|

|

|||||||

| Home | Rules & Guidelines | Register | Member Rides | FAQ | Members List | Social Groups | Calendar | Mark Forums Read |

| Tech Talk Technical Discussion About The Nissan 240SX and Nissan Z Cars |

|

|

|

Thread Tools | Display Modes |

|

|

|

|

#1 |

|

Quest alternator in sr20det

Posted this is S-Chassis section but not getting much response.

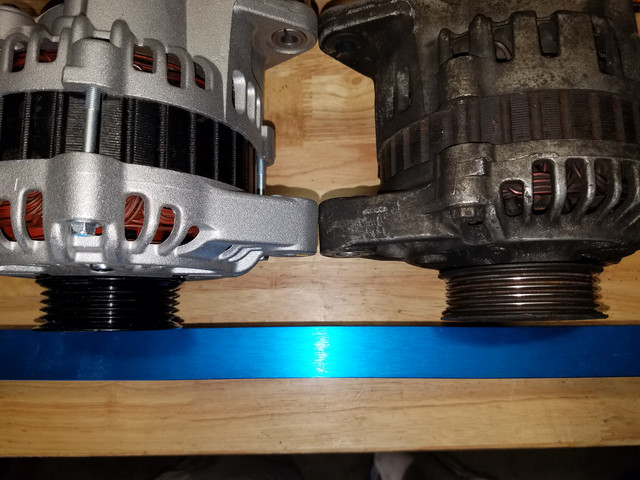

Hey all, I've researched using a Quest alternator on an sr20det and know you need to drill out the mounting holes and modify the tensioner mounting bracket or buy the Cody Ace mount. I bought the 125 amp alternator for the 99-02 Quest and when comparing to the stock SR alternator, the pulley seems to stick out farther then the stock alternator pulley would be. There's about a 3mm difference which I would think would be enough of a difference to cause issue. Did anyone compare the 2 alternators before installing? In these pics, you can see the new alternator mounting tabs are higher, so when installed the pulley would be farther out. I could probably grind some of the inside tab closest to the pulley and use washers on the inside of the other tab to take up the difference. Both alternators have the same amount of space between the mounting holes. Did anyone have to grind these mounting tabs? (not the tensioner mounting tab)   In these pics, the mounting holes are lined up and the pulley on the Quest alternator sticks out farther.    |

|

|

|

|

| Sponsored Links |

|

|

#2 |

|

Nissanaholic!

Join Date: Jul 2001

Location: San Gabriel, CA

Age: 37

Posts: 1,654

Trader Rating: (5)

Feedback Score: 5 reviews

|

I've been poking around for an answer to this as well. It looks like people haven't really had an issue with it... or they haven't really posted about it ha ha I don't know. Did you ever get to the bottom of this?

|

|

|

|

|

|

#5 |

|

Zilvia Addict

|

Did this get sorted out? Was it the correct part, didn't fit, etc? Getting some voltage drop issues so looking into upgrades myself.

Last edited by LoSt180; 11-13-2020 at 01:51 PM.. |

|

|

|

|

|

#6 |

|

Post Whore!

|

Machine 3mm off either mount, problem solved! It should be pretty easy to take a grinder and use the blade as a guide for the amount needed to remove.

In all honesty, it is less than an 1/8th of an inch and quite a distance from the crank. If it was in close proximity to the crank, it probably would cause more of an issue.

__________________

My SR20VET |

|

|

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|