|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Builds (and builds only) Got a build thread? It goes here, build threads anywhere else on the forum will be locked and never moved. |

|

|

|

Thread Tools | Display Modes |

|

|

#91 |

|

Zilvia Addict

Join Date: Feb 2014

Location: Arizona ٩( ᐛ )و Subaru Parts Consultant

Age: 26

Posts: 812

Trader Rating: (3)

Feedback Score: 3 reviews

|

Got to work ripping the car apart today. Didn't have an extra pair of hands out with me so I just prepped it to pull, but I did take the turbo off so I can have it cleaned out.

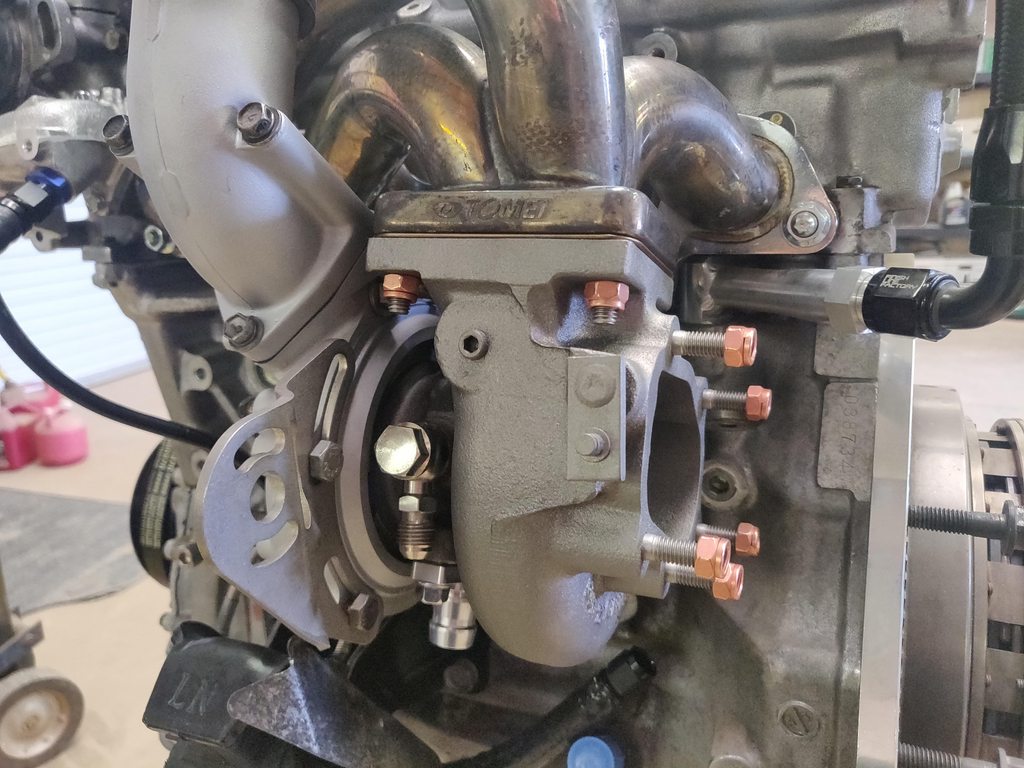

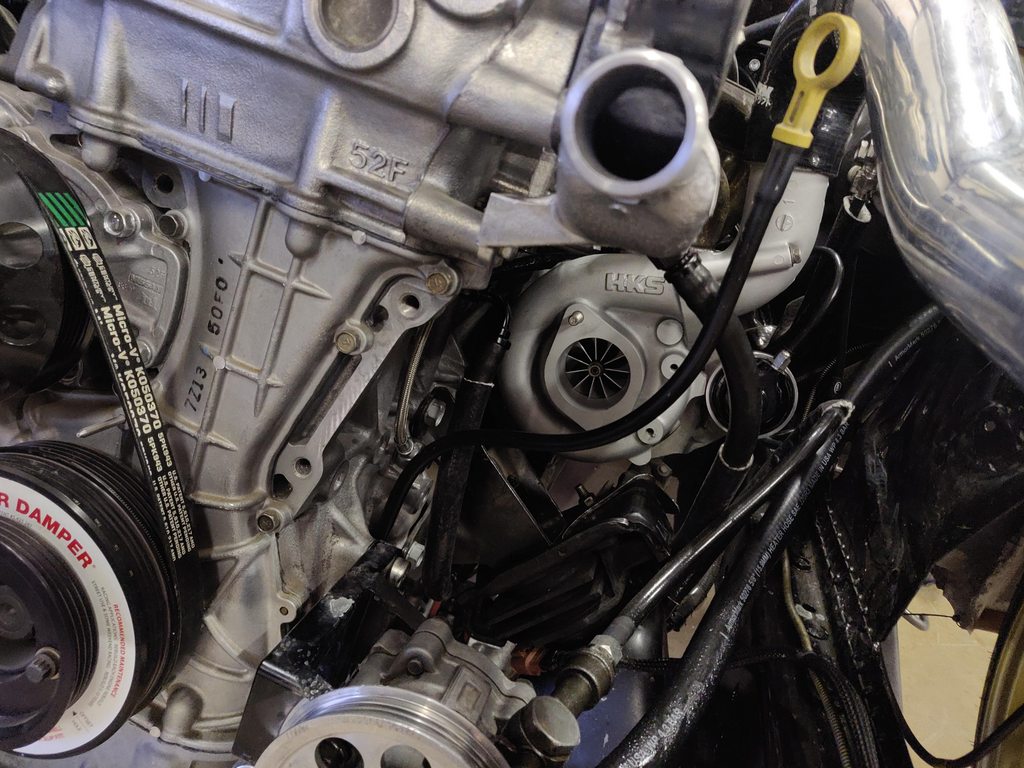

Made an executive decision that the S13 is going to borrow the Z32's SR for the time being. Its going to take some time to get another engine together so I may as well put the build engine I have to use. Really excited to finally see this engine running and its going to make the S13 an absolute animal! Run down on the engine is: S13 SR20DET block WPC treated crankshaft WPC treated Nissan OEM main and rod bearings Nissan OEM oil pump w/ WPC treated gears CP 86.5mm 9.0CR pistons Manely Rods Sianar Motorsports -10AN breather Nissan OEM main bolts Nissan OEM timing components ATI super damper 180SX head ported & polished by Port Flow Ferrea dual valve springs Ferrea +1mm valves Dual guides Tomei 260 procams Apexi head gasket Mazworx ARP Headstuds S13.5 valve cover w/ -10AN fittings      Since the G25-550 setup currently on the built SR has an exhaust suited for the Z chassis, I'm going to run the Tomei manifold and HKS turbo that were on the S13 with it. Separated the turbo and manifold, manifold was covered in some nasty heat wrap that was falling apart. Got it all stripped off and covered myself in fiberglass