|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Engine Tech Technical discussion related to all relevant engines such as KA, SR, RB, CA, 2JZ , L24/26/28, VG, VQ, and LSx series. |

|

|

|

Thread Tools | Display Modes |

|

|

#1 |

|

Join Date: Oct 2020

Location: Tampa, FL

Age: 30

Posts: 21

Trader Rating: (0)

Feedback Score: 0 reviews

|

KA24DET PCV Questions

I have a 2004 Frontier with a KA24DE that I have turbocharged. I have installed an Xcessive intake manifold originally meant for a 240SX and I am running a Z32 mass air flow sensor on the turbo inlet pipe.

I currently have the PCV valve on the lower passenger side of the engine venting to atmosphere and the nipple from the valve cover venting to atmosphere as well. If I remember correctly, not having the PCV hooked up to the intake manifold screws with the readings of the MAF? Do I need to find a way to plumb the PCV back into the intake manifold with a sealed can in between? Would I need an additional check valve in that instance? Should I just run the nipple from the valve cover to a sealed can and then onwards to the turbo inlet after the MAF or can I get away with venting to atmosphere? The build was originally venting the valve cover to atmosphere and the PCV was still plumbed into the stock intake manifold. It was originally running off an Apexi SAFC2, which wasn't the best, but it ran. Now that I'm running an S13 ECU I'm trying to get everything running properly. With the different intake manifold installed, I was wondering if I should run the PCV the same way or differently. |

|

|

|

| Sponsored Links |

|

|

#7 | |

|

BANNED

|

Quote:

Without vacuum on the crankcase, the gas pressure builds and blows out seals/rings. |

|

|

|

|

|

|

#8 | |

|

Zilvia Junkie

Join Date: Nov 2012

Location: wisconsin

Age: 29

Posts: 447

Trader Rating: (7)

Feedback Score: 7 reviews

|

Quote:

I was reading on it, it said the vacuum helps to remove the gases and a sealed system extends oil life. so far is about all ive found for negative effects created from venting to atmosphere. most of the reasons seemed to be pollution

__________________

The Game you lose haha |

|

|

|

|

|

|

#9 |

|

BANNED

Join Date: May 2019

Location: Florida-FAIL

Posts: 2,497

Trader Rating: (8)

Feedback Score: 8 reviews

|

Was told a sealed, vacuumd system helps seal rings

On my sr, i never ran a pcv system, 6 years daily drove not one issue. On my new setup im going to run a "proper" pcv and catch can setup. |

|

|

|

|

|

#10 | |

|

BANNED

|

Quote:

|

|

|

|

|

|

|

#13 |

|

Leaky Injector

|

That's not the case at all. PVCs on stock KAs are built for emissions and that's it. If you boost an old KA with a blocked or no PCV system then you blow rings, foul valve seats.

|

|

|

|

|

|

#15 |

|

Leaky Injector

|

No we are not, we are talking about what a stock PCV system actually does. Which is to vent blow by to the intake for emissions. Venting to atmosphere is perfectly fine, use a one way valve though. Luckily most people don’t have to worry about emissions.

|

|

|

|

|

|

#16 | ||

|

BANNED

|

Maybe read the title of the thread. But if this discussion about PCVs has to be had for the 35,000th time:

https://help.summitracing.com/app/an...cv-valve-do%3F Quote:

http://www.hastingsfilter.com/Literature/TSB/94-2R1.pdf Quote:

Last edited by zombiewolf513; 12-22-2020 at 07:21 AM.. |

||

|

|

|

|

|

#17 |

|

Leaky Injector

|

Thanks for proving my point. We are not talking about the OP's stock NA KA emissions system. We are talking about how to properly vent crankcase pressure on a modded KA. If your KA is boosted, big mani, SR ECU, why on earth would you ever keep an NA PCV emissions system? You seem to be really wanting to add an emissions system to a modded motor, not something I recommend if you don't need to pass a smog test. None of these mods will pass an inspection, nor will they reduce emissions vs a stock KA. If the OP wants to vent through a one way valve ( not PCV valve) to a catch can, then to atmosphere, or if he wants to vent through a PCV valve to a catch can, back to his intake is his choice. One way is easier and cheaper than the other. Only one way is correct for a boosted KA.

|

|

|

|

|

|

#18 |

|

Leaky Injector

|

[QUOTE=zombiewolf513;6403656]Maybe read the title of the thread. But if this discussion about PCVs has to be had for the 35,000th time:

It's really not that difficult to understand. Oh and thanks for the 3rd grader Summit, NA PCV google search lesson. You are dead wrong though, here is an "Actual Authority" on why I have been doing it my way for 10yrs. OP, dont listen to this guy. http://www.youtube.com/watch?v=TvazViNq12M&t=431s |

|

|

|

|

|

#19 |

|

BANNED

|

You linked an hour long video about crankcase ventilation, but youre still rambling about emmissions lol. Not only that, your guy in your video describes how my '3rd grader' shit is exactly right. Did you even watch it? Or just the first 431 seconds?

