|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

#5191 |

|

Zilvia Member

Join Date: Sep 2007

Location: Kingston

Age: 33

Posts: 252

Trader Rating: (1)

Feedback Score: 1 reviews

|

Just wanted to post up what I was up to this weekend. I know car nuts love seeing some welding porn.

There are lots more pictures on facebook for those interested! www.facebook.com/HellaFab

__________________

www.facebook.com/HellaFab |

|

|

|

| Sponsored Links |

|

|

#5192 |

|

Nissanaholic!

Join Date: Sep 2003

Location: Andrews Air Force Base

Posts: 1,905

Trader Rating: (1)

Feedback Score: 1 reviews

|

ITB setup I've been doing for a buddy. I can reproduce these...

oh and his cage is done now too. I just did the welding on this beast. the door bars through the B pillar turned out great. the sit flush with the door skins for super sweet door banger action.      |

|

|

|

|

|

#5196 |

|

Zilvia Junkie

Join Date: Mar 2009

Location: Kelowna BC Canada

Age: 35

Posts: 428

Trader Rating: (3)

Feedback Score: 3 reviews

|

Looks like a 5/8" rod end. Head size on them is a little tiny, but if they're quality brand name they should be fine. If it was me I would have gone with a 3/4", but that's probably overkill.

|

|

|

|

|

|

#5200 |

|

Post Whore!

Join Date: May 2006

Location: where waldo is

Age: 39

Posts: 3,256

Trader Rating: (16)

Feedback Score: 16 reviews

|

I just picked up a Miller Diversion 180, I'm just wondering if anyone can help me figure out why my arc is not straight when I weld. It goes all over the place. The tungsten is sharpen correctly, I used chem sharp to sharpen the tungsten.

Any other thoughts.

__________________

18g and 20g turbo users click on me http://zilvia.net/f/tech-talk/261219-18g-20g-turbo-users.html

|

|

|

|

|

|

#5201 | |

|

Zilvia Junkie

Join Date: Mar 2009

Location: Kelowna BC Canada

Age: 35

Posts: 428

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

Most likely a grounding issue, current issue, or contamination issue? |

|

|

|

|

|

|

#5202 |

|

Zilvia FREAK!

Join Date: Feb 2009

Location: north carolinazzz

Age: 30

Posts: 1,009

Trader Rating: (4)

Feedback Score: 4 reviews

|

What color tungsten are you using? I have found that using Chemsharp with purple, orange, and gold leads to a funky arc. Use a grinding wheel and keep it just for tungsten.

|

|

|

|

|

|

#5205 |

|

Zilvia Member

Join Date: Sep 2007

Location: Kingston

Age: 33

Posts: 252

Trader Rating: (1)

Feedback Score: 1 reviews

|

Colors didnt come out right being that I took it at night with fluorescents... but...

As always, more pictures on my Facebook page.

__________________

www.facebook.com/HellaFab |

|

|

|

|

|

#5206 |

|

Nissanaholic!

Join Date: Sep 2003

Location: Andrews Air Force Base

Posts: 1,905

Trader Rating: (1)

Feedback Score: 1 reviews

|

People typically do it solely for throttle response. Why specifically he did it dk. Didnt ask. I personally wouldn't bother with a turbo motor but im sure low end will noticeably benefit. They are slightly modded gtir throttles. The plenum was the only thing that really needed fabricated. Pretty cheap if you know the right people.

|

|

|

|

|

|

#5207 | |

|

Nissanaholic!

Join Date: Aug 2011

Location: France - Toulouse

Age: 41

Posts: 1,851

Trader Rating: (0)

Feedback Score: 0 reviews

|

Quote:

it looks cool it is supposed to give a bit more engine response on NA cars Cons: it is bloody expensive and complex (more parts = more chances of failures) you need to sync the butterflies every now and then - usually at the worst possible time most of the time the caps on the sync plugs end up leaking - again, usually at the worst possible time |

|

|

|

|

|

|

#5208 |

|

Zilvia Addict

|

First time I've done this much on my own and my welds have improved quite a bit over the past few months. Still using the same flux core mig.