nastiness. Thinking I'll have it ceramic coated before it goes back in to manage heat in the bay without needing to re-wrap it. Turbo came home with me to be dropped to a local and have it torn down, cleaned and to see if it needs a rebuild after being pumped full of bearing material

__________________

|

|

|

|

| Sponsored Links |

|

|

#92 |

|

Zilvia.net Advertiser

Join Date: Nov 2005

Location: Michigan

Age: 33

Posts: 5,430

Trader Rating: (16)

Feedback Score: 16 reviews

|

Damn that's a bummer about the bottom end. Yeah no magnetic material is a good sign!

That other SR sure is gonna be snappy though! Wish I could afford to put Ferrea stuff in mine before it goes back together. Oh well!

__________________

Build: http://zilvia.net/f/showthread.php?t=643065 Friends don't let friends buy knock-offs. |

|

|

|

|

|

#93 |

|

Premium Member

Join Date: Mar 2009

Location: Maricopa, AZ

Age: 30

Posts: 7,679

Trader Rating: (10)

Feedback Score: 10 reviews

|

New motor is going to be awesome. I'm jealous of all the WPC parts! I asked mazworx about doing wpc if I send an engine in for a build and they said it wasn't worth it -_-

|

|

|

|

|

|

#94 | |

|

Zilvia Addict

Join Date: Feb 2014

Location: Arizona ٩( ᐛ )و Subaru Parts Consultant

Age: 26

Posts: 812

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

I'd really love to know why they don't think its worth while. Any friction reduction on moving parts seems like win in the event of dropping oil pressure.

__________________

|

|

|

|

|

|

|

#95 | |

|

Interested in selling voggards once new wheels are done?

Quote:

|

||

|

|

|

|

|

#96 |

|

Zilvia Addict

Join Date: Feb 2014

Location: Arizona ٩( ᐛ )و Subaru Parts Consultant

Age: 26

Posts: 812

Trader Rating: (3)

