|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Premium Member

Join Date: Jun 2006

Location: New Jersey

Age: 35

Posts: 584

Trader Rating: (20)

Feedback Score: 20 reviews

|

S14 Suspension build thread.....Pic Intensive

I would first like to thank Donovan of Yamato Garage and Ryan from BallerBolts for the fantastic products. They unknowingly, motivated me to go into greater detail with the build to compliment their products. This thread will focus primarily on the process from beginning to end of the restoration and upgrade of the suspension, brakes, and chassis on my S14 240sx. Feel free to ask questions and post comments, positive or negative are fun too.

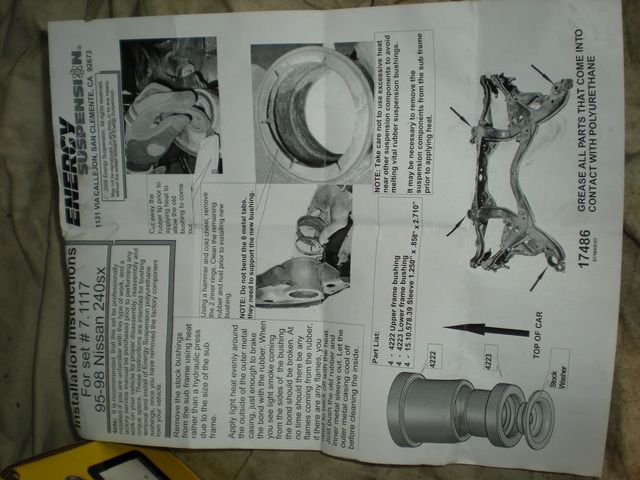

The car started off as a completely stock S14 SE from New Jersey, which is why the suspension is such a rusty horrible mess. Every square inch was covered with rust and was extremely difficult to disassemble for that reason.   Every bushing was torn and rotted, which was the first order of business. Started by burning out the old subframe bushings, which is pretty easily done with a small torch and a hammer.    After the inserts are have been removed, you must burn and chisel away as much of the rubber as possible. The result will be something like this.....  At this point the sleeves are ready to be removed according to the instructions provided by the manufacture of bushings you are using. I opted to use Energy Suspension bushings, which include reasonably clear instructions on how to remove the sleeves. The bushings ended up fitting perfectly. http://www.energysuspension.com/asse.../pdf/17486.PDF  To remove the inner cage, you will need to make relief cuts around the inside and bend the cage inward. A mini pneumatic reciprocating saw will make this task much easier. Two cuts 180 degrees apart will allow the metal the fold in towards the middle. Be careful not to cut through the sill on the bottom of the hole. It can then be hammered out through the bottom with a chisel.  The inner sleeve it a little more difficult to remove, as the metal is a thicker and you must be very careful not to cut through to the subframe. I accomplished this by carefully making relief cuts about an inch apart, and bending the sleeve inward. You will then be able to hammer the whole sleeve through from the bottom.  Starting come out.....  All the way out.....  After they are out wire wheel everything clean, and you should end up with something like this....    The subframe was then washed, sanded, primed and painted Graphite Gray    The bushings are then simply pushed in (ended up switching to black bushings, for cosmetic reasons only)  I next moved on to the rear spindles, which were especially difficult to separate from the hubs. If you come across this problem, partially thread the 4 bolts into the hub and evenly hit the bolts until the hub separates from the spindle. I then burned out the bushings,and cut out the metal sleeves in a similar fashion as the subframe sleeves. They were then bead blasted, taped, and powder coated matte black. I then installed the Energy Suspension bushing set using a lot of lubrication and a vice.    Last edited by doyle4281; 11-06-2011 at 10:01 AM.. |

|

|

|

| Sponsored Links |

|

|

#8 | |

|

Guild of Skullduggerous Intent

|

Quote:

drill a hole on each upright location to the ID where each bushing is installed tap the holes and install zerk fittings that you can use a grease gun on these will allow you to service the bushings for grease periodically as needed and keep them from squeaking and/or binding do a little bit of searching as a few people have done and written about this |

|

|

|

|

|

|

#13 |

|

Nissanaholic!

|

I like this thread.

