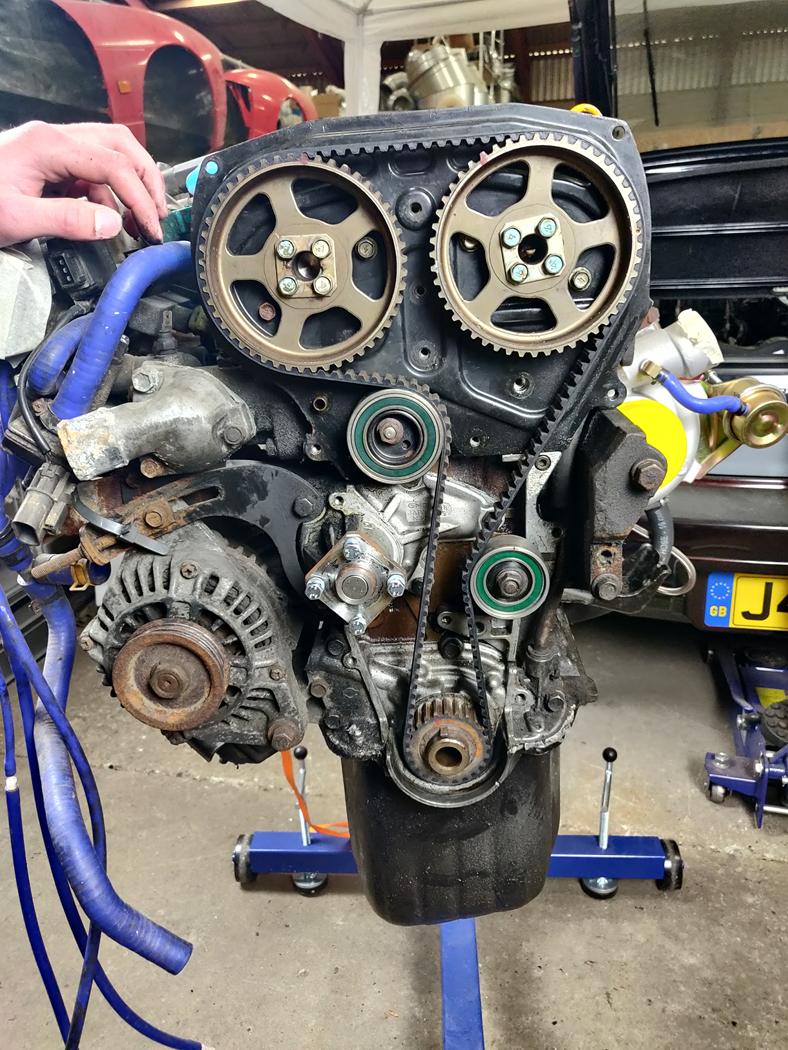

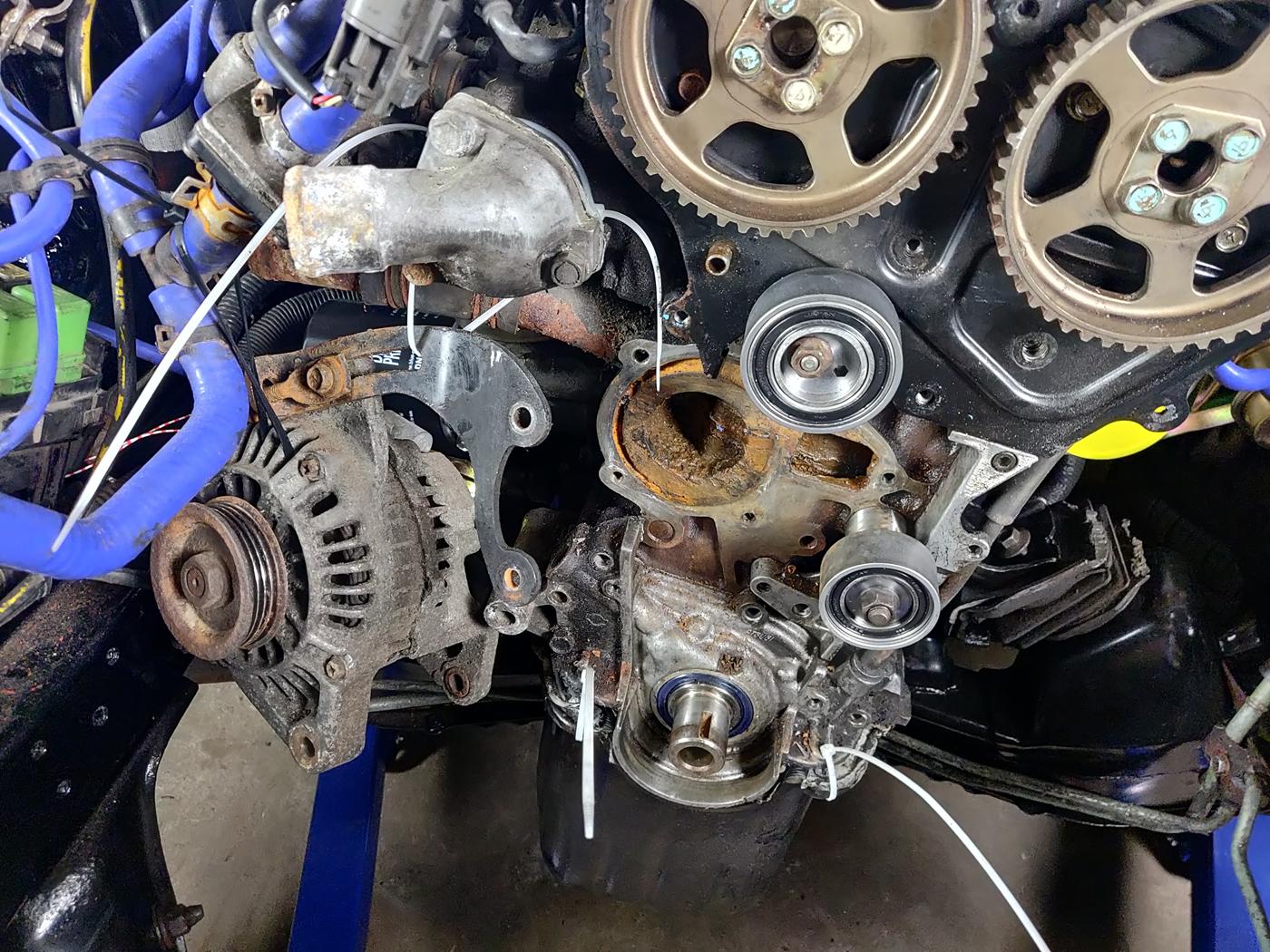

I think its time for a little bit of good news, and a lot of bad.

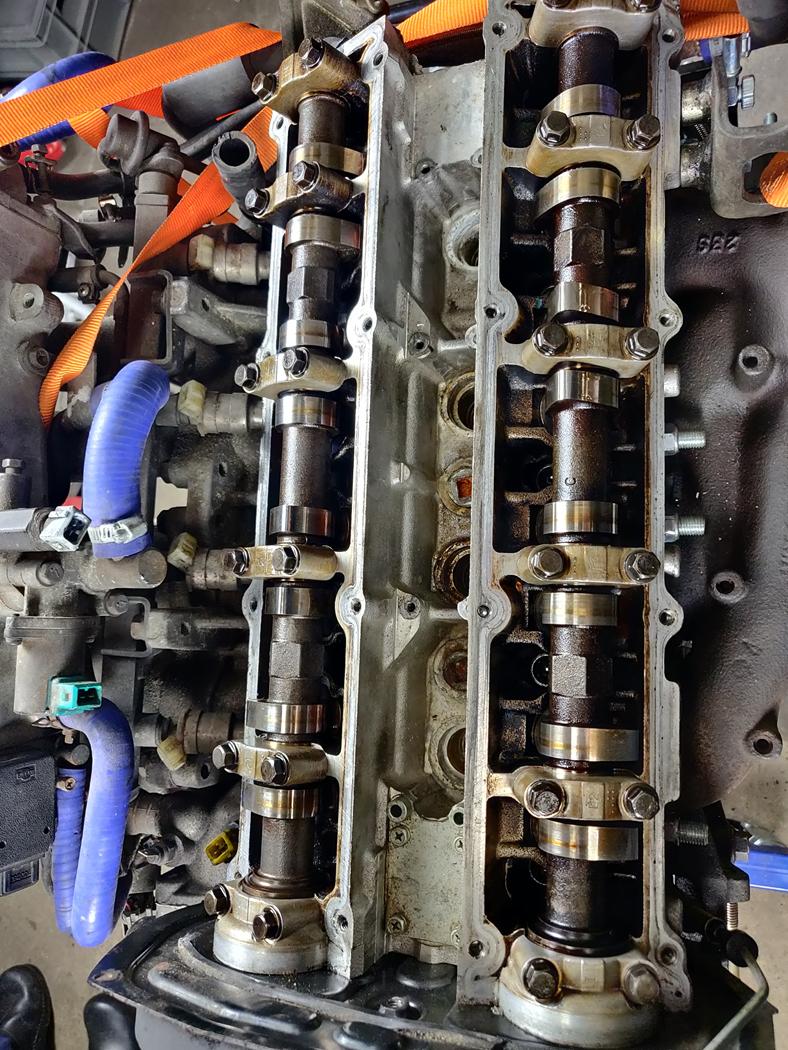

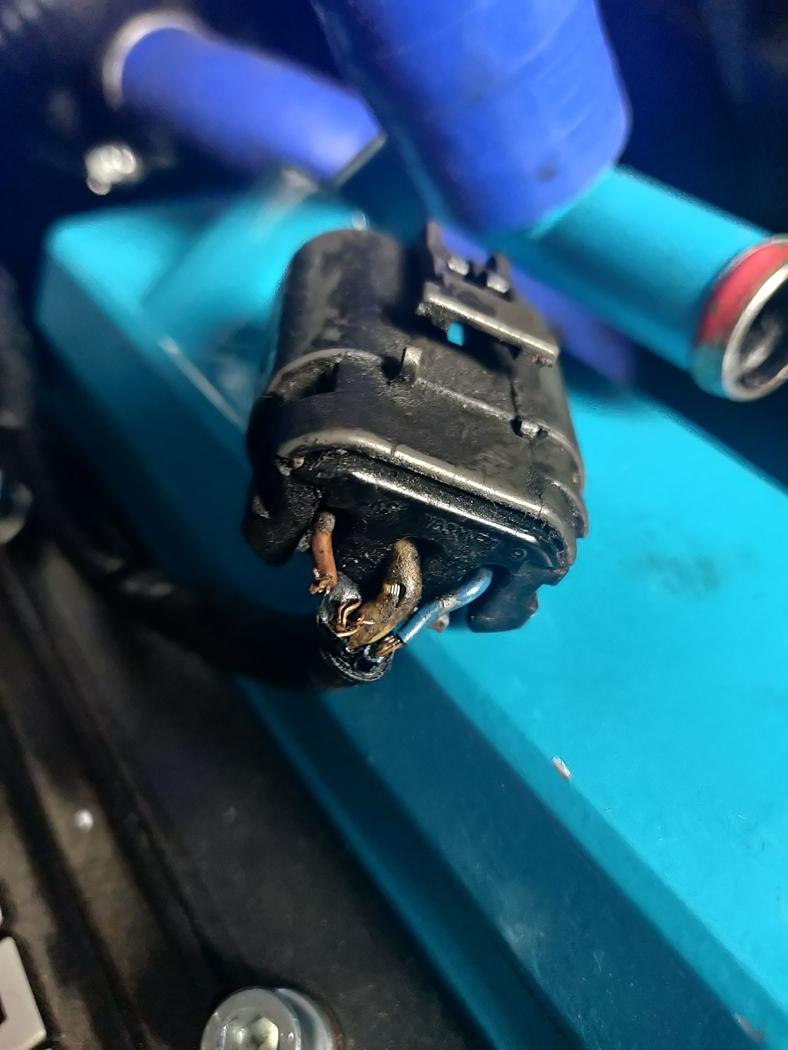

So we installed a new timing belt as I didn't know the condition of the old one.     At the same time we took off the cam covers as my friend wanted to see if the cams were stock or not. They were   He also showed me his latest 3D print. A funnel with thread that fits perfectly into the CA18DET. Its a really cool design, and he let me keep the prototype :P  When the covers were off the engine, i also painted the front  Next stop was to install the clutch and gearbox onto the engine. This was pretty simple and we almost didnt use a hammer  And it was dropped into the engine bay  I thought it was VERY close to everything, so i cant imagine how to get a RB in there   I quickly installed all the boring stuff around the engine   And found a small problem. Its the plug for the O2 sensor. New one have been ordered, so i just have to replace it when im in the mood  At this time, the engine was ready to be started, or so i thought. We disconnected the fuelpump and turned the key. Engine didnt do anything. But after a bit of google search, we figured out that we need to shortcircuit a plug in the enginebay because it was original a automatic. This was done, and the engine turned just as it should Video can be seen here: https://www.instagram.com/p/CGpbLIsH..._web_copy_link But... its not that simple.. it didnt create any oil pressure  Im happy that i didnt actually start the engine, it could have been bad. but again, i dont know the condition of the engine. A new oil pump have been ordered, so i hope that it would solve all problems.  In the meantime i started working on the interior. Main thing was to pull new wires for speakers as previous owner didnt do a good job. Just look at this:  Anyway. I did put everything back together inside the car with only a few things needed to be done.        As you can see, im going for a rather simple interior. Unfortunally i need to install some gauges on the dashboard as theres a hole i want to cover. But its okay, i have a oil pressure gauge that can fit there  I also wired up the TypeX Kouki lights  One of the left lights dont work because its a EU model, and we dont have any wires going to that one. But ill change it in the near future. I also worked a bit on the rear. Started with the brakes. I hoped i just needed some new discs and pads, but both calipers were rusted so much i had to rebuild them. Im still waiting for the rebuild kit, so i did clean and paint them in the meanwhile       We also did remove the rest of the Veilside bodykit and the spoiler. I dont know why, but EVERYTING in this car is held together with selftapping screws. Even the spoiler! I removed the spoiler after drilling the selftappers out and found a small problem :/ More rust    Yet another moneypit  Rear bumper got removed, and theres only a small bit of rust behind, this i can accept :P  But behind right rearwheel theres a lot of rust. I didnt take pictures of it as i dont wanna be reminded of it. But hopeful i can find somebody who can fix it as a reasonable price. Full bodykit is now removed and i put it for sale locally as i dont have any option to ship it out  Lastly, a couple of pictures of how the car sits now      And to finish it off, i got a set of Tein Super Street coilovers with the car. So a few days ago, I noticed there were missing a few things on them. So i contacted Tein in UK to ask for a parts list so i could order the parts. Just to find out that they are not available anymore. So now i also have to spend money on a new set of coilovers. Im already thinking about buying a set of Tein Street Basis Z to keep the car and cost down. |