Feedback Score: 3 reviews

|

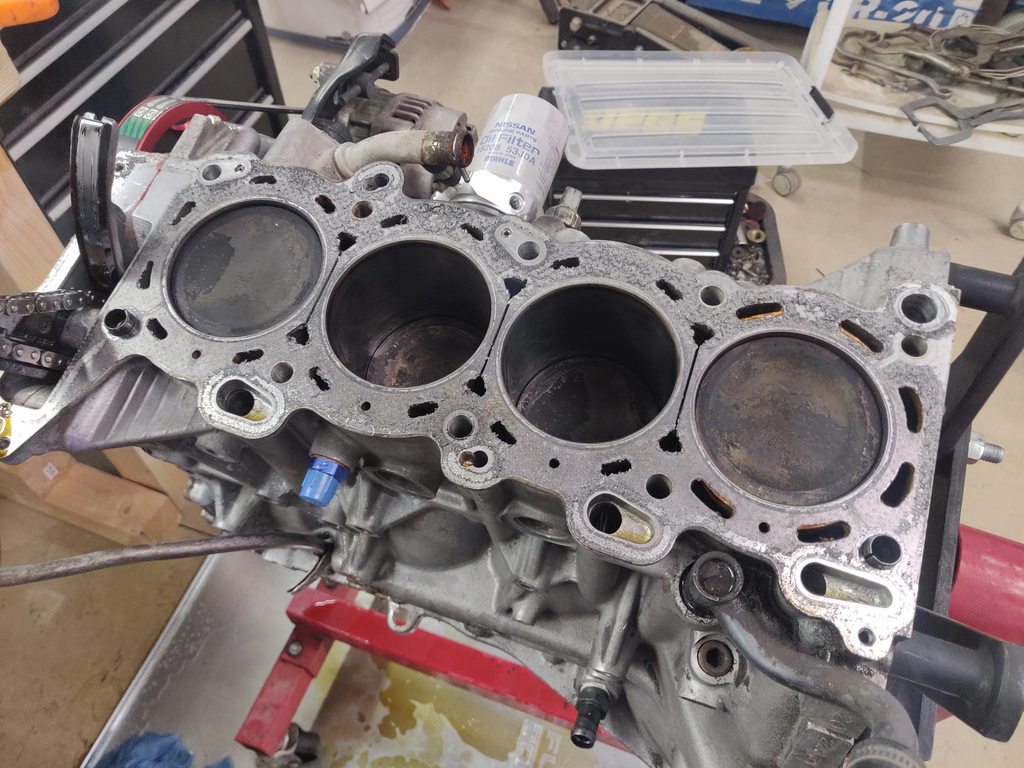

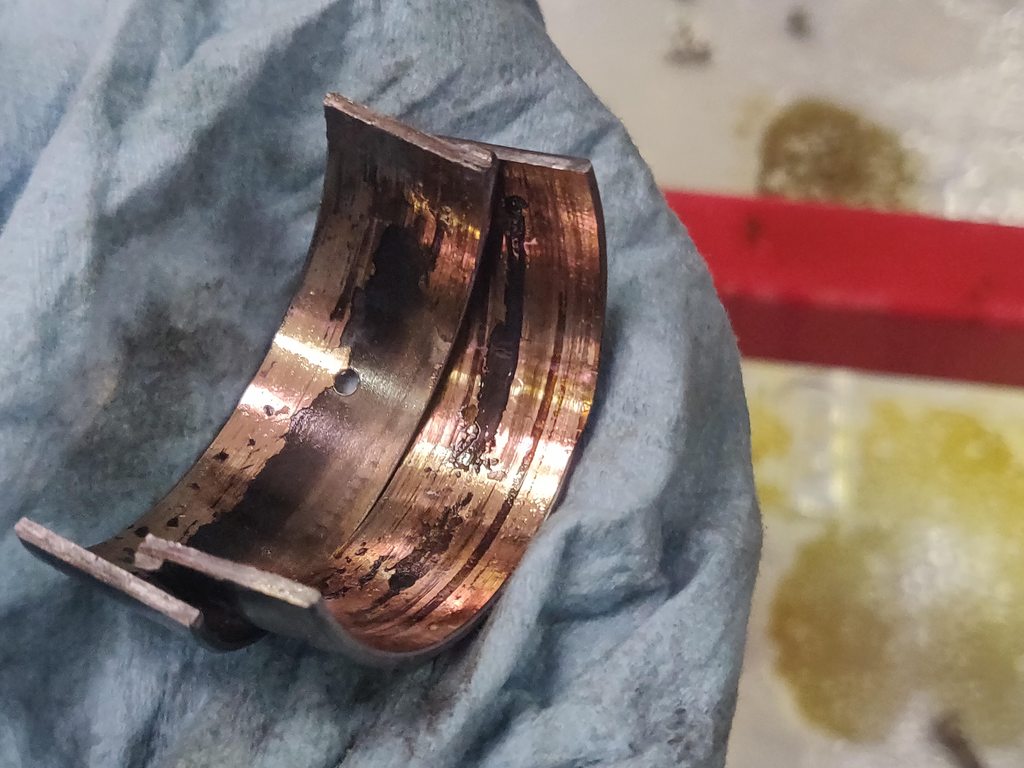

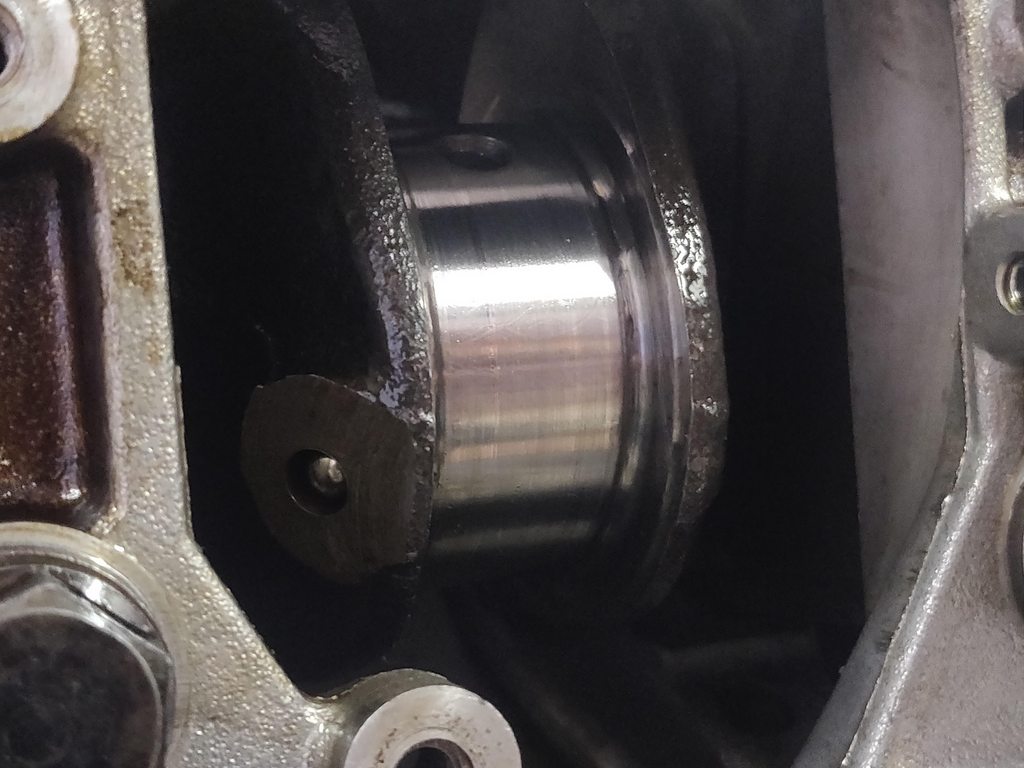

