|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

#541 |

|

Zilvia Member

Join Date: May 2011

Location: eugene

Age: 29

Posts: 229

Trader Rating: (0)

Feedback Score: 0 reviews

|

this thread is amazing, one of the better ones out there for sure, just a few questions

#1 for all this welding work, and running fittings and lines, and cutting holes in your downpipes and all this extra work would it not just be easier to modify the valve cover internally and improve the baffling design to rival that of the s13.4 valve covers? #2 if your gonna go through all this work would it not make more sense to run the side valve cover vent and the top valve cover vent to a catch can with a baffled vacuum source and with a drain to the block vent with an inline filter that way your still seeing vacuum, still pulling air through the system and still collecting oil but instead of possibly filling a catch can or having the blowby oil from the side vent draining directly into the pan via the block vent its being filtered then drained? also while I agree they do a lot of stupid shit they aren't all junk, I owned a old first generation jetta with 824,000 miles on it, trans had been replaced multiple times but the engine was still original, had a litteral book of repair paperwork that dated from 10,000 miles to 720,000 miles I had never seen anything like it in my life |

|

|

|

| Sponsored Links |

|

|

#543 | |

|

Premium Member

Join Date: Oct 2004

Location: San Francisco, CA

Posts: 5,824

Trader Rating: (13)

Feedback Score: 13 reviews

|

Responding in line

Quote:

__________________

Turn and Burn! Turn and Burn!

|

|

|

|

|

|

|

#545 |

|

Zilvia.net Advertiser

Join Date: Nov 2005

Location: Michigan

Age: 33

Posts: 5,430

Trader Rating: (16)

Feedback Score: 16 reviews

|

Just to further the discussion we have going here, this was recommended by a very successful mechanical engineer with quite a large list of accomplishments. Now it's for a V engine but it applies equally to an inline. I was opposed to it at first, but it does make sense. Evacuation under all conditions.

__________________

Build: http://zilvia.net/f/showthread.php?t=643065 Friends don't let friends buy knock-offs. |

|

|

|

|

|

#546 |

|

Premium Member

Join Date: Oct 2004

Location: San Francisco, CA

Posts: 5,824

Trader Rating: (13)

Feedback Score: 13 reviews

|

Yeah I agree in theory this would totally work. My issue is that there would be possible multiple point of failure if we include it in the vacuum system. I do like it a lot sort of like how our stock pcv system? What do you think about even a belt or electrical vacuum pump? That might be easier?

__________________

Turn and Burn! Turn and Burn!

|

|

|

|

|

|

#547 | |

|

Zilvia.net Advertiser

Join Date: Nov 2005

Location: Michigan

Age: 33

Posts: 5,430

Trader Rating: (16)

Feedback Score: 16 reviews

|

Quote:

A vacuum pump is definitely the all-in-one solution, but I would imagine you'd want to vent it to a catch can regardless. Probably a can with a drain back as well unless you have some really good baffling in your valvecover. Not the cheapest route, but by far the most effective this side of a drysump.

__________________

Build: http://zilvia.net/f/showthread.php?t=643065 Friends don't let friends buy knock-offs. |

|

|

|

|

|

|

#549 |

|

Zilvia FREAK!

|

|

|

|

|

|

|

#550 |

|

Post Whore!

Join Date: Nov 2004

Location: Honolulu, Hawaii

Age: 41

Posts: 3,159

Trader Rating: (27)

Feedback Score: 27 reviews

|

Just seen this posted on Facebook. Thoughts? https://www.facebook.com/groups/2727...6855802402872/

|

|

|

|

|

|

#552 | |

|

Post Whore!