|

|

|

|

|

#14 |

|

Leaky Injector

|

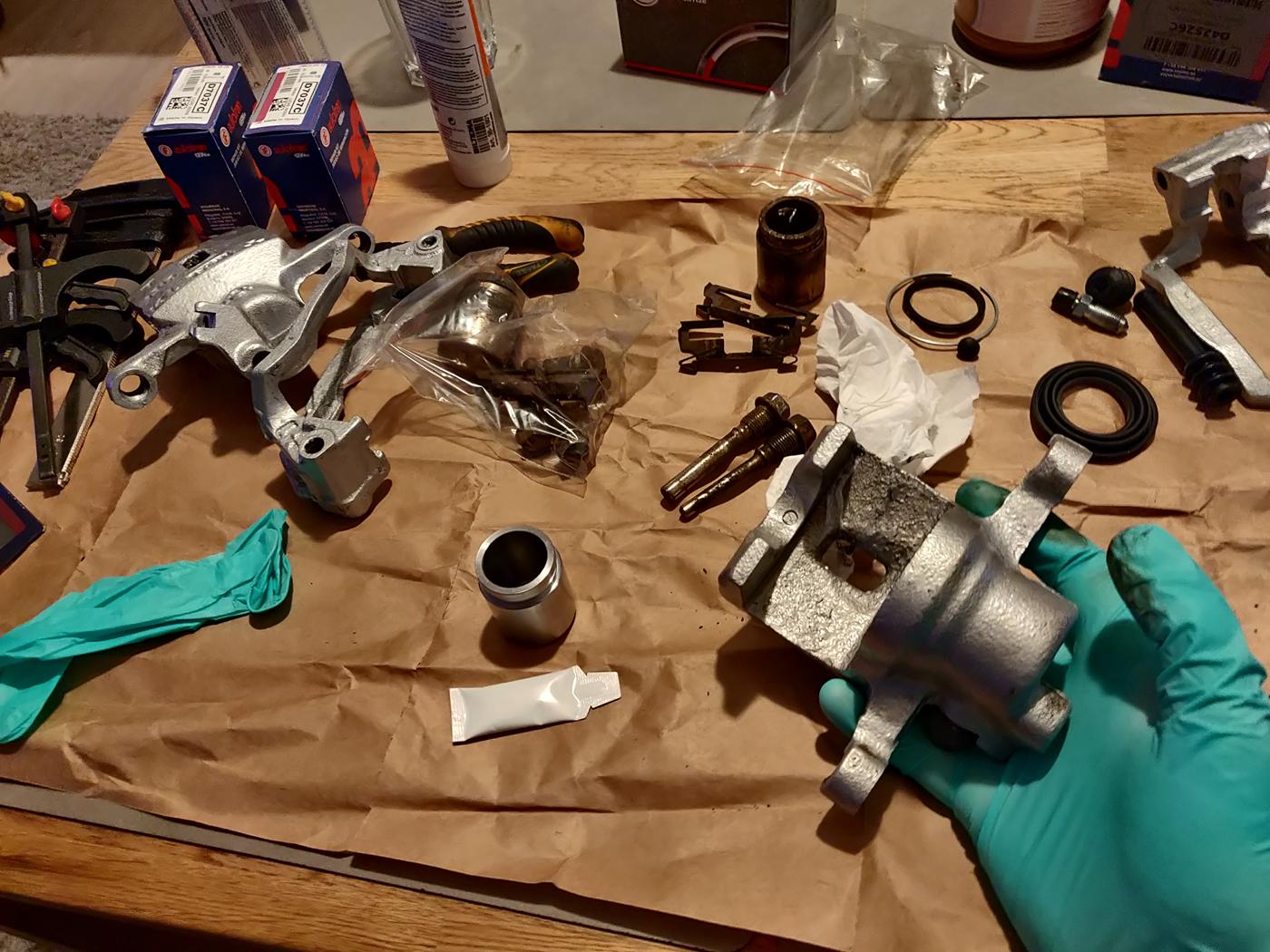

Finally i received my rep-kit for my rear calipers, so i spend one evening putting them back together.