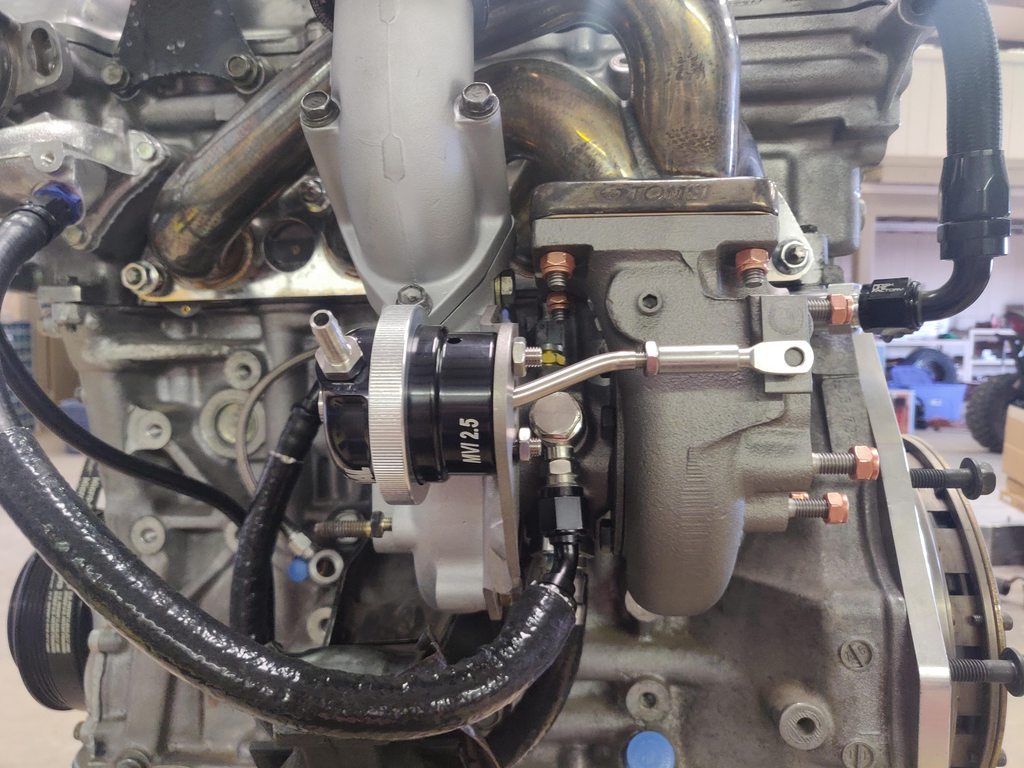

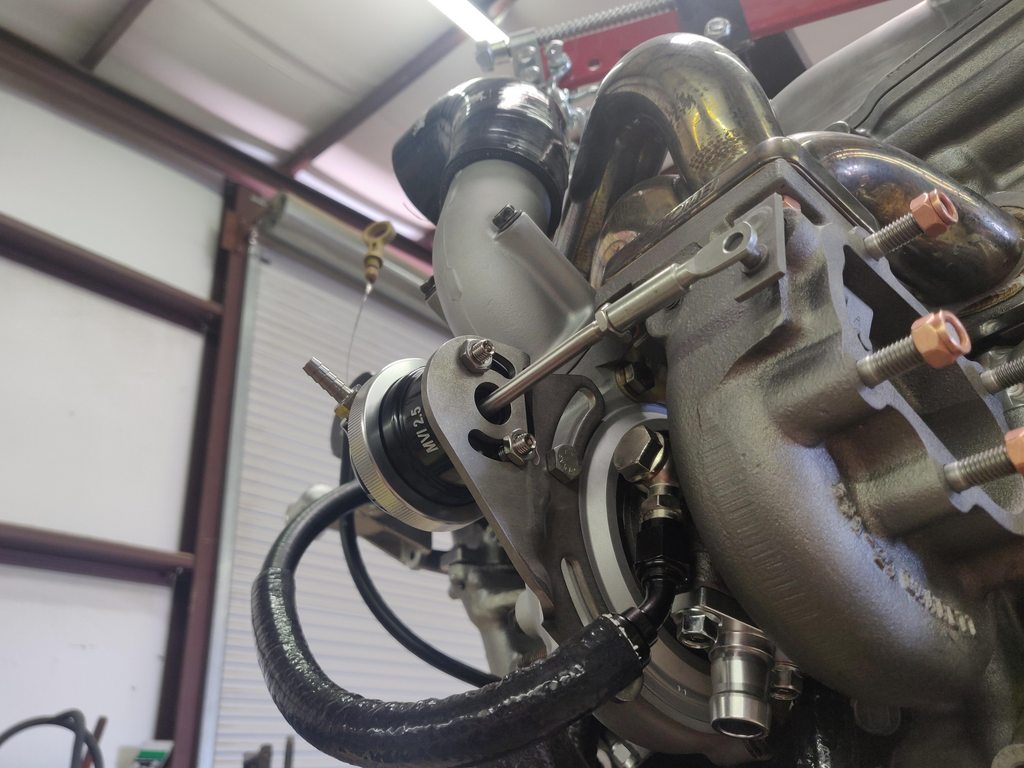

Okay, so some progress has been made since the SR committed seppuku.

