|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Builds (and builds only) Got a build thread? It goes here, build threads anywhere else on the forum will be locked and never moved. |

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Leaky Injector

Join Date: Jan 2011

Location: Seattle

Age: 33

Posts: 124

Trader Rating: (2)

Feedback Score: 2 reviews

|

S14 1JZ Vvt-i drift car build

I have always wanted to make a build thread, so here it is.

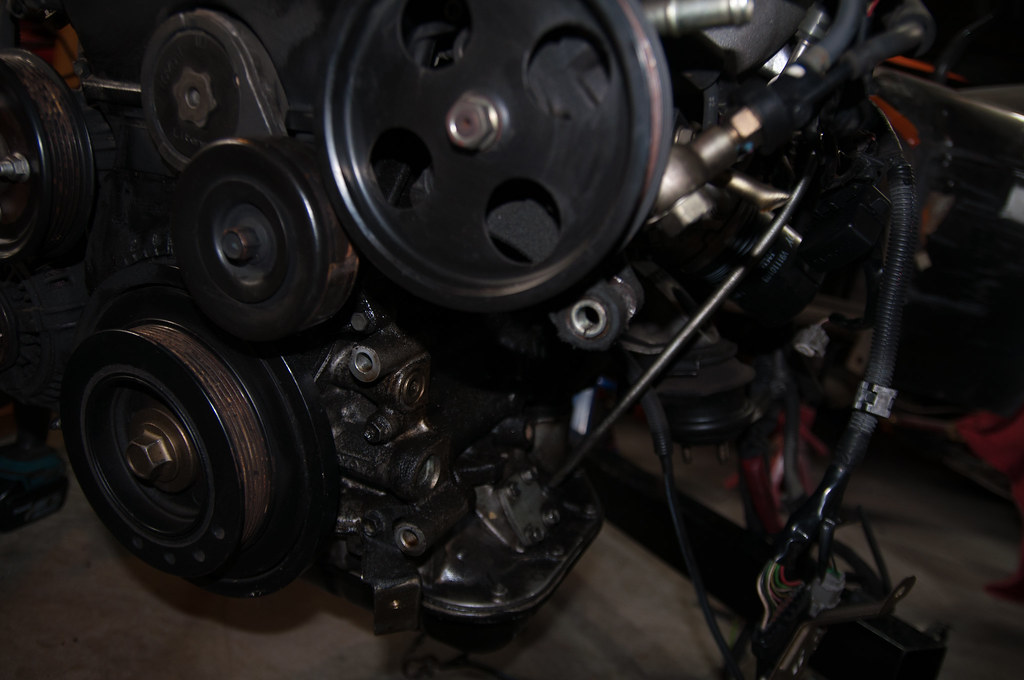

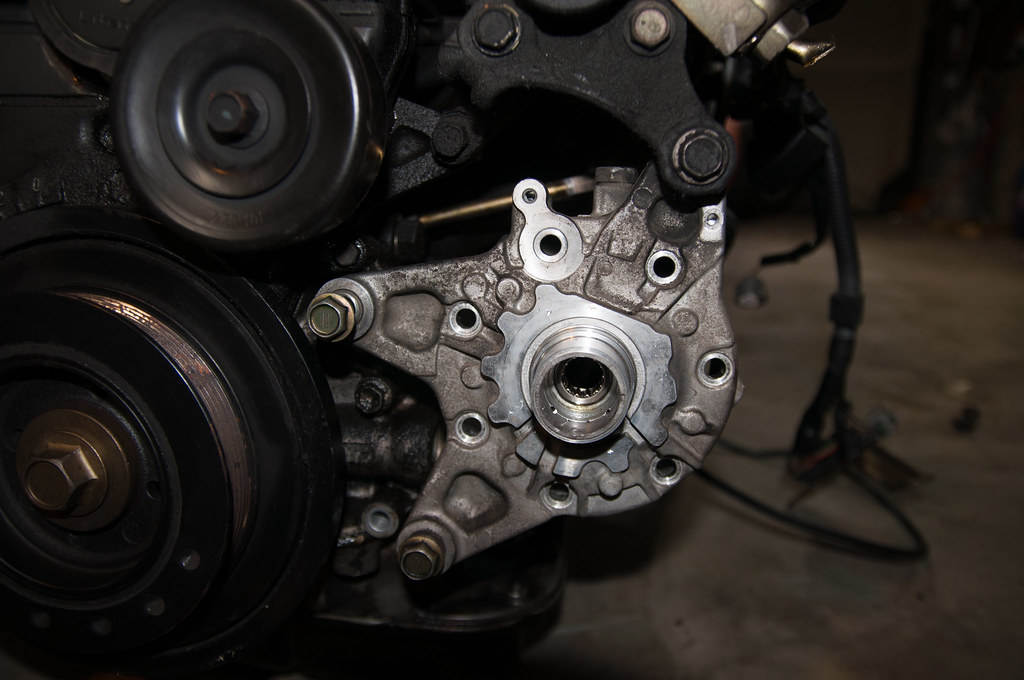

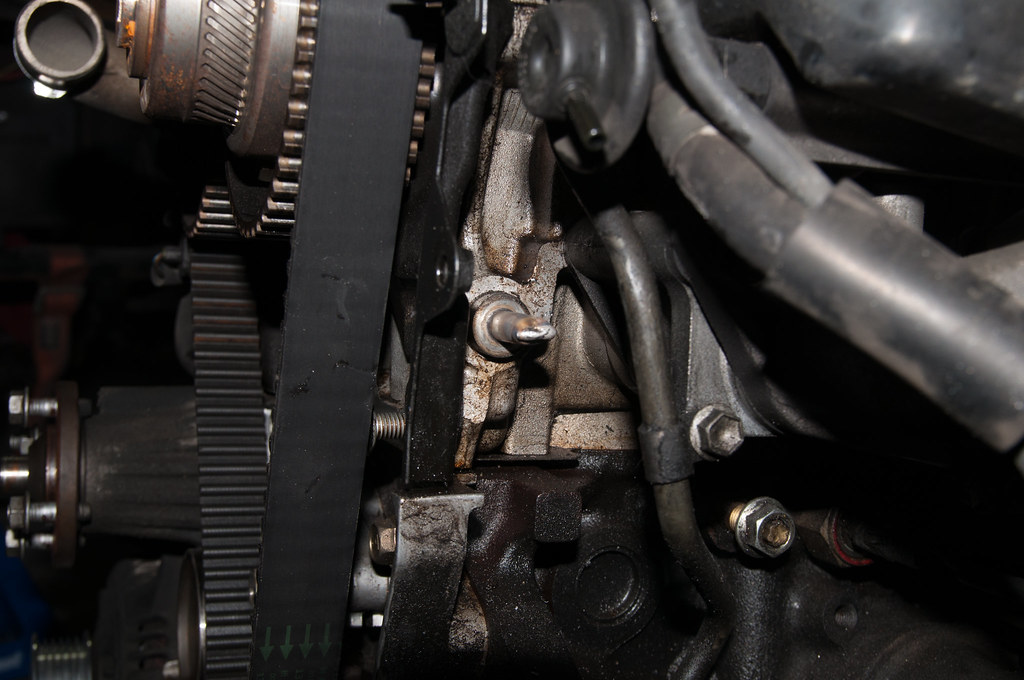

I wanted to document this on zilvia because I always find the information I seek on here and I'd like to try to give back to the car community, and if I can help anyone great. Granted what I am doing is a little different because this is a track car, but some of the information is still the same. Any insightful comments are appreciated I will be posting some random tech tips in this thread as well The build will be relatively simple, stock turbo (aiming for 14psi and whatever power that gets me great, I hope the neighborhood of 300whp would be nice), stock everything running on AEM V2, with a Z33 6 speed transmission. The car previously had a S14 SR with a Garrett GT28rs, Z33 trans, power fc (and many supporting mods). I'll only post my favorite picture of my car:  When I received the engine:     To remove a flywheel or flexplate use a open box wrench, use the close end and thread a bellhousing bolt through it and use another bolt to thread through another bolt on the flexplate (I also had to use a nut behind the flexplate since it's not threaded, with a flywheel you can just use the pressure plate bolt), set it up in a manner where the flywheel can't spin counter-clock wise, and loosen the bolts using a breaker bar, this is assuming you don't have an impact wrench. You can also use this to break the crank bolt loose.  