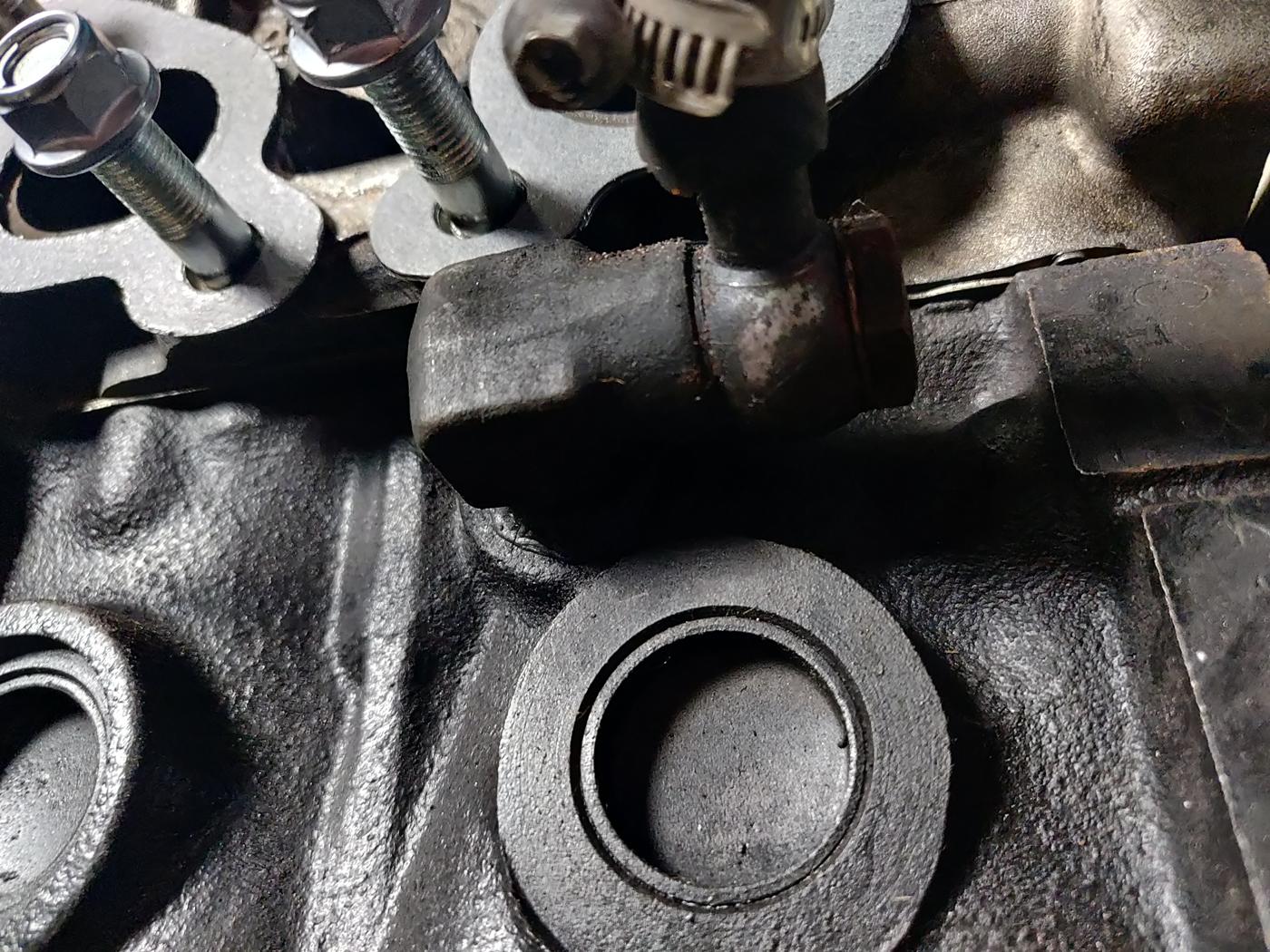

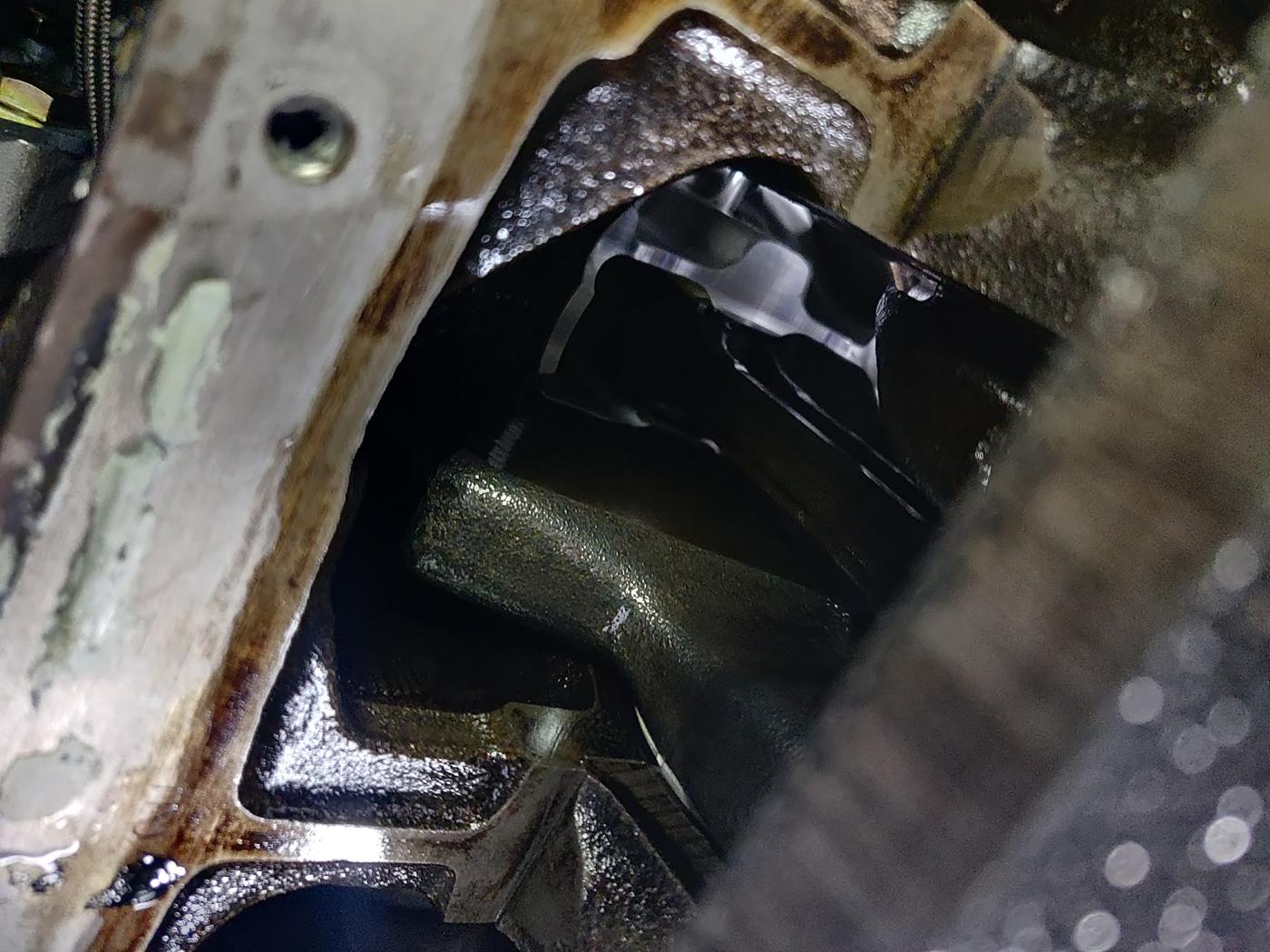

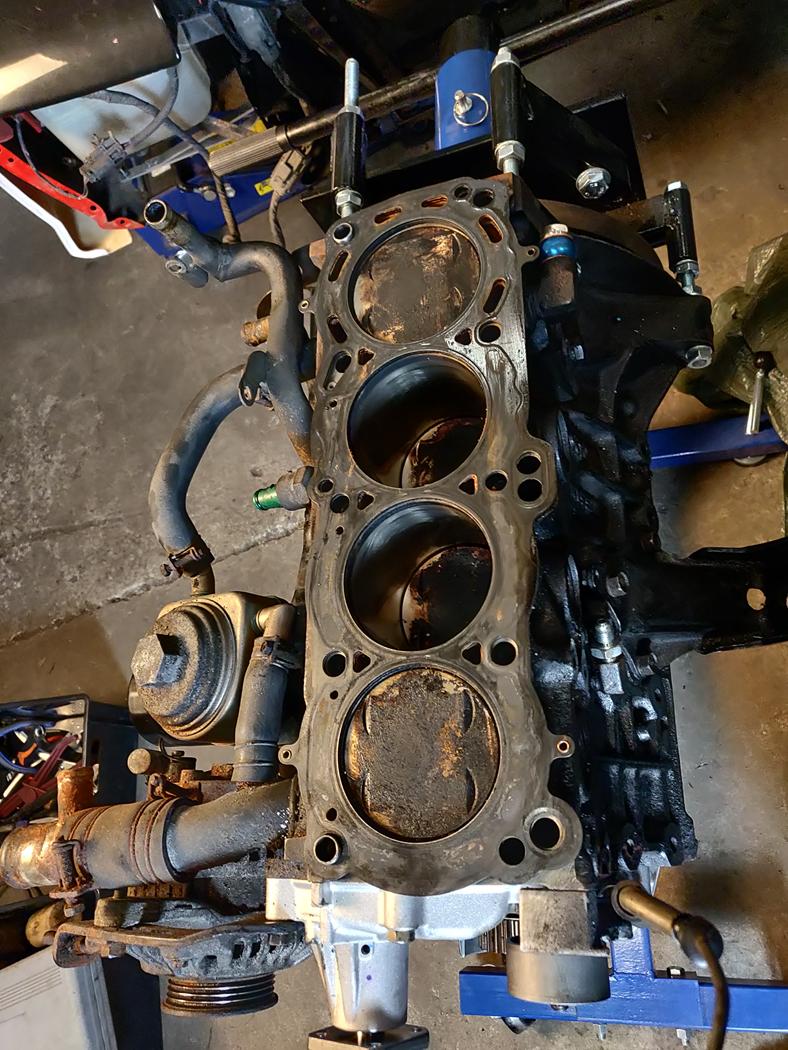

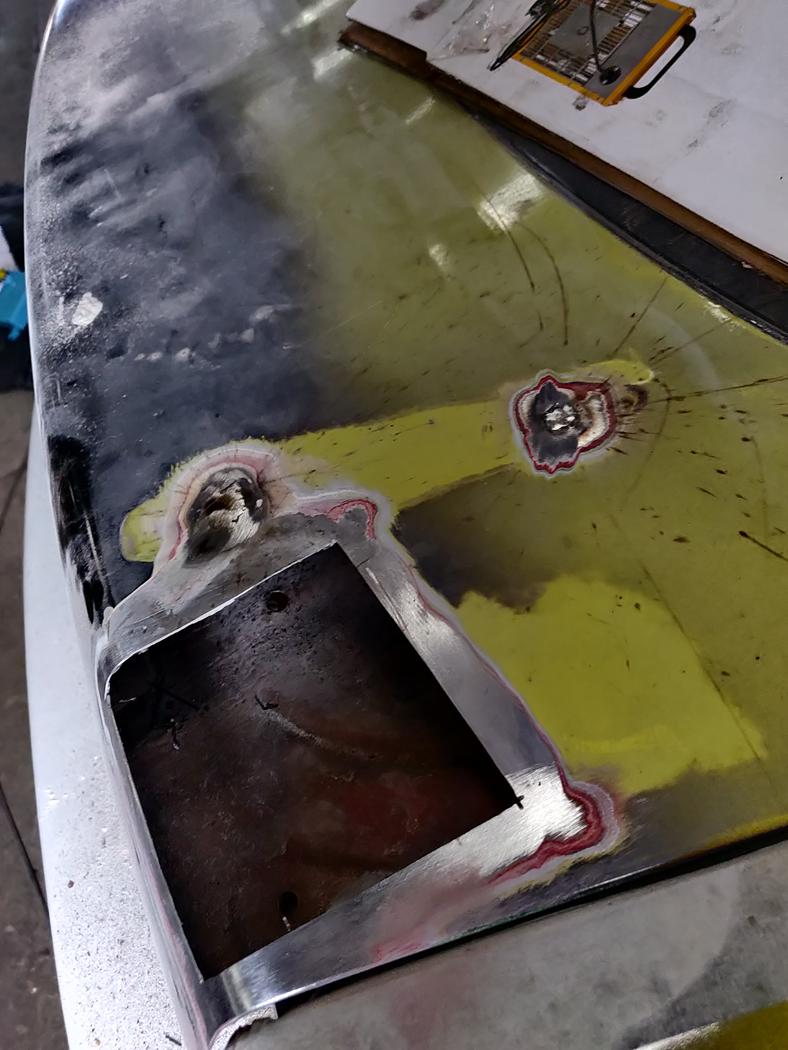

We also deleted the clutch dampener loop as it was impossible to bleed it probably.  I know there was a bit of rust in the trunk, so i sanded the paint down to see how bad it actually was, and let me tell you... Previous owner really liked fiberglass and selftapping screws! Everything was mended with these 2 things.    As i was a bit defeated with some of the stuff going on with this car, i wanted to relax a bit and get the front bumper to sit perfect. A few hours and this is how it looks. Im pretty happy with the fitment at this point.   After i mentioned i needed some coilovers, Maxpeedingrods.co.uk reached out to me, and a week later, i had new coilovers for the car. Cant explain how great this is. Its not the top of the line, but for the price, and my plans with the car, its perfect. Ill go into details with the set in the near future. Even my dog approves    I did a quick testfit with my Work Euroline DH wheels, and it looks great   As mentioned earlier, the engine wasnt creating oil pressure, so i ordered a new oilpump. As i have very little experience with mechanics, i went to the workshop manual to figure out how to replace the pump. Guide was easy AF. 7 steps where its something like: "Loosen enginemount nuts", "lift engine" "remove oilpan", "remove oil pump" and job done... Whoever wrote that piece of  should be fired! should be fired! Reality is more like: unbolt engine mount nuts. Lift engine so the gearbox hits the firewall and then some. Drop the whole front subframe. remove brackets that holds the gearbox to access bolts in the oilpan. And THEN remove oilpan. This took WAY to long, and looking back, we should just have removed the engine. Because thats the next step.        When the oilpan got out, i cleaned the inside, and i found these 3 fuckers.  Do you know where they belong? No? let me tell you... Its the oil squirters. Previous owner got installed Wiseco pistons, and put them in the wrong way, so the skirt of the piston hits the squirters and they brake off. Now you might ask: "But Jacob, why is there only 3 rods, but the engine has 4 cylinders?" Well... previous owner got one of the pistons in the right way... So now i NEED to remove the engine, remove the top to turn the pistons 180 degrees around... And install new squirters. But at least i was lucky enough that i bought an engine a year ago so my friend could make an upgraded oil pan for my other car, so i went to pick it up earlier today. Ill just take the squirters from this engine and maybe ill rebuild it in the future, But with 2 S13 that i want to finish first, it might take many years   |

|

|

|

|

|

#15 |

|

Zilvia Addict

|

wow, that is certainly sketchy. After that I'd be cautious of every engine component you DIDN'T replace.

What all did you use to mount the front bumper? All OEM brackets?

__________________

WTB SR20 *Non-Rep* Bottom Mount Manifold WTB Bride Zieg II |

|

|

|

|

|

#16 | |

|

Leaky Injector

|

Quote:

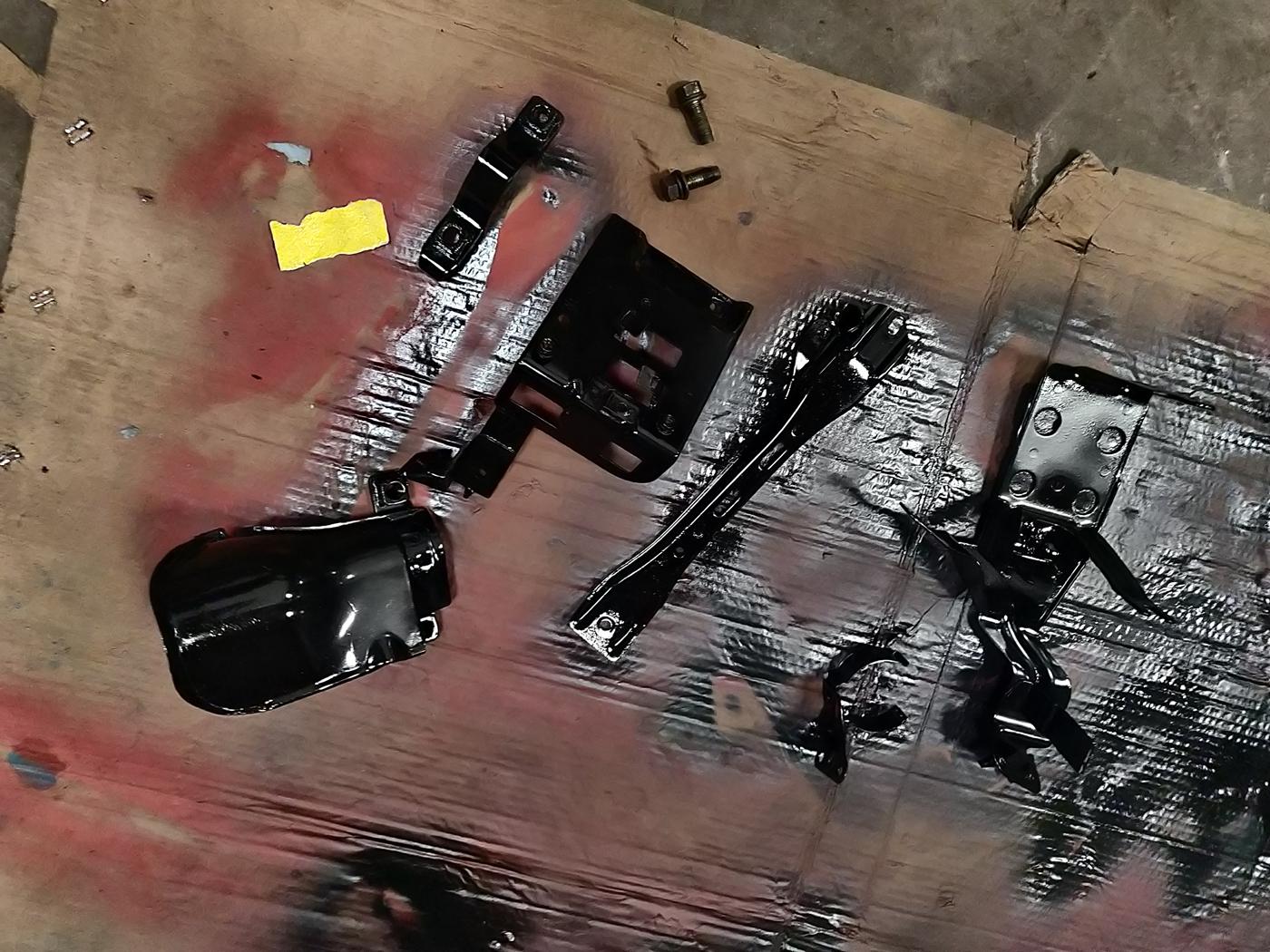

And the bumper is installed with a lot of the original brackets from a pig nose bumper, and a bunch of bolts and nuts to secure it in place. |

|

|

|

|

|

|

#17 |

|

Leaky Injector

|

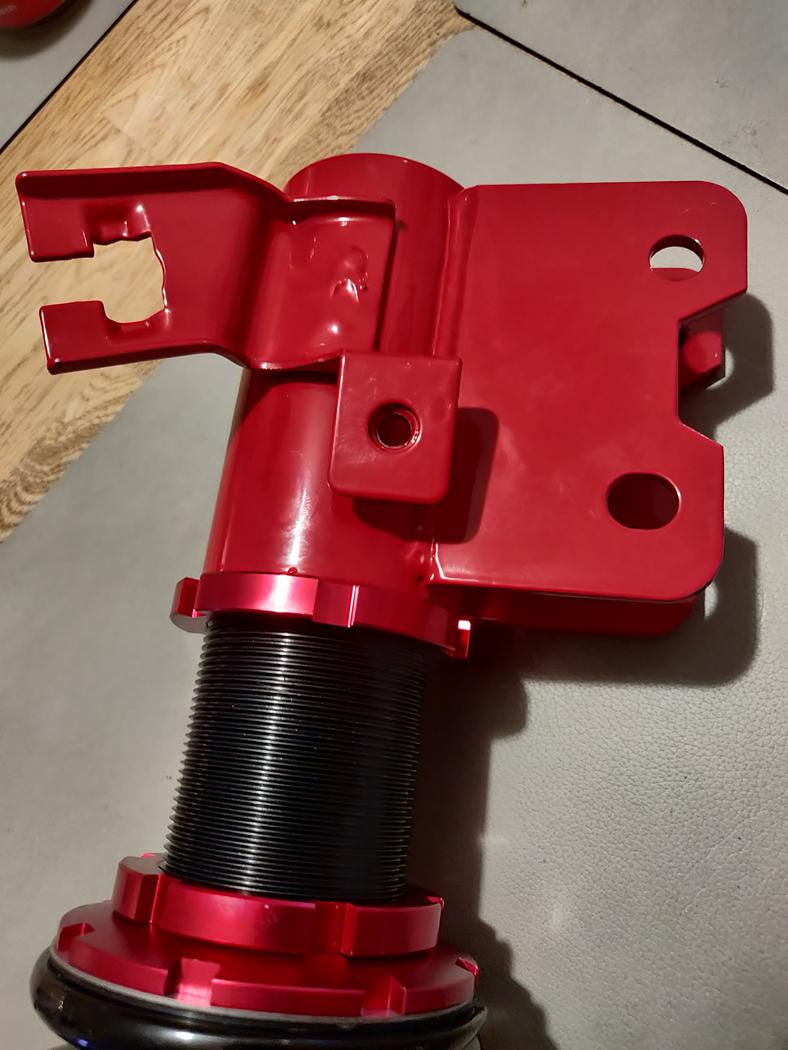

As i have mentioned earlier, my Tein coilovers were so outdated that i couldnt get any replacement parts for them. I was fortunate to have MaXpeedingRods reach out to me, and ask me if i wanted to try their coilovers, since the coilovers that i got with the car were old and useless. And of course I was thrilled by the idea of trying a new product. So here comes my honest review and some specs about the item.