Engines came out of both cars and I started tearing down the knocking SR. Found even more bearing material in the pan, but other than that everything looks really good.     Wiggled the rods around and #2 wasn't having it so I pulled the cap to find this wonderful sight under it. Bearing is torn apart almost to the shell, but was not spun and the crank looks okay. Engine had great oil pressure and fresh VR1 in it, I'm sure I this saved it from completely killing itself. Looked into the markings on the bearings, they are eBay special trash someone must have slapped into the engine.    The HKS turbo went out for a rebuild to get all of the bearing material out of it. Local friend took care of the rebuild and was able to get a slightly bigger wheel stuffed into it while it was apart. While it was apart we figured out its some odd sized GT25, not sure what its going to be capable of, but seeing it make 230whp on 8psi gives me hope it will be able to make mid 300's with the boost turned up and the new wheel.   Before the turbo setup went back on I wanted to address the hardware and wastegate. Ordered some nice studs and copper locking washers to hopefully keep the gaskets intact. Also picked up a PBM cobra downpipe to have a flex section in the exhaust.   Original wastegate wasn't going to cut it for this engine, was planning to just order a 1 bar Garrett replacement, but this compressor housing mounting points are different from T28. Ended up going with a Tial 12psi IWG actuator and adjustable mount from ATP. Seems like it'll do the trick after I remove a bit of material from one of the ears on the compressor housing.   Cleaned the lower pan in the parts washer and made sure to get all of the junk out of it. Threw the Z's engine up on the hoist and swapped the pans. I hate leaving an engine swaying away, but I was too lazy to pull the clutch and put it on a stand. Engine is pretty much ready to go back in the car, hoping this next weekend it'll be in place!   Since I can't find anyone to buy the RG's, I figured I'd get some smaller tires on them and run them. Found some tires cheap on closeout through work and snagged a set. Moved from a 265/35 to a 235/40, fitment is way better, need to work out front fitment a bit still though because I'm hitting the firewall at partial lock. Thinking it has something to do with these GKTech RCC blocks pushing the bottom of the wheel out way too far. Car looks goofy as hell with the front so high and no kit. I actually sold the kit that was on the car and ordered some new hotness that should show up in the next few months!

__________________

|

|

|

|

|

|

#97 |

|

Zilvia.net Advertiser

Join Date: Nov 2005

Location: Michigan

Age: 33

Posts: 5,430

Trader Rating: (16)

Feedback Score: 16 reviews

|

I know a thing or two about one step forward, two steps back! Haha. Looks good as always though, it'll be interesting to see what that turbo does.

__________________

Build: http://zilvia.net/f/showthread.php?t=643065 Friends don't let friends buy knock-offs. |