On the JZ when you remove the A/C compressor, the power steering pump looses one of it's brackets for support, now some people don't care and just run it that way, I will be using a Xcessive manufacturing bracket for this, however if you are trying to save some money you can take apart the compressor, and only use the front cover to properly hand the power steering pump:      This is my McGiver idea for removing the crank pulley without a puller:  This is more for myself than anything, but here are the timing marks for the engine: Crank (see the notch on the oil pump lines up to the slot on the crank gear):  Exhaust cam gear:   Now this is one of the heater core lines coming off the cylinder head, I will not run a heater core, so I decided to weld the plug shut, you could also just remove the pipe, thread the head and put a plug there:  And this is the water outlet for the coolant running through the throttle body, I modified mine to remove TRAC so I won't need this, I just welded it shut  Since I will not be running a MAF sensor, I won't need to recirculate the air back to the intake, so I modified the turbo outlet to remove the pipe that brings the air to the bov/intake. I am deleting trac and I wanted to remove the extra plate in the throttle body, and try to give myself more room in the engine bay, I did not do a very good job of cleaning and the welds did not come out so great.. but I don't really care, as long as it's sealed. Welding cast sucks...   However when you modify the throttle body this way the wheel can turn much further without actuating the flap itself, so I tacked the back to prevent this from happening:  This is just the beginning more later |

|

|

|

| Sponsored Links |

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|