Making my own mustang 2 front end for my 78 courier. Cross member, steering rack mounts and control arm mounts. All using 1/8" 2x2 square tube and 2" flat stalk. ImageUploadedByTapatalk1363578430.659927.jpg ImageUploadedByTapatalk1363578449.313633.jpg ImageUploadedByTapatalk1363578464.832771.jpg

__________________

Last edited by c72c; 03-17-2013 at 10:26 PM.. |

|

|

|

|

|

#5209 | |

|

Nissanaholic!

Join Date: Sep 2003

Location: Andrews Air Force Base

Posts: 1,905

Trader Rating: (1)

Feedback Score: 1 reviews

|

Quote:

here is something solid to fill your brains with rather than someones misconstrude opinion. Benefits of Individual Throttle Bodies - CarsDirect ITBs are used by automobile manufactures solely on high performance engine due to COST. they dont use them because it looks cool either. the fact that you said that makes me question everything you put on here. thats some ricer shit. i never thought they even looked cool. ill let you read for yourself. its all there. one downside is that they could become a choke point for force air. However, this is a factory setup. those throttles are designed for that motor. the Rb26 is a turboed ITB motor and they make plenty of power so i think it will be just fine for the 400 bucks he has in the setup.  |

|

|

|

|

|

|

#5210 |

|

Zilvia FREAK!

Join Date: Mar 2011

Location: Land of Purple Rain

Posts: 1,255

Trader Rating: (21)

Feedback Score: 21 reviews

|

Quick question for you fabrication/metal guys. What thickness metal are you using for extending your lower control arms?

__________________

DLG - DIRTYLOVE |

|

|

|

|

|

#5211 | |

|

Nissanaholic!

Join Date: Aug 2011

Location: France - Toulouse

Age: 41

Posts: 1,851

Trader Rating: (0)

Feedback Score: 0 reviews

|

Look, i think i have been pretty clear last time; you got a serious mental issue, so go get it fixed. I dont care about you, your life or anything; as strange as it may occur to you, my mind denies your association to the human race whatsoever. You are just an "internet thing" that frankly i could not care less, except your sole presence pollutes every thread you post in by your overall ignorance, harshness and language.

Dont you think there is a reason i ignored your PMs after you posted maybe 10 posts insulting me ? I really hope some mods will pink you for good this time. TL;DR :  Copy of one of these PMs so ppl can see what you are made off, i did not read them until now, but i guess the other one is the same. Quote:

Now as far as ITBs setup go, i have had enough bikes and worked on enough bike engine powered hill climbers to know their downsides, thank you. Finally, this is zilvia, nor NRR; someone asking for ITBs here is just interested in the bling effect. |

|

|

|

|

|

|

#5212 |

|

Nissanaholic!

Join Date: Sep 2003

Location: Andrews Air Force Base

Posts: 1,905

Trader Rating: (1)

Feedback Score: 1 reviews

|

Pink me for good? Was never pinked. And my overall ignorance produce the only tangible answer for the guys question. My feelings aren't hurt for you posting my pm. I had the same thing typed on that thread but i refuse to ruin a good thread which you are attempting to do. If you have something to say pm. All your doing is making yourself look like a fool.

Sent from my SPH-D710 using Tapatalk 2 |

|

|

|

|

|

#5215 |

|

Zilvia Member

|

Guys, its the internet. It's very important we get back on topic.