|

|

|

|

|

#98 | |

|

Zilvia Addict

Join Date: Feb 2014

Location: Arizona ٩( ᐛ )و Subaru Parts Consultant

Age: 26

Posts: 812

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

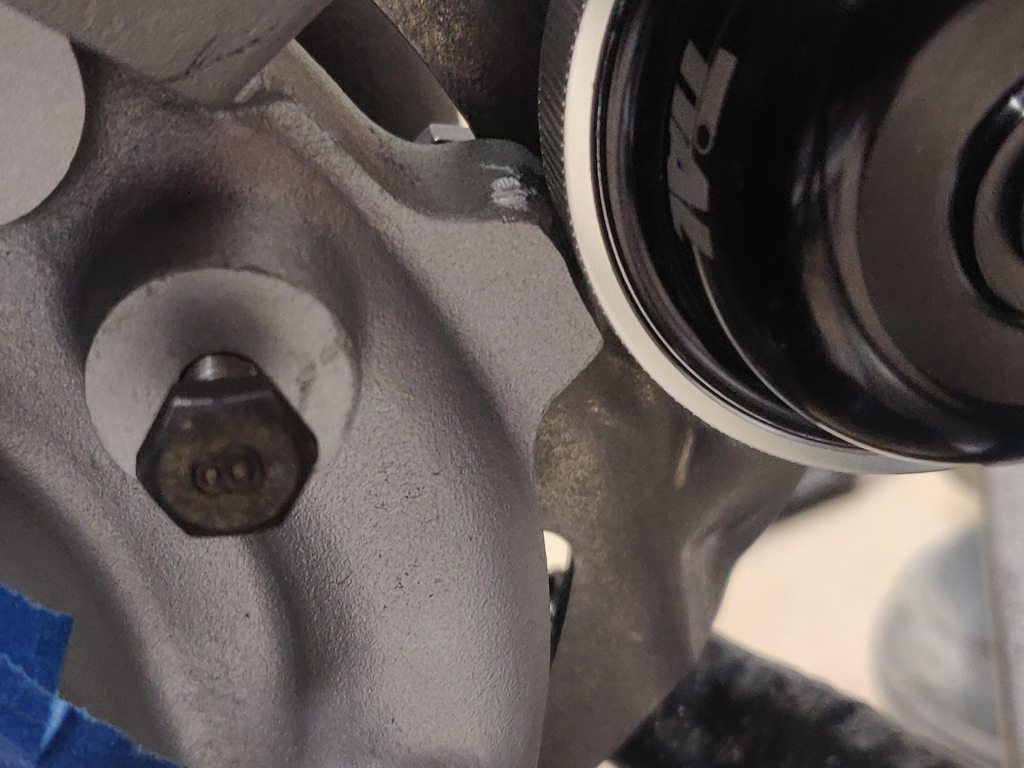

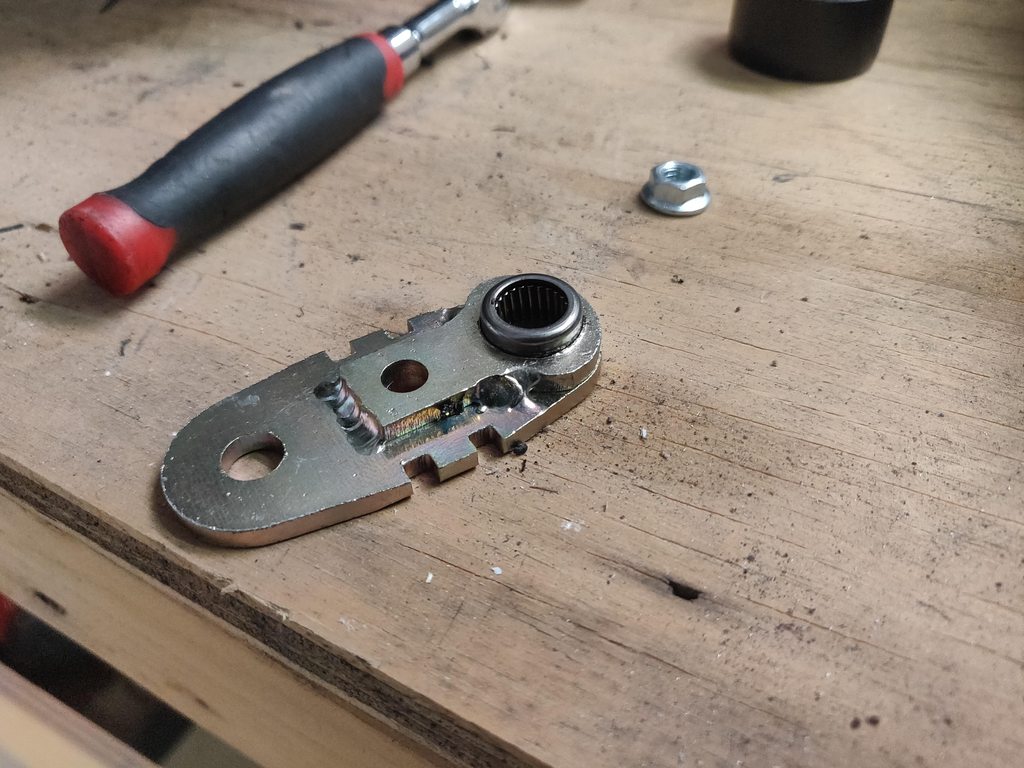

Its the little things that can bring the entire process to halt... Its the little things that can bring the entire process to halt...Wastegate fitment is worked out, ground down the ear it was hitting on the compressor housing and everything lines up pretty well. Threw some compressed air into it and everything moves freely. Drilled and tapped a 1/8NPT port into the turbo outlet for boost reference, decided to put it low on the outlet to keep a clean look. Really happy with it overall, need to throw some heat sleeve over it, but its got some good clearance from the manifold as is.    Intake manifold went back on the engine, hopefully for good this time. Fuel rail is back on with the Radium DMR and ID1050X's, really love how the short ID1050 and radium rail look on the Greddy manifold. Again I'm running more push lock fittings for vacuum to keep everything easily serviceable and reduce the need for zipties or clamps.  Got an Xcessive (short) shifter relocation for the Z32 trans, instructions kinda sucked. Got the old linkage cut off, pressed the little needle bearing caps out with the vice and it went on perfectly. I love the FS5R30A feeling and I shouldn't need to mess with or worry about this setup.

__________________

|

|

|

|

|

|

|

#99 |

|

Zilvia.net Advertiser

Join Date: Nov 2005

Location: Michigan

Age: 33

Posts: 5,430

Trader Rating: (16)

Feedback Score: 16 reviews

|

You're telling me man, story of my whole life :P.

Now I'm wishing I would have gotten that direct mount FPR, that thing is slick. Oh well, haha. Definitely shield that plastic tubing well, we had plenty of cars come through the shop with holes in the blocks from melted or popped off wastegate lines. "It felt so fast" lol.

__________________

Build: http://zilvia.net/f/showthread.php?t=643065 Friends don't let friends buy knock-offs. |

|

|

|

|

|

#100 |

|

Zilvia Addict

Join Date: Feb 2014

Location: Arizona ٩( ᐛ )و Subaru Parts Consultant

Age: 26

Posts: 812

Trader Rating: (3)

