|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

#61 |

|

Leaky Injector

Join Date: Aug 2007

Location: Minneapolis, MN

Age: 31

Posts: 93

Trader Rating: (0)

Feedback Score: 0 reviews

|

Here is another pic showing where it sits. Its right at the tall section on the side before the shifter extension

http://www.soarerworld.com/forum/att...8&d=1358163820 |

|

|

|

| Sponsored Links |

|

|

#62 | |

|

Join Date: Nov 2012

Location: Germany

Age: 37

Posts: 26

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

Thanks, will be replacing this. |

|

|

|

|

|

|

#63 |

|

I totally took off that dynamic dampener (as nissan calls it) and built my own cross member. I'm going to track down an OEM crossmember, mount, damper bolt and dynamic dampener and see if this calms down the vibration.

On top of this, I'm doing a Mazworx bellhousing as well as an ATI super damper. This motor better be smooth as all hell after all of this... If it isn't, something internal is broken or way out of balance. |

|

|

|

|

|

|

#64 |

|

So I've been tackling this issue in a more scientific manner lately lol. One thing at a time so I can rule out causes. Hopefully it helps someone else on here. I get a surprising number of PM's about this.

Anyways, I built a mount using the OEM 350z transmission mount. It made the vibration WORSE. So far using the 240sx transmission mount seems to be better. I didn't check if the 350z mount is harder or softer than the 240sx mount. I'll test that out tonight. After this the next thing to try is the damper on the side of the transmission. |

|

|

|

|

|

|

#66 |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,646

Trader Rating: (17)

Feedback Score: 17 reviews

|

make sure the engine exhaust system does not contact the chassis in any point. If you use a hanger for the exhaust to drivetrain, tie it to the trans crossmember like a factory mount (use the same sort of bushing the OEM uses).

I think you are having two issues. One is the mounting/vibration/noise related to the way the trans and exhaust system is mounted. The other, resonance/vibration at specific RPM under load sounds like a pinion angle issue. The trans tail shaft and differential input flange need to be at identical angles (equal and opposite), with the trans higher than the differential so the driveshaft has a downward slope. |

|

|

|

|

|

#67 |

|

Premium Member

Join Date: Mar 2009

Location: Maricopa, AZ

Age: 30

Posts: 7,679

Trader Rating: (10)

Feedback Score: 10 reviews

|

With the pbm max downpipe and s13 trans mount you can retain the factory hanger between the downpipe and trans mount with cd009.

Sent from my iPhone using Tapatalk |

|

|

|

|

|

#68 | |

|

Quote:

Also the vibration is present with the car in gear and clutch in. The pinion angle was measured and set correctly. Its also not speed sensitive. I'm positive it's not driveshaft related. There is another thread about this on here where the op mentioned it may be caused by worn input shaft bearings allowing some slop. Thats gonna get replaced when/if I do a mazworx vq->Sr bell housing. Next up is the damper on the side of the tranny and then the ATI super damper. Transmission rebuild and new bellhousing is the last resort. |

||

|

|

|

|

|

#69 | |

|

Zilvia FREAK!

|

Quote:

|

|

|

|

|

|

|

#70 |

|

Update: Did an ATI super damper, hoping to smooth things out a bit more. Motor is smooth as butter at idle now, still horrific under load.

There's a thread on here where someone else had a similar issue, and came to the conclusion the input shaft bearings on these trans are shit. I think that can be agreed on now. Solution (I think) is to replace the input shaft bearing and do the mazworx bellhousing. If this doesn't fix it I guess time for a hollinger  |

|

|

|

|

|

|

#71 | |

|

Zilvia FREAK!

|

Quote:

|

|

|

|

|

|

|

#72 | |

|

Quote:

|

||

|

|

|

|

|

#73 |

|

Not much of an update yet. I drove it the rest of the summer with the vibration present. It survived a bunch of track events and some street abuse just fine. So I'd say the vibrations this trans puts out are not detrimental to longevity.

However I haven't tried the OEM nissan vibration dampers. ATI super damper and different mounts all did absolutely nothing. If you have this vibration I'd say it's likely internal. I have purchased the Mazworx bellhousing kit as well as new input shaft bearings. I will be doing this over the winter, then will report back here in the spring! Last edited by canadians14sr20det; 10-22-2018 at 01:54 PM.. |

|

|

|

|

|

|

#74 | |

|

Leaky Injector

|

Hate getting those underlying issues, you've done a swell job of sorting out the bs and doing some research +1 for that. Hope this is the final fix

Quote:

|

|

|

|

|

|

|

#75 |

|

Update: I installed the new bearings and mazworx bellhousing. Vibration still present.