Maybe you should weld your PCV ports shut. |

|

|

|

|

|

#20 | |

|

Leaky Injector

|

WOW. My friend you must not have watched it at all. Or you just don’t understand it, or modified motor building for that matter. Just reading the click bait title doesn’t make you any more correct. It’s plain as day. Either way let me list the cliff notes for you.

1) 3:50 Modded engines produce more blow by than stock. 2) 6:00 Factory PCV breather system explained (Emissions) 3) 8:10 PCV valves on modified motors are bad.(Owned) 4) 11:00 Venting crankcase oil vapor in to the intake or pre turbo of a modified motor is very bad. Heard of detonation?(Owned) 5) 16:38 Keeping the factory breather system in a modified motor is bad (Owned) 6) 18:00 how to improve breather systems on a modified motor 7) 20:15 PCV on a turbo motor is again very bad. (Owned) 8) 23:30 Breather system design 9) 24:24 PCVs on a turbo motor are again very bad. (Owned) 10) 25:35 Catch can routing. Venting to atmosphere on a modified motor is good. 11) This whole thread:00 Your knowledge, attention span and reading/listening comprehension is very bad. But you do get a banana sticker for the drawing. Quote:

And yes. I stated the “fact”PCV systems are for emissions, not for turbo KA’s. You seem to think they belong on a turbo motor(wrong). You seem to think venting oil vapor in to the intake or before a turbo is good(wrong). They are only good for stock cars to reduce emissions. And no I will not weld shut my crankcase venting. I vent to atmosphere like a sane person. Last edited by JDM240z; 12-22-2020 at 03:29 PM.. Reason: ? |

|

|

|

|

|

|

#21 |

|

BANNED

|

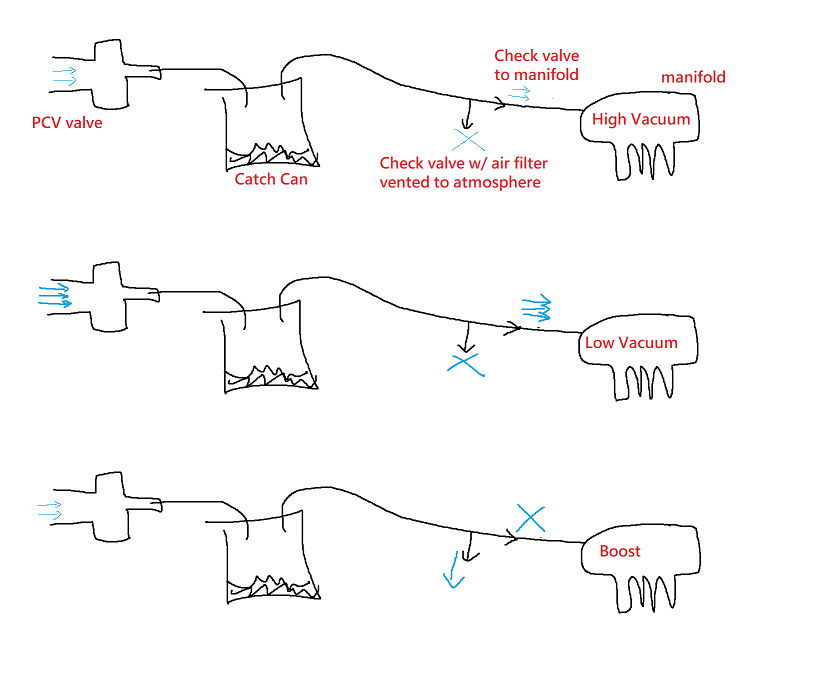

I guess I should've followed your lead and gotten a clickbait education.

The dude literally explains exactly why the PCV system on a boosted KA should reflect what my masterpiece of a PCV diagram shows. I seriously have no idea wtf you're hearing in his accent to make you think there's an argument otherwise. Half of those time stamps your labeling aren't even what he talks about. For example #3. he doesn't say its bad. He says it doesn't do anything when the engine is in boost, and needs modifications. Hence the vented check-valve in my artwork. Maybe work on your own comprehension before attempting to disparage others. Here's some quick notes for your dumb ass: 2) 6:00 Factory PCV breather system explained (Emissions). nope venting case pressure. 3) 8:10 PCV valves on modified motors are bad.(Owned) Not bad. Don't work when in boost, hence a check valve and vent to atmposphere/or airpump req'd. 4) 11:00 Venting crankcase oil vapor in to the intake or pre turbo of a modified motor is very bad. Heard of detonation?(Owned) Heard of a catch can? 5) 16:38 Keeping the factory breather system in a modified motor is bad (Owned) Hence the modifications to the system I talked about 6) 18:00 how to improve breather systems on a modified motor see my beautiful piece of gradeschool fingerpainting 7) 20:15 PCV on a turbo motor is again very bad. (Owned) Heard of a catch can? 9) 24:24 PCVs on a turbo motor are again very bad. (Owned) Heard of a catch can? 10) 25:35 Catch can routing. Venting to atmosphere on a modified motor is good. That also has a vacuum source from the manifold, dumb fuck. |