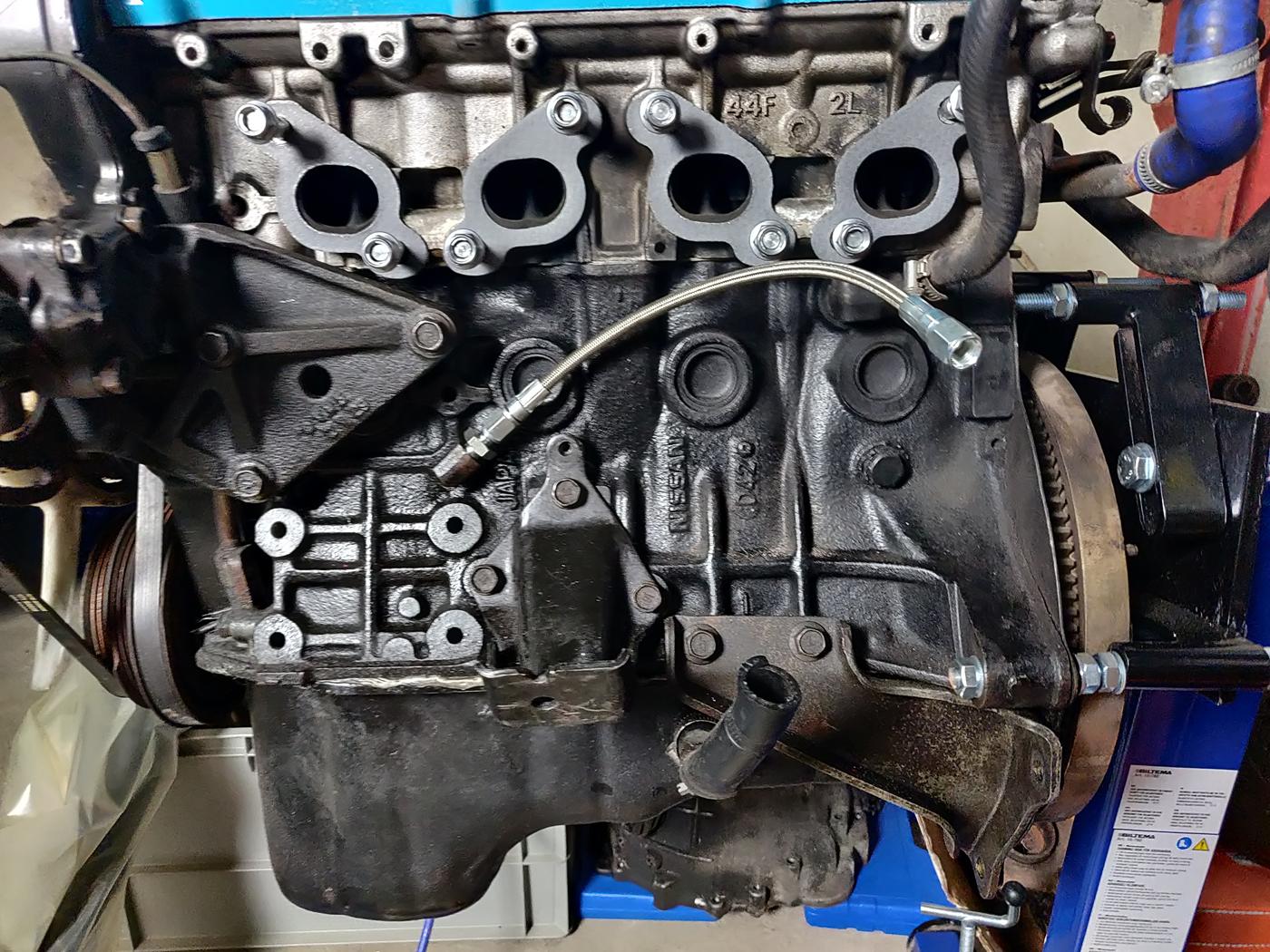

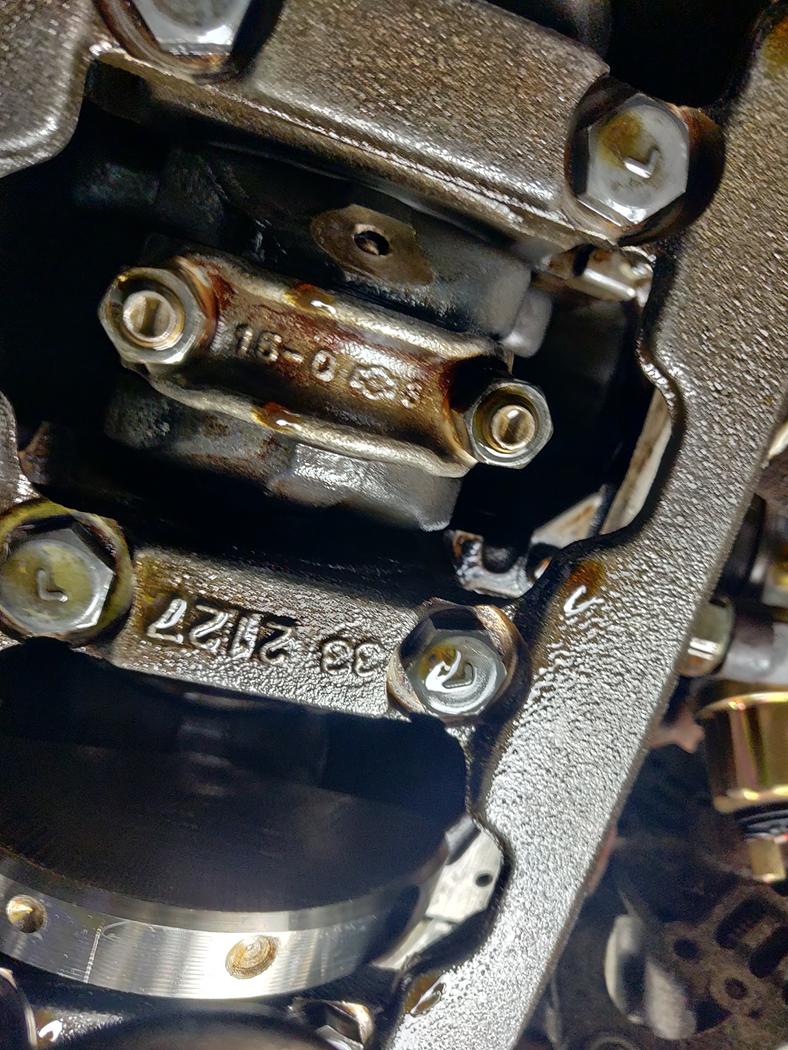

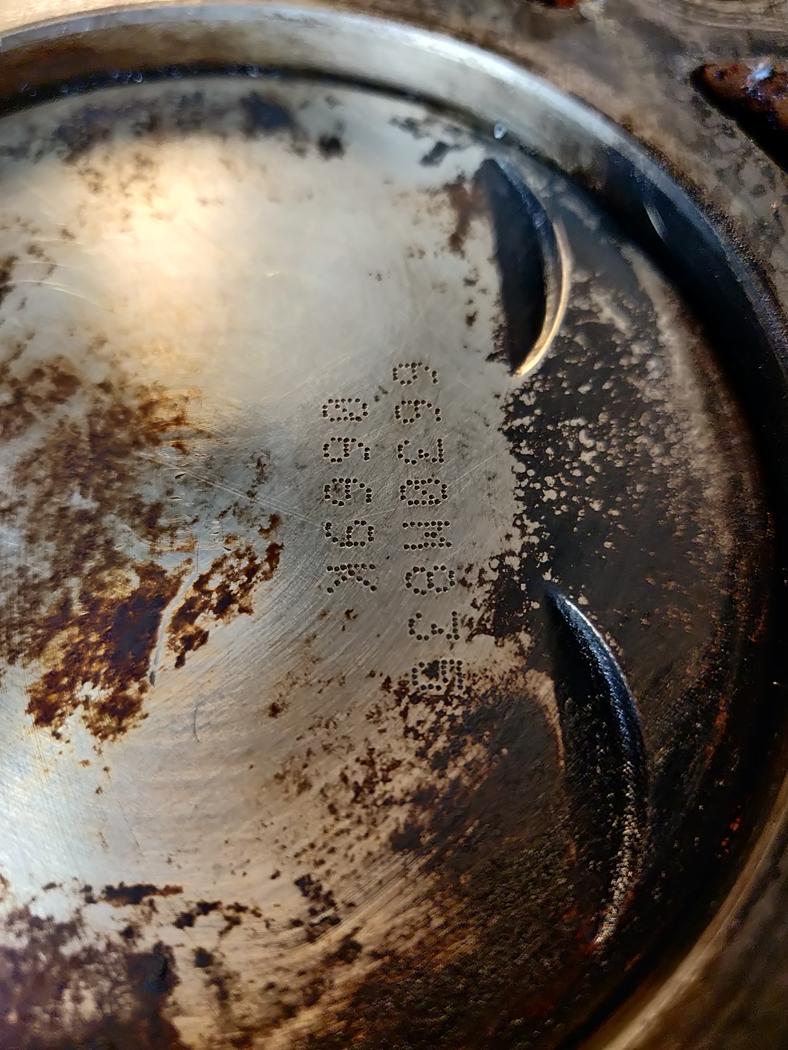

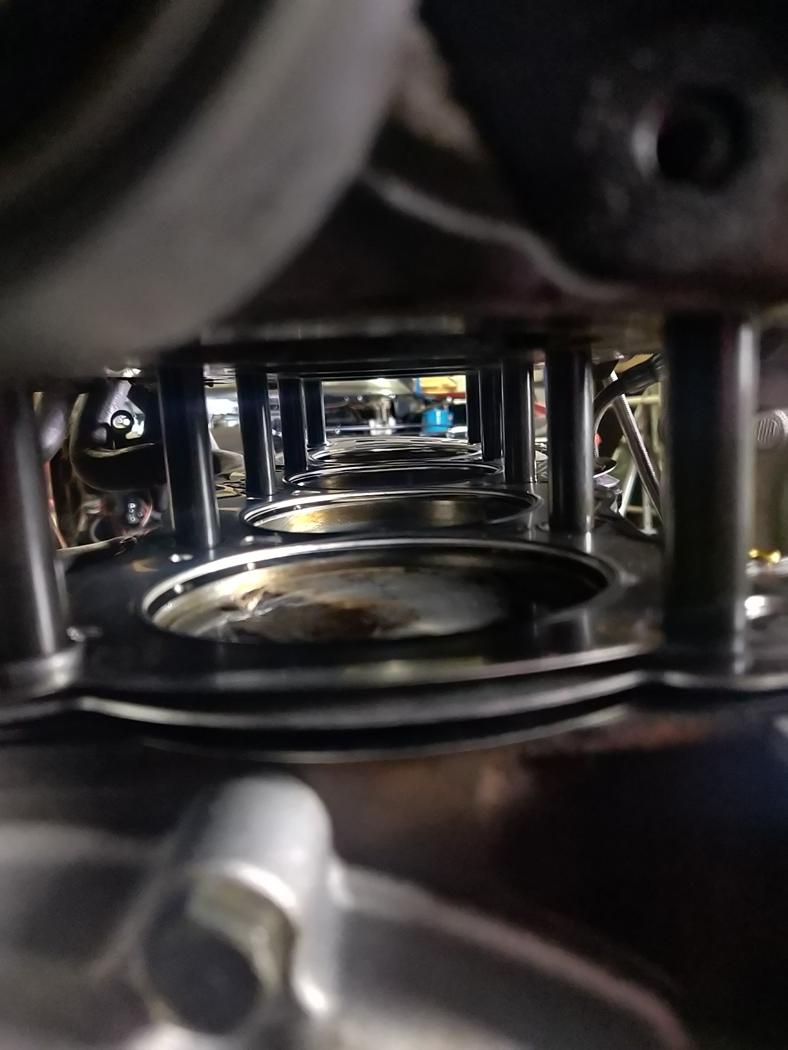

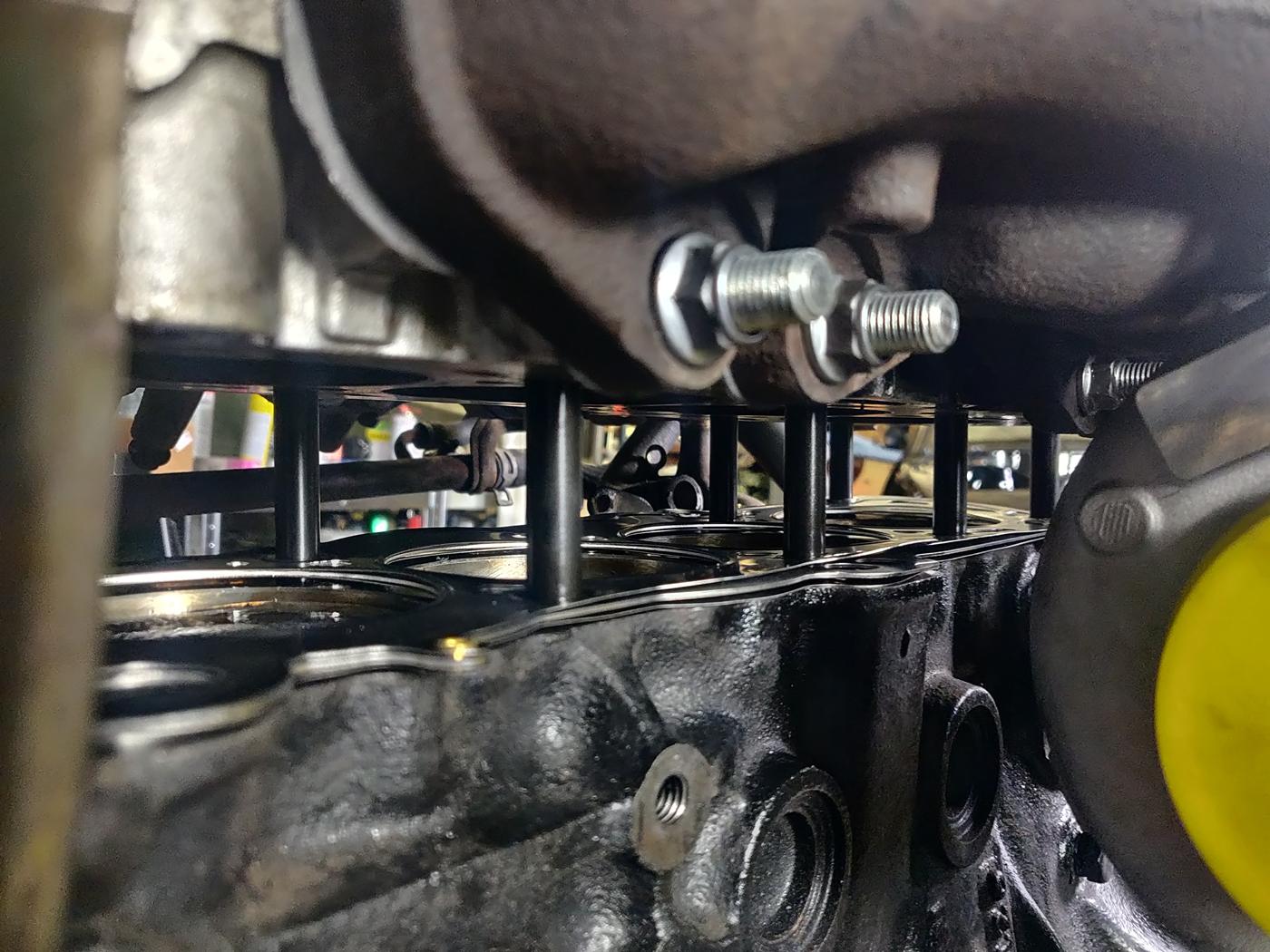

The product is the CO-NIS-S13-R-LC which is a 24-way adjustable damper. The box is nicely made, and even has the MaXpeedingRods logo on the side - A nice touch. My coilovers came powdercoated and anodized in red, but the ones in the link at the bottom is yellow. Unfortunally the box did take a bit of damage in shipping, but the coilovers are intact. So i cannot complain about that.    Some little specs about the dampers: The coilover is designed with a classic monotube construction. The front: Spring rate Front: 8 kg/mm (448 lbs/in) The front can be adjusted about 8,5cm from highest point ot the lowest. Preload in the front is 7,6mm. Piston is 22mm wide Spring outer diameter is 96mm The Rear: Spring rate Rear: 7 kg/mm (392 lbs/in) The rear can be adjusted about 6,7cm from higest point to the lowest. Preload in the rear is 6,7mm Piston is 12,5mm wide Spring outer diameter is 95,5mm     The spring rate might be on the higher end for a streetcar, but that should definitely be a big plus for a trackcar as it makes your speed demon feel like a gocart. I will try driving with the original springs to start off with, and if i will not like them, i will see if i can find some softer replacements in the range of 7kg/5kg. I will keep you guys posted. The dampers come adjusted from the factory. So no need to re-adjust the preload. Which saves a lot of time and unnecessary stress! Highly appreciated minor detail. I would absolutely recommend to go through everything and tighten it up just to be on the safe side. In my case, the locking rings were loose on my set, and that can never be a safe thing. So please pay attention to this when getting your own set. We dont want any casualties due to a mishap like that. The topmounts are made of machined aluminum with a pillowball. The topmount also have camber adjustments. The Nissan S13 (180SX, 200SX and 240SX) normally have the camber adjustments on the spindle, so this option can give some extra camber, if you are into that. #cambergang! When looking for the damper stiffness adjustment you should know that it is done from the top. It has 24 clicks that goes from hard to soft. Trust me I counted myself!   