Join Date: Nov 2004

Location: Honolulu, Hawaii

Age: 41

Posts: 3,159

Trader Rating: (27)

Feedback Score: 27 reviews

|

Quote:

|

|

|

|

|

|

|

#553 |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,646

Trader Rating: (17)

Feedback Score: 17 reviews

|

This one is for a V8 using the OEM sr20det pcv flow:

1. if possible, use only 1 check valve. "More checkvalves is worse, not better" I say that from common sense. Always use the minimum equipment to minimize failure of equipment. 2. Select hose diameter carefully, adjust with no additional containers. Less crankcase volume overall means higher response to vacuum, more effectively/effectiveness of vacuum signal. 3. Select orifice diameter "on the high side" as opposed to the entire hose. Account for potential flow and sludge with hose diameter if necessary. This depends on power and maintenance interval. making diagrams: try to keep flow all the same direction make sure its obvious which side of the air valves you are on, and where it is Last edited by Kingtal0n; 05-08-2019 at 06:43 AM.. |

|

|

|

|

|

#554 |

|

BANNED

|

Ok Fine... Most SR slanted valve auto clicker word unscrambler jumble solver covers can do this no problem, why? Because their baffling in the valve cover is better than or flat tops and their valve covers ARE that little black air oil separator cans if you look up slant top pics... So what do you do?

Last edited by marcoch; 01-12-2020 at 11:03 AM.. |

|

|

|

|

|

#556 | |

|

Premium Member

Join Date: Oct 2004

Location: San Francisco, CA

Posts: 5,824

Trader Rating: (13)

Feedback Score: 13 reviews

|

Quote:

__________________

Turn and Burn! Turn and Burn!

|

|

|

|

|

|

|

#557 |

|

Leaky Injector

|

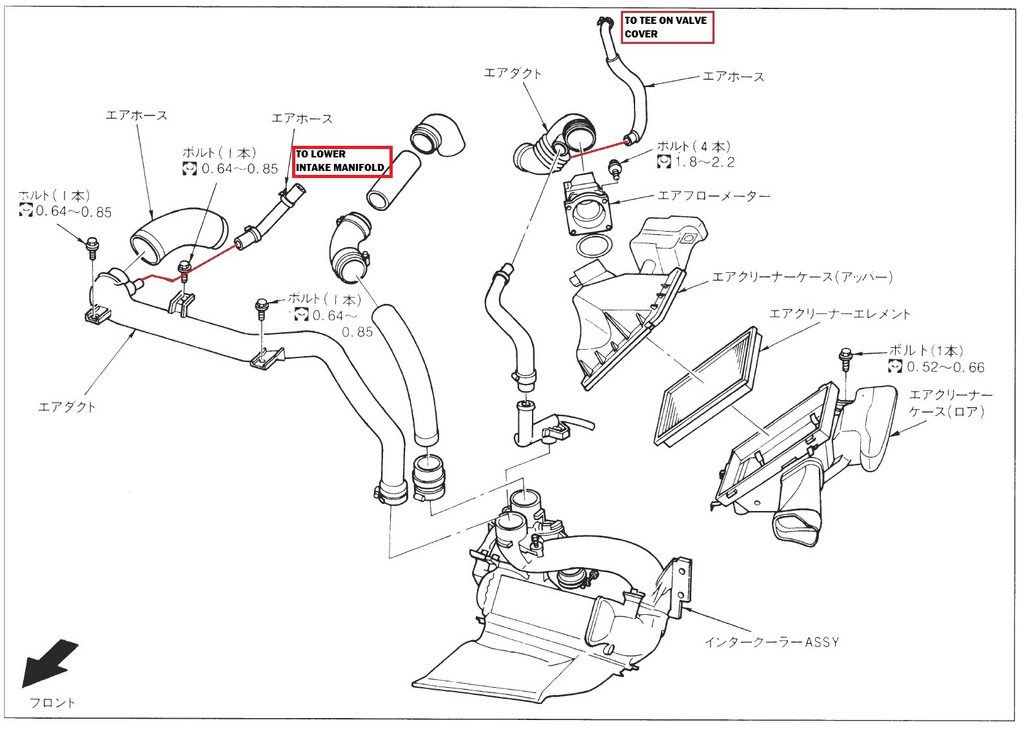

In my attempt to better understand the factory PCV system here are a few diagrams from the Japanese FSM for the SR20DET showing the pipes connected to the intake related to the PCV system.