|

|

|

|

|

#22 |

|

Leaky Injector

|

SMH... He says PCV’s on a modified motor is a terrible idea. He told you over and over again. We told you.Then he told you some more. He told you venting to the intake is even worse. And then showed you what to do, then told you again why you can’t comprehend WTF he just told you. And you tell the OP to vent to his intake with a PCV valve, and expect people to believe you when you say you will blow rings and seals if you don’t! Oh my dude thanks for the laugh. I knew I was getting trolled. Good on you.

|

|

|

|

|

|

#25 |

|

BANNED

|

All you've said is 'some guy said PCV bad ditch pcv' (which he didn't even say).

You're not even make a coherent argument. If you're so confident that PCV is bad, weld your ports shut. Lemme know how long that motor lasts. I'm sure your oil wont be fouled at all either. Anyone reading the thread can make their own determination on their PCV, as they should anyway. |

|

|

|

|

|

#26 | |

|

Leaky Injector

|

Quote:

__________________

Summit quotes don't earn you reps.. smh |

|

|

|

|

|

|

#28 | |

|

Leaky Injector

|

Quote:

__________________

Summit quotes don't earn you reps.. smh |

|

|

|

|

|

|

#30 | |

|

Post Whore!

Join Date: Jul 2005

Location: South Florida

Age: 38

Posts: 4,648

Trader Rating: (17)

Feedback Score: 17 reviews

|

Quote:

PCV is the most important system on an engine. All engines whether performance, turbo, etc come with PCV. All race cars use some form of PCV, without it the oil would be out of control, its not a race car. PCV is essential in every application, because: 1. low pressure pulls light chain hydrocarbons out of engine oil 2. rapid evacuation prevents oil contamination 3. low pressure enables fully intended piston ring seal function 4. low pressure reduces windage, gobular interference, and flattens rivults (too low and it can starve wrist pins for oil as a testament to its effects) 5. low pressure prevents oil leaks and seal blow-out, helps keep oil out of seals 6. low pressure keeps oil out of the engine's oil baffles and intake If you vent an engine to atmosphere it will cut the engine's life in half or worse. It will ensure leaking seals after 20k-50,000 miles. It will ensure a smoking low compression engine is the result of typical service. It will ensure crusty piston rings and damaged cylinder walls with increased blow by due to contamination of engine oil with unfiltered air. It will ensure that at some point the hood will become fully splattered with engine oil and dark sludge and that you will find oil everywhere, not just the intake. This is because: Oil spray increases with crankcase pressure, and piston ring function decreases with increasing crankcase pressure. More crankcase pressure means more blow-by and oil spray Lower crankcase pressure is highly desirable and somewhat easily to achieve with a little effort. Naturally this leads to desire to control and set a specific crankcase pressure range for our engine, And that becomes PCV since pcv is the only thing that can control the crankcase pressure (its the words we chose to represent taking control of the crankcase pressure). Desired crankcase pressure would be -0.8" to 2.5"Hg of crankcase pressure in wet sump application -0.8"Hg is -0.4PSI the minimum for most engines recommended. 2.5"Mercury or -1.22PSI is around maximum for typical wet sump application. Too much vacuum will risk damaging the oil pump and altering oil system expectations. The air filter paper works together with PCV for the sake of longevity and cleanliness, when the engine is modified you need to re-visit the goal of each system and deviate the power(paper OEM style air filter flow rate for a modified engine) how you see fit by adjusting the PCV valve orifice and fresh air inlet orifice diameters while keeping at least one or more paper air filters on the inlet. We measure crankcase pressure the same way as intake pressure, using 2-bar map sensor. If you can measure intake PSI then you can measure crankcase PSI. Its a 0.5v to 4.5v style sensor for every engine in the world so very easy to detect as no voltage divider is necessary. $20 Arduino micro controller has like 15x 0-5v inputs for example. HPtuners 411 OEM ecu has EGR input, 0-5v same as wideband input. You can switch between wideband and Crankcase pressure. All stand-alones can use 0-5v inputs. No excuses not to understand and measure crankcase pressure and setup required PCV function to get maximum life from an engine and maximum oil control fantasy Imagine not knowing how pcv works Last edited by Kingtal0n; 12-26-2020 at 09:31 AM.. |

|

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|