The Installation of the coilovers is fairly easy. They are only connected with nuts at the top and bolts and nuts at the bottom. Easy peasy and straight forward. The process should go as follows: just unbolt your old suspension - start with removing the brake lines and ABS-line, if you have this. Put a jack or a jackstand under your Lower controlarm. Then remove the bottom bolts and nuts, so the dampers would not fall down. and finish removing the bolts from the top. The safest step by step procedure. Ask my toes, they once had a hobby related injury. To install the MaXpeedingRods coilover, is as simple as the removal. Just reverse the procedure of removal. But pay attention to the front coilovers as there is a left and a right one, the rear ones are the same. Start with the top, and work your way down. I always find that very easy and thorough. And make sure that the brake lines are secured properly, and please remember to tighten all bolts and nuts to the factory specifications. Unfortunally i can?t testdrive the car with the MaXpeedingRods coilovers at the moment. First of because its december, but the bigger problem is that my engine is taken apart to repair a "small" problem. But i will get back in the start of 2021 with an updated review. If you are interested in buying a set of your own, MaXpeedingRods have made an offer for you where you can save a few bucks: https://www.maxpeedingrods.co.uk/pro...racking=gojira Anyway? I went to pick up some tools to take apart the engine to see the damage.  I also needed to take apart the spare engine to take out the oil squirters.      And a also needed to take out the other CA18DET so I can take it apart?      This is how the oil squirters have to look, and how the ones in my engine looked?    When took of the head, I found a Cometic 85mm 1.3mm MLS headgasket and nicely machined cylinders together with some 83,5mm Wiseco pistons.       While I was waiting for parts for the engine, I made the wires for the 3 gauges Ill install on the dash. Its oil temp, oil pressure (ofc) and a boost gauge. To make it look half decent, I used some cable sleeve from when I modded and watercooled computers.   And the parts for the engine arrived. I guess the pictures speak for themselves?   |

|

|

|

|

|

#18 |

|

Leaky Injector

|

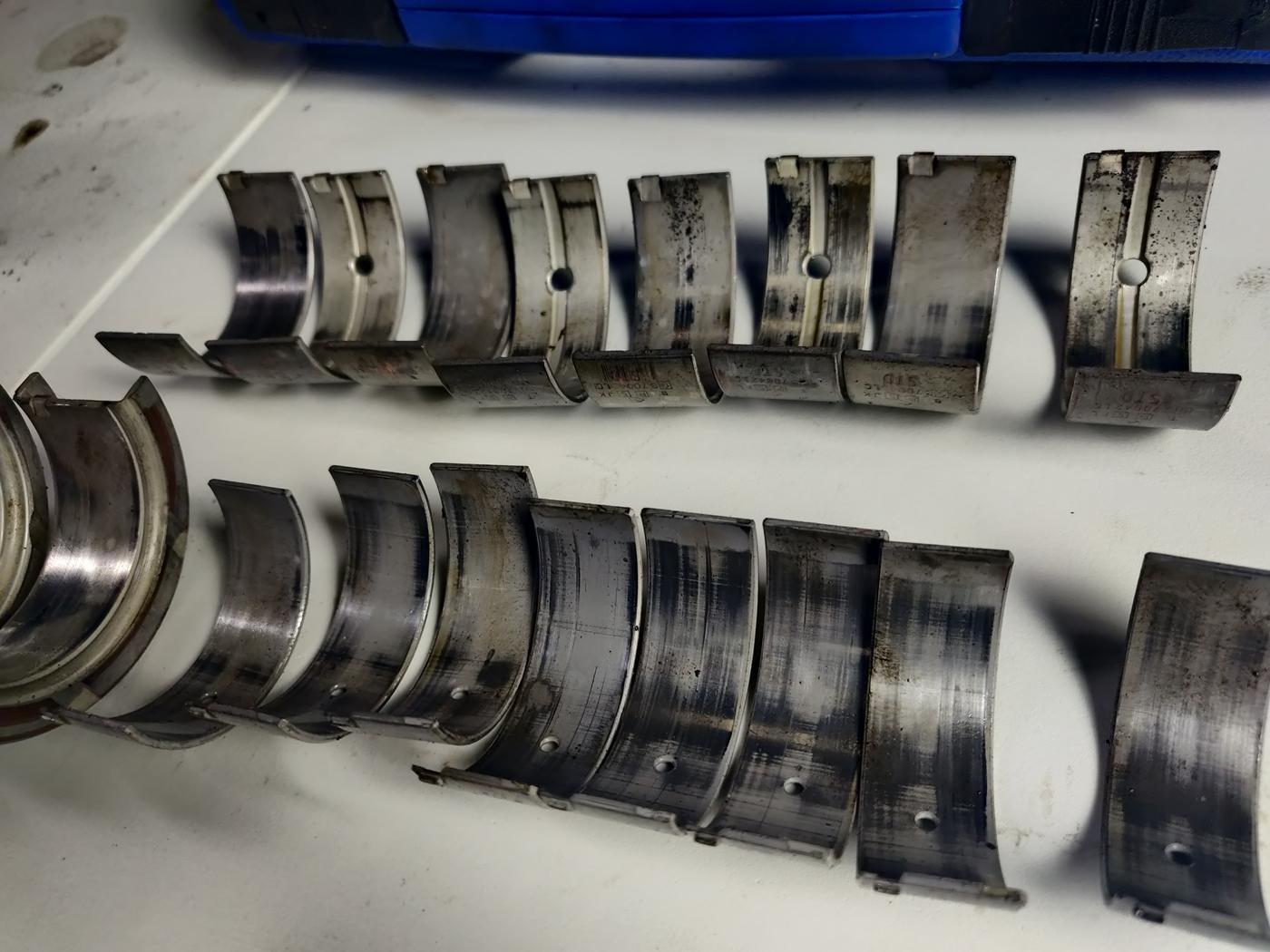

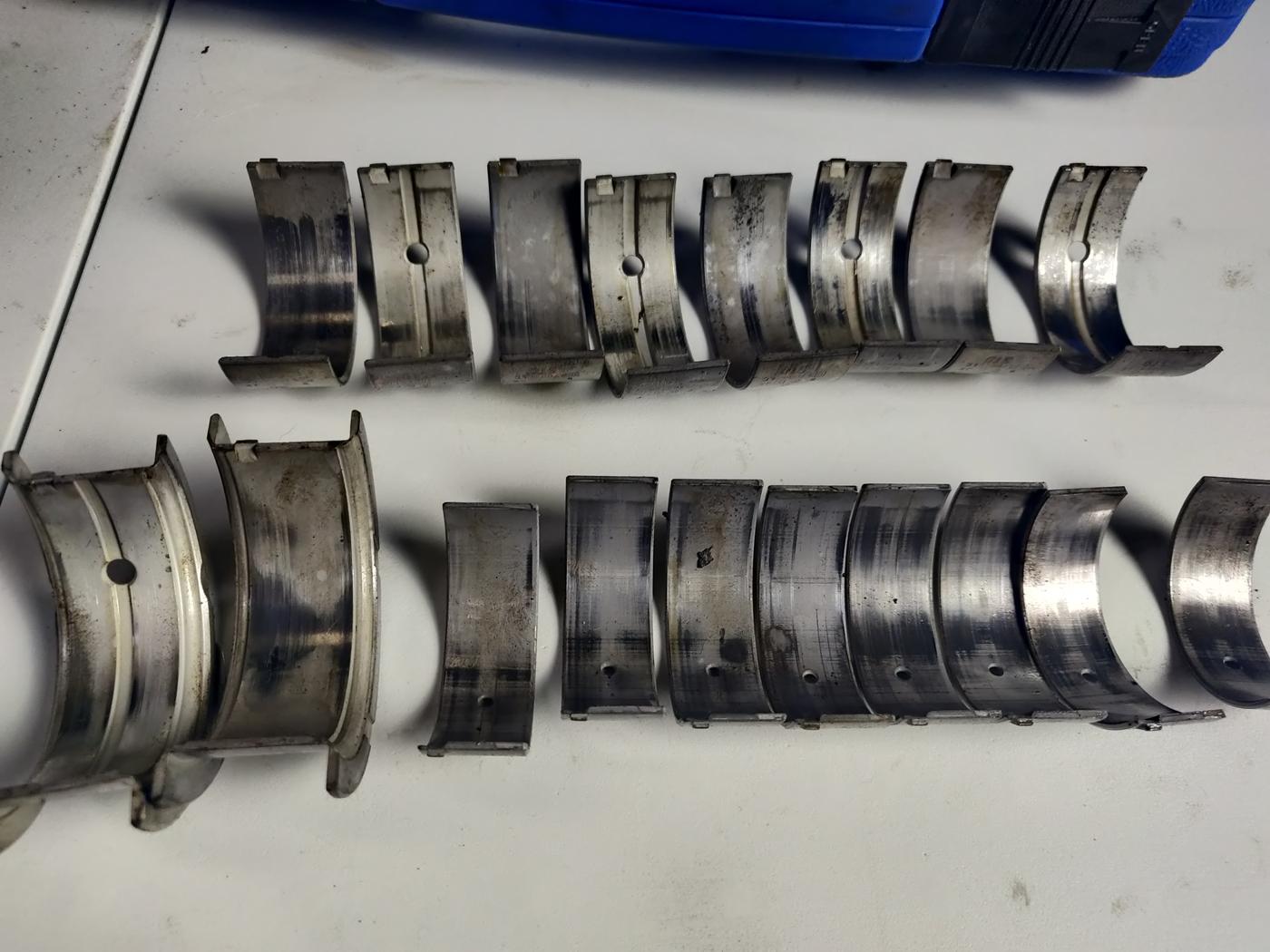

Well... In the Christmas holidays i had a friend over to help me with the engine.