Feedback Score: 3 reviews

|

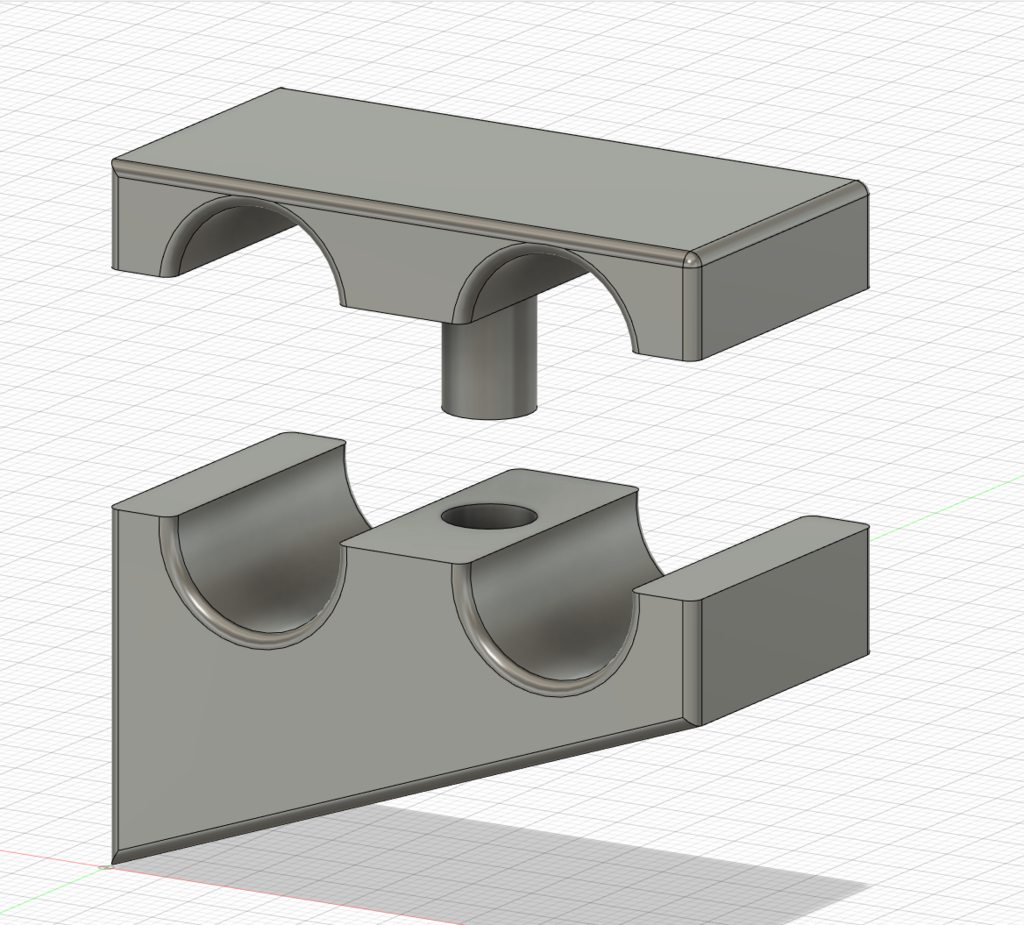

Engine is in the car, finally. I have been kicking sand and working on my WRX recently so the 240 hasn't seen much love. Had some small issues fitting everything in with the Z32 trans, but it ended up just being a bolt sticking through the trans tunnel. Mazworx transmission crossmember and Xcessive shifter bracket put the shifter right where it needs to be which I couldn't be happier about!

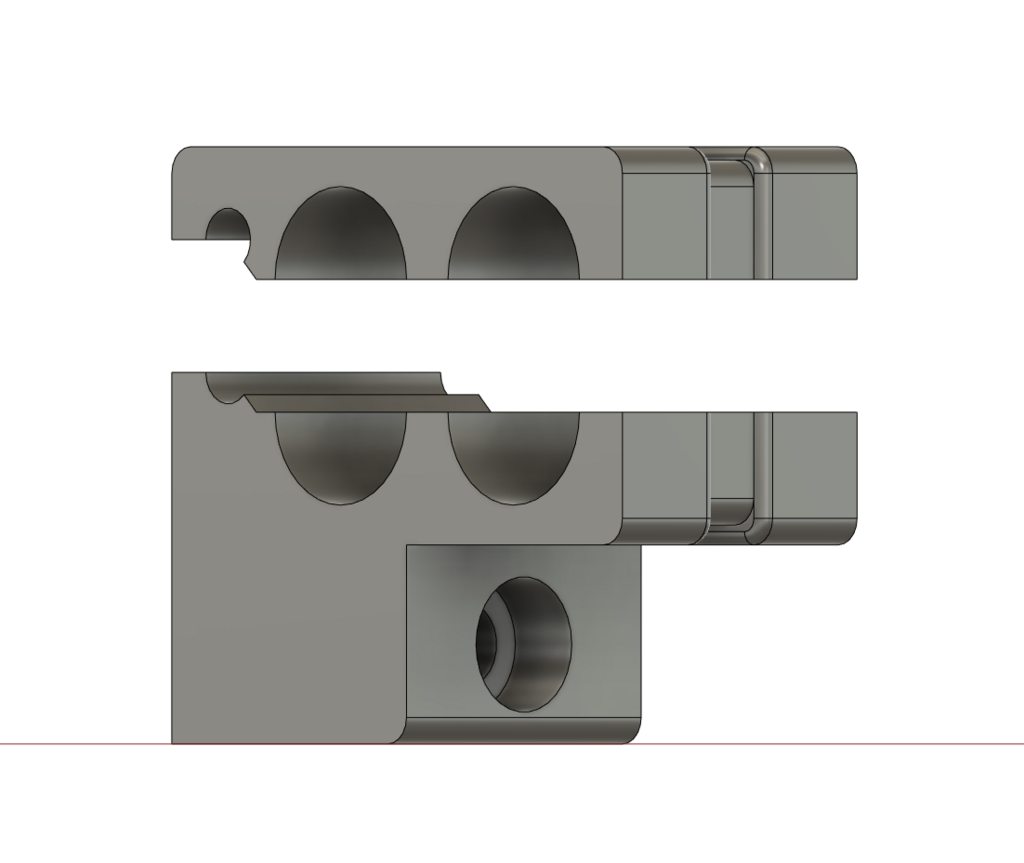

Picked up another set of 17x9 GT-R spec Panasports. These are cracked/bent to hell which makes them perfect candidates to re-build for the S13! Going for a 17x9.5 for the front and 17x10.5 for the rear, plus the pair of 18x10.5 for the rear.  I bought a 3D printer a while back and have been playing with it a bit recently. Since the S13 will be getting new fuel lines from the tank forward, I wanted a more elegant solution for line routing. Figured P-Clamps would work, but since I have the printer I wanted to try and make some proper line holders. This is the first "Prototype" i have printed, copied the size of the original metal brackets, made it a bit thicker, two 14mm holes and a counter bore for the mounting hole to accept an M6 cap bolt. Really happy with how it turned out, going to clean up the edges, make the top removeable and print the final parts from ABS.    Hoping to spend some more time with the car this week/weekend and maybe get it started for the first time!

__________________

|

|

|

|

|

|

#101 |

|

Zilvia Addict

|

Hell yeah! The posibilities with 3d printers are so good! Can't wait to see it done.

__________________

|

|

|

|

|

|

#102 | |

|

Zilvia Addict

Join Date: Feb 2014

Location: Arizona ٩( ᐛ )و Subaru Parts Consultant

Age: 26

Posts: 812

Trader Rating: (3)

Feedback Score: 3 reviews

|

Quote:

__________________

|

|

|

|

|

|

|

#103 |

|

Zilvia Addict

Join Date: Feb 2014

Location: Arizona ٩( ᐛ )و Subaru Parts Consultant

Age: 26

Posts: 812

Trader Rating: (3)