Where in Jersey are you from? Do you drive CL at all? |

|

|

|

|

|

#14 |

|

Zilvia Member

|

Polyurethane bushing grease fitting install - Nissan Road Racing Forums there is a thread talking about the zerk fittings he got the idea from a friends mustang bushings that came like that, Im in the process of doing this myself

|

|

|

|

|

|

#15 | |

|

Post Whore!

Join Date: Apr 2006

Location: North Jersey

Posts: 5,481

Trader Rating: (55)

Feedback Score: 55 reviews

|

Quote:

thanks alot i was up all night looking for something like this. I guess i can go to town now with my extra spindle set haha |

|

|

|

|

|

|

#16 |

|

Premium Member

Join Date: Jun 2006

Location: New Jersey

Age: 35

Posts: 584

Trader Rating: (20)

Feedback Score: 20 reviews

|

Update

Thank you for the kind words. If anyone has any questions, please feel free to ask.

The rear lower control arms were up next, which were in desperate need of refreshment. The ball joints were worn, the bushings were rotted, and covered in rust. I started by burning out the old bushings, and removing the sleeves, again using the same technique as the subframe. The arms were then taken to the press and the ball joints were pushed out. After a good cleaning, I stripped the factory paint off, bead blasted, and powder coated "Mirror Silver". The bushings were then lubed up and pushed in with the vice, and ball joints were carefully pushed in on the press.    Since there is no part number for an S14 rear ball joint, an alternative needed to be sourced. After some research, I saw quite a few different possibilities, however very few concrete answers. I used a dial indicator to compare the front and rear S14 ball joints, and they were nearly identical. They went in without a problem, and the snap ring fit in the proper place. Like everything else, the axles had seen better days. Although they showed no signs of mechanical problems, they were cosmetically deceased.  I started by Glass beading them clean, and taping them off for paint. I had considered powder coat, but I was unsure how they would handle the oven.   VHT paint was the applied, which appears to be strong enough to take some abuse.    Aside from looking like I pulled it from the bottom of a lake, the open-diff had to go.  I opted to go with a J30 VLSD, as it was compatible with my 6-bolt axles. It was in excellent condition, and only required minor cleaning. I applied copper anti-seize to the flanges to prevent corrosion.    |

|

|

|

|

|

#17 |

|

Zilvia Member

Join Date: Oct 2006

Location: Kansas

Age: 33

Posts: 217

Trader Rating: (0)

Feedback Score: 0 reviews

|

nice. I just did this exact thing to my s14.

bought an extra subframe and took the time to build it with mostly new parts, cleaned up and painted the subframe, replaced the bushings, ballerbolts kit. I didn't take apart the spindles and paint them, but I did everything else. nice work man. |

|

|

|

|

|

#18 |

|

Zilvia Addict

Join Date: Jul 2007

Location: Las vegas

Age: 33

Posts: 673

Trader Rating: (8)

Feedback Score: 8 reviews

|

if you can answer this for me that would be great.

Why didnt you use a dremel to make the notches and install zerk fittings to make greasing them easier? is it not necessary? from what i know, people that dont do it just remove the parts to grease them. |

|

|

|

|

|

#19 |

|

Premium Member

Join Date: Jun 2006

Location: New Jersey

Age: 35

Posts: 584

Trader Rating: (20)

Feedback Score: 20 reviews

|

The installation of zirc fittings is new to me, however seems like an efficient means of lubricating the bushings. I may decide to install them down the road, as it seems to be pretty simple, however it is too late now. The old fashion way will have to do until then.

|

|

|

|

|

|

#20 |

|

Post Whore!

Join Date: Dec 2004

Location: Poconos, PA

Age: 36

Posts: 8,030

Trader Rating: (58)

Feedback Score: 58 reviews

|

Your work is great, and effort even better

But if I had to suggest anything, it would really behoove you to look into the Roll Center Thread on Zilvia, as well as checking out NissanRoadRacing for some tips/suggestions/better ideas in regard to parts for your rear subframe...some of the work you're performing on stock parts could easily be spent on upgraded ones, which would really benefit your car. Again, great stuff, but do some real suspension modification searching and you'll thank all of us for getting at it while the subframe is off the car, rather than on.