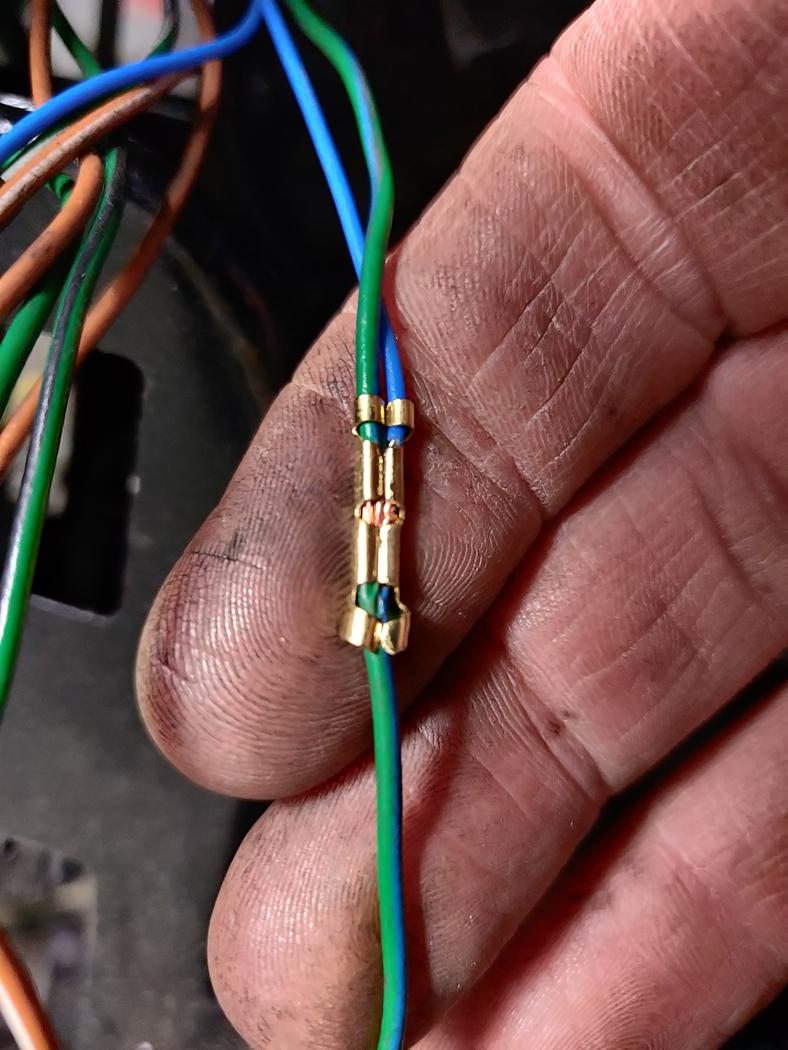

We replaced the main and rod bearings and he noticed that my crankshaft did have a little bit of scoring. But luckily i had a spare engine where we could take the crank from. This was in a lot better condition. The old bearings weren't the worst, but after finding the oil squirters were damaged, we did not take any changes.       I still havent found a socket for the ARP headstud bolts, but im working on it. So the head sits loose on the engine. I also had visit from another friend who have to weld the rust in the car. We started last saturday where there only was -3 degree celsius in my workshop. So he only welded the hatch. It was way to cold.     While he was welding, I was fixing the wiring harness after previous owner fucked it up. So now i also have reverselight. Great success  Its really great to make the harness proper with the right tools instead of some buttconnectors and masking tape :P  And at my job we had tons of old seats laying around. So i scored a classic Recaro 229.41.1354 It needs a clean, and i have to pull power wires for it as its fully electronic adjustable :P  |

|

|

|

|

|

#19 |

|

Leaky Injector

|

Well well well... The last few months have been one hell of a rollercoaster.