Factory SR20DET Intake Diagram  PCV and I'm not really sure where that lower pipe goes? Lower intake manifold? EDIT: Looks like it goes to the AAC valve  Split air pipe to intake manifold and lower pipe to lower intake manifold? EDIT: Looks like it goes to the AAC valve  I just thought this looked funny.  Another view  Picture  Ever since converting to Speed Density I have a catch can vented to atmosphere and have had a fucked up rich idle issue which led me to this thread. I am going to re-plumb the hose from the Tee on the valve cover to the catch can and back to the intake before the turbo. I will edit this post with results. In my opinion -AN isn't really necessary for anything in the system. Simple barbs/hose/hose clamps are adequate. -AN only needed for pressurized fluid. EDIT: Ha! I find it hard to believe that a working PCV system vs Venting to atmosphere would actually net HP gains, but I think it actually will/does. Something so simple but necessary for applying vacuum to the crankcase. 5-13-20 EDIT: I hooked up my catch can to a nipple on the intake pre-turbo and it didn't really seem to do anything noticeable. However, while trying to determine my idle issue I removed the intake manifold and noticed a pool of oil in my intake manifold. This was probably because I didn't have the vacuum source hooked up causing pressure to build up and push oil out the PCV into the IM. I have not yet checked the PCV valve. Idle problem may be related to IACV, but it looked and tested fine.

__________________

1990 240SX SR20DET GTX2863R Last edited by nick_d_240sx; 05-13-2020 at 10:43 AM.. |

|

|

|

|

|

#558 |

|

Premium Member

Join Date: Oct 2004

Location: San Francisco, CA

Posts: 5,824

Trader Rating: (13)

Feedback Score: 13 reviews

|

The pipe between the black canister, has a silver reducer in it. Without it you going to suck up a lot of oil on the track..... hence pipe through the valve cover.....

Also you actually DO need AN fittings and a push lock, cause when pulling 20psi, it WILL collapse a shitty heater hose.... Just FYI... The pipes from factory are hard for a reason.... Hope that helps.... I am also running a MAP sensor via a PowerFC DJetro, I wonder if your injector latency is wrong or your ecu can't control super large injectors. I recently also been reading more into side feed vs. top feed and top feed is a lot better at idle from what people are saying.

__________________

Turn and Burn! Turn and Burn!

|

|

|

|

|

|

#559 |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,646

Trader Rating: (17)

Feedback Score: 17 reviews

|

Air is a fluid and we are definitely under pressure on the surface of Earth

perform pressure test to find all leaks of crankcase pcv system replicate OEM pcv situation in wet sump application... or else |

|

|

|

|

|

#560 | |

|

Zilvia FREAK!

|

Quote:

The gains here are doubtful - for one thing, running a huge line to pull huge vacuum actually takes power, that's energy spent one way or another, coming out of the same total volume of energy in your gas tank. Vacuum's good in the motor, but there's going to be diminishing returns past a mild point, which is why production cars don't come with hoovered out PCV systems. Cars with excessively positive OR negative crankcase pressure develop all sorts of weird problems, like seals flipping and wearing, or other solenoids or systems not doing what you'd think because they can never bleed vacuum as fast as they need, or whatever. |

|

|

|

|

|

|

#561 | |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,646

Trader Rating: (17)

Feedback Score: 17 reviews

|

Quote:

It varies depending on the engine's current state and pcv orifice diameter but somewhere within that range is acceptable to majority of production engines... Performance engine vacuum range is actually the same, 1 to 3" of Hg in a wet sump application. So your statement about excessive vacuum is accurate whether we are discussing production engines or high performance engines with oil in the pan. The difference you neglected to mention however is in the flow rate of each situation. A production engine which has been turned up (say, a sr20det turned up to 400whp or a 4.8L truck engine turned up to 600rwhp) to around double of the intended output is going to require around double the pcv flow rate to maintain the same vacuum (roughly 10KPA) given all else equal, due to the roughly double pressure integral experienced by the piston area. This is a classic example of pressure vs flow, just like in oil systems we are familiar with. What it really means is that when attempting to hit production pcv standards (10KPA pressure drop ranges) in highly modified (often production) engines, the requirements for adequate pcv performance change as much as the power does, you can't always re-use the factory pcv components and expect to achieve a factory level of PCV on highly modded engines. The orifices likely need to be larger and the filter situation needs to be addressed, since the air filter essentially drives WOT pcv action. In other words, crankcase pressure should be discretely measured, to ensure that phenomenal range of 1 to 3" Hg is being hit at WOT and cruise. If that can't be done, then at least adequate paper filtration and correct pcv orientation should be used to give it a fighting chance at least. |

|

|

|

|

|

|

#562 |

|

This is a buddy of mines product, he's interested in hearing feed back on how people like it, it was developed around a boosted honda motor, but he makes them for all the japanese 4 cyl motors. So far he says the nissan guys have been slow to adopt. He's an engineer by trade. |

|

|

|

|

|

|

#563 | |

|

Premium Member

Join Date: Oct 2004

Location: San Francisco, CA

Posts: 5,824

Trader Rating: (13)

Feedback Score: 13 reviews

|

Quote:

__________________

Turn and Burn! Turn and Burn!

|

|

|

|

|

|

|

#564 | |

|

BANNED

Join Date: May 2019

Location: Florida-FAIL

Posts: 2,497

Trader Rating: (8)

Feedback Score: 8 reviews

|

Quote:

|

|

|

|

|

|

|

#567 |

|

Zilvia.net Advertiser

Join Date: Nov 2005

Location: Michigan

Age: 33

Posts: 5,430

Trader Rating: (16)

Feedback Score: 16 reviews

|

Hey Slider, can you rehost pictures of your setup, photobucket has long ago died. Maybe edit your first post to include the pics?

__________________

Build: http://zilvia.net/f/showthread.php?t=643065 Friends don't let friends buy knock-offs. |

|

|

|

|

|

#568 |

|

Nissanaholic!

Join Date: Feb 2012

Location: Oxnard, CA

Age: 28

Posts: 1,876

Trader Rating: (31)

Feedback Score: 31 reviews

|

Felt like this thread is reasonable to post this. Ive been tossing around the idea of using an electric pump for crank case evacuation (sr20). I still want to keep the OEM pcv side intact. My idea was using a secondary air injection pump (they max out at 3-4" hg) that's triggered on a 1 psi pressure switch. So basically is idle/cruise the regular PCV will handle evacuation, and then in boost the PCV will close and the pump will take over. The point of the switch is so the pump isn't in constant operation.

Sent from my Galaxy Note 10+ using Tapatalk |

|

|

|

|

|

#570 | ||

|

Zilvia.net Advertiser

Join Date: Nov 2005

Location: Michigan

Age: 33

Posts: 5,430

Trader Rating: (16)

Feedback Score: 16 reviews

|

Quote:

Quote:

Also, technically speaking, the pipe that attaches to the air intake isn't to draw pressure out of the crankcase, it's to allow fresh air into the crankcase when the PCV valve is doing it's job at cruise. This allows it to pull the combustion gases (which are acidic) and water vapor out of the crankcase and dump them in the intake manifold more easily. So it really comes down to whether or not you want to risk getting oil vapor in your intake pipe. You should be able to mitigate the risk with a properly setup catch can with good baffling, or you could just run an open catch can with an air filter and not worry about it. Engine longevity does rely heavily on good air filtration though, so that's something to consider in itself. It's all about balance.

__________________

Build: http://zilvia.net/f/showthread.php?t=643065 Friends don't let friends buy knock-offs. |

||

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|