__________________

Want Air Conditioning in your SR20 Swapped car? Check out www.sr20acbrackets.com for more information! Quest Alternator Conversions for SR20! Check my Group Buy! Tired of lousy internal gates? Go external wastegate with one of my manifolds, Check out my group buy |

|

|

|

|

|

#22 | |

|

Premium Member

Join Date: Jun 2006

Location: New Jersey

Age: 35

Posts: 584

Trader Rating: (20)

Feedback Score: 20 reviews

|

Quote:

The flanges were only coated with a copper anti-seize compound to prevent corrosion. After dealing with that rusted disaster, I wanted to be sure I would not have problems like that in the future. Anything that is susceptible to rust, I apply anti-seize to. I opted to install polyurethane bushings as opposed to solid because the car is not going to see enough track time to merit their benefits. For that very same reason, I did not fill the subframe with foam, weld supports, or other track preparations. I knew realistically that the benefits of those type of upgrades would were not going to be utilized. Thank you for the comments, and I will keep the updates coming..... |

|

|

|

|

|

|

#23 |

|

Premium Member

Join Date: Jun 2006

Location: New Jersey

Age: 35

Posts: 584

Trader Rating: (20)

Feedback Score: 20 reviews

|

Update

I want to thank Donovan of Yamato Garage for all of his help and patience. The quality and fit of these products are amazing, and for the price you can't get better. They use QA1 rod ends, stainless steel tubing, heat treated hardware, and a powder coated finish. I cannot say enough good things about this company, and the people who run it. Contact Donovan, make mention of the thread, and I am sure he will help with anything you need.

home-yamato garage I purchased the full set, and for an extra fee, they were powder coated the color of my choice. QA1 2-piece rod ends, chrome plated ball  Monobeam T-6061 aluminium tension rod   Stainless steel ball-head design RUCA   Stainless steel monobeam toe control rod   Stainless steel traction rod    |

|

|

|

|

|

#26 |

|

Post Whore!

|

Watch out for those rear lower control arm ES bushings too... those binded the worst when I had them on my car. Same deal as the uprights... trim or washers so the poly does not get sandwiched and bind against the brackets. I trimmed mine down with the side of a stone grinder (keeps the trim flat)... just don't trim them too much or the arms will move around as the suspension travels. It's best if the inner sleeves are flush or barely sticking out from the poly bushing.

You could chop those ES subframe bushings down a little on the top to raise the subframe and correct the geometry some if your car is lowered. Not sure what else he could upgrade for about the same amount of money.... every quality adjustable part costs a good amount. Looks like a good "stockish" build. |

|

|

|

|

|

#27 |

|

Post Whore!

Join Date: Dec 2002

Location: Atlanta

Age: 47

Posts: 13,812

Trader Rating: (12)

Feedback Score: 12 reviews

|

While the subframe was out I would have replaced the rear differential bushings too.

Otherwise good work.

__________________

FORMERLY R240NA Learn what's really going on and protect your assets now before they're gone forever: www.paypalsucks.com |

|

|

|

|

|

#28 | |

|

Post Whore!

Join Date: Dec 2004

Location: Poconos, PA

Age: 36

Posts: 8,030

Trader Rating: (58)

Feedback Score: 58 reviews

|

Quote:

My comment was directed at trimming the top of the subframe bushings down (and the metal sleeve), possibly filling the subframe with foam while it's out (great cheap modification), maybe welding some gussets on the OE lower control arms to replicate 'nismo' ones, etc etc...small things. It wasn't meant as a 'you're doing it wrong' but more of a 'while it's out, maybe address these issues' kinda thing.

__________________

Want Air Conditioning in your SR20 Swapped car? Check out www.sr20acbrackets.com for more information! Quest Alternator Conversions for SR20! Check my Group Buy! Tired of lousy internal gates? Go external wastegate with one of my manifolds, Check out my group buy |

|

|

|

|

|

|

#29 | |

|

Post Whore!

Join Date: Jan 2004

Location: los angeles

Age: 37

Posts: 3,120

Trader Rating: (82)

Feedback Score: 82 reviews

|

Quote:

|

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|