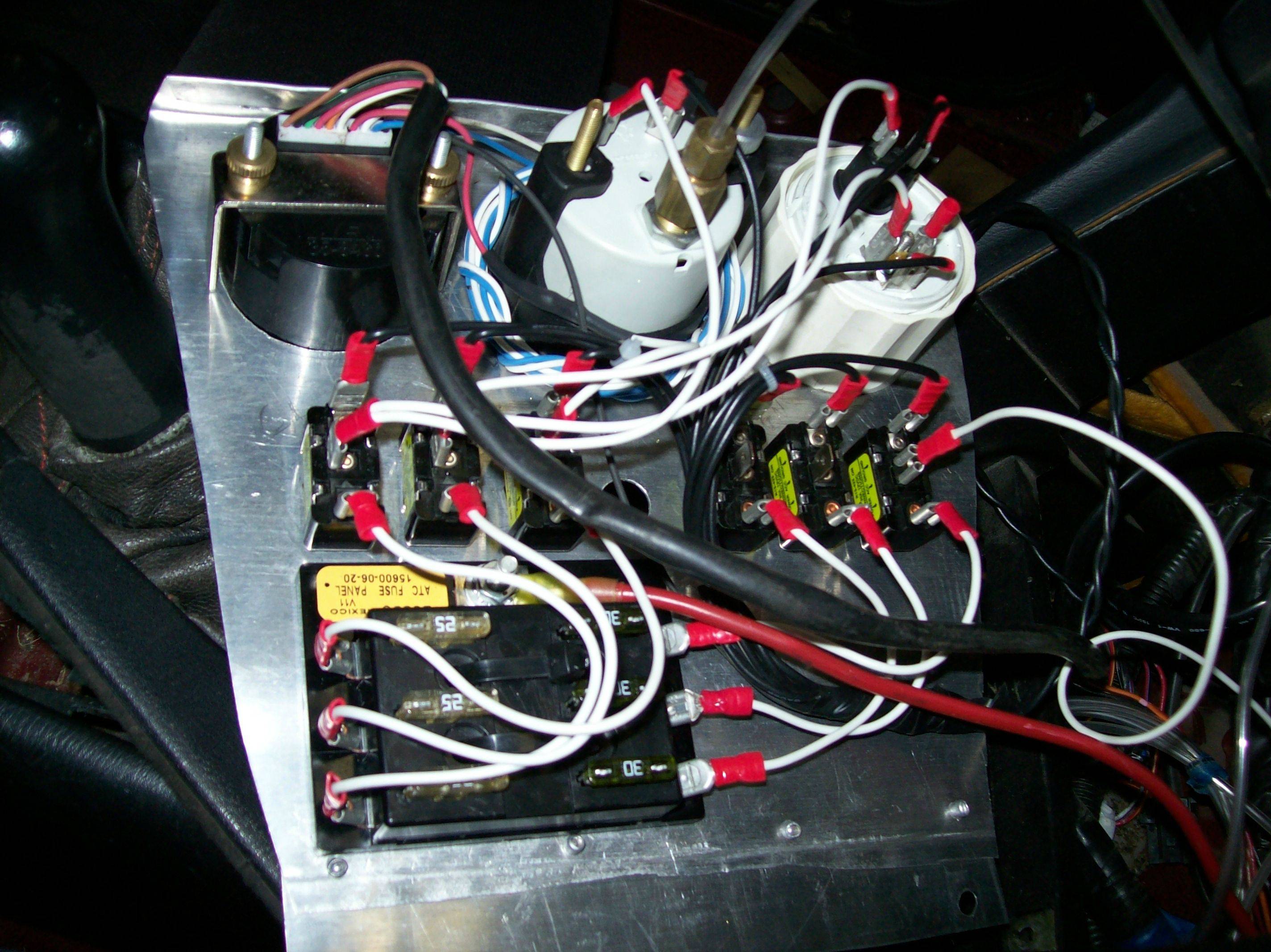

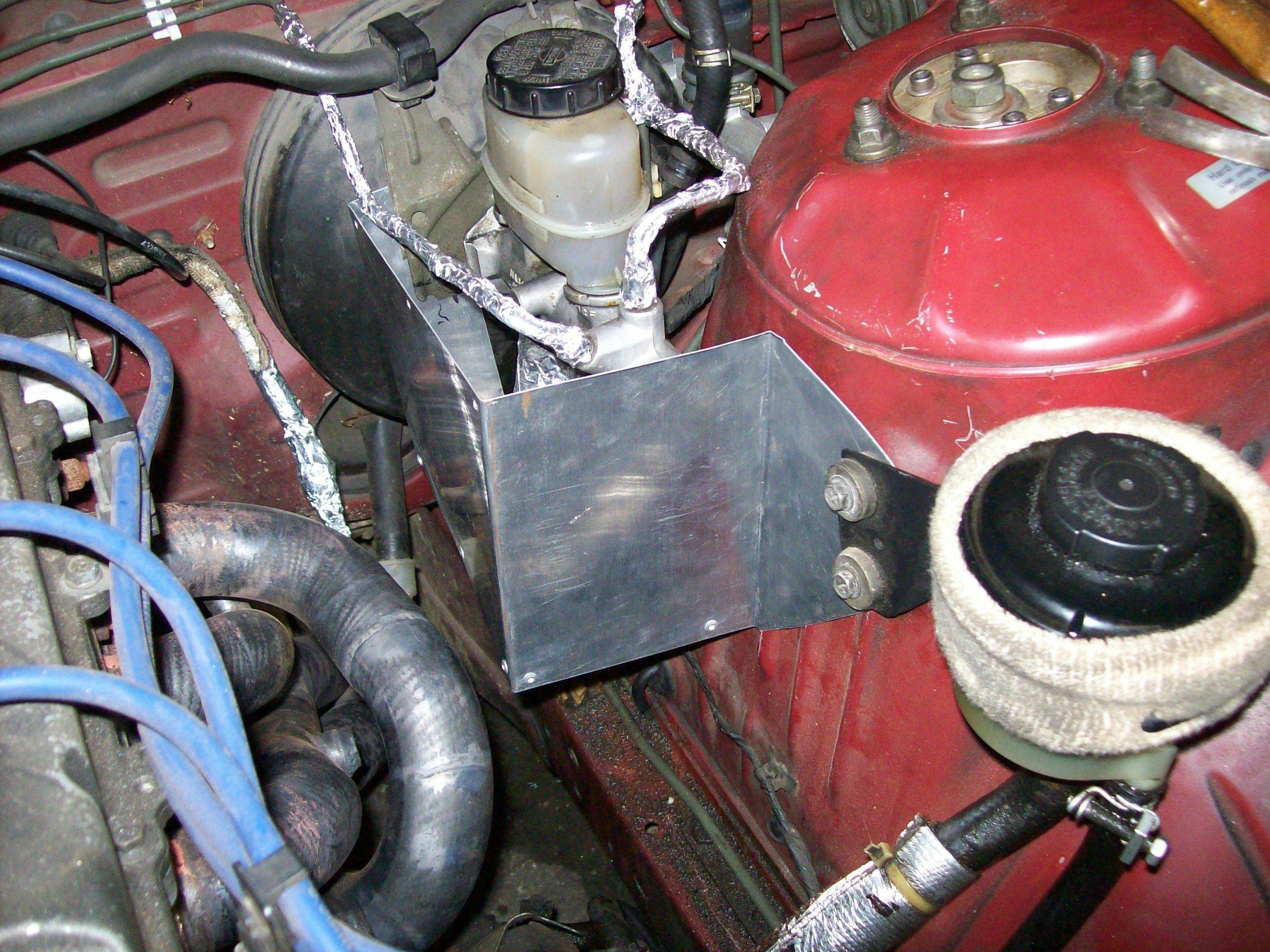

Exhaust I made Hood vent  Switch Panel  What takes up all the time when making a switch panel.  Brake heat shield  Holly fuck, do these not get auto re-sized? My bad.

__________________

'95 240 | @SleepySteve72 |

|

|

|

|

|

#5217 |

|

Zilvia Member

|

Yeah, I had some aluminum left over from the hood vent, really thin stuff. Bent by hand with a block of wood on the edge of a table as a 'brake' since I don't have a real one. I had to hammer most of the edges to be sharper and closer to a true 90 since a hand bend can only get you so close.

I keep forgetting lessons I learn from previous sheet metal projects like drilling holes where bends meet to prevent stress risers, and I never really measured that heat shield very closely, so it got seriously un-square when I bolted it on. But good enough for my needs, it should still do its job just as well.

__________________

'95 240 | @SleepySteve72 |

|

|

|

|

|

#5218 |

|

Zilvia Junkie

Join Date: Aug 2009

Location: Washington

Age: 37

Posts: 588

Trader Rating: (16)

Feedback Score: 16 reviews

|

I would like to know this also.. i dont think i have seen this posted anywhere.

__________________

Check Out My S13 Build |

|

|

|

|

|

#5219 |

|

Zilvia Junkie

Join Date: Jun 2010

Location: Arizona/LA, California

Posts: 476

Trader Rating: (3)

Feedback Score: 3 reviews

|

I normally have another set of bad LCA's that I cut a piece out of to weld into another LCA and then just weld on thicker stuff to add strength. Thats normally because I have a bunch though that we wont use.

When I get home, I will see how thick the metal my friend uses for his arms, he just gets the precut plates at industrial metals and uses those for whatever he needs so.. Ill post here again tonight.

__________________

S14 KA NA two cylinders, 75whp limper |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|