However the vibration doesn't seem to be a "problem". I said fuck it, drove it all summer, hit a few drift events, and the transmission hasn't had any issues. Shifts nicely. Just sounds like the car is coming apart at 4000RPM plus. I'll be buying a new OEM Z33 trans over the winter and installing that. If that doesn't fix it I guess I'll just live with it. |

|

|

|

|

|

|

#76 |

|

Zilvia Member

|

I cant be bothered to go back and read the whole thread, but could it be the propshaft out of balance?

jack the car up so its arse is right in the air and take the prop off and 'drive' it. |

|

|

|

|

|

#77 |

|

Leaky Injector

|

I had this same issue after installing my mazworx bellhousing with the driveshaft they provided. Ended up being the universal joint not being lubricated properly.

When I was holding the driveshaft (off the car), i grabbed the u-joint and would move it around and noticed a few dead spots where it wasn't smooth and sort of catching a bit. I had Drivelines NW replace the U-Joint and voila, vibration gone.

__________________

IG: Touge.Tough |

|

|

|

|

|

#78 |

|

So to close up this thread. Ended up buying a brand new from Nissan cd00a trans. Vibration and noise is still present. These transmissions are just insanely noisey. The chassis vibration is just a factor of my motor and trans configuration. I'm going to live with it till something lets go.

|

|

|

|

|

|

|

#79 |

|

Solved! (Mostly)

So I'm bringing this back from the dead. I never got over this vibration. With the latest Covid lockdown up here I've had some time on my hands so I went full science on this. This is gonna be a long one.