Feedback Score: 3 reviews

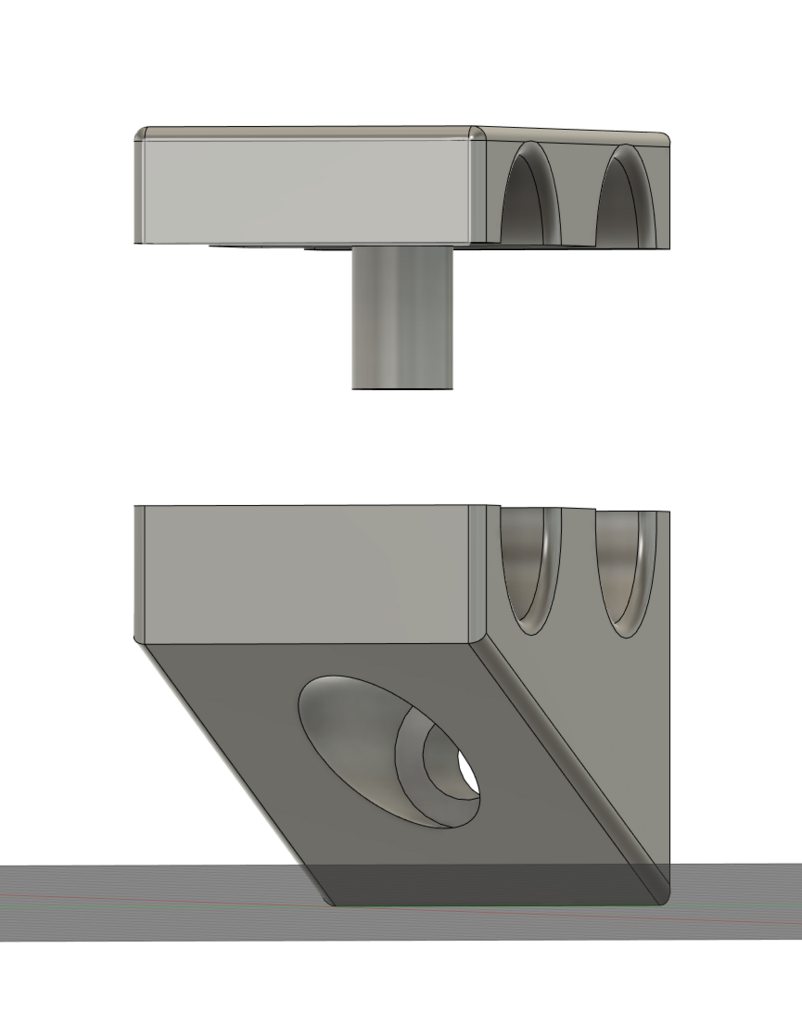

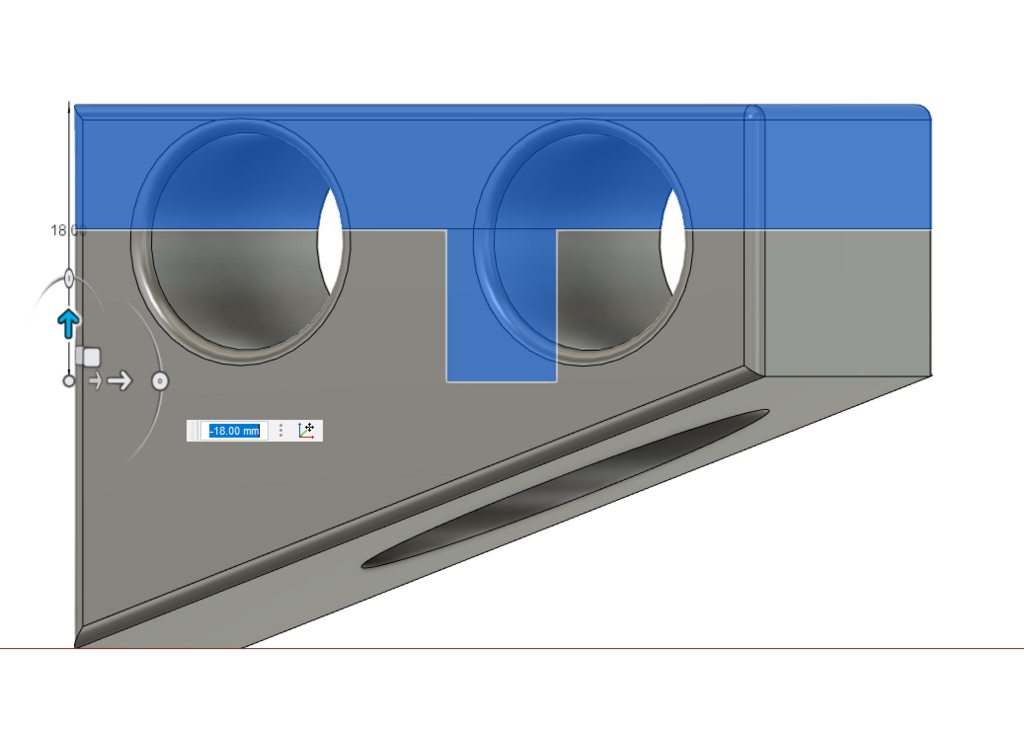

|

Revised my fuel line retainer again and came up with a much better looking design that is significantly more functional. Used the original retainer/metal bracket to model this part and ensure there won't be any fitment issues against the bottom the the chassis. This design is meant to use a metal zip tie to hold the upper and lower halves together, snugly clamping the hose. For the final part I wanted a much stronger material than basic PLA, upgraded my 3D printer to allow higher print temperatures and made a test part from reinforced nylon/carbon fiber filament. Part came out awesome!

With knowing the design was going to work, I revised the part one more time and added the brake line provision. Final part has a slightly revised fillet around the channel for the zip tie to allow for a cleaner print with less overhang as well. Will be making some of these tomorrow and test fitting them on the car!    Also finally set the car on the ground with an engine in it and the RG's on, seeing it at the correct ride height gets me more hyped to work on it!

__________________

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|