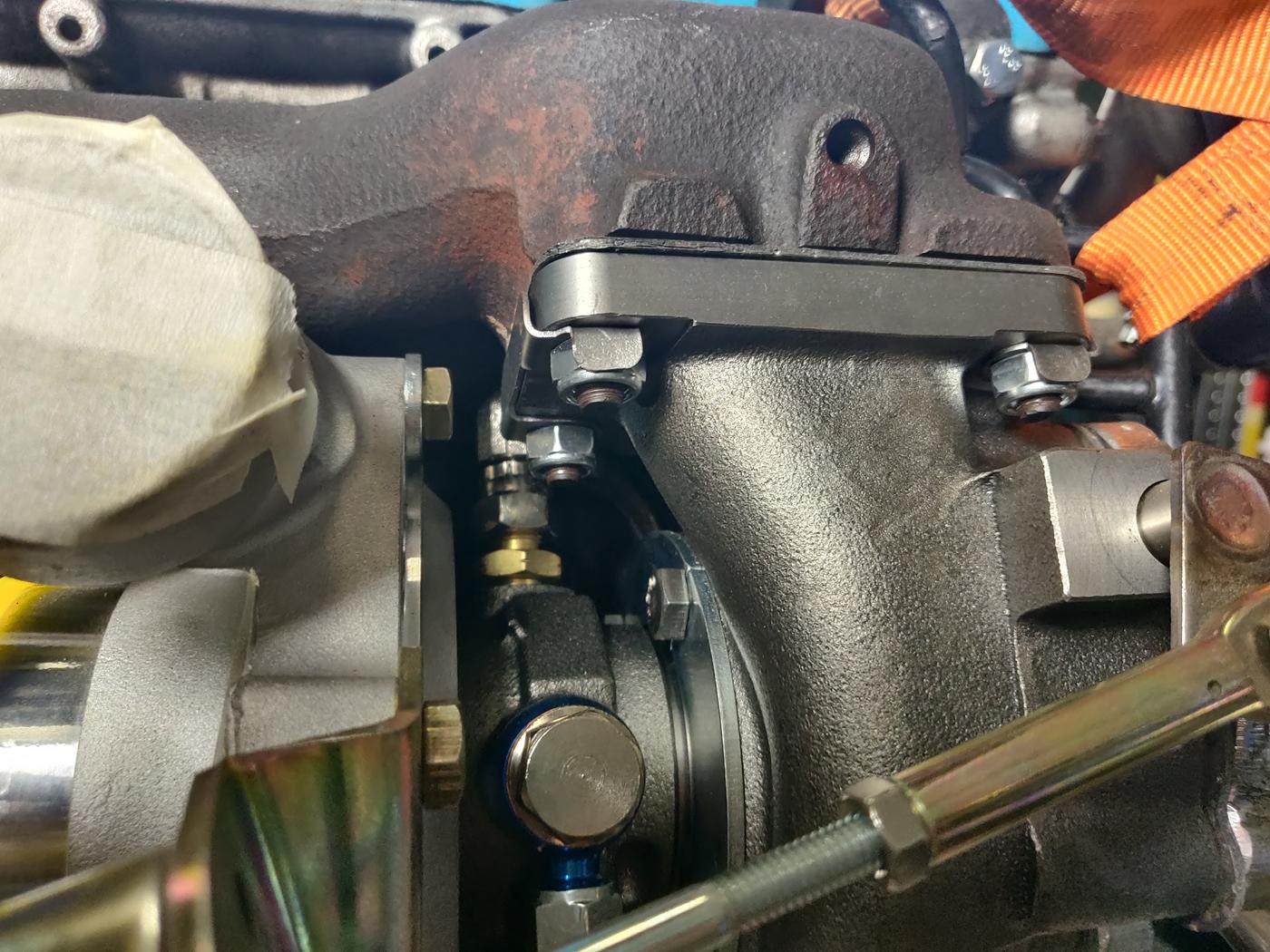

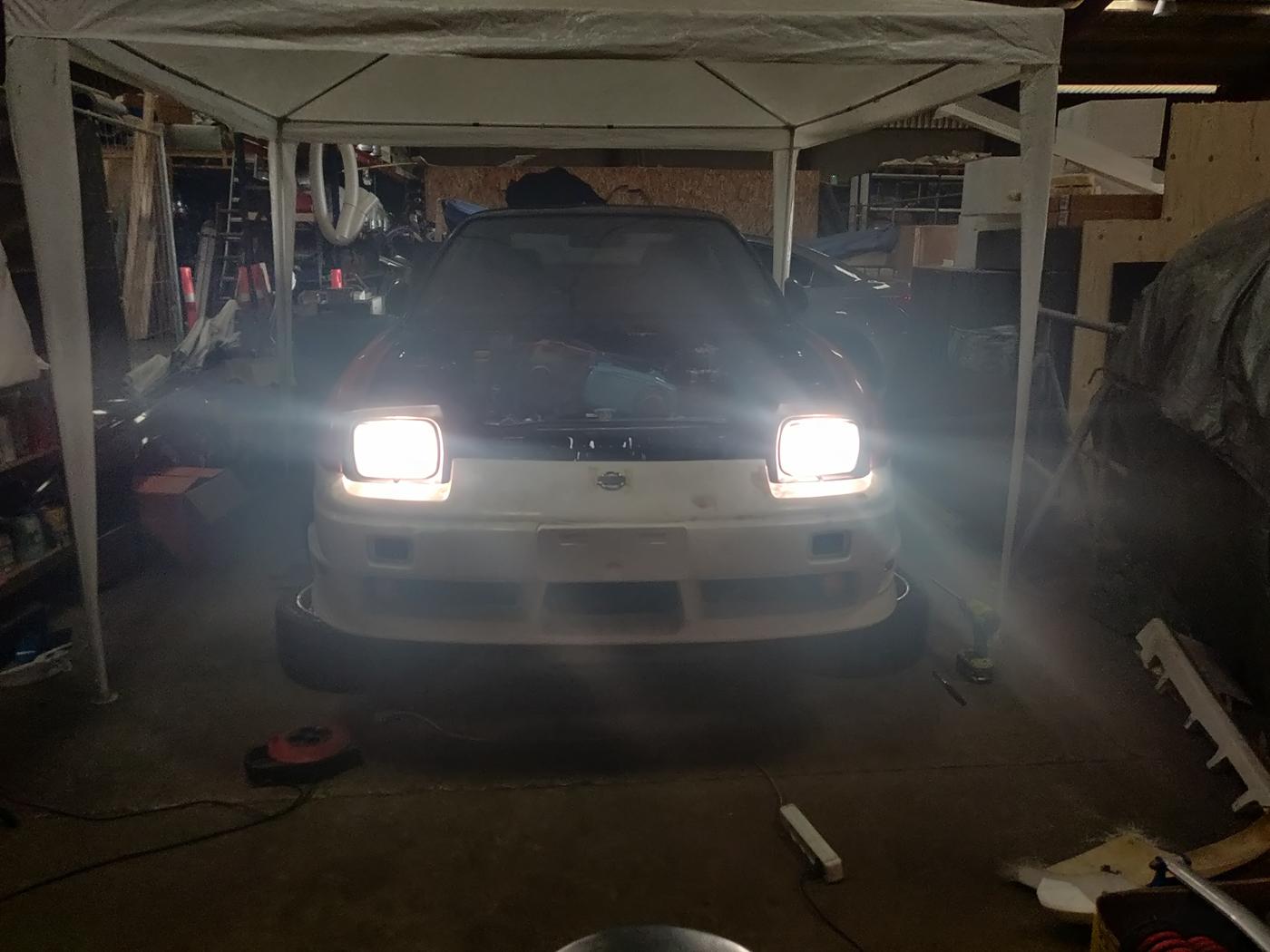

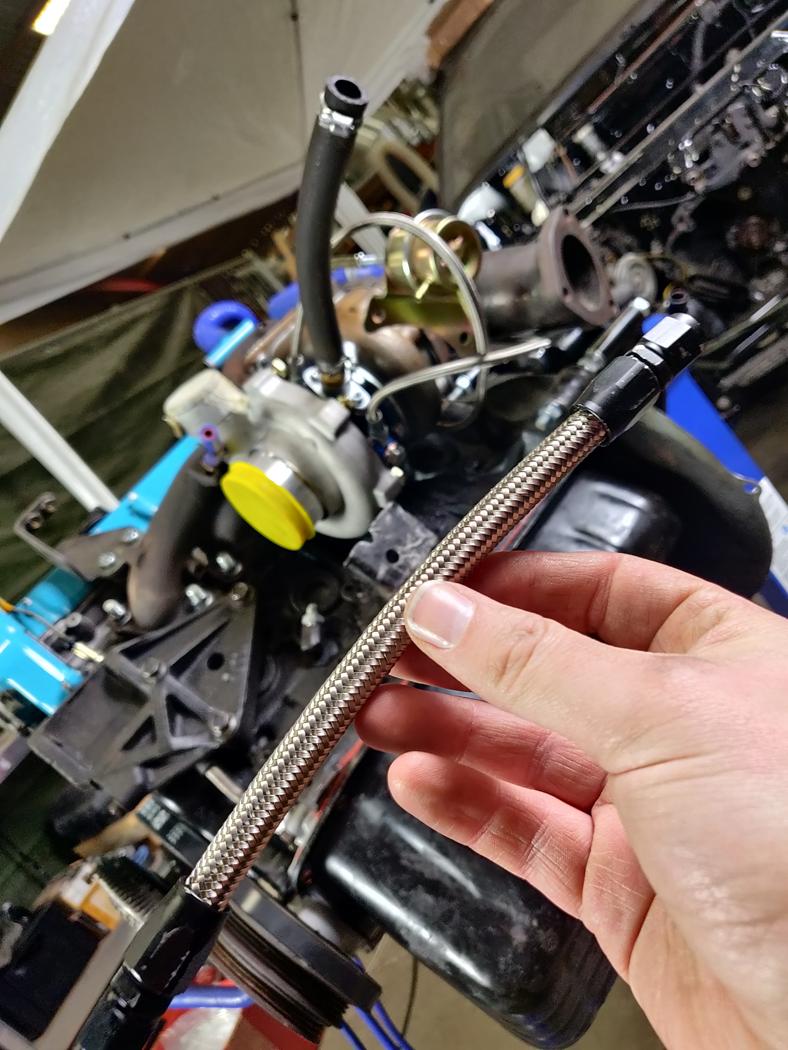

Lets dive in! First off, i purchased a 3D printer (Ender3 V2) because i wanted to be able to make my own parts and get something more unique. So i started with a cupholder.  Nothing special. But it gave me the inspiration to create more things. Im still a newbie in Fusion360, but im practicing in making a center for my Work Euroline   So i finally found a 12point top that fit the ARP headstuds, so i could get the head installed on the engine, and get the engine back into the car.   Its so nice to see the engine finally together. I had some problems with the oil feed line as the ones i purchased was for m10 on the turbo side, but my turbo was a M12, so i had to make my own.   And everything is finally together  Getting ready for gearbox install   And we threw the engine and gearbox in the car.    I was a idiot and didnt drain the gearbox for oil before doing this, so i had 2 liters of gearoil on the floor... Not the greatest thing... But shit happens  I fixed all the small things like installing a cheap oilpressure gauge and installed all the vacuum lines and intercooler piping   We turned the key, and the car started right up. It was a moment i was super afraid of, but engine started and sounded healthy. Only problem was the timing belt that was to tight and was singing a lot. i figured it wasnt the worst thing to let it idle and bleed the watersystem.  After about 10 minutes the exhaust manifold started to smell like burned oil. By some reason the oil feed line wasnt tightened properly, so i had to tighten it. But there was a small highup... I cant tighten it with the turbo installed on the manifold... Only thing to do is to remove the manifold and turbo, take them apart, and then tighten the bolt... That was a pain in the ass!!! Next time ill go topmount turbo :P    And the disaster is coming closer... I was under the car to install the driveshaft and saw this  Not the worst thing, but damn... at least fix a fuel line leak properly... And now for the worst news.... But first, some high quality danish bacon!  And the disaster... I let the pictures speak for it self... but just guess what happend.. I will take care of it next weekend with some help from a CA18DET-guru  Anyway. Yesterday my friend started cutting up the sills to replace them with new ones.  The right side didnt look to bad, but the clumps in there is actually bondo from when they installed the Veilside bodykit    And while he cut open the car, i changed the headlights from RHD to LHD. Thats one thing less the car can fail inspection on.  |

|

|

|

|

|

#20 |

|

Leaky Injector

|

Time for another update.

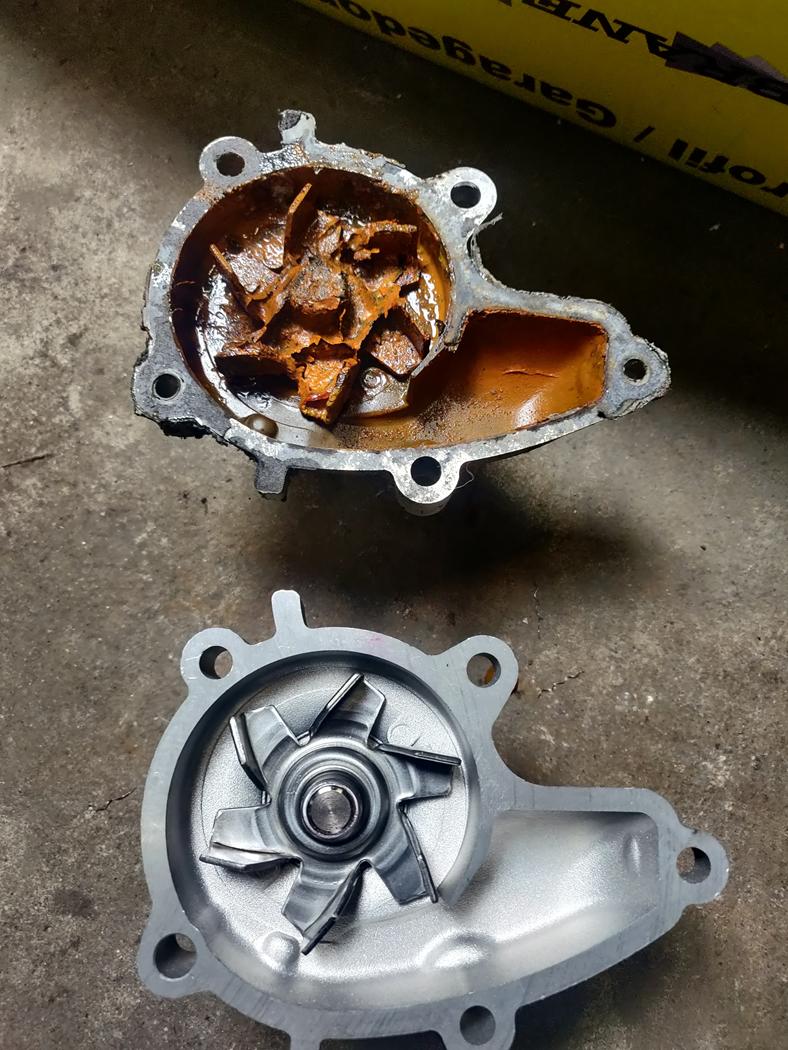

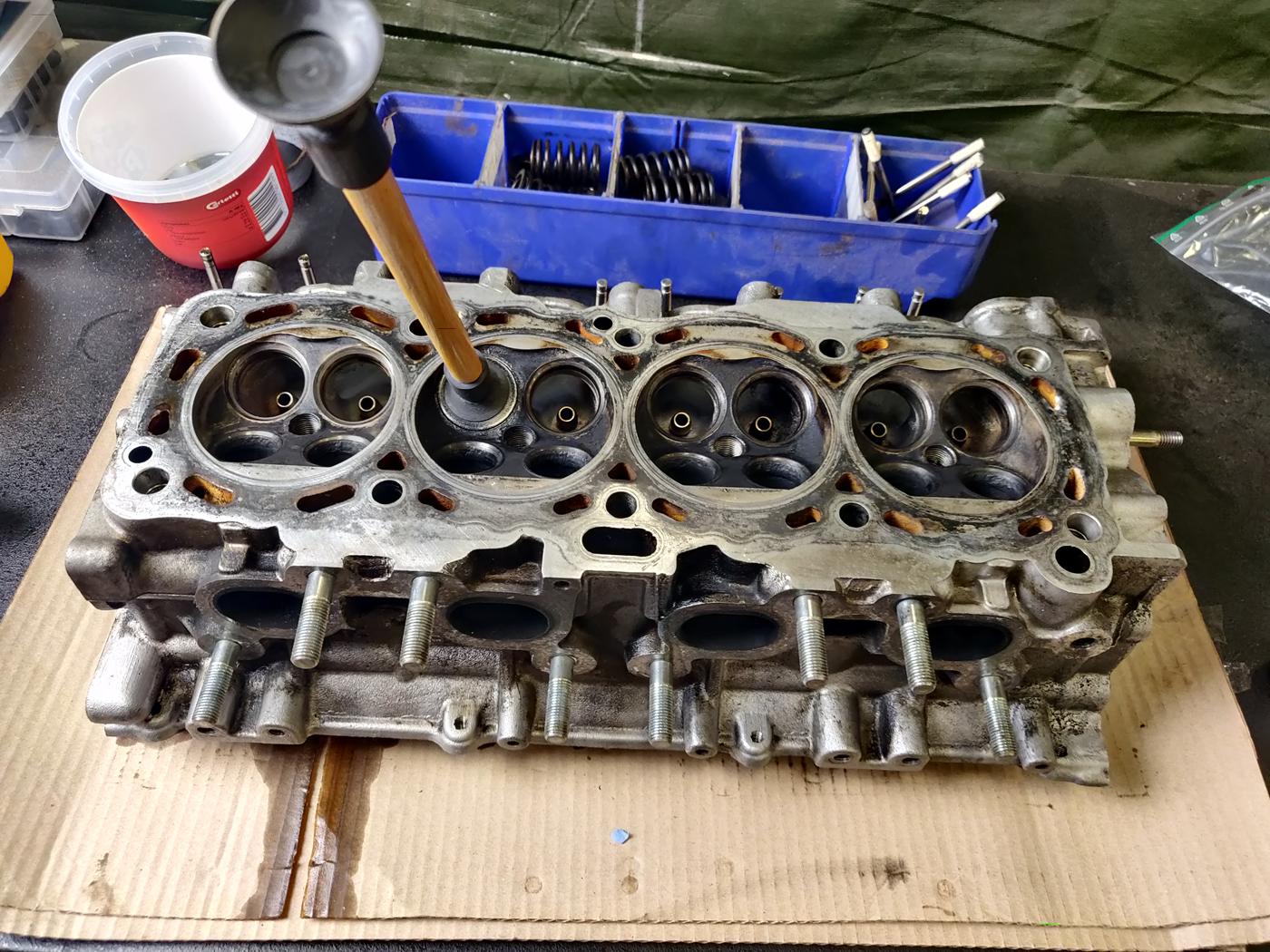

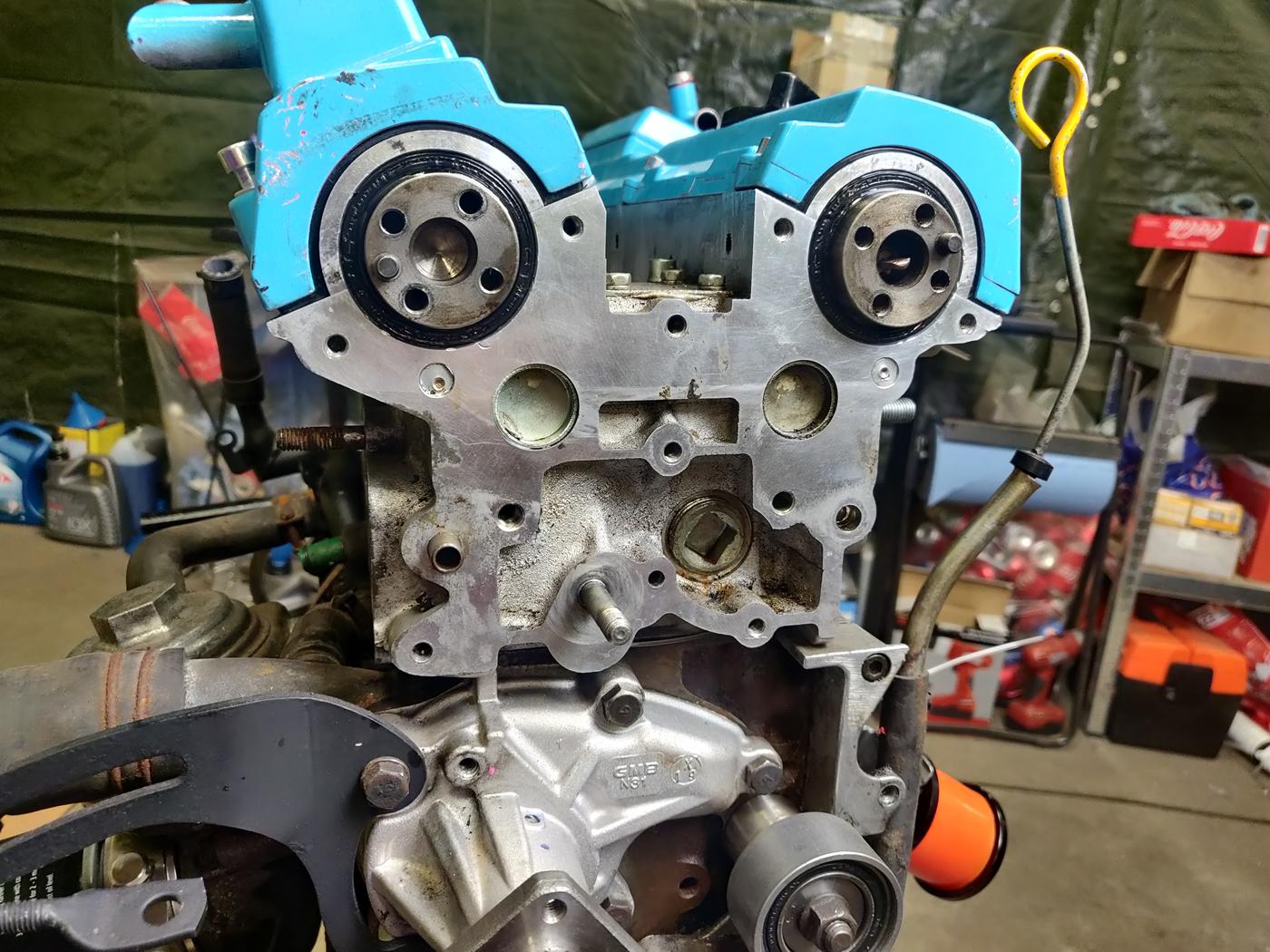

We pulled the engine... again as the timing belt skipped, and i wanted to be sure that everythings put together correct.  I also removed the manifolds so i can work on the head.  Im astually happy that i removed the engine and went through everything this time, as i found a hose that was cracked, and it would be impossible to replace if the engine is in the car.   We also got a 12ton press in the workshop. I talked to some local professional workshops, and they wanted way to much money for me to press some bearings, so i bought this one. Its cheap, but it works fine for wheel bearings and other small stuff.  As i had a extra cracked head for the CA18DET laying around, i went to town with cleaning the valves, so they can be installed in the good head   Another reason that we removed the engine is that one of the enginemounts are broken, and also tightened with about 69 ugga-duggas and fucked the nut... So the only way to remove it was to saw and drill it. What a fucking nightmare!   And also it was possible to replace the clutch bearing when there was easy access. And it was so easy with the new press :P   I also did the front wheel bearings https://billeder.bazoom.dk/biler/album/474/xl/2365847/rengoering-af-motorrum.jpg[/IMG] Since the engine have been sitting for a long time, i might as well get new tempsensors and thermostat. And i guess it was a good idea  The old ones were pretty rusty! The old ones were pretty rusty!    |

|

|

|

|

|

#21 |

|

Leaky Injector

|

My friend also did a lot of work welding the sills on the car. It took a bit longer than expected, but ended up pretty great. Im happy with the result. Even though its gonna be hidden by the bodykit.

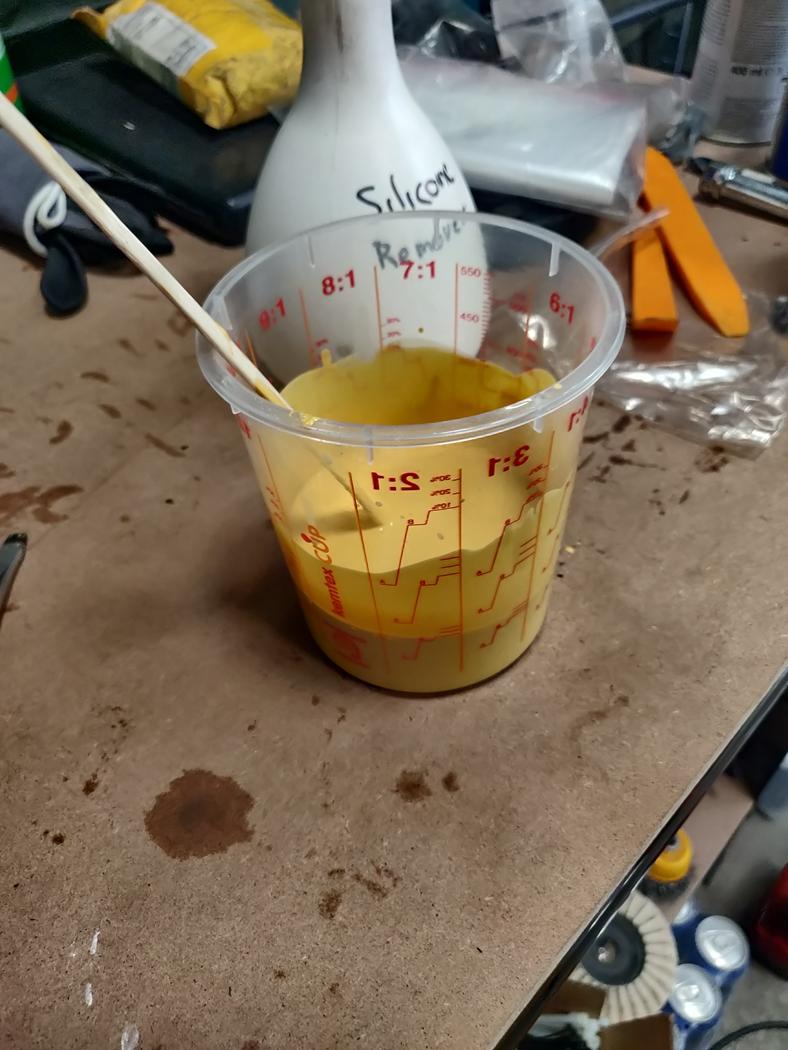

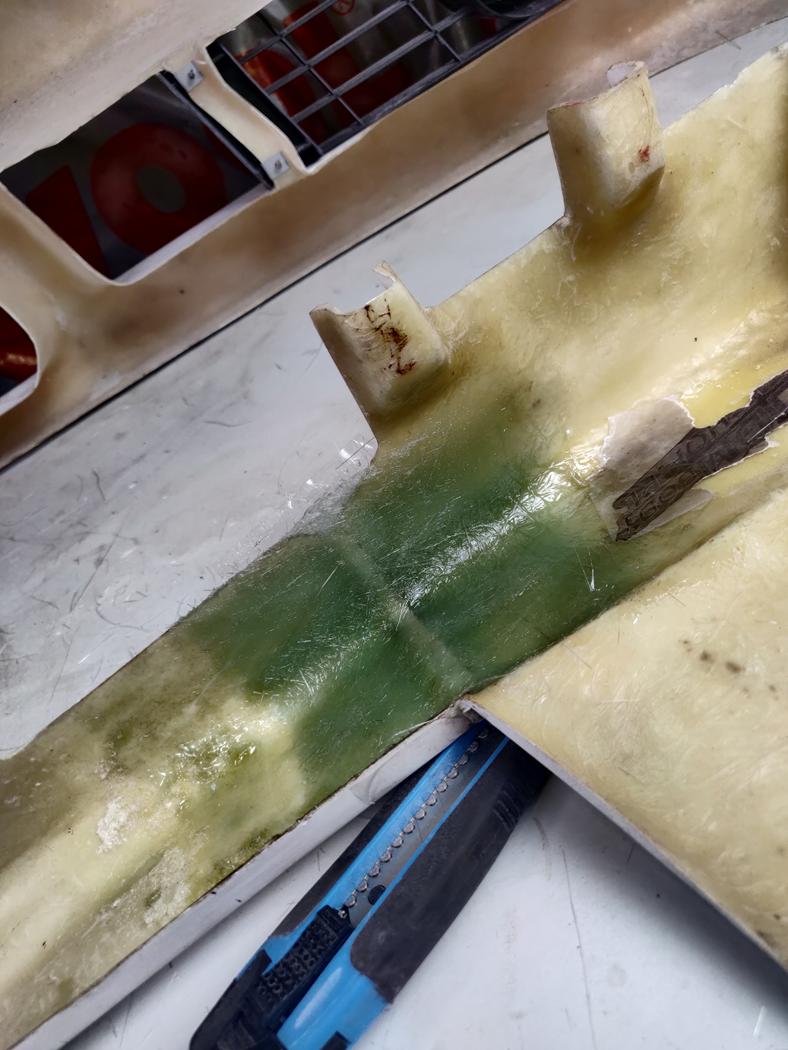

And the finished result.   After i took the pictures, i gave it a quick layer of epoxy primer on the ourside, and some penetrating cavity wax in the sills and everywhere there was bare metal to make sure it doesnt rust again. I also went crazy on the head. I have no experience in doing this, so i just went for it. I changed the following: Front seals on the camshafts refurbished valves and lapped them refurbished lifters new valve seals new Continental timing belt     I also did a quick leaktest with some soapy water, and after an hour everything that should be dry was still dry. So great success!  I also did a quick trip to a friend to look at a few cars   Engine is coming together. And hopeful for the last time!    This is it for now. But hopefully the engine is back in the car next week, and with all interior installed again. And then its on to making the fiberglass fit |

|

|

|

|

|

#23 | |

|

Leaky Injector

|

[QUOTE=tuzzio;6410018]

Quote:

But heres the link: https://www.ebay.com/itm/392928775389 And i used a crimp tool just like this one: https://www.ebay.com/itm/12469882102....c101195.m1851 |

|

|

|

|

|

|

#25 |

|

Leaky Injector

|

|

|

|

|

|

|

#26 |

|

Leaky Injector

|

Finally we got the engine back into the car!

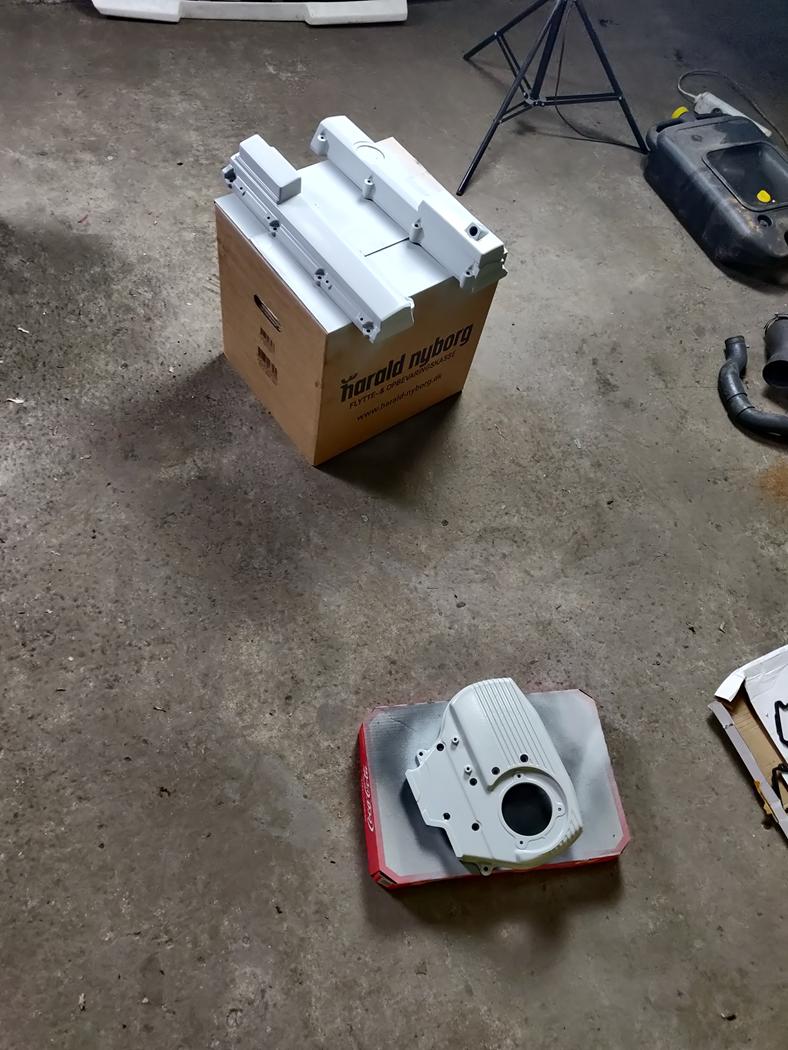

It does turn over and idle without problems, but cant do much more as we still havent filled coolant in it.    After the engine was installed we rolled the car outside to flush the engineblock with a waterhose - there was SO much rust inside of it because it has been standing dry for a long time.   But we did work alot on the fiberglass.  And we also did some eating of "kanel gifflar" (small Cinnamon rolls from Sweden) Tastes delicious, by the way!  To make our lives much easier, we desided to fiberglass the sideskirts into one piece. And did the same with the front bumper. It saves me for a lot of money as i dont need to purchase the brackets. And also makes it look cleaner when my painter hits it with a bit of bondo             While i was installing the side skirts, i took a few pictures of the underside. And im surprised that it looks pretty good underneath. Cars from England to not have a good reputation rustwise.    I also installed the fake Bride gear-fabric  Many years ago i did a lot of RC drift, and my body of choice was always the 180SX kit with a specific rear lights. And recently i found the rearlights for my car. So i just had to have them. The plan is to use it for my other S13, and keep the Kouki lights on this car.   When installing the rear bumper, i needed some support so it doesnt sag in the middle as fiberglass bumpers often do. I used some 90degree metal i had laying around and put some foam tape on top.     I guess ive already mentioned the hole in the dashboard. Ive made a small plug to close it off, and still have the space for cables for the 3 gauges i want to install. (oil temp, oil pressure and boost) Its 3D printed in ASA, so it should be more than suitable to be in the sun all day.   My friend also reached out to me to make him a cup holder for his S14. So after some designing and printing, he can do crazy stuff without his drinks spilling all over   I will put them up on Order42 instagram when i have them ready  I got tired of the teal details in the enginebay, so desided to paint the parts in some other color, and after a lot of looking around, i found a original S13 color that would fit the car perfectly.     I also picked up a set of used tires, so i finally can install the Work Euroline on the car and roll it out   Lastly a few pictures of the car with almost all fiberglass installed     |

|

|

|

|

|

#27 |

|

Leaky Injector

|

Another small update.

I went to pick up a bunch of parts for my other S13, that ill be installing on this one instead. Among these parts are a Varex muffler, Defi Advance, Nardi wheel, Mishimoto intercooler, oilcooler, carbon stuff and a lot of other stuff.     I had huge problems with the engine making a whine. Everybody thought it was the timing belt being to tight, but after a LOT of problems, we figured out it was the lower timing belt cover that was bent slightly and the belt was hitting it. I did a bit of magic with a small hammer, and everything sounds great! Video for proof: https://www.instagram.com/p/CQ3ld6hnUfp/  And yes. I made a gearknob with a 10mm in it. Its always good to have a 10mm close by!    Its so wierd to see the car almost complete, but its nice! Theres still a lot of small things i need to sort out. some of them is coolant leak, power steering, power for stereo, cablemanagement under the dash and so on. And when i get the other S13 into the workshop, i need to install 5lug conversion with Z32 brakes. So thats gonna be fun :P |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|