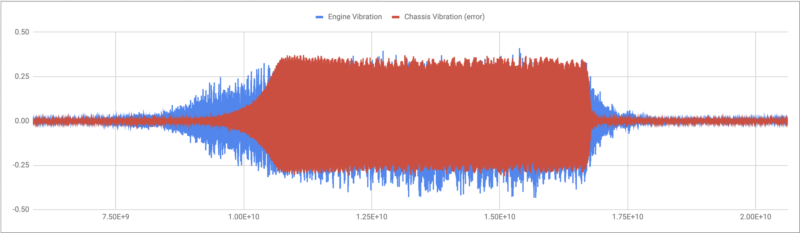

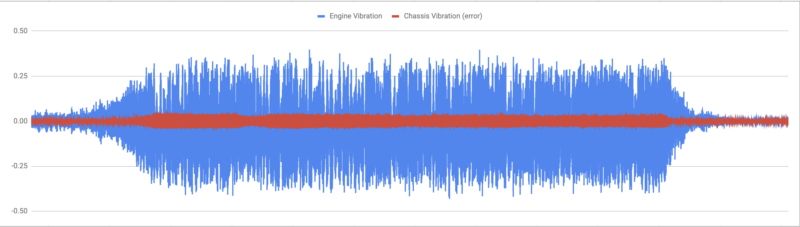

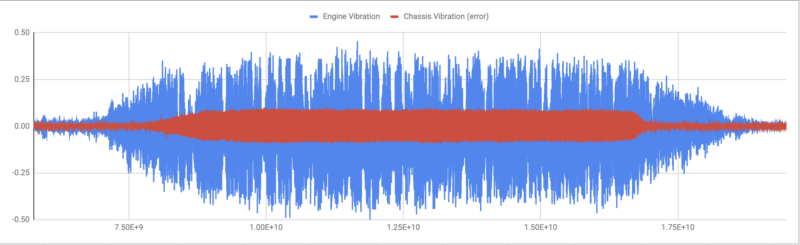

I went and setup a Raspberry Pi and hooked up two accelerometers to it via an ADCDAC expansion board. Parts I used were: RaspberryPi: https://www.raspberrypi.org/products...-pi-4-model-b/ ADCDAC board: https://www.abelectronics.co.uk/p/74...xpansion-board Accelerometers: https://www.digikey.ca/short/4c5fwj I then wrote some code to record the vibrations from each sensor: https://github.com/linds14sr20det/race_car_avc For the setup to measure this vibration I attached one accelerometer to the transmission (unused bolt hole near the shifter bracket) and the other sensor to the transmission crossmember. My trans crossmember setup uses the 370z mount as it's fluid filled and _should_ dampen vibrations better than any of the other mount solutions, or at least that's what I thought.  Here's the first graph of engine vibration (blue) vs. chassis vibration (red). This is a recording of me revving the engine slowly from idle to 4500rpm. As you can see engine vibration increases as the rev's rise with not a lot of chassis vibration until you hit 4000rpm when chassis vibrations exponentially increase and are now stronger than the engine's vibration. This is a clear resonance in the chassis. The force the chassis is experiencing here is about 4g's. Considering the trans mount supports over 100 lbs, this is actually a pretty significant force. I wouldn't be surprised if over time this cracked the crossmember or the chassis spot welds. If you zoom in on the graph you can also see that the vibration occurs at ~150Hz. This works out to the equivalent of 9000rpm (150 cycles/second * 60 seconds/minute), which actually makes sense. 4 cylinder engines are inherently unbalanced with a pronounced second order vibration (vibration at twice engine speed). So this supports a resonance at 4500rpm. Also explains why these trans don't have this problem behind a VQ35 or an inline 6. Okay so the next step was to confirm the crossmember is the vibration transfer path. This is easy to do, support the trans on a floor jack, remove the transmission mount, and bolt everything back up. Since the transmission is no longer connected to the crossmember, we would expect to see little chassis vibration if the trans mount is the culprit. If it isn't the source of the vibration we should see no change.  Pretty dramatic decrease. So we know it's the trans mount causing the problem. There are 3 ways to reduce vibration transfer from all the reading I've now done. 1. Stiffen the receiver (ie. thicker floorpans and a roll cage. This is a street car so nope. Also explains why s-chassis with cages aren't as bad for this vibration) 2. Reduce vibration at the source (Increase the mass of the transmission, add a dual mass flywheel, change the gear mesh patterns, swap to an inline 6, etc. Not gonna do those either.) 3. Soften the engine mount. Vibration elimination has two parts, isolation and damping. Damping increases vibration transmission to the receiver but reduces the peak amplitude. We want to isolate the vibration and to do this we need to soften the engine mount. To test this theory, I went and grabbed two valve springs from a vq35de. Since a 4 cylinder second order vibration is only in the vertical direction a spring is a perfect candidate for the mount isolation. This is also how jaguar used to mount it's transmission back in the 70's and 80's so this isn't as hair brained as it seems. Anyways, the VQ35 springs were soft enough they support the weight of the cd009 but compress about an inch each. So I'd ballpark them at a spring rate of 75 lbs/inch. Here's the graph:  We have a winner. Chassis vibration is way reduced and you actually can't feel the buzz or hear the floor resonating anymore. So I'm going to build out a more permanent version of the spring trans mount and report back on it. |

|

|

|

|

|

|

#83 |

|

Premium Member

Join Date: Oct 2004

Location: San Francisco, CA

Posts: 5,824

Trader Rating: (13)

Feedback Score: 13 reviews

|

Dude this is legit AF..... I knew CD009s were noisey but this is insane. But this leads to think its something internal to the tranny?

Is the vibration the same if you remove the driveshaft? I've read about driveshaft pinion angles and stuff? What are your thoughts? Maybe change fluids I know this helped for me moving from shockproof to amsoil. But not sure how significant is your vibrations.

__________________

Turn and Burn! Turn and Burn!

|

|

|

|

|

|

#84 |

|

Premium Member

Join Date: Mar 2009

Location: Maricopa, AZ

Age: 30

Posts: 7,679

Trader Rating: (10)

Feedback Score: 10 reviews

|

With a sprung transmission mount isn't the driveshaft angle going to be variable while driving the car and over bumps etc? That seems like it might introduce some weird vibrations.

Kudos to you for actually finding the source though. Interesting that the characteristics of the I4 engine introduce this vibration to the transmission that doesn't happen with the V6. |

|

|

|

|

|

#86 | |

|

Quote:

|

||

|

|

|

|

|

#87 | |

|

Quote:

|

||

|

|

|

|

|

#89 | |

|

Premium Member

Join Date: Mar 2009

Location: Maricopa, AZ

Age: 30

Posts: 7,679

Trader Rating: (10)

Feedback Score: 10 reviews

|

